Overview of CO2 laser cutting technology

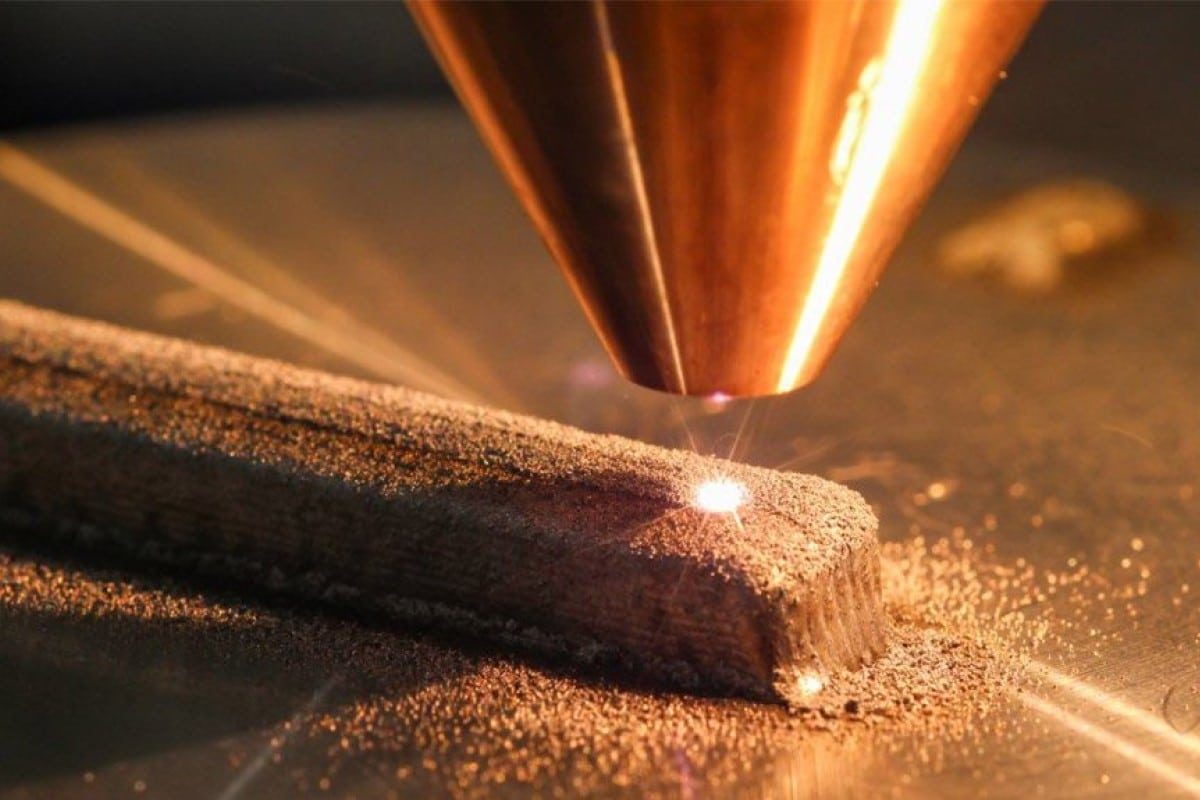

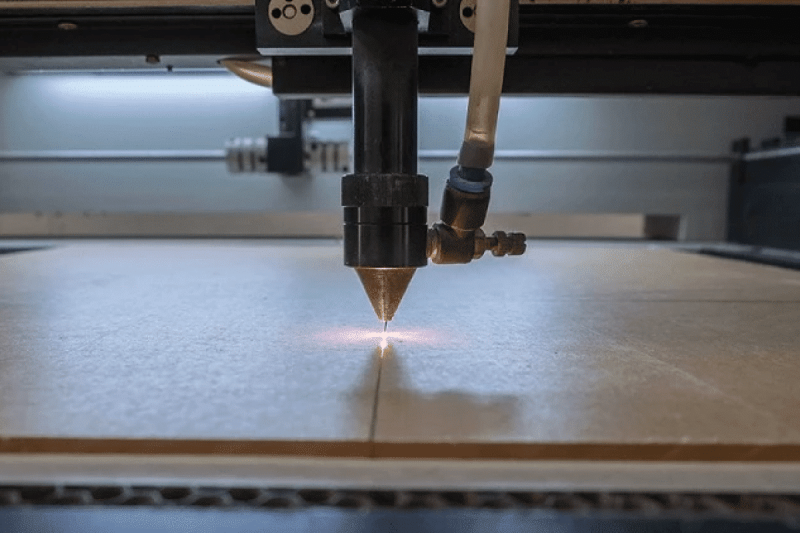

CO2 laser cutting technology uses the laser beam generated by a carbon dioxide (CO2) laser generator to achieve cutting by focusing the laser beam to a very small point to generate enough energy to melt, vaporize, or burn the material. CO2 laser cutting technology has the following characteristics and advantages:

- High energy density: The laser beam generated by the CO2 laser generator has high energy density and can be concentrated into a very small area to achieve precise cutting of materials.

- Multi-material applicability: CO2 laser cutting technology is suitable for a variety of materials, including metals, non-metals, and composite materials, and has a wide range of applications.

- High precision and efficiency: Due to the high energy density and precise control of the laser beam, CO2 laser cutting technology can achieve high-precision and high-efficiency cutting, and is suitable for workpieces that require high-precision processing.

- Flexibility: CO2 laser cutting technology has good flexibility and can achieve cutting of various shapes, including straight lines, curves, complex contours, etc., to meet the processing needs of different workpieces.

- In the fields of automobile manufacturing, aerospace, electronic equipment, metal processing, etc., CO2 laser cutting technology has been widely used, providing efficient and precise processing solutions for industrial production.

Basic principles of beam delivery systems

- Non-contact processing: CO2 laser cutting is a non-contact processing technology that does not produce mechanical stress or deformation and is suitable for applications with high requirements on the material surface. The following are the basic principles of beam delivery systems:

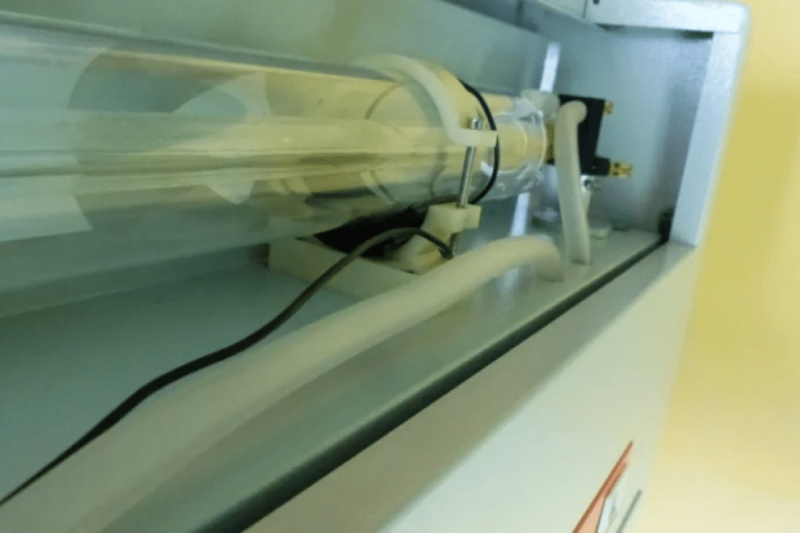

- Laser generator generates laser beam: CO2 laser generator generates laser beam by exciting carbon dioxide gas. These laser beams have a certain wavelength and energy and are used to process materials.

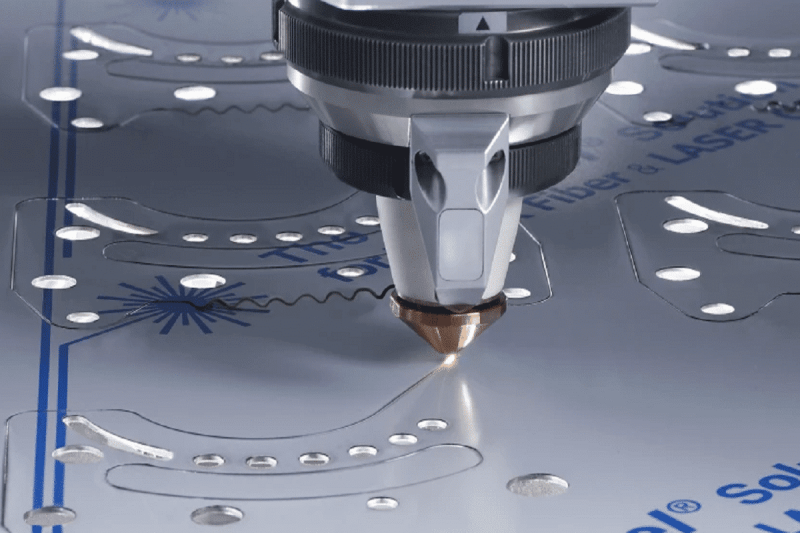

- Lenses focus the beam: A beam delivery system typically contains one or more lenses that focus the beam. The function of the lens is to change the propagation direction and diameter of the beam and focus it on a small point, thereby increasing the energy density of the beam.

- Reflectors control the direction of the beam: The beam transmission system usually also includes some reflectors to control the direction of the beam. These mirrors can direct the beam from the laser generator to the processing area, while also reflecting the beam to the laser generator for regulation and control.

- Fiber optic delivery systems: In some cases, beam delivery systems may use fiber optics to deliver the laser beam. Fiber optics are highly flexible and stable and can transmit laser beams from the laser generator to remote processing areas while reducing energy loss and interference.

- Maintain beam quality and stability: One of the key tasks of the beam delivery system is to ensure beam quality and stability. Through precise design and optimized selection of optical components, the defocus, dispersion, and distortion of the beam can be minimized, thereby maintaining the high quality and stability of the beam.

Factors affecting the performance of beam delivery systems

The performance of the beam delivery system is affected by many factors, which directly affect the cutting quality, efficiency, and stability of the CO2 laser cutting machine. The following are the main factors influencing beam delivery system performance:

- Quality of optical components: Optical components include lenses, mirrors, etc., and their quality directly affects the transmission quality of the light beam. Precision optical components can reduce the defocus, dispersion, and distortion of the beam and ensure the stability and collimation of the beam.

- Beam quality adjustment: The quality parameters of the beam include beam diameter, spot shape, wavefront quality, etc. These parameters are affected by optical components. Good beam quality ensures cutting quality and accuracy.

- System loss: Energy loss occurs during the transmission process of the beam, including absorption, scattering, reflection, etc. The reduction of system loss can improve energy utilization and improve cutting efficiency.

- Energy transmission efficiency: The design and optimization of the beam transmission system directly affects the energy transmission efficiency. Measures such as reasonable system layout, high-quality optical component selection, and stable optical fiber transmission can improve energy transmission efficiency.

- System Stability: The stability of the beam delivery system is critical to cutting quality and stability. Factors such as the stability of the mechanical structure, the impact of temperature changes on optical components, and the stability of the optical path will all affect the stability of the system.

- Environmental factors: Environmental factors include the impact of temperature, humidity, dust, etc. on the performance of the beam transmission system. Harsh environmental conditions may lead to contamination of optical components, generation of bubbles, etc., thus affecting beam quality and stability.

- Beam correction and alignment: The optical components in the beam delivery system require regular correction and alignment to ensure normal transmission and stability of the beam.

How does the beam delivery system affect the performance of CO2 laser cutting machines?

Cut quality

Cutting speed

Processing accuracy

Energy efficiency

System stability

Optimization and improvement of beam delivery system

Optimization and improvement of the beam transmission system are crucial to improving the performance of CO2 laser-cutting machines. The following are some possible optimization and improvement measures:

- Optimizing the quality of optical components: Choosing high-quality, high-precision optical components, including lenses, mirrors, etc., can reduce the defocus, dispersion, and distortion of the beam and improve the quality of the beam.

- System layout optimization: Carry out a reasonable layout design for the beam transmission system, reduce the optical path length, and reduce energy loss and system loss during the beam transmission process.

- Application of optical fiber transmission system: Optical fiber is highly flexible and stable, which can reduce the energy loss and interference of light beams during long-distance transmission, and improve energy transmission efficiency and cutting quality.

- Temperature control and stability improvement: Temperature control and stability improvement of the beam transmission system can reduce the impact of temperature changes on optical components and maintain the stability and accuracy of the beam transmission system.

- Real-time monitoring and adjustment: Introduce a real-time monitoring system to monitor the beam transmission process in real time, detect problems in time, and make adjustments and corrections.

- Application of new materials and new technologies: Explore the application of new materials and new technologies in beam transmission systems, such as the use of optical thin film coating technology, photonic crystal materials, etc., to improve the performance and efficiency of beam transmission systems.

- Regular maintenance and upkeep: Perform regular maintenance and upkeep on the beam transmission system, including cleaning optical components, calibrating the optical path, adjusting beam parameters, etc., to ensure that the system is in optimal condition, improving working performance, and extending service life.

Summarize

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.