What Are The Factors That Affect The Thickness of Laser Welding

Explore the key factors influencing the thickness of laser welding, including laser power, welding speed, material properties, beam focus, and more, to achieve optimal welding results.

How to Maintain The Laser Cleaning Machine?

Learn essential maintenance practices for laser cleaning machines, including daily, weekly, monthly, and annual tasks, troubleshooting tips, and best practices to ensure long-lasting performance.

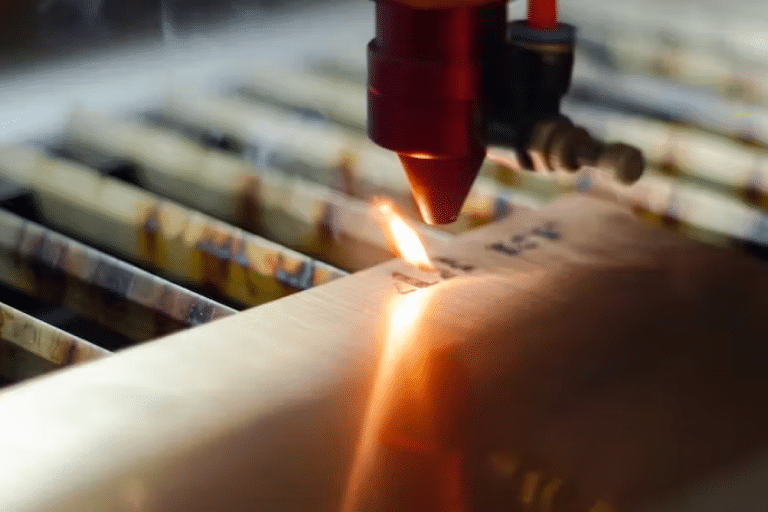

What Are The Three Main Types of Laser Cutting?

Discover the three main types of laser cutting—Fusion Cutting, Flame Cutting, and Sublimation Cutting—and learn their unique processes, advantages, and applications in manufacturing.

What Are The Advantages And Disadvantages of Fiber Laser Marking Machines?

Discover the key advantages and limitations of fiber laser marking machines, including precision, speed, durability, material versatility, costs, and industry applications. Make informed choices for your marking needs.

What Factors Determine The Speed And Accuracy of CO2 Laser Cutting?

Explore the key factors that determine the speed and accuracy of CO2 laser cutting, including laser power, material properties, assist gases, beam focus, and more.

What Welding Defects Can Occur in Laser Welding? How To Solve It?

Learn about common welding defects in laser welding, their causes, and practical solutions to enhance weld quality and reliability, ensuring optimal performance in your applications.

What Are The Factors That Affect The Cost of a Laser Cleaning Machine?

Discover the key factors influencing the cost of laser cleaning machines, including power output, technology, customization, market dynamics, and support services, for informed purchasing decisions.

The Range of Materials That Fiber Laser Cutting Can Cut

Explore the versatility of fiber laser cutting technology and discover the wide range of metals it can precisely cut, from carbon steel to titanium, across diverse industries.

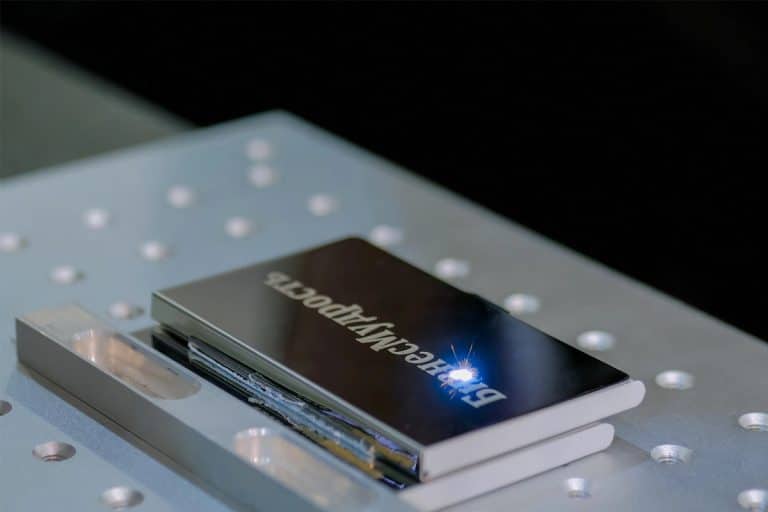

What is The Laser Marking Machine? How Does it Work?

Laser marking machines create precise, permanent markings on various materials. This article explores how they work, their applications, benefits, and key considerations.

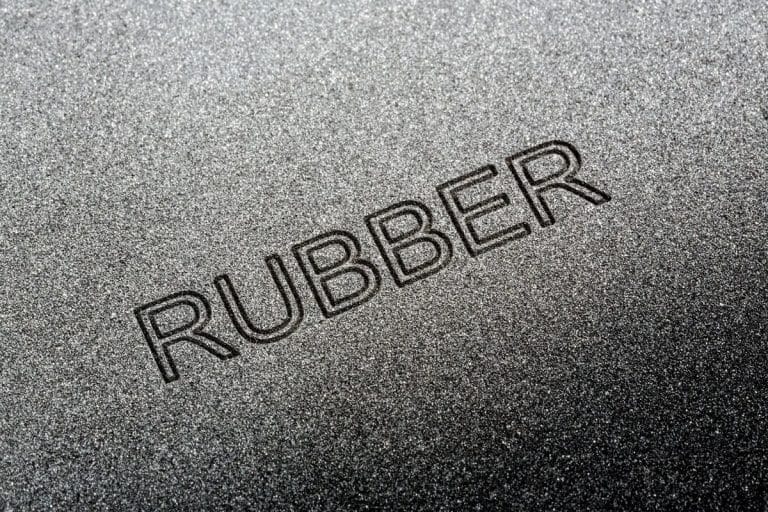

Laser Marking Machine VS Laser Engraving Machine

Explore the key differences between laser marking and laser engraving machines, including their unique applications, benefits, and industry-specific uses, to help you choose the right solution.

Environmental Advantage: The Sustainability Benefits Of Laser Cutting

This article will introduce the basic principles of laser cutting technology, discuss the importance of laser cutting in environmental protection, analyze the advantages of laser cutting and environmental protection, and look forward to the future development trend of laser cutting.

Effect Of Laser Power And Wavelength On Marking Ability

Laser power and wavelength are two key parameters in the laser marking process. We will explore its impact on marking capabilities and provide reference and guidance for the optimization of laser marking processes.

Cooling System And Maintenance Of Laser Welding Machine

This article will introduce the cooling system of the laser welding machine and its principles, the conditions for the effective operation of the cooling system, the importance of maintaining the cooling system, and specific maintenance methods. Protect equipment from overheating damage, ensuring the stability and reliability of your laser welding process.

Factors Affecting Laser Cutting Speed And Efficiency

This article comprehensively explores the factors that influence laser cutting speed and efficiency, enabling users to harness the potential of laser cutting technology to drive innovation in manufacturing processes.

Analysis Of Cost And Influencing Factors Of CO2 Laser Cutting Machine

This article will explore how much a CO2 laser cutter costs, the factors that affect those costs, and compare it to other types of laser cutters. It makes it easy for users to choose the one that best suits their needs.

Maintenance And Repair Requirements For Laser Marking Equipment

With the use of laser equipment, maintenance, and repair have also become important aspects to ensure the operation of the equipment. We will provide a comprehensive introduction to the maintenance and repair requirements of laser marking equipment. To help readers better understand how to effectively manage and maintain these devices.

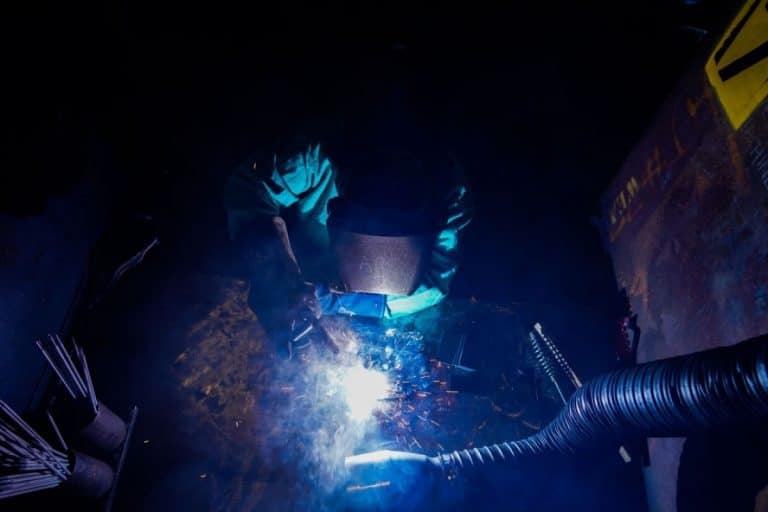

Power Requirements And Electrical Safety Precautions For Laser Welding Machines

This article will discuss the power requirements and electrical safety precautions of laser welding machines, including understanding the working principle of laser welding machines, the power and voltage requirements of laser welding machines, what electrical safety risks laser welding machines have, and how to avoid them, etc.

Beam Transmission System in CO2 Laser Cutting Machine: Analysis of Principles And Performance Impact

This article will discuss the basic principles of the beam transmission system in CO2 laser cutting machines, performance influencing factors, and how the beam transmission system affects the working performance of CO2 laser cutting machines, and take corresponding optimization measures to improve the application of CO2 laser cutting technology. Levels are of great significance.

Choosing The Right Laser Cutting Machine For Your Specific Application

It is important to understand the key factors to consider when choosing a laser cutter. In this article, we’ll delve into the importance of each factor and explore how to choose the best laser-cutting machine for your specific application needs.

What is The Marking Speed of The Laser Marking Machine?

In this article, we delve into the complexities of laser marking machine speed to standard, revealing what it means and the many factors that influence it.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.