Laser Cleaning Machine Safety Guide

This article will discuss in depth the key safety matters that need to be paid attention to during the operation of the laser cleaning machine.

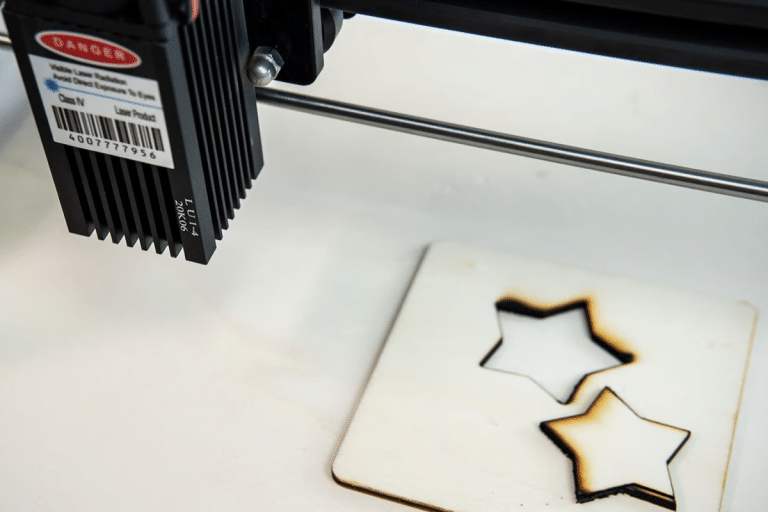

What Materials Can Be Marked With Different Types of Laser Marking?

This article will focus on the best of these three types of laser marking technologies, outline how they work, and delve into the materials and applications that can be effectively marked using fiber optic, CO2, and UV laser marking technologies.

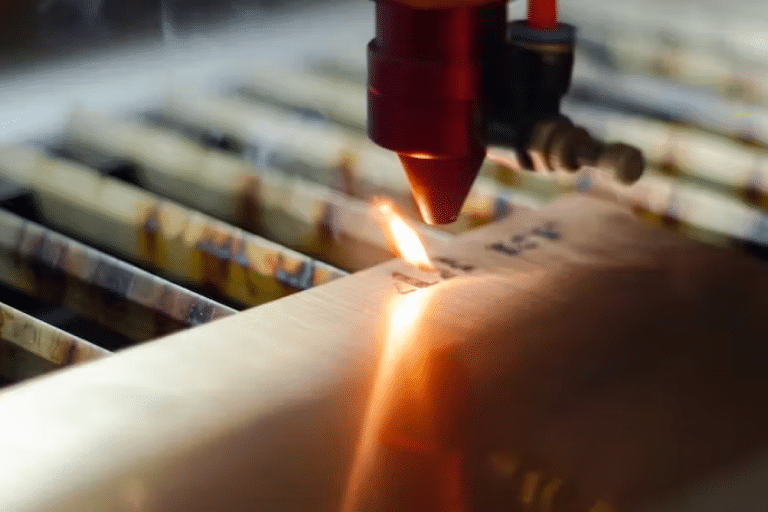

Typical Service Life And Influencing Factors of CO2 Laser Tubes

This article will discuss the typical service life of CO2 laser tubes in CO2 laser cutting machines and the factors that affect its service life.

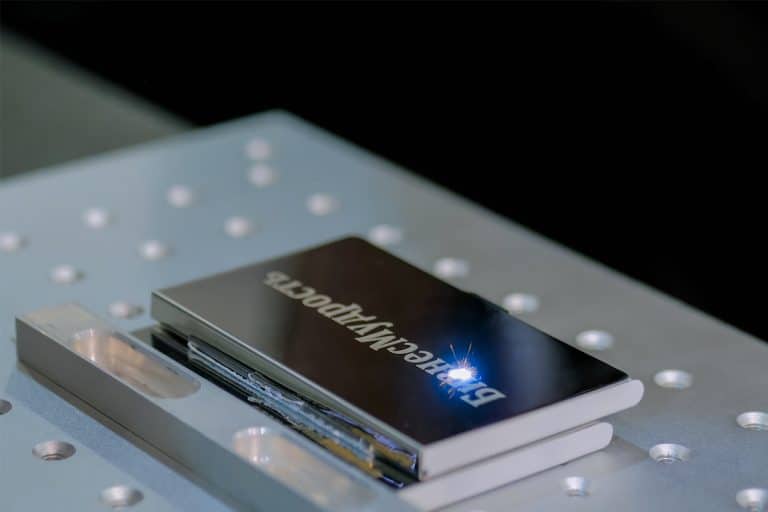

Affordable Laser Welding Machine Buying Guide

his article will analyze the many factors that contribute to the high price of laser welding machines and provide some suggestions on how to obtain an affordable and high-performance laser welding machine while meeting manufacturing needs.

How to Maintain The Cooling System of The Laser Cleaning Machine?

This article will explain the working principle of laser cleaning machines, several common cooling system types, specific maintenance methods of laser cleaning machine cooling systems, and the importance of cooling systems, so as to ensure the efficient performance of laser cleaning machines during operation.

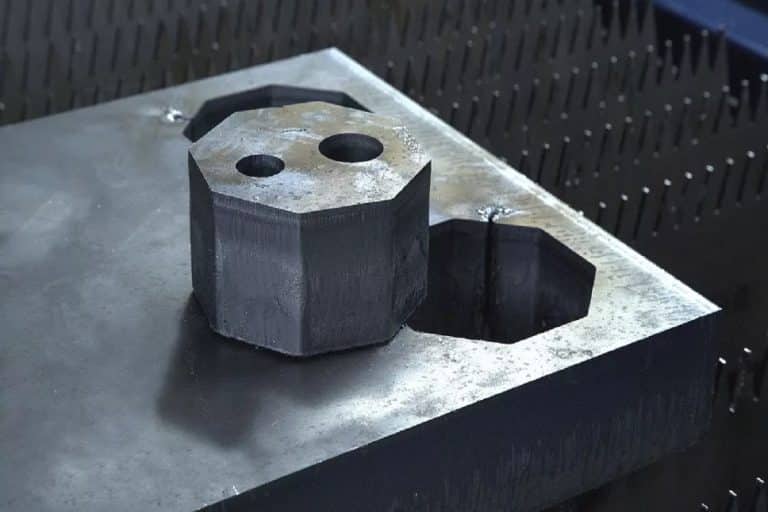

Decoding Laser Cutting Costs: Key Considerations Unveiled

This article discusses the cost-effectiveness of laser cutting, explores the cost considerations related to laser cutting, and conducts a comparative analysis of laser cutting costs and benefits.

Safety Precautions When Using CO2 Laser Cutting Machine

This article will discuss in detail the specific safety precautions when using a CO2 laser cutting machine to ensure the safety of the operator and the efficient operation of the equipment.

Revealing the Depth of Laser Marking: Discovering Maximum Laser Marking Depth

Laser marking is a versatile and precise technology, and marking depth is a key parameter that determines the longevity, visibility, and functionality of the marked material. This article will fully reveal the complexities of laser marking maximum depth.

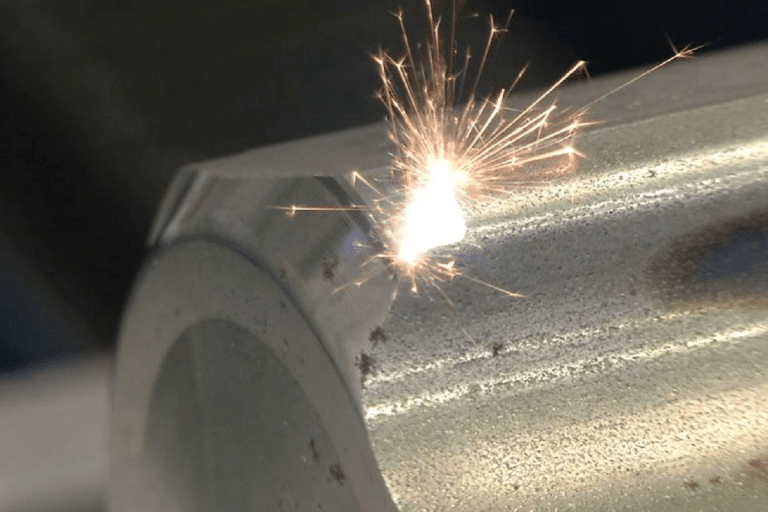

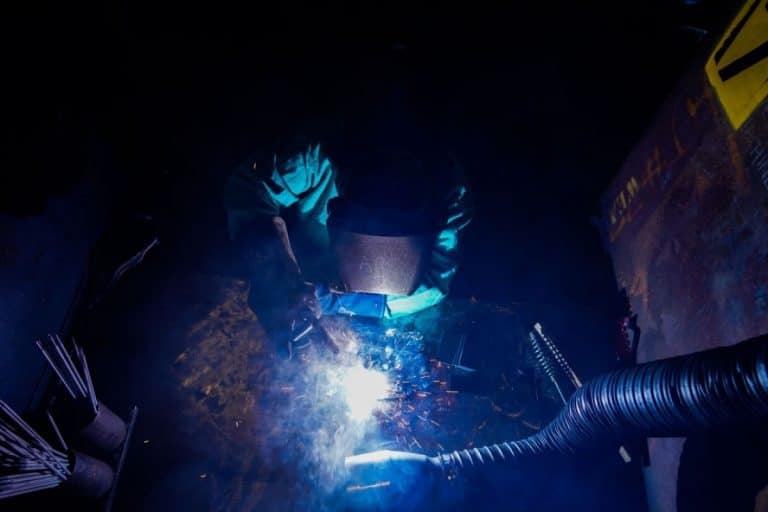

Welding Methods Comparison: Unveiling Optimal Performance

This article will compare several common welding methods, including laser welding, tungsten inert gas welding, metal inert gas welding, shielded metal arc welding, submerged arc welding, and resistance spot welding, to understand their working principles and discuss which welding method has The most outstanding performance.

Laser Cleaning: Eco-Friendly Assessment

This article will delve into the working principles and advantages of laser cleaning, the potential impacts on the environment caused by the use of laser cleaning machines, and environmentally friendly measures.

What Plastics Can CO2 Laser Processes?

This article will discuss the plastic materials that CO2 laser marking can process, including explaining the principles of CO2 laser cutting technology, its advantages in plastic processing, the types of plastics that can be marked, different plastic processing applications, and the types of plastics that can meet the standards.

Environmental Advantage: The Sustainability Benefits Of Laser Cutting

This article will introduce the basic principles of laser cutting technology, discuss the importance of laser cutting in environmental protection, analyze the advantages of laser cutting and environmental protection, and look forward to the future development trend of laser cutting.

Effect Of Laser Power And Wavelength On Marking Ability

Laser power and wavelength are two key parameters in the laser marking process. We will explore its impact on marking capabilities and provide reference and guidance for the optimization of laser marking processes.

Cooling System And Maintenance Of Laser Welding Machine

This article will introduce the cooling system of the laser welding machine and its principles, the conditions for the effective operation of the cooling system, the importance of maintaining the cooling system, and specific maintenance methods. Protect equipment from overheating damage, ensuring the stability and reliability of your laser welding process.

Factors Affecting Laser Cutting Speed And Efficiency

This article comprehensively explores the factors that influence laser cutting speed and efficiency, enabling users to harness the potential of laser cutting technology to drive innovation in manufacturing processes.

Analysis Of Cost And Influencing Factors Of CO2 Laser Cutting Machine

This article will explore how much a CO2 laser cutter costs, the factors that affect those costs, and compare it to other types of laser cutters. It makes it easy for users to choose the one that best suits their needs.

Maintenance And Repair Requirements For Laser Marking Equipment

With the use of laser equipment, maintenance, and repair have also become important aspects to ensure the operation of the equipment. We will provide a comprehensive introduction to the maintenance and repair requirements of laser marking equipment. To help readers better understand how to effectively manage and maintain these devices.

Power Requirements And Electrical Safety Precautions For Laser Welding Machines

This article will discuss the power requirements and electrical safety precautions of laser welding machines, including understanding the working principle of laser welding machines, the power and voltage requirements of laser welding machines, what electrical safety risks laser welding machines have, and how to avoid them, etc.

Beam Transmission System in CO2 Laser Cutting Machine: Analysis of Principles And Performance Impact

This article will discuss the basic principles of the beam transmission system in CO2 laser cutting machines, performance influencing factors, and how the beam transmission system affects the working performance of CO2 laser cutting machines, and take corresponding optimization measures to improve the application of CO2 laser cutting technology. Levels are of great significance.

Choosing The Right Laser Cutting Machine For Your Specific Application

It is important to understand the key factors to consider when choosing a laser cutter. In this article, we’ll delve into the importance of each factor and explore how to choose the best laser-cutting machine for your specific application needs.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.