Analysis Of Cost And Influencing Factors Of CO2 Laser Cutting Machine

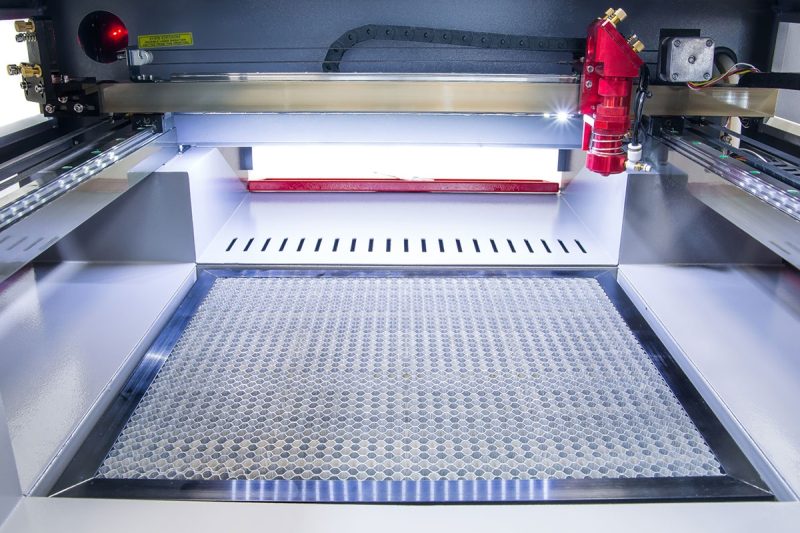

As an important tool in modern manufacturing, laser cutting technology plays a key role in various industries. CO2 laser cutting machines are popular due to their wide applicability and relative cost-effectiveness. However, for many businesses and individuals, the cost of CO2 laser-cutting machines is a key issue. They need to consider various factors when deciding whether to purchase such equipment. This article will explore how much a CO2 laser cutting machine costs, the factors that affect those costs, and compare it to other types of laser cutters. It makes it easy for users to choose the one that best suits their needs.

Table of Contents

Cost Analysis Of CO2 Laser Cutting Machine

For businesses and individuals, the cost of CO2 laser-cutting machines is one of the important factors in deciding whether to adopt this technology. The following is an analysis of the cost of CO2 laser-cutting machines:

Initial Investment Cost

The initial investment cost of the CO2 laser cutting machine mainly includes the following aspects:

- Price of the machine itself: AccTek CO2 laser cutting machines range in price from $3,000 to USD 6,000, depending on model, specifications, and features. Generally speaking, high-power, high-precision equipment is more expensive, while low-power, low-precision equipment is relatively cheap. Lower-end desktop CO2 laser-cutting machines may cost around $3,000, while large industrial-grade equipment may cost upwards of $6,000.

- Cost of accessories and accessories: CO2 laser cutting machines usually require additional accessories and accessories. For example, accessories such as more advanced laser heads, cutting tools, and cooling systems will increase the cost of the equipment.

- Installation and debugging costs: After purchasing a CO2 laser cutting machine, installation and debugging are usually required. This may require additional labor and time costs, especially for complex equipment or special processing requirements. For complex equipment, additional training and commissioning time may be required, and these costs also need to be taken into account.

Operating Costs

The operating costs of CO2 laser cutting machines mainly include the following aspects:

- Energy consumption cost: CO2 laser cutting machines usually require a large amount of electricity to drive the laser generator and other components. The power consumption of the laser generator and the energy consumption of auxiliary equipment (such as cooling systems) need to be calculated. Therefore, energy consumption costs also increase accordingly.

- Maintenance costs: To ensure the normal operation and long-term stability of the equipment, regular maintenance work is essential. This includes cleaning, lubrication, replacement of wearing parts, etc. These costs also need to be included in operating costs.

- Labor costs: Operating a CO2 laser cutting machine requires specially trained operators, and their salary costs are also part of the operating costs. In addition, technical support and after-sales service may also require additional manpower investment.

Factors Affecting The Cost Of CO2 Laser Cutting Machine

In addition to the initial investment and operating costs, the cost of a CO2 laser cutting machine is also affected by many factors such as technical level, cutting materials, and machine brand. The following are the main factors that affect the cost of CO2 laser-cutting machines:

Technical Level And Performance

The technical level and performance of a CO2 laser-cutting machine have a direct impact on its cost. For example, laser power is one of the important factors that determine the cutting capabilities of the equipment, and high-power laser cutting machines are usually more expensive. In addition to laser power, performance indicators such as cutting speed, cutting accuracy, and repeat positioning accuracy will also affect the price of the equipment. Generally speaking, equipment with better performance usually costs more.

Type And Thickness Of Cutting Material

Different types and thicknesses of materials require different power laser generators and specific cutting parameters, which affects the cost of a CO2 laser cutting machine. For example, cutting metallic materials requires a higher-power laser, while cutting non-metallic materials may require a lower-power laser generator. In addition, some special materials, such as thick steel plates or special alloy materials, may require more complex and expensive equipment to meet their processing requirements.

Equipment Dimensions And Working Area

The size of the CO2 laser cutting machine and the size of the work area will also affect its cost. Larger pieces of equipment are generally more expensive because they require more materials and more complex structures to support and stabilize the entire machine. At the same time, the size of the work area will also affect the price of the equipment, because a larger work area usually requires more lasers and other components to cover and meet processing needs.

Degree Of Automation Of Equipment

The degree of automation of the equipment is also one of the important factors affecting the cost of CO2 laser-cutting machines. Equipment with a high degree of automation is generally more expensive because they have more functions and more complex control systems, allowing for more efficient production and more flexible processing. For example, equipment with functions such as automatic loading, automatic unloading, and automatic adjustment of cutting parameters are usually more expensive.

Manufacturer And Brand

CO2 laser cutting machines produced by different manufacturers and brands will also vary in price. Well-known brands usually provide more reliable product quality and technical support, but their prices may also be relatively high. Some small or emerging brands may offer cheaper equipment, but users need to pay attention to product quality and after-sales service.

Market Competition And Supply And Demand

Market competition and supply and demand relationships will also have an impact on the cost of CO2 laser-cutting machines. When supply and demand are tight, equipment prices may rise, and when market competition is fierce, manufacturers may lower prices to attract customers. Therefore, market conditions and industry environment are also one of the important factors affecting equipment costs.

To sum up, the cost of CO2 laser cutting machines is comprehensively affected by many factors, including technical level, cutting materials, equipment size, degree of automation, manufacturer brand, and market competition. When purchasing a CO2 laser cutting machine, users need to fully consider these factors.

Comparison Of CO2 Laser Cutting Machines With Other Types Of Laser Cutting Machines

Laser cutting machines each have a range of advantages and disadvantages compared to other types of laser cutting machines, depending on specific processing needs, material characteristics, and budget constraints. The following is a comparison of the advantages and disadvantages of CO2 laser cutting machines compared to other types of laser cutting machines:

Advantages Of CO2 Laser Cutting Machine

- Wide application: The CO2 laser cutting machine is suitable for a variety of materials, including metals, non-metals, and organic materials. They can be used for a variety of machining tasks such as cutting and drilling.

- Faster cutting speed: In some cases, CO2 laser cutting machines can achieve higher cutting speeds, especially when cutting thick plates.

- Relatively low initial investment cost: Compared to other types of laser cutting machines, CO2 laser cutting machines generally have a lower initial investment cost, which makes them more attractive to users with limited budgets.

- Suitable for a variety of application scenarios: CO2 laser cutting machines can be used in many different application scenarios, including metal processing, textile processing, woodworking processing, etc. They offer high flexibility and versatility.

Disadvantages Of CO2 Laser Cutting Machine

- Relatively low cutting accuracy for metal materials: Compared with fiber laser cutting machines, CO2 laser cutting machines may be slightly less precise when cutting metal materials. Especially when cutting thin plates and cutting complex structures, its accuracy may not be as good as that of fiber laser cutting machines.

- Higher energy consumption: CO2 laser cutting machines have higher energy consumption, which increases operating costs. Especially when working continuously for a long time, energy consumption may become an issue that cannot be ignored.

Comparison With Fiber Laser Cutting Machine

- Cutting accuracy: In comparison, fiber laser cutting machines are generally able to achieve higher cutting accuracy, especially in thin plate cutting.

- Energy consumption: Fiber laser cutting machines generally have higher energy conversion efficiency and can utilize laser energy more effectively, so energy consumption is relatively low.

- Applicable materials: Fiber laser cutting machines are mainly suitable for cutting metal materials and have weak processing capabilities for non-metallic materials, while CO2 laser cutting machines are better at cutting non-metallic materials.

Summarize

The cost of a CO2 laser cutting machine is affected by many factors, including initial investment cost and operating cost, as well as factors such as technology level, cutting materials, and machine brand. Compared with other types of laser cutting machines, CO2 laser cutting machines have their unique advantages and disadvantages, and they need to be selected according to specific needs. An in-depth understanding of CO2 laser cutting machine costs and influencing factors can help develop effective purchasing and operating strategies to increase production efficiency and reduce costs. By gaining a deeper understanding of its costs and influencing factors, we can better understand the technology and provide users with more appropriate choices and decision support.

As technology continues to advance, CO2 laser cutting is likely to become more precise and efficient, opening up new possibilities and applications in various fields. In a world where precision and accuracy are paramount, CO2 laser cutting is a testament to human ingenuity and innovation in manufacturing and manufacturing. If you are looking for a CO2 laser cutting machine, you can contact us. AccTek Laser can provide you with customized solutions based on your specific application.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions