Fiber laser generator is an advanced technology widely used in modern industry and is widely popular for its efficient and precise cutting, welding, and cleaning capabilities. This technology uses optical fibers to conduct high-energy laser beams to precisely process various materials. Its significant advantage lies in improving production efficiency and processing quality. Fiber laser generators transmit the laser beam to the target area through optical fibers, achieving high energy density concentration for fast and precise cutting and welding. This technology is widely used in industries such as automotive manufacturing, aerospace, electronic equipment, and medical devices, demonstrating excellent performance.

Although fiber laser generators perform well in industrial applications, their high energy output and complex operating environment also bring certain safety hazards. Laser radiation may cause damage to the operator’s eyes and skin, and electrical system failure may pose a risk of fire or electric shock. In addition, the harmful gases and chemical hazards of materials produced during the cutting process cannot be ignored. Therefore, understanding the working principle, composition structure, main characteristics, and common applications of fiber laser generators, and mastering relevant safety measures are crucial to ensuring the safety of operators.

Learn About Fiber Laser Generators

Working Principle of Laser Generator

Fiber Laser Generator Components

- Pump source: The pump source is the energy input part of the fiber laser generator, and semiconductor laser diodes (LD) are usually used as pump sources. It provides light energy to excite the gain medium (fiber doped with rare earth elements) in the optical fiber, thereby achieving population inversion and providing conditions for the generation of lasers.

- Gain fiber: The gain fiber is the core part of the fiber laser generator. It contains a fiber core doped with rare earth elements (such as erbium, ytterbium, neodymium, etc.). When the pump light enters the gain fiber, it is absorbed by the rare earth ions, causing the rare earth ions to transition from a low energy level to a high energy level. Subsequently, under the feedback of the resonant cavity, the rare earth ions at a high energy level transition back to a low energy level through stimulated radiation, and release laser light with the same wavelength or a specific wavelength as the pump light.

- Optical resonant cavity: The optical resonant cavity is composed of two reflectors (or fiber gratings) located at both ends of the gain fiber. The role of the resonant cavity is to provide optical feedback, so that the laser is reflected and amplified multiple times in the optical fiber, thereby enhancing the intensity and stability of the laser. By adjusting the length of the resonant cavity and the reflectivity of the reflector, the wavelength and mode of the laser can be controlled.

- Coupler and isolator: The coupler is used to couple the pump light into the gain fiber while allowing the laser to be output from the fiber. The isolator is used to prevent the laser from reflecting to the pump source or gain fiber to protect these components from damage and ensure the stability of the laser.

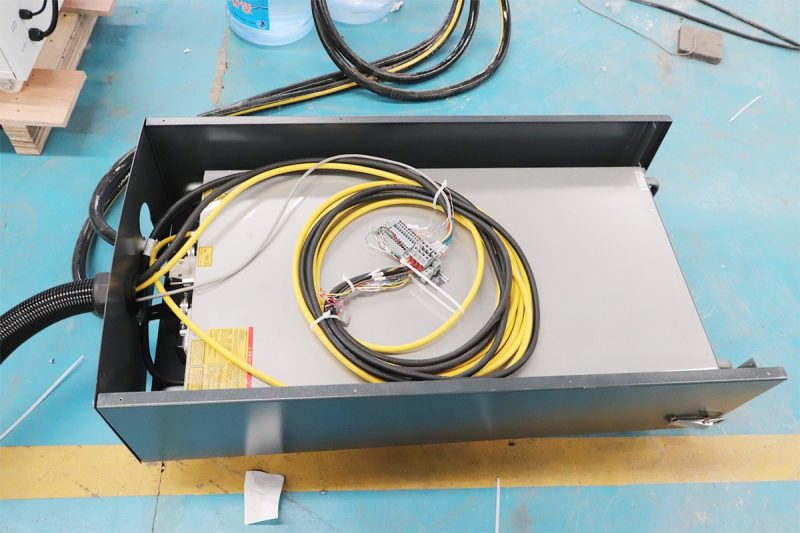

- Control system: The control system includes a power supply, temperature controller, and monitoring circuit. The power supply provides stable power for the pump source and control system; the temperature controller is used to monitor and adjust the temperature of the gain fiber to ensure that it operates in the best working state; the monitoring circuit is used to monitor the output power, wavelength and other parameters of the laser generator in real time to ensure that the performance of the laser generator is stable and reliable.

- Cooling system (depending on the specific power): For high-power fiber laser generators, the cooling system is essential. It reduces the temperature inside the laser generator by circulating cooling media (such as water, air, etc.) to prevent performance degradation or damage due to overheating.

- Housing and support structure: The housing is used to protect the components inside the laser generator from the influence of the external environment, such as dust, humidity, and vibration. The support structure is used to fix the laser generator and ensure its stability and safety during operation.

Main Features of Fiber Laser Generator

- High efficiency: The fiber laser generator uses optical fiber as the gain medium, which can achieve extremely high light-to-light conversion efficiency. This means less energy is lost during the conversion of electrical energy into laser energy, increasing overall efficiency. High efficiency not only reduces energy consumption but also improves the output power and stability of the laser generator.

- Low energy consumption: Due to the high-efficiency characteristics of fiber laser generators, they can significantly reduce energy consumption compared with traditional laser generators at the same output power. This is particularly important for long-term operations and large-scale applications, helping to reduce production costs and environmental impact.

- Good stability: The design of the fiber laser generator gives it excellent stability. The temperature controller can accurately monitor and adjust the temperature of the gain fiber to ensure it operates in optimal working conditions, thereby reducing performance fluctuations caused by temperature changes. In addition, the monitoring circuit monitors key parameters such as the output power and wavelength of the laser generator in real-time, further improving the stability and reliability of the system.

- Superior beam quality: The laser beam produced by the fiber laser generator is of high quality, with an extremely small beam divergence angle and a good beam pattern. This enables the laser beam to maintain high energy density and precision during long-distance transmission, which is very suitable for precision machining, cutting, welding, and other applications.

- Low maintenance cost: The structure of the fiber laser generator is relatively simple, and due to the characteristics of the fiber material, it has strong resistance to corrosion and aging. Therefore, in daily use, fiber laser generators are less expensive to maintain, reducing downtime and repair costs.

- Long service life: Thanks to the excellent performance of fiber optic materials and the stable design of the laser generator, fiber laser generators usually have a long service life. This is particularly important for companies that require continuous production to ensure stable operation and efficient output of the production line.

Common Applications of Fiber Laser Generators

- Metal cutting: Fiber laser generators excel in metal cutting, capable of processing a variety of materials from thin plates to thick plates, such as stainless steel, carbon steel, aluminum, and copper. Due to its high energy density, smooth cutting edges, and no need for secondary processing, it is very suitable for manufacturing industries that require precision processing, such as the production of automotive parts.

- Welding: In the field of welding, fiber laser has the advantages of deep penetration welding and high speed, and is suitable for industries such as automobiles, aerospace, and shipbuilding. Its high precision and low heat-affected zone ensure the quality and structural strength of the welded joint, which has significant advantages especially when welding thin-walled materials and complex structures.

- Cleaning: Fiber laser cleaning technology is an environmentally friendly and efficient surface treatment method, often used to remove oxide layers, oil stains, coatings, and corrosion on metal surfaces. Compared with traditional cleaning methods, fiber laser cleaning does not damage the substrate and releases no chemical waste, so it is widely used in molds, mechanical parts, and building maintenance.

- Marking: Fiber laser generators are also widely used for fine marking and engraving, including QR codes, serial numbers, text, and patterns. Because fiber laser marking is fast, has high resolution, and performs well on both metallic and non-metallic materials, it is widely used in electronic products, medical devices, jewelry, and tool manufacturing.

- Electronic equipment: In electronic equipment manufacturing, fiber laser generators are used for micro-processing, such as cutting and drilling, ensuring high precision and low loss, which is crucial to improving product quality and extending equipment life.

- Medical devices: In the medical device industry, fiber lasers are used to manufacture precision instruments such as scalpels, implants, and stents. Its advantages include smooth cutting edges, no thermal damage, and the ability to handle very small and complex components, ensuring products meet strict medical standards.

Potential Hazards Associated with Fiber Laser Generators

Laser Radiation Exposure Risks

Electrical Hazards

Fire and Overheating Risks

Chemical Hazards of Cutting Materials

Gas Hazards

Safety Features of Fiber Laser Generators

Enclosure and Interlocking System

Emergency Stop Button Safety Switch

Cooling System

Regulatory Compliance and Standards

Operator Training and Education

Theoretical Training

- In-depth explanation of the working principle, structure and performance parameters of the fiber laser generator.

- Emphasis on the hazards of laser radiation and protective measures, including the importance of wearing protective glasses and protective clothing.

Practical Operation Training

- Simulate actual work scenarios, allowing operators to operate the equipment by hand and become familiar with the operating procedures.

- Cultivate standardized operating habits and ensure that operators always comply with safety standards in their daily work.

Regular Safety Training and Drills

- Invite professionals to share the latest safety knowledge and technical trends.

- Simulate emergency situations such as laser leakage, electrical failure, etc. to improve the operator’s ability to respond.

Training Files and Assessment Mechanism

- Establish operator training files to record training experience, test scores and practical performance.

- Develop reward and punishment measures based on assessment results to encourage operators to continue learning and improvement.

Common Misconceptions

Misunderstanding 1: Fiber Laser Generators Are Completely Safe Due to Their Enclosed Design

- Fact: Although the equipment is designed with a closed housing and interlock system, improper operation or equipment failure may still cause laser beam leakage, which in turn may cause safety risks.

- Emphasis: Operators must strictly abide by safety regulations and conduct regular equipment inspections and maintenance.

Misunderstanding 2: Wearing Ordinary Glasses Can Protect Against Laser Radiation

- Fact: Laser radiation has high energy density and penetration, and ordinary glasses cannot provide effective protection.

- Emphasize: You must use specially designed laser protection glasses, and ensure that the glasses meet the standards, are intact, and are worn correctly.

Summarize

Get Laser Solutions

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.