CW Laser Cleaning Machine VS Pulse Laser Cleaning Machine

In the field of industrial cleaning, laser cleaning machines have become the best choice for industrial cleaning equipment with higher reliability, stability, and flexibility. As the two major components of laser cleaning machines, continuous(CW) laser cleaning machines and pulse laser cleaning machines firmly occupy the leading positions in the macro material processing and precision material processing markets respectively.

For emerging laser cleaning applications, there is disagreement over whether a CW or pulsed laser should be used. Many users do not know how to choose when purchasing a machine. Here, we compare the laser cleaning applications of CW laser cleaning machines and pulsed laser cleaning machines and analyze their respective characteristics and applicable application scenarios. Hope to provide useful references for users when choosing the corresponding laser cleaning technology.

Table of Contents

What is Laser Cleaning

Before introducing CW laser cleaning and pulsed laser cleaning, let’s first understand the working principle of laser cleaning. Laser cleaning is an environmentally friendly process used to remove rust, paint, oxides, and other contaminants from the surface of metal and other objects. Due to its high efficiency, it is used in more and more applications.

How laser cleaning works

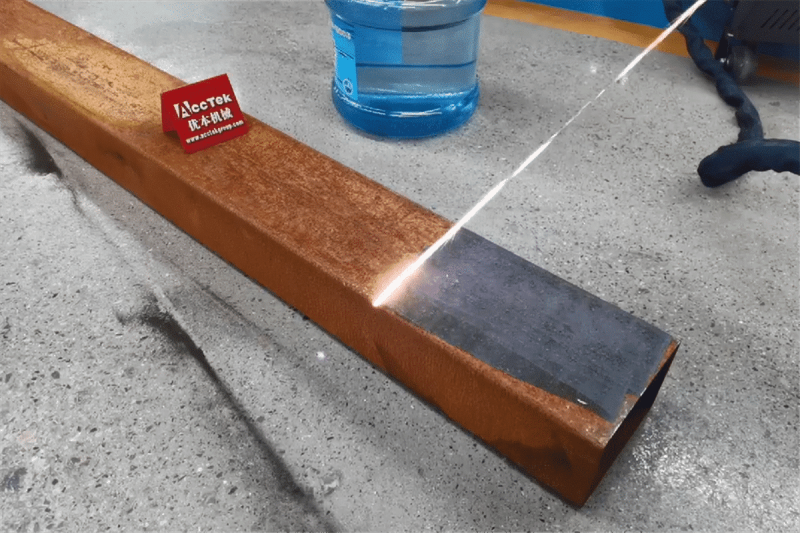

Laser cleaning works by firing a high-powered laser beam at the surface of the material. Here, the light beam interacts with contaminants on the surface of the material, which absorb energy and rapidly raise their temperature until they reach their ablation threshold, the point at which molecular bonds break. This results in particles of the contaminant being ejected from the substrate, or completely vaporizing the contaminant.

The parameters of the laser cleaner (i.e., power, wavelength, repetition rate, scan speed, and beam diameter) are carefully chosen so that only the ablation threshold of the contaminants is reached, and not the ablation threshold of the substrate itself. This targeting of the correct ablation threshold, combined with the fact that laser cleaning can be controlled with micron-scale precision, ensures that the underlying substrate is completely undamaged. This process of scanning the laser beam is repeated until all contamination has been removed and the material surface is clean.

Composition of laser cleaning machine

Laser cleaning machine is a kind of industrial cleaning equipment, mainly composed of three parts: laser generator, hand-held laser cleaning gun and operating system. A laser generator is a device that generates coherent electromagnetic waves through stimulated emission to generate narrow and intense beams, mainly composed of optical fibers and semiconductor diode pumps. The handheld laser cleaning gun is ergonomically designed and the handle feels comfortable to hold. The operator only needs to hold the handle, point the laser cleaning gun at the workpiece to be cleaned and scan. The operating system is the part that provides power to the laser generator and adjusts the working state of the laser generator. It can control the output power (energy per unit area) of the laser generator and its pulse length.

CW Laser Cleaning Machine

We call a cleaning machine that uses a continuous laser generator as a laser source a continuous laser cleaning machine. Continuous wave means that the laser remains on continuously until it is stopped. At present, the commonly used power range of continuous laser cleaning machines is 1000W-3000W. This kind of high-power continuous laser cleaning machine is usually used in application scenarios with large volume and fast heat dissipation, such as automobiles, pipelines, and large steel structures.

Main application fields of CW laser cleaning machine

- In automotive production, laser cleaners are used to remove phosphate layers from bevel gears and other parts before welding to ensure less spatter and porosity. In the field of car maintenance, laser cleaning can be used to remove rust and paint on the car surface, thereby restoring the smoothness of the car surface.

- In the field of aviation, the surface of the aircraft needs to be painted regularly, but the original old paint needs to be completely removed before painting. Fiber laser cleaning machines can achieve high-quality removal of aircraft surface paint and are easy to automate production. At present, this technology has begun to be applied to the maintenance of some high-end models.

- In the marine industry, laser cleaning machines can effectively remove paint, vegetation, or algae from large panels and propellers on ships.

- In the oil and gas industry, pipelines can be affected by various buildups that must be dealt with to ensure uninterrupted operation. Here, laser cleaning can be performed remotely by automated robots. The technology has a particular advantage here because it requires no consumables, just power for the robot over long distances.

- In the railway transportation industry, the laser cleaning machine is used for regular maintenance of the track, which can quickly remove the rust on the track and ensure the safety of railway transportation.

- Lasers can also be used to clean graffiti on wall surfaces or floors. Especially in tourist attractions, some uncivilized tourists will leave marks on the walls of scenic spots. Using a laser cleaning machine will not damage the surface of the wall under appropriate parameters, especially suitable for cleaning the walls of scenic spots or stone cultural relics.

- The safety and pollution-free advantages of laser cleaning machines make them popular in the food processing industry. Using laser cleaning technology, grease deposits on metal baking trays and baking molds can be quickly cleaned without any residue or contamination.

- Laser cleaning machines have great advantages in the field of tire molds. Due to the geometric diversity and tight texture of tire mold profiles, it is difficult to clean them thoroughly with traditional cleaning methods. The laser can be easily focused on the parts that need to be cleaned, effectively removing dead corners of tire molds and other difficult-to-clean parts. For molds with complex shapes, the final product after laser cleaning is much finer than other cleaning methods.

Advantages of CW laser cleaning machine

As a new industrial cleaning method, laser cleaning machine is widely welcomed in the industrial market. Compared with mechanical cleaning, chemical cleaning, and ultrasonic cleaning, laser cleaning technology has greater advantages. Some of its advantages include:

- No damage to the substrate. Laser surface cleaning systems work by directing a powerful, high-pulse laser at a rusted, painted, or coated surface. This energy breaks down existing contaminants and effectively removes them from the substrate. Removal of the degraded layer or coating affects only a few microns. It doesn’t go on to burn off the underlying solid surface, making the laser’s action more specific.

- Safe and pollution-free. The laser cleaning process does not use chemicals, is more environmentally friendly, and does not pose a health hazard to workers. The safe and pollution-free cleaning method allows laser cleaners to be used in the food and pharmaceutical industries.

- More efficient and cost-effective. Of all industrial cleaning methods, laser cleaning machines have the lowest operating costs. Lasers are many times faster than using chemicals, reducing labor costs. Since laser cleaning leaves no waste or debris behind, a significant amount of material and tooling costs are eliminated. Return on investment can often be seen in less than a year.

- Selectively and accurately peel off the cleaning layer. Unlike sandblasting, lasers are selective and can be easily focused on very small spots or stripes without affecting adjacent materials. Precise and spot cleaning is easier with laser cleaning methods. Additionally, the nooks and corners of intricately designed objects can be reached more easily with laser cleaning. The final product after laser cleaning is much finer than other cleaning methods.

- Compared with pulse laser cleaning machines, CW laser cleaning machines have more price advantages.

Disadvantages of CW laser cleaning machine

Although laser cleaning has more advantages, CW laser cleaning machines still have disadvantages compared with pulsed laser cleaning machines.

- Compared with other cleaning methods, the continuous laser cleaning machine has less damage to the substrate. However, compared with the pulse laser cleaning machine, the surface quality is still insufficient, so it is not suitable for cleaning high-precision materials and precious metals.

- Compared with the pulse laser cleaning machine, under the same power condition, the cleaning efficiency is low.

- Continuous laser cleaning machines are more widely used in cleaning metal materials, and their cleaning effect in non-metallic scenes such as wood and plastic is far inferior to that of pulse laser cleaning machines.

Pulse Laser Cleaning Machine

We call a cleaning machine that uses a pulsed laser generator as a laser source a pulse laser cleaning machine. A pulsed laser produces a series of pulses at a certain pulse width and frequency until stopped. At present, the commonly used power range of pulse laser cleaning machines is 100W-500W. This low-power pulse laser cleaning machine is usually used in molds, medical devices, precious metals, and other high-precision application scenarios that require non-destructive substrates.

Main application fields of pulse laser cleaning machine

- In the medical industry, pulsed lasers can be used to clean steam sterilizer systems, which themselves are used to clean medical tools at high temperatures. As tools are cleaned, contaminants can become embedded in the interior surfaces of the sterilizer, contaminating them and promoting corrosion. Pulsed laser cleaning offers a fast and efficient method to remove such embedded contaminants.

- In the pharmaceutical industry, pulsed laser cleaning machines can be used to clean objects such as reaction vessels, mixers, storage tanks, tools, molds, and conveyors.

- Pulsed laser cleaning machines are also playing an increasingly important role in the restoration of historical relics, and can be used to clean artworks damaged by air pollution, dust, or soot particles.

- In the electronics industry, typical applications of pulsed laser cleaning machines include cleaning the contact area of plugs and pads and removing insulation in cables.

Advantages of pulse laser cleaning machine

Pulse laser cleaners also have the advantages of continuous laser cleaners. In addition, compared with continuous laser cleaning, pulsed laser cleaning can better control the heat input and prevent the substrate temperature from being too high or slightly dissolved. Therefore, the pulse laser cleaning machine can clean a wider range of materials. In addition to cleaning metal, the pulse laser cleaning machine also has a good cleaning effect on non-metals such as wood, plastic, glass, and porcelain. In terms of cleaning efficiency, under the same power conditions, the efficiency of pulsed laser cleaning machines is much higher than that of continuous laser cleaning machines.

Disadvantages of pulse laser cleaning machine

Compared with continuous laser cleaning, pulsed laser cleaning machine has more advantages, but its biggest disadvantage is that the price is very expensive, which exceeds the purchase budget of many enterprises.

How Much is the Laser Cleaning Machine

The price of a laser cleaning machine ranges from several thousand dollars to tens of thousands of dollars, and the specific price is affected by many factors.

Effect of laser generator type on price

Through the above introduction, we have learned that different types of laser generators have different application scenarios. The high precision of the pulsed laser generator determines the higher cost of the machine. Therefore, the prices of pulse laser cleaning machines and CW laser cleaning machines are quite different. At present, the common power range of CW laser generators is 1000W-3000W, and the price range is 5000 US dollars-30000 US dollars. The common power range of pulsed laser generators is 100W-500W, and the price range is between US$6,800 and US$40,000.

Effect of laser generator power on price

The same brand and the same type of laser generator, the higher the power, the higher the price. Taking the Max laser generator as an example, the price of a 1000W CW laser cleaning machine is about US$5,500, and that of a 3000W machine is about US$11,000. The price of a 100W pulsed laser cleaning machine is about $8,000, and that of a 1000W machine is about $40,000.

Effect of laser generator brand on price

For continuous laser cleaning machines, we take Raycus and IPG as examples. The same 2000W laser cleaning machine, the price of Raycus laser cleaning machine is about 8,000 US dollars, while the price of IPG laser cleaning machine is about 24,000 US dollars. For the pulse laser cleaning machine, which is also a 200W laser cleaning machine, the price of the JPT laser cleaning machine is about 10,000 US dollars, and the price of the Max laser cleaning machine is 12,000 US dollars. This is because different brands of laser generators have different technologies, and the cleaning efficiency and fineness will be different.

CW Laser Cleaning Machine VS Pulse Laser Cleaning Machine: Which One to Choose

For laser cleaning applications, whether to buy a CW laser or a pulsed laser should be selected according to the actual cleaning material, not that the more expensive the better. Through the above introduction, we can know that both the continuous laser cleaning machine and the pulse laser cleaning machine can clean the surface of the material. But with the same average output power, the cleaning efficiency of pulsed laser is faster than that of CW laser. At the same time, heat is better controlled during cleaning without damaging the substrate. However, the cost of pulsed laser cleaning machines is much higher than that of continuous laser cleaning machines.

Therefore, it will be a correct way to choose different laser cleaning machine models according to different cleaning applications. For applications with high precision and no damage to the substrate, pulsed laser cleaning machines should be selected. For some large steel structures, pipelines, etc., CW laser cleaning machines can be selected due to the large heat dissipation block and low requirements for substrate damage.

Summarize

The emergence of laser cleaning machines has changed the time-consuming and laborious situation of traditional industrial cleaning. It is a cost-effective cleaning solution. Although the price of laser cleaning machines is higher than that of traditional cleaning equipment, there is no increase in the cost of consumables in the later period, and the operating cost of long-term use of laser cleaning equipment is lower. In addition, the laser cleaning machine is more efficient, and one person can complete the cleaning of multiple materials, which can reduce labor costs to a certain extent.

If you are still hesitating about CW laser cleaning or pulse laser cleaning when purchasing a laser cleaning machine, please contact us, and AccTek engineers will provide you with the best solution according to your cleaning application.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions