Can Laser Mark Colors?

Current industry regulations require parts to have clear and legible markings, and as a result, laser marking processes are becoming more popular. Traditional engraving or screen printing processes are expensive to mark material surfaces and often result in part defects and unclear markings that wear away over time. Therefore, since the advent of the new laser marking process, it has been welcomed by manufacturers for its many advantages such as permanent marking, low operating costs, and no damage to workpieces.

Laser marking is a versatile process in which a laser beam is illuminated on the surface of a material, often creating black, gray or white marks. However, in the metal decorative industry or other industries that pursue higher product differentiation, color marking begins to have a higher demand. So can lasers perform color marking? This article explores the possibilities of laser color marking by taking you through the principles and types of laser marking.

Table of Contents

What is laser marking

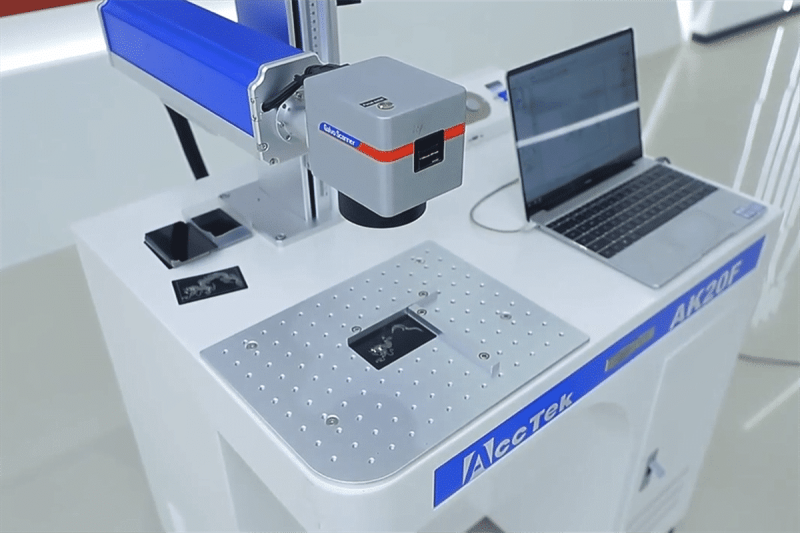

The laser marking machine is a device that can leave permanent marks on the surface of materials. Laser marking machines can achieve automation and high-speed processing, and can leave permanent traceable marks on the surface of a range of materials such as stainless steel, carbon steel, plastics, wood, and rubber. These markings include serial numbers, barcodes, QR data matrix codes, or graphics and are primarily used to identify parts and products.

How laser marking works

Laser marking works by using a focused beam of light to mark the surface of a material. When a beam of light interacts with a material’s surface, it changes the material’s properties and appearance. This concentrated beam is targeted only at a designated area, allowing laser marking to create precise, high-quality, high-contrast marks. This feature makes laser marking machines ideal for high-precision and permanent marking applications.

How does the laser marking machine work

To create long-lasting marks, laser marking machines produce a focused beam containing high energy. The accumulated energy is released via mirrors into a coherent beam of light onto the material surface. As the beam interacts with the component surface, thermal energy is transferred from the beam to the surface. As a result, the appearance and properties of the material change, resulting in different pattern marks. The process is typically performed with a laser marking machine using an oscillator, scanning mirror, and focusing lens. The speed, power, and focus of the laser beam on the part will result in different laser processes. Choosing the correct laser configuration and parameters is key to successfully marking materials.

What are the applications of laser marking

- Laser Engraving: Create deep and permanent marks that are resistant to wear and corrosion. Laser engraving carves marks deep into the material by breaking down part of the material into dust. For example, laser engraving can be used for VIN markings, which often require deep markings to ensure durability and prevent counterfeiting.

- Laser Etching: High speed and high contrast permanent marking. Laser etching is often used when the laser marking process must be integrated into the production line as quickly as possible. The technology melts the surface of the material almost instantly, creating high and low bumps on the material’s surface. This creates high-contrast black-and-white marks, for example.

- Laser annealing: Creates markings beneath the surface without affecting the base metal or its protective coating, used to protect the material from damage. Laser annealing causes chemical changes beneath the surface of the material without causing anything to be broken down, displaced, or melted. It is one of the only solutions for marking stainless steel, whose surface must be unaffected by marking. Laser annealing is also used in aesthetic applications such as signage. Although laser annealing is slower than other laser marking processes, it creates the most beautiful surface finish.

- Laser ablation: Laser ablation is the process of marking by removing coatings. Laser ablation creates marks by removing something other than material from a surface, usually paint, and can be used to remove portions of paint to mark identifiers such as barcodes. Laser ablation is the same as laser cleaning, the only difference is the application: the purpose of laser ablation is to mark, not to clean. In some cases, laser ablation is the fastest laser marking solution, such as removing paint faster than marking steel.

What types of laser marking machines are there

Most industrial laser systems emit wavelengths that are invisible to the naked eye, and different materials react differently to different wavelengths. Every material has a unique composition that absorbs certain wavelengths and not others. Because laser generators produce a single wavelength, different types of laser marking machines are used in different application scenarios. You need to choose the appropriate laser marking machine based on the material properties.

CO2 laser marking machine

CO2 laser marking machine is typically sealed tube marking systems with a galvanometer-controlled beam designed to mark non-metallic surfaces. The CO2 laser generator stimulates CO2 gas to produce wavelengths between 9000nm and 11000nm, which can provide the best marking effect for organic materials such as paper, wood and certain plastic polymers. They are also suitable for leather and glass marking. CO2 laser marking machines are a popular choice for product identification marks, logos, date stamps, and more. These machines help create serial numbers, logos and barcodes on appliances, integrated circuits, food and medical packaging, and electronic components.

Fiber laser marking machine

In recent years, fiber laser marking machine has become increasingly popular. The fiber laser generator excites a rare earth metal called ytterbium to produce photons with a wavelength of 1064nm. This wavelength is ideal for marking metallic materials because a large amount of its energy can be absorbed by the material. Fiber laser marking machines are suitable for deep engraving or etching, and they can provide better marking results on harder metals. Due to their small spot size, high beam quality and large lens, fiber laser marking machines are ideal for batch marking of small parts.

UV laser marking machine

The UV laser marking machine is designed with a high absorption wavelength of 355nm and can be used for parts marking. Due to the material’s high absorption of UV laser, they are ideally suited for “cold marking”, ensuring there is no thermal stress on the material. UV laser generators can mark surfaces on a variety of materials, such as plastics, glass and ceramics. The high-quality beam also enables precise micromarking of electronic materials and medical devices.

Can the laser marking machine be used for color marking

Here we explore the possibility of laser color marking on the surface of metal materials. Color marking metal has a wider range of functions and applications. For small businesses, color laser marking can help them stand out from the competition and gain more customer support. So how to perform laser color marking?

Which laser generator is needed for color marking

Typically, MOPA fiber laser generators are used for color marking of metals. In color laser engraving, the surface of the material is heated by a laser to a temperature high enough to oxidize it, creating a permanent mark with color. Metal has a shiny surface and can oxidize quickly, making it the most commonly used material for color laser engraving. Compared with conventional fiber laser generators, MOPA fiber laser generators can better control parameters such as power, frequency, pulse duration, etc. This fine control can vary the amount of energy absorbed by the metal, resulting in differently colored engravings.

In which materials can color marking be performed

However, not all metals are suitable for color engraving by changing laser parameters. Metals such as aluminum, stainless steel, and titanium are the best for color laser engraving. Among them, titanium is a material that is relatively easy to mark and comes in a variety of bright colors, but the commercial opportunities for such applications are somewhat limited because the use of titanium in the consumer product market is limited to jewelry and high-end luxury watches. Stainless steel is capable of producing the greatest range of colors under different laser engraving parameters, making it an ideal metal for color engraving applications. The use of stainless steel is more widespread in products such as mobile phones, cameras and personal speakers. Therefore, color laser engraving can be used for a variety of projects such as making metal art, engraving knives, personalized jewelry and watches, and more.

What factors affect laser color marking?

Because the color marking process is thermally driven, the material grade and surface finish, as well as the thickness of the material, all have an impact on the marking process. Thicker materials provide adequate overall heat dissipation capabilities, while thinner materials may be subject to many thermal effects. Heat accumulation can cause product deformation and gradual color changes. For thin materials, careful control of heat input and heat dissipation needs to be considered to optimize results.

Summarize

Color laser marking can be used for a variety of purposes, including creating personalized designs on products or enhancing a business’s branding by marking products with a company logo. This is an interesting technology that can enhance the visual beauty of an engraving and increase its level of detail through color marking. If you are interested in laser color marking, contact us to learn more about the Mopa laser marking machine.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions