Decoding Laser Cutting Costs: Key Considerations Unveiled

As an advanced material processing technology, laser cutting has been widely used in the manufacturing industry in recent years. However, when companies adopt laser-cutting technology, they often consider the question: “How much does laser-cutting cost?”. To answer this question, it is important to understand the factors that affect a laser-cutting machine‘s overall cost.

This article will discuss the cost-effectiveness of laser cutting, delve into the cost considerations related to laser cutting, and conduct a comparative analysis of laser cutting costs and benefits to help companies better understand and make informed decisions.

Table of Contents

The importance of understanding the cost of laser cutting machines

As manufacturers explore the modern production landscape, understanding the importance of laser-cutting machine costs is critical to manufacturing business decision-making and long-term development for businesses that want to thrive in the highly competitive manufacturing industry. Here are some aspects regarding the importance of laser cutting machine cost:

Drive informed investment decisions

The purchase price of laser cutting machines is usually relatively high, which is one of the main factors that companies initially need to consider when introducing this technology. By understanding the costs involved, manufacturers can make informed investment decisions, ensuring that the chosen machine meets their budget and operational requirements. Whether you are a small-scale operation or a large manufacturing facility, a clear understanding of laser-cutting machine costs allows businesses to allocate resources efficiently and avoid unnecessary financial stress.

Manufacturing and improving production efficiency

Laser-cutting machines can improve production efficiency and reduce the manufacturing cycle. By completing cutting tasks faster and more accurately, companies can respond more flexibly to changes in market demand. Understanding manufacturing efficiency helps companies better plan production plans and improve overall production capacity.

Impact On Overall Production Costs

Understanding the overall cost of a laser-cutting machine can help companies evaluate the actual cost of production. The cost of a laser cutting machine also includes operating expenses, maintenance expenses, and potential labor costs. Recognizing the overall impact of production costs can help ensure a balance between production efficiency and long-term returns. Laser-cutting machines typically have lower energy consumption and higher levels of automation, which can reduce operating costs in the long term. The efficiency gains and material savings achieved through laser cutting can have a positive impact on the overall cost structure of the manufacturing process.

Adapt to evolving technology trends

Manufacturing is dynamic, with technological advancements shaping how products are designed and produced. Understanding the costs associated with laser-cutting machines can help companies adapt seamlessly to changing trends and improve their competitiveness. A new generation of laser-cutting machines may bring higher efficiency and lower energy consumption. Whether upgrading to a more advanced laser-cutting system or incorporating automation capabilities, a clear understanding of costs can aid in strategic planning for technology integration. This adaptability is critical to staying ahead of the curve in a rapidly changing manufacturing environment.

What are the considerations related to laser cutting costs?

Laser-cutting technology is increasingly used in modern manufacturing, and its high precision and efficiency bring many advantages. It also involves many factors in terms of cost, and companies need to consider them comprehensively when making decisions.

Main factors to consider in laser cutting costs

Initial investment cost

The purchase of laser-cutting equipment is the primary consideration when companies introduce this technology. The price of laser cutting machines is usually relatively high, involving the purchase cost of the equipment itself and possible supporting equipment, software, etc. Businesses need to weigh the initial investment against expected production benefits to ensure that choosing laser-cutting technology is economically viable.

Operating costs

The operating costs of laser cutting include energy consumption, maintenance costs, labor costs, etc. Compared with traditional cutting methods, laser cutting can often achieve higher energy efficiency, reduce maintenance frequency, and reduce labor costs through automation. Companies need to have a comprehensive understanding of operating costs to ensure that the long-term operating costs of laser cutting can be effectively controlled.

Manufacturing efficiency

The high precision and speed of laser cutting technology give it obvious advantages in improving manufacturing efficiency. By reducing production cycles, companies can meet market demand more flexibly and improve order execution capabilities. The improvement of manufacturing efficiency not only directly affects production capacity, but also helps reduce the manufacturing cost of unit products, thus improving overall cost-effectiveness.

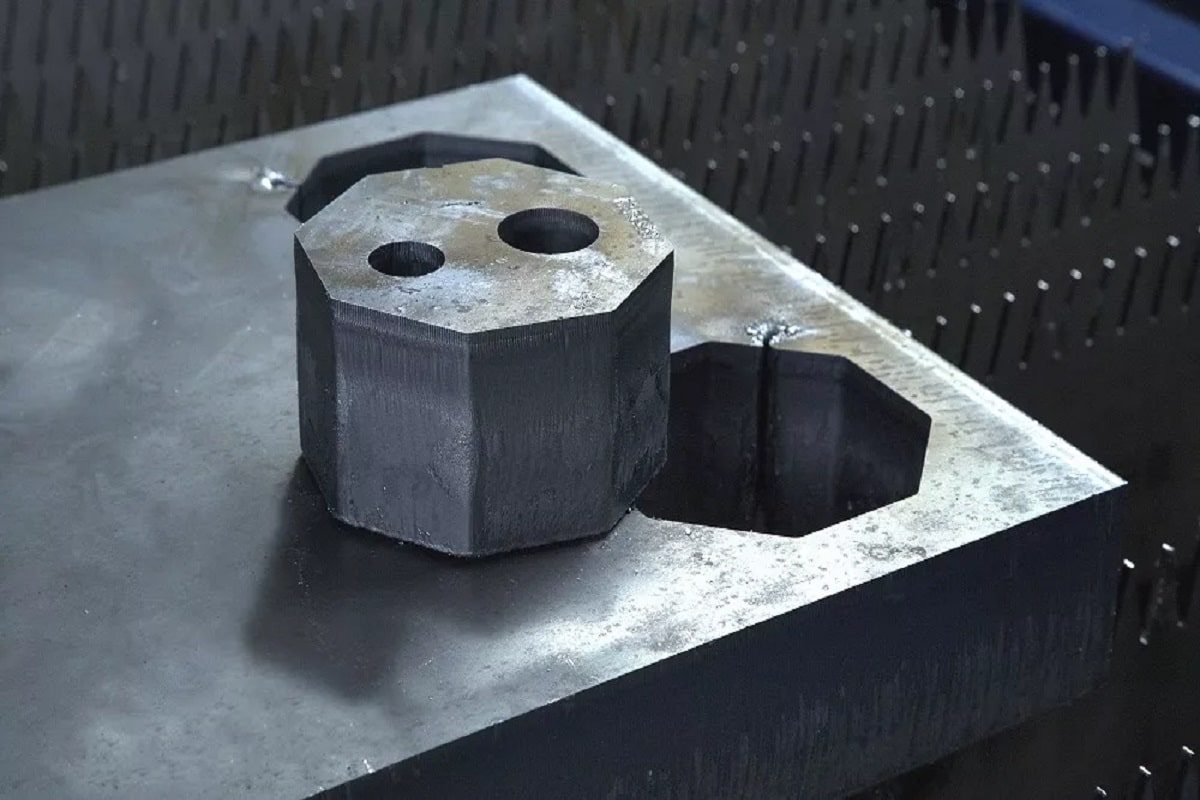

Material utilization rate

Laser cutting maximizes material utilization through precise control of the laser beam. Compared with traditional cutting methods, laser cutting reduces the generation of scrap and waste of raw materials, thus having a positive impact on material costs. Businesses need to seriously consider this, especially in cost-sensitive industries.

Potential factors to consider in laser cutting costs

Installation and Setup

Installation and setup costs are often overlooked but are crucial in the overall investment. Ensuring that machines are installed correctly and calibrated to meet specific production requirements is critical for optimal performance. Professional installation services may cost extra but contribute to the long-term reliability and efficiency of your laser-cutting machine.

Maintenance and repair

Laser-cutting equipment requires regular maintenance to ensure its performance and accuracy. Understanding maintenance and repair costs helps companies prevent potential equipment failures, reduce the risk of production interruptions, and plan effective maintenance programs. This also includes considering the cost of parts replacement and repair service.

Training and Certification

Laser-cutting technology requires a higher level of technical personnel to operate and maintain than traditional processes. Understanding labor training costs can help businesses budget and plan to ensure operators have the necessary skills and knowledge. High-level training can help improve the operating efficiency of laser-cutting equipment, reduce operating errors, and improve production efficiency.

Considering these factors, companies can more comprehensively evaluate the cost-effectiveness of laser cutting technology and provide a more reliable basis for decision-making during technology introduction and production processes.

What are the relevant factors for improving laser cutting efficiency?

The benefit analysis of laser cutting technology is of great significance to corporate decision-making and long-term profitability. In the global manufacturing industry, many companies adopt laser-cutting technology to improve production efficiency, reduce costs, and enhance market competitiveness. The following analyzes some:

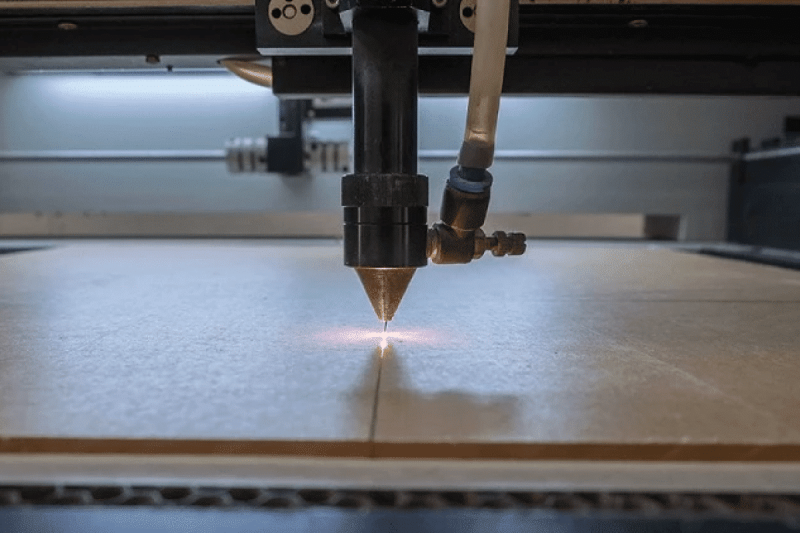

factors about improving laser cutting efficiency

Laser-cutting technology is known for its high precision and speed. By using laser beams for cutting, production speeds are significantly increased without affecting cut quality. This is crucial for large-scale production companies because it can shorten the production cycle and meet market demand faster. Improvements in production efficiency directly impact a company’s profitability, allowing it to launch products more quickly and meet customer demand.

Improvement of raw material utilization

Laser-cutting technology maximizes material utilization by precisely controlling the laser beam. Compared with traditional cutting methods, laser cutting reduces the generation of waste materials and lowers raw material costs. Not only does this save costs, but it also helps businesses become more environmentally friendly, as reduced waste has a smaller impact on the environment.

Improved cost-effectiveness

Although the initial investment in laser cutting equipment is relatively high, it is usually more cost-effective in the long term. Efficient production processes, lower energy consumption, and raw material savings from reduced waste all help improve corporate profitability. Through higher manufacturing efficiency and lower operating costs, businesses can better manage and control their financial health.

Improvement of product quality

Laser cutting technology enables high-precision cutting, thereby producing higher-quality parts and products. This not only improves the competitiveness of the product but also reduces the rate of defective products and the need for subsequent processing. High-quality products usually command higher prices in the market, thereby increasing a company’s profit margins.

Increased flexibility and customization

Laser cutting technology allows for fast and precise cutting of materials of different shapes and sizes. This increases the flexibility of the production process, allowing companies to better adapt to changes in customer demand. In a market with increasing demand for customization, companies can provide more flexible and personalized products to gain a competitive advantage in the market.

Improvement of technical level

The introduction of laser cutting technology often requires the training of high-level technicians. This not only helps improve the operating efficiency of laser cutting equipment but also improves the technical level of employees, making it more market-competitive. The improvement of technological level helps enterprises to better adapt to technological changes and market trends, thereby increasing the profit potential of enterprises.

The introduction of laser-cutting technology can often bring significant profit advantages to enterprises. By improving production efficiency, reducing costs, improving product quality and flexibility, laser cutting creates a more favorable operating environment for enterprises.

Summarize

Taken together, laser cutting has a series of advantages in terms of cost-effectiveness. However, companies still need to comprehensively consider multiple factors when making decisions. From initial investment and operating costs to manufacturing efficiency and material utilization, the various cost considerations associated with laser cutting all need to be weighed holistically. At the same time, the cost-effectiveness of laser cutting will also vary for different industries and enterprises. Therefore, when making decisions, enterprises should comprehensively consider various factors based on their actual conditions to ensure that the introduction of laser-cutting technology can bring maximum economic benefits to the enterprise.

If you are looking for a laser cutter, be sure to contact AccTek Laser! We can provide almost any business solution you might need, just let us know your needs and our friendly service technicians will be happy to provide you with professional support!

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions