How to Choose A Suitable Laser Cleaning Machine?

Learn how to choose the right laser cleaning machine for your needs by exploring key factors like material type, laser power, automation, safety, and support for optimized performance.

The Application of Laser Cleaning Machines in The Industry

Laser cleaning machines provide precise, efficient, and eco-friendly solutions for industrial applications, removing contaminants like rust, paint, and grease without damaging underlying materials.

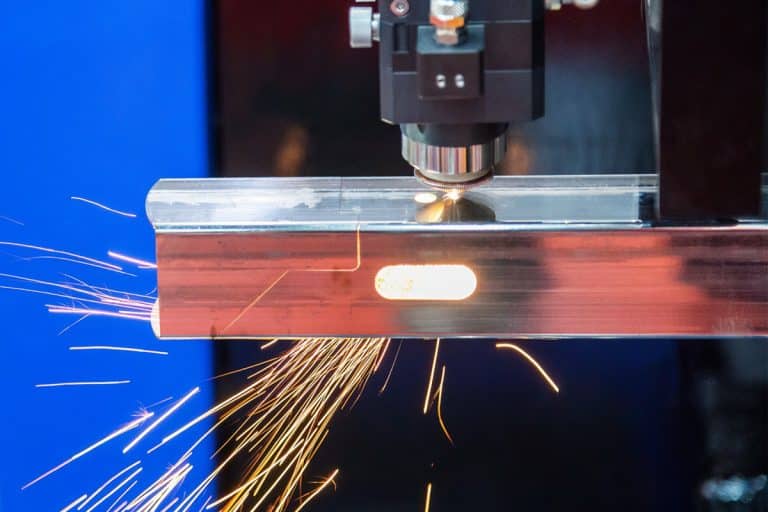

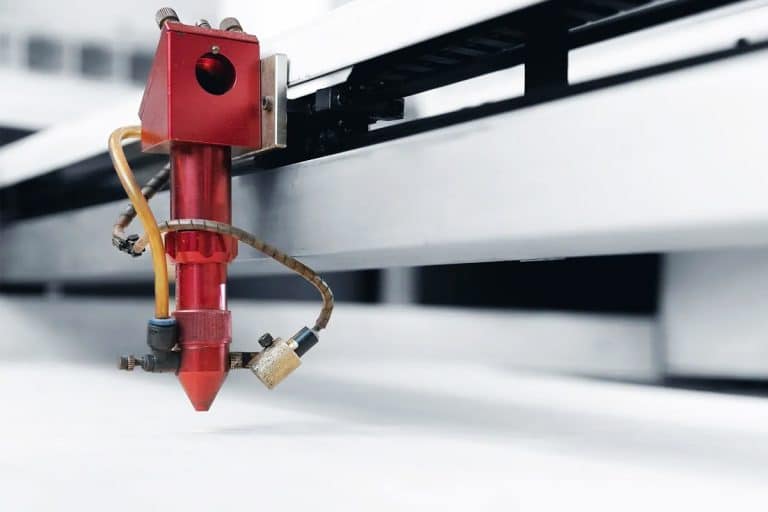

Why Do You Need A Professional Tube Laser Cutting Machine?

Learn why investing in a professional tube laser cutting machine can help improve the precision, efficiency, and versatility of your manufacturing process, and how it can give your business a competitive edge in today’s market.

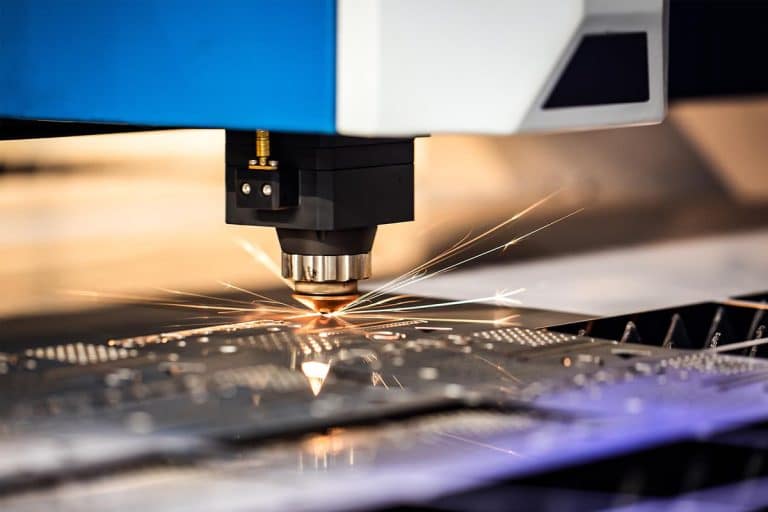

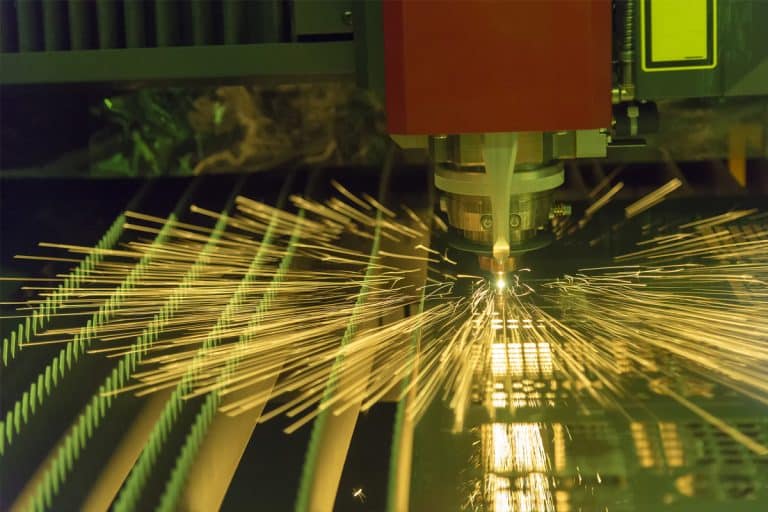

Fiber Laser Cutting VS Plasma Cutting

This article compares fiber laser cutting and plasma cutting, exploring their differences in precision, speed, material compatibility, cost, and applications to help you choose the best method for your needs.

Top 6 Reasons to Use Laser Cutting for Sheet Metal Fabrication

Discover the top six reasons why laser cutting is essential for sheet metal fabrication. Learn how advanced machines enhance precision, efficiency, and cost-effectiveness in modern manufacturing.

How To Choose The Right Laser Cutting Machine?

Learn how to choose the right laser-cutting machine for your needs. Explore key factors like material types, cutting speed, precision, and costs to make an informed decision.

What Is The Price of A Laser Cutting Machine?

Laser cutting equipment can provide enterprises with fast and efficient metal-cutting and carving methods. Laser cutting and carving projects are more accurate and environmentally friendly than most cutting technologies.

What Is Laser Marking?

Laser marking is a precise, non-contact process that uses focused laser beams to create permanent marks on various materials, enhancing product identification, traceability, and quality.

How Much Does A Laser Cleaning Machine Cost?

Discover the factors that impact the cost of laser cleaning machines, from power output to automation, and learn how to choose the right solution for your budget and cleaning needs.

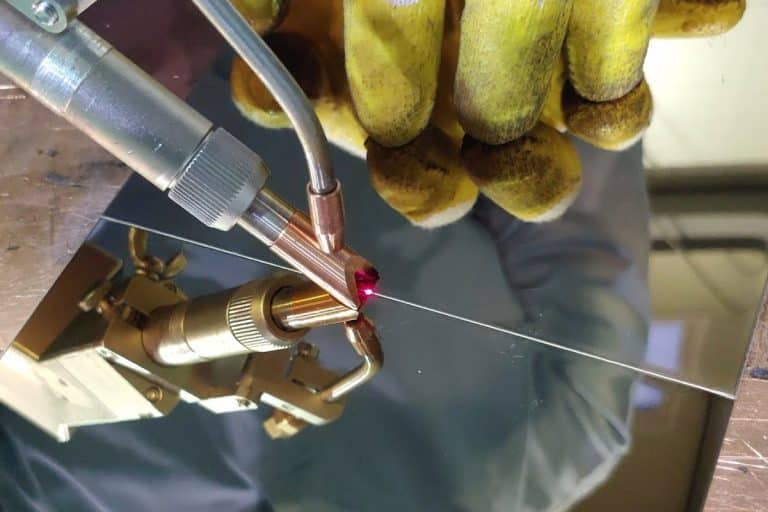

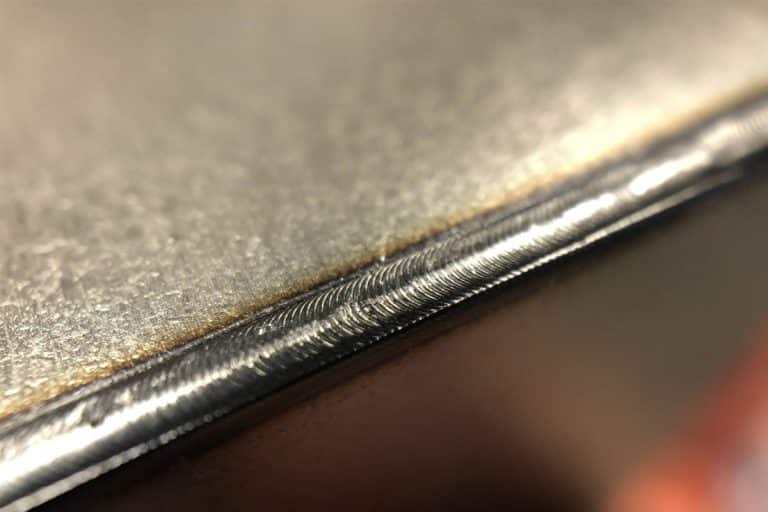

What Is Laser Welding?

Laser welding is a precise, high-speed process using concentrated laser beams to join materials. Learn its benefits, applications, and key considerations in modern manufacturing.

The Influence of Fiber Laser Beam Quality on Cutting Accuracy and Quality

The quality of fiber laser beam has an important influence on the accuracy, efficiency and surface quality of laser cutting. Optimizing the beam quality can significantly improve the cutting effect and production efficiency.

Understanding Operating Costs: Factors Affecting Fiber Laser Cutting Machine Costs

This article deeply analyzes the key factors that affect the operating costs of fiber laser cutting machines and provides optimization strategies to help companies reduce costs, and improve efficiency and market competitiveness.

How to Choose a Suitable CO2 Laser Cutting Machine?

This guide deeply analyzes the working principle of CO2 laser cutting machines, key factors for purchase, market brand comparison, and future technology trends, helping companies choose the most suitable laser cutting equipment to improve processing efficiency and competitiveness.

How Fast Is Laser Cleaning?

This article mainly discusses the principles of laser cleaning technology, factors affecting speed, and methods to improve cleaning efficiency, to help companies optimize laser cleaning processes and improve overall production efficiency.

Precautions for Operating Fiber Laser Cutting Machine

This article mainly introduces the safety risks, personal protection and maintenance measures in the operation of fiber laser cutting machines, aiming to help companies create a safe and efficient production environment.

What Is the Difference Between CO2 and Fiber Laser Welding Machines?

This article mainly discusses the differences betweenCO2 laser welding machines and fiber laser welding machines in terms of key technical parameters and applications, helping companies make equipment choices based on their needs.

Laser Cutting VS Waterjet Cutting

Laser cutting and water jet cutting each have their own advantages and disadvantages. Through a comparative analysis of the principles, advantages, and limitations, this article helps readers choose the cutting technology that best suits their needs.

How to Achieve Minimum Weld Width in Laser Welding

This article mainly discusses how to achieve the minimum weld width by optimizing the laser welding process, and introduces its important role in improving joint strength, improving welding appearance quality, and reducing thermal deformation.

How Can Laser Cleaning Help Reduce Waste and Improve Sustainability?

This article will take a deep look at how laser cleaning technology can reduce waste, protect resources, and promote new possibilities for sustainable development!

How CO2 Laser Cutting Minimizes Material Waste?

This article introduces how to minimize material waste in the CO2 laser-cutting process by precisely controlling laser-cutting parameters, optimizing material arrangement, and selecting appropriate equipment and materials.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.