CO2 Laser Cutting Machine Maintenance Guide

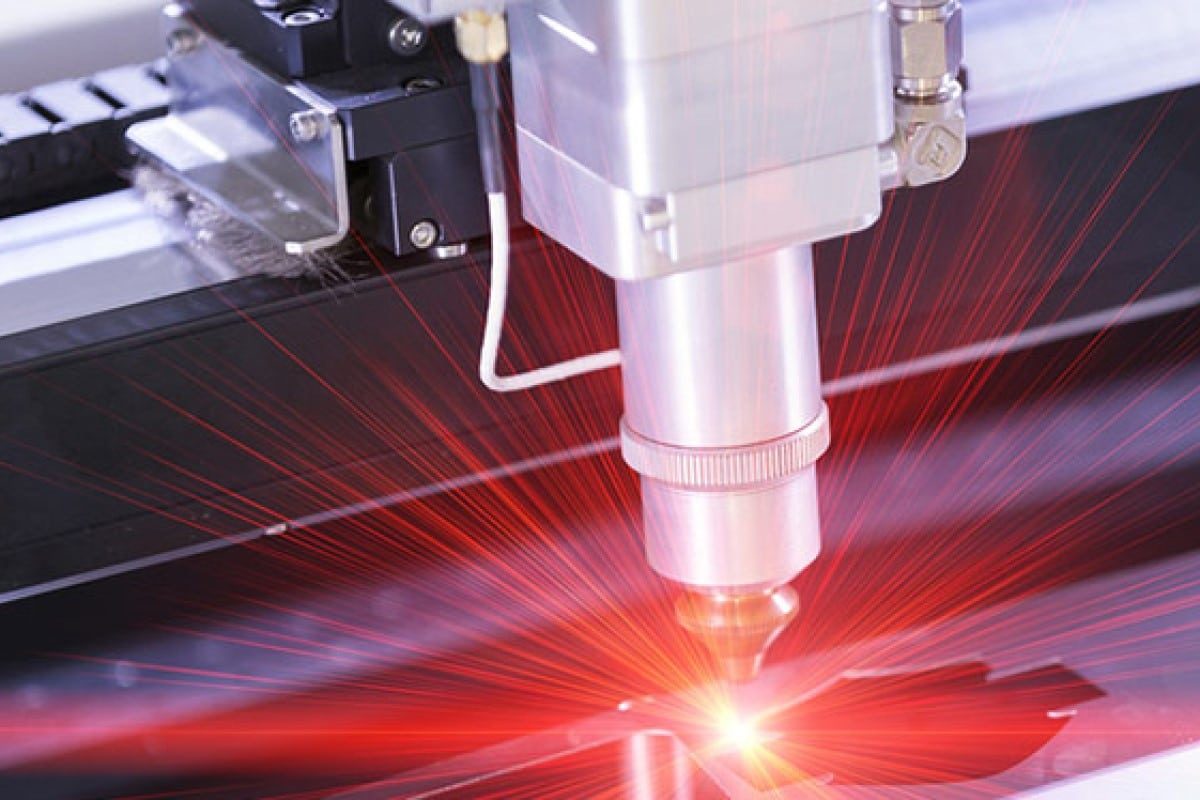

Laser technology plays an important role in modern manufacturing, and the CO2 laser cutting machine is one of the key equipment, which is widely used in non -metal cutting, marking, carving and other fields. However, in order to maintain the stability and performance of the CO2 laser cutting machine, maintenance and maintenance is essential.

This article will explore the typical maintenance and maintenance requirements of the CO2 laser cutting machine, help users understand the specific maintenance and calibration procedures, and ensure the long -term reliable operation of the equipment.Laser technology plays an important role in modern manufacturing, and the CO2 laser cutting machine is one of the key equipment, which is widely used in non -metal cutting, marking, carving and other fields. However, in order to maintain the stability and performance of the CO2 laser cutting machine, maintenance and maintenance is essential.

Table of Contents

Routine maintenance

Routine maintenance of CO2 laser cutting machines is a key part of ensuring long-term stable operation of the equipment and maintaining cutting quality. The following is the daily maintenance content of the CO2 laser cutting machine:

Cleaning of laser cutting head

The cleaning operation of the CO2 laser cutting machine is an important part of daily maintenance. First, clean the laser cutting head regularly. During the cutting process, the laser cutting head usually becomes unclear due to dust and dirt, which affects the cutting quality. Using appropriate tools, such as cotton swabs and alcohol, gently wipe the cutting head to ensure its surface remains clean.

Lens and Lens Maintenance

Another important cleaning task is maintaining lenses and lenses. Lenses and lenses are affected by smoke and dust during the laser cutting process, so it is important to check and clean them regularly. Use appropriate cleaners and special cloths to clean these optical components to ensure the quality of the laser beam.

Cleaning of exhaust system

The exhaust system of the CO2 laser cutting machine is used to discharge the generated exhaust gas and smoke. It is important to regularly inspect and clean your exhaust system’s filters and exhaust ducts to ensure the system is functioning properly. A clogged filter may prevent exhaust gas from being discharged, affecting cutting quality and the operating environment. Replace filters regularly to maintain proper system operation.

Maintenance of air-cooled or water-cooled systems

The exhaust system of the CO2 laser cutting machine is used to discharge the generated exhaust gas and smoke. It is important to regularly inspect and clean your exhaust system’s filters and exhaust ducts to ensure the system is functioning properly. A clogged filter may prevent exhaust gas from being discharged, affecting cutting quality and the operating environment. Replace filters regularly to maintain proper system operation.

Regular inspection and maintenance

Regular inspection and maintenance of CO2 laser cutting machines are key to ensuring equipment performance and cutting quality. The following are regular inspection and maintenance steps for CO2 laser cutting machines:

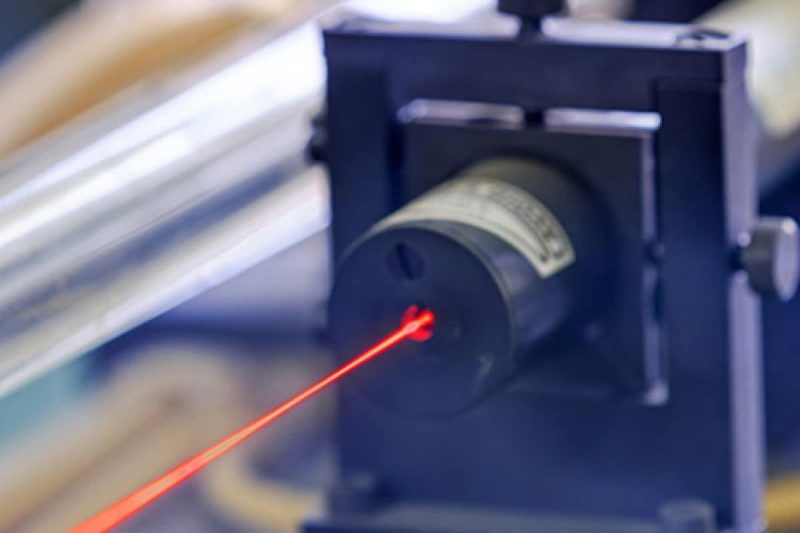

Periodic calibration of optical system

The optical path system is the core part of the CO2 laser cutting machine and affects the cutting accuracy and quality. Regularly calibrate the optical system, including the position and angle of mirrors and lenses, to ensure the correct positioning of the laser beam. Improper optical alignment can lead to cut deviations and unevenness, so this step is critical.

Forced cooling system maintenance

Forced cooling systems are used to cool the laser generator and keep it operating within the appropriate temperature range. Check coolant temperature and flow regularly to ensure system stability. Clean build-up in your cooling system to avoid clogging and overheating.

Inspection of vacuum pumps and gas supply systems

CO2 laser cutting machines usually use vacuum pumps to maintain low-pressure gas in the laser tube. Regularly check the operation of the vacuum pump to ensure that its adsorption effect is good. In addition, check the gas supply system to ensure the combined gas pressure and flow requirements.

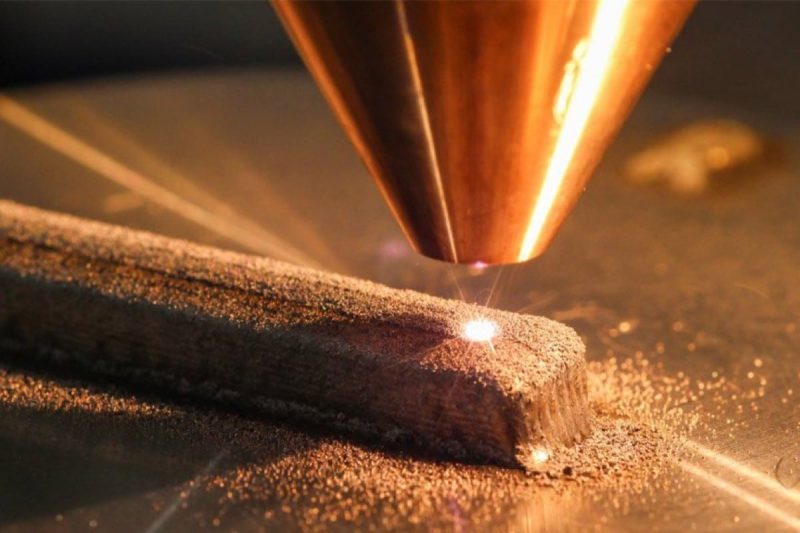

Laser tube life test

The laser tube is one of the core components of the CO2 laser cutting machine, and its life is usually related to the frequency of use and maintenance. Regularly check the performance of the laser tube and record its service life. Once a laser tube reaches the end of its life, it needs to be replaced to maintain the performance of the device.

Security and Protection

Safety and protection of CO2 laser cutting machines is critical because laser radiation and other potential hazards pose potential risks to both personnel and equipment. The following are safety and protection measures for CO2 laser-cutting machines:

Laser Safety Measures

Safety is one of the primary considerations in the maintenance and upkeep of CO2 laser-cutting machines. Laser radiation is harmful to the human body, so appropriate safety measures, such as wearing goggles and adhering to laser safety standards, must be taken to reduce the risks to the eyes and skin from laser radiation. Make sure the device is in safe mode during maintenance and follow relevant operating procedures.

Gas leak inspection

If high precision and fine welding are required, laser welding is often the better option due to its high precision and weld quality. Traditional welding technology cannot meet this precision requirement.

Fire Risk Management

Sparks and high temperatures can be generated during the operation of laser cutters, so appropriate fire risk management measures need to be taken. Ensure that fire alarms and fire extinguishing equipment in the work area are in normal working condition, and conduct regular fire drills to improve staff’s awareness of fire emergency handling.

Lockdown and Quarantine Procedures

CO2 laser cutting machines should be locked and isolated when performing maintenance or repairs to prevent misoperation. Ensure that only trained maintenance personnel have access to the interior of the equipment and use appropriate locking procedures to ensure safety.

Calibration and Setup of Components

In addition to inspecting and maintaining components, it is also important to calibrate and set them regularly. The following are some calibration measures for CO2 laser cutting machine components:

Optical system calibration

Make sure that the various components of the optical system, such as mirrors and lenses, are in the correct position and angle. Perform light path calibration regularly, especially after replacing lenses or lenses. Calibrate the optical system to ensure accurate positioning of the laser beam with the help of calibration tools and procedures provided by the laser cutting machine manufacturer.

Gas flow calibration

For laser cutting machines using assist gas, make sure the gas flow and pressure are within the correct range. Check the gas supply system using pressure gauges and flow meters and adjust according to the manufacturer’s specifications.

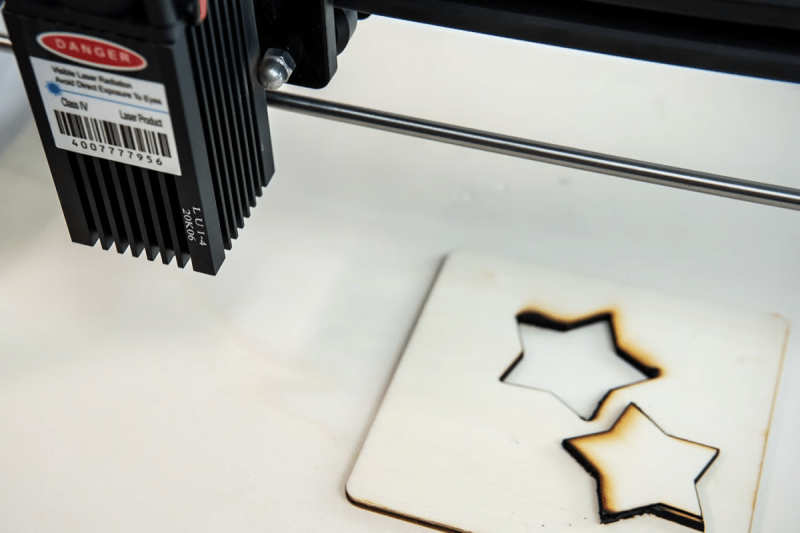

Cutting parameter settings

Set the correct cutting parameters such as laser power, cutting speed, and focus position according to the material type, thickness, and cutting requirements. Make test cuts to verify the accuracy of the parameters and fine-tune if necessary.

Regular replacement and upgrade of components

As the use time increases, some parts of the CO2 laser cutting machine will have the risk of wearing out and reducing performance. Regular replacement and upgrade of these parts can reduce certain risks. The following are the regular replacement and upgrade steps for CO2 laser cutting machines:

Lens and Lens Replacement

Lenses and lenses often need to be replaced regularly as they are susceptible to contamination from smoke, heat, and dust. Before replacing, make sure the device is secure and turned off. Remove old lenses and lenses and install new ones according to the manufacturer’s recommendations. After replacement, calibrate the optical system to ensure accurate positioning of the laser beam.

Laser tube replacement

The laser tube is the core component of the CO2 laser cutting machine and has a limited lifespan. Before replacing the laser tube, make sure the equipment is in a safe condition and switched off. After completing the replacement of the laser tube, it needs to be initialized and adjusted, usually by professionals.

Optical system calibration

Make sure that the various components of the optical system, such as mirrors and lenses, are in the correct position and angle. Perform light path calibration regularly, especially after replacing lenses or lenses. Calibrate the optical system to ensure accurate positioning of the laser beam with the help of calibration tools and procedures provided by the laser cutting machine manufacturer.

Gas flow calibration

For laser cutters using assist gas, make sure the gas flow and pressure are within the correct range. Check the gas supply system using pressure gauges and flow meters and adjust according to the manufacturer’s specifications.

Cutting parameter settings

Set the correct cutting parameters such as laser power, cutting speed, and focus position according to the material type, thickness, and cutting requirements. Make test cuts to verify the accuracy of the parameters and fine-tune if necessary.

Training and Operating Procedures

CO2 laser cutting machine training and operating procedures are critical to ensuring safe operation, efficient operation, and maintenance of the equipment. The following are general guidelines covering training and operating procedures:

Operator training

All operators must receive professional training to understand the basic operation and safety requirements of CO2 laser-cutting machines. Training should include equipment start-up, shutdown, operating controls, laser safety, emergency stop procedures, and basic maintenance.

Development and compliance of safe operating procedures

Develop safe operating procedures and ensure that operators and maintenance personnel are familiar with and strictly follow these procedures. Safe operating procedures should include safe operation of equipment, maintenance plans, and emergency procedures. Make sure everyone understands and follows these protocols.

Device records

Record all operation and maintenance activities, including equipment operating parameters, maintenance date, maintenance content, and maintenance personnel information. These records are important for tracking equipment performance and maintenance history.

Summarize

Maintaining and maintaining a CO2 laser cutting machine is crucial to ensuring the stability and performance of the equipment. Through measures such as routine maintenance, regular inspection and maintenance, safety and protection, component replacement and upgrades, training and operating procedures, and documentation, users can ensure long-term reliable operation of their CO2 laser cutting machines, improve production efficiency, and reduce risks.

Maintenance and upkeep not only protect the investment but also ensure high-quality cutting work. Therefore, to ensure long-term reliable operation of the equipment, operators and maintenance personnel should follow the above requirements and perform regular maintenance and upkeep work.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions