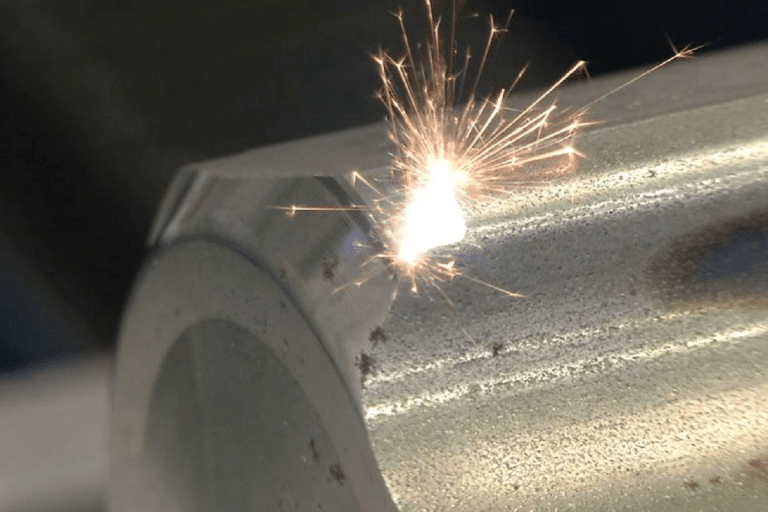

How Does the Focal Point of the Laser Beam Affect the Quality of the Weld?

This article discusses how laser beam focusing affects welding quality, including its impact on penetration depth, weld width, etc., and how to optimize laser beam focusing to achieve high-quality welding.

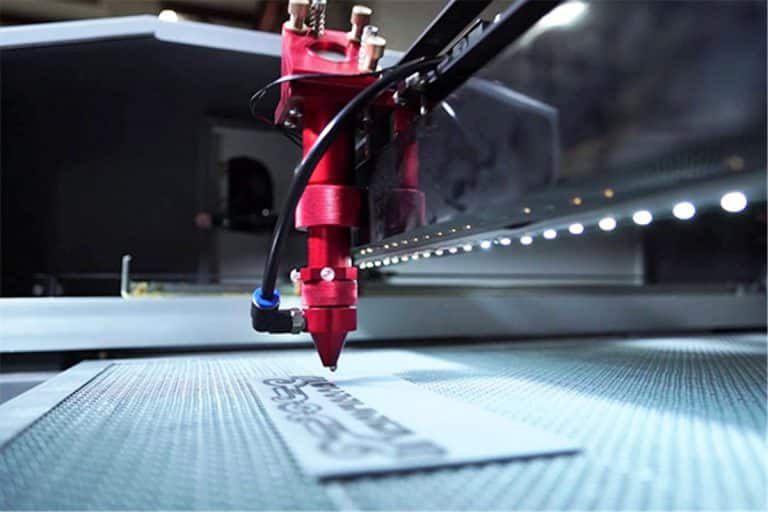

What Factors Affect the Quality of Laser Marking?

This article mainly introduces the key factors that affect the quality of laser marking, including laser type, material properties, laser parameter settings, environmental conditions and operator skills, to help readers optimize the marking effect.

Is the Smoke Produced by Laser Cutting Machines Toxic?

This article introduces the hazards of laser cutting fumes, their composition, health risks, safety regulations, mitigation strategies, and the importance of educating operators to ensure a safe working environment.

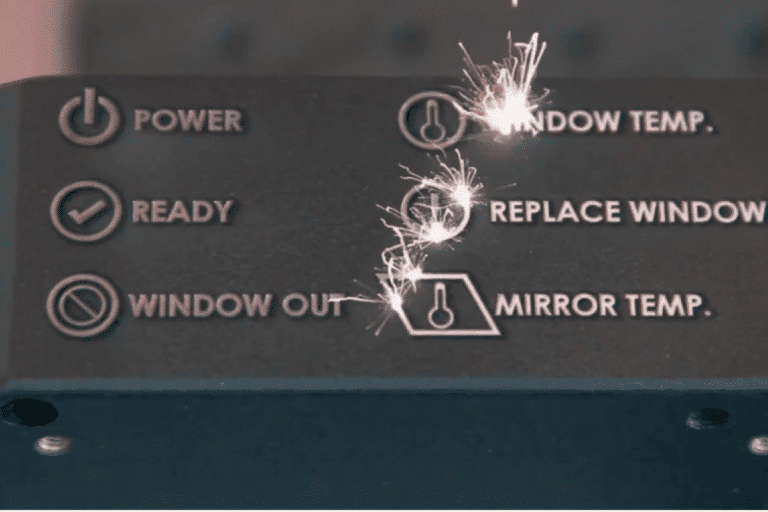

Are Fiber Laser Generators Safe?

This article will discuss in detail the working principle, composition structure, main features, and common applications of fiber laser generators to help readers fully understand the safety and usage precautions of fiber laser generators.

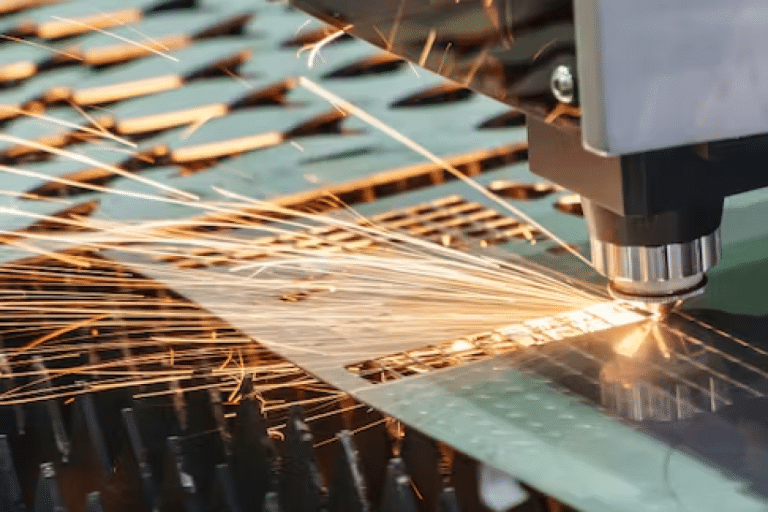

Is a Cheap Laser Cutting Machine Worth Buying?

This article explores the pros and cons of buying a cheap laser cutting machine to help readers understand its suitability, possible pitfalls, and key factors to consider before purchasing.

How to Choose the Power of a CO2 Laser Cutting Machine: A Comprehensive Guide

Choosing the right CO2 laser power is key for efficiency and quality. This guide covers principles, power relationships, and material-specific recommendations for optimal results.

Laser Welding Aluminum Guide

This article mainly introduces the basics of laser welding of aluminum, discusses the challenges and solutions faced in the welding process, provides detailed steps and techniques for welding aluminum, and introduces the application areas of welding aluminum.

Common Problems and Solutions for Fiber Laser Cutting

This article will delve into the common problems and challenges of fiber laser cutting and provide corresponding solutions to help you improve processing productivity and extend equipment life.

Factors to Consider When Installing Ventilation and Exhaust Systems for CO2 Laser Cutting Machines

This article mainly studies the factors that need to be considered when installing the ventilation and exhaust system of the CO2 laser cutting machine, to help you consider the importance of ventilation and exhaust issues to the safety of later production in the early stage of the project.

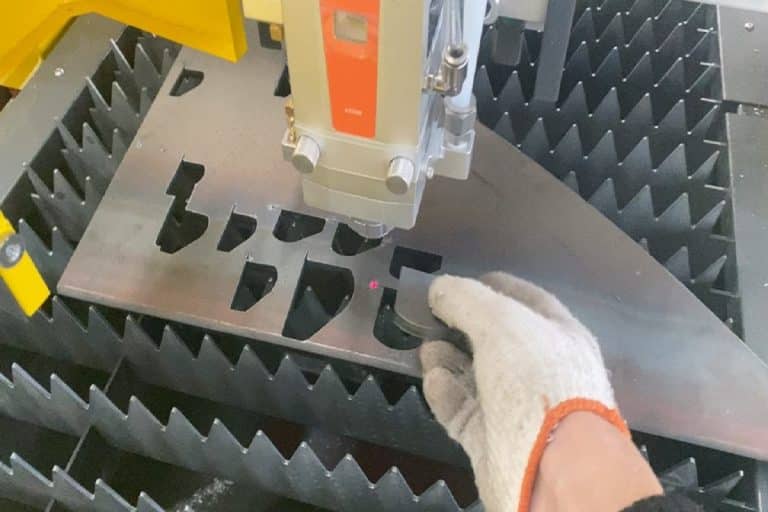

How Does a Fiber Laser Cutting Machine Handle Reflective Materials?

This article focuses on how laser cutting machines handle highly reflective materials and introduces some advanced technologies and best practices.

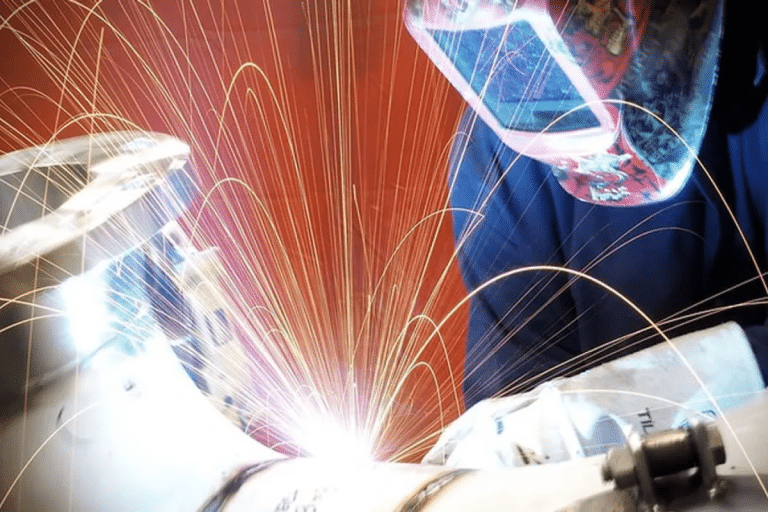

Welding Methods Comparison: Unveiling Optimal Performance

This article will compare several common welding methods, including laser welding, tungsten inert gas welding, metal inert gas welding, shielded metal arc welding, submerged arc welding, and resistance spot welding, to understand their working principles and discuss which welding method has The most outstanding performance.

Laser Cleaning: Eco-Friendly Assessment

This article will delve into the working principles and advantages of laser cleaning, the potential impacts on the environment caused by the use of laser cleaning machines, and environmentally friendly measures.

Laser Cutting VS Sawing

This article will take an in-depth look at two mainstream cutting technologies – sawing and laser cutting, understand how they work, and compare their advantages and disadvantages in the field of material processing to help readers better choose the cutting method that suits their needs.

Mastering CO2 Laser Cutting: Essential Skills And Training

This article will discuss the necessary skills and training to operate a CO2 laser cutting machine, explain the potential risks when using a CO2 laser cutting machine, and understand the specific safety operation requirements to better ensure that operators can use CO2 laser cutting machines safely and efficiently.

How Accurate is Laser Marking?

Laser marking provides a highly precise and efficient method of adding permanent marks to a variety of materials. Let’s take a look at how accurate laser marking is and what factors affect laser marking accuracy.

What Are The Factors That Affect The Edge Quality of CO2 Laser Cutting?

In this article, we explore the many factors that affect the edge quality of CO2 laser cutting and provide you with various strategies to improve the edge quality of your workpiece.

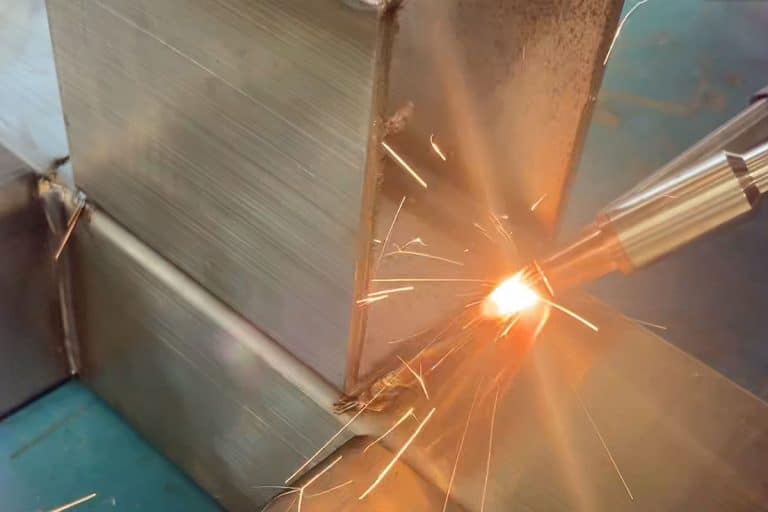

Laser Welding: Material Selection And Limitations

This article will discuss the material selection and limitations of laser welding, explore the types of materials that laser welding can weld and the materials that are not suitable for laser welding, and analyze the reasons in depth.

What Types of Materials And Surfaces Can Laser Cleaning Machines Clean?

This article will explore the use of laser cleaning machines for cleaning various types of materials and surfaces, as well as the necessity and application areas of choosing laser cleaning technology.

Ventilation And Extraction Requirements For Operating a Laser Cutting Machine

Laser-cutting machines produce smoke, dust, and potentially harmful by-products that need to be managed to ensure a safe and healthy work environment. In this article, we will explore the specific ventilation and extraction requirements necessary for the safe operation of a laser-cutting machine.

A Comprehensive Analysis of Laser Welding vs MIG Welding

This article provides an analysis of laser welding and MIG welding, comparing their differences to help users make the right choice based on their specific needs.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.