Does The Laser Cleaning Machine Have Specific Power Requirements?

Laser cleaning is a cutting-edge technology that has revolutionized surface preparation and maintenance across industries. From rust removal in the automotive industry to restoration of historical artifacts in museums, laser cleaning machines have proven their ability to deliver precise, efficient results. However, operating laser cleaning machines is not as simple as pressing a button, they have specific power requirements that are critical to their functionality and safety.

This article will explore the intricacies of laser cleaning machine power supplies, providing an in-depth look at the technology, appliance specifications, safety considerations, and best practices to ensure optimal performance.

Table of Contents

Learn about laser cleaning technology

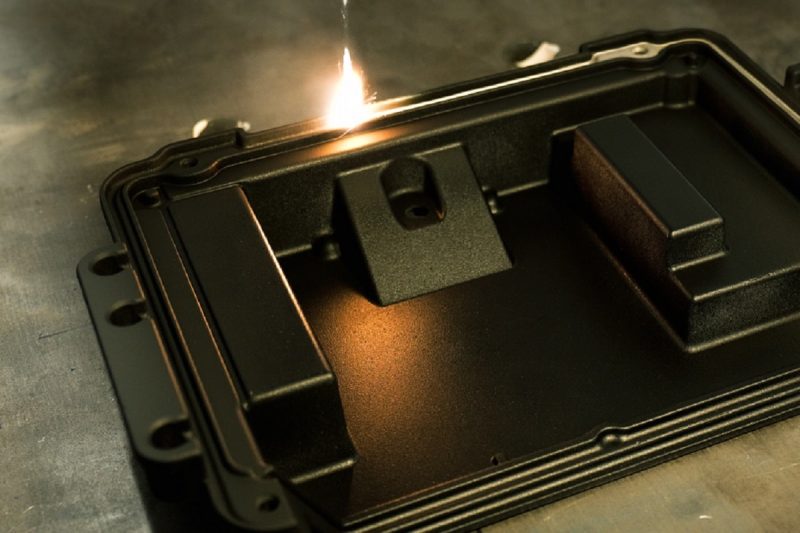

Before delving into power requirements, it’s necessary to understand the basics of how laser cleaning works. Laser cleaning machines utilize high-intensity laser beams to remove contaminants and coatings from a variety of surfaces. The process is highly efficient because the laser energy is absorbed by the contaminant or coating, causing it to evaporate or sublime without affecting the underlying substrate. The versatility of laser cleaning is noteworthy as it can effectively remove rust, paint, oil, grease, and even graffiti. Its precision makes it ideal for delicate applications, such as cleaning historical artifacts and artwork without causing damage. Additionally, laser cleaning machines are not limited to a single type of laser generator. Some common laser generator types are continuous laser generators and pulsed laser generators. Each laser generator has its power requirements, let’s explore these specific power requirements in more detail.

The role of power supply in laser cleaning machine

Powering a laser cleaning machine is not a one-size-fits-all job. Specific power requirements depend on a variety of factors, including the machine’s size, design, and intended application. Let’s examine these requirements in more detail.

Power and electrical requirements

Laser cleaning machines typically run on electricity, and the type of power source required can vary. Most machines are designed to operate at standard voltages and frequencies. Common specifications include 110-120V or 220-240V AC at 50-60 Hz. Consult the manufacturer’s documentation for accurate details on voltage and frequency requirements.

Factors affecting power supply specifications

Several factors affect the power supply specifications of a laser cleaning machine. These factors include the power output of the laser generator, the cooling system, and additional safety systems. As we explore these factors more deeply, we gain a better understanding of the importance of power.

Power device overview

Laser cleaning machines are composed of various power components, each of which plays a specific role in the overall operation. Major power components include:

- Laser source: The heart of the laser cleaning machine, responsible for generating high-intensity laser beams.

- Cooling system: Necessary to maintain the laser generator and other components at the correct operating temperature.

- Safety system: interlocking devices and safety mechanisms to ensure safe operation.

In the next sections, we’ll take a closer look at each power supply component, starting with the power requirements.

Power requirements

Power consumption is an important aspect to consider when powering a laser cleaning machine. The power requirements of a machine can vary greatly depending on its size and design. Smaller portable laser cleaning machines may have lower power requirements, typically a few hundred watts to several kilowatts, while larger industrial machines may require more power. Power requirements are not arbitrary, they are governed by safety standards and industry regulations to ensure reliable and safe operation. Complying with these standards helps prevent accidents, ensure consistent performance, and extend the life of your machine.

Voltage and frequency

The voltage and frequency specifications of the laser cleaning machine must match the power supply available where the machine is used. The voltage and frequency required by a machine may vary depending on the manufacturer and the intended use of the machine. Deviating from specified voltages and frequencies can cause performance issues, component damage, and even safety hazards. To ensure compatibility, be sure to verify your machine’s power requirements and consult a qualified electrician for proper installation.

Power consumption and machine size

The power consumption of a laser cleaning machine is generally related to its size and the energy output required for the application. Smaller machines generally consume less power than larger machines. When selecting a machine, power consumption must be balanced against the specific needs of the application. Additionally, when investing in a laser cleaning system, consider future scalability requirements.

Power supply safety standard

Safety is paramount when working with high-power laser systems. Regulatory agencies such as the U.S. Occupational Safety and Health Administration (OSHA) have developed guidelines for the safe operation of laser generators. Complying with these standards involves ensuring that the laser system’s power supply is configured correctly to prevent accidental activation. To meet safety standards, laser cleaning machines are often equipped with safety systems including interlocks and safety shutdown mechanisms. These systems require power to operate properly, and their operation helps prevent unauthorized access and accidental exposure to laser beams.

Cooling system

The efficient operation of a laser cleaning machine depends on maintaining proper operating temperatures. These machines generate a lot of heat, mainly in the laser generator. Excessive heat can cause equipment damage, reduce laser efficiency, and pose safety risks. The cooling system is an important part of the laser cleaning machine and requires part of the power supply.

The importance of cooling in laser cleaning machines

The cooling system is responsible for dissipating the heat generated during the operation of the laser generator. It comes in many forms, from air cooling to liquid cooling systems, depending on the design of the machine. These systems help keep laser generators and other critical components within recommended temperature ranges, ensuring consistent performance and longevity.

Power requirements for cooling systems

Cooling system power requirements may vary depending on the design of the machine and the cooling method used. Air-cooled systems may have lower power requirements than liquid-cooled systems but may provide slightly less effective cooling than liquid-cooled systems. It is recommended to consult the machine’s documentation to understand the specific cooling system power requirements and ensure that the power supply can meet these needs.

Maintain proper operating temperature

To ensure that your laser cleaning machine operates optimally, proper operating temperatures must be monitored and maintained. Deviating from the recommended temperature range can cause performance issues, reduced laser output, or even damage to sensitive components. Routine maintenance, including cleaning cooling system components and monitoring temperature levels, can help extend the life of your machine.

Laser safety system

Safety in laser cleaning operations is a top priority. High-intensity laser beams can cause eye and skin injuries, so safety measures are an integral part of the machine design. Laser safety systems, such as interlocks and safety mechanisms, help prevent accidents and ensure that laser generators only operate when they are supposed to.

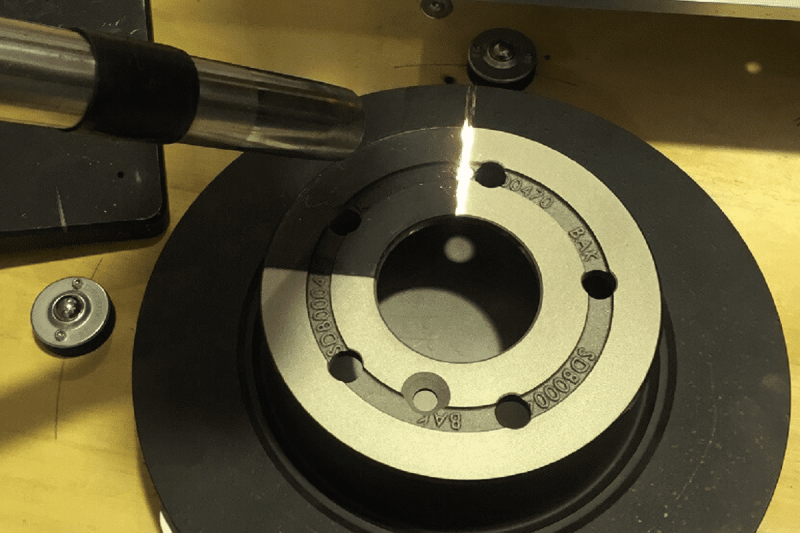

Laser safety interlocking device and its power requirements

Laser safety interlocks are designed to prevent unauthorized access to laser generators and ensure that the laser beam is only emitted when the machine is in a safe operating condition. These interlocks require power to operate and are often integrated into the machine’s electrical system. Their electrical requirements must be met to ensure they effectively maintain a safe working environment.

Ensure safe operation during laser cleaning

Laser safety involves not just the design of the machine, but also the proper training of operators and compliance with safety protocols. In addition, regular maintenance and inspection of safety systems, including interlocks and emergency shutdown mechanisms, can help ensure that the machine is ready to operate safely.

Power supply stability

Power supply stability is another key consideration when operating a laser cleaning machine. A stable power supply is crucial for the reliable and safe operation of laser cleaning machines. Any fluctuations or interruptions in electrical power can negatively affect the performance of the machine and may lead to safety hazards. Here are some considerations for power supply stability:

The impact of power instability on laser cleaning

The unstable power supply will bring serious consequences to the laser cleaning machine. Voltage fluctuations can cause unstable laser generator performance and may even damage the laser source and other electrical components. To avoid these problems, it is crucial to provide stable, clean power. Some users choose to install an uninterruptible power supply (UPS) for their laser cleaning machines. UPS provides temporary power during brief power outages or fluctuations, ensuring that machines can continue to operate without interruption. While a UPS cannot replace the need for stable power, it can be a valuable addition to critical applications.

Surge protection and voltage regulation

To mitigate the risks associated with unstable power supplies, many laser cleaning machines are equipped with built-in surge protection and voltage regulation systems. These features prevent damage to the machine’s sensitive electronic components caused by power fluctuations and ensure consistent laser performance, even in areas with unreliable power supplies.

Best practices for powering laser cleaning machine

To ensure reliable and safe operation of your laser cleaning machine, certain best practices should be followed:

Precautions before installation

Before installing a laser cleaning machine, it is necessary to evaluate the power available at the intended location. Make sure the machine’s voltage and frequency requirements are met. If necessary, consult a qualified electrician to make any necessary modifications to the electrical infrastructure.

Proper electrical installation

Laser cleaning machine installation should be performed by experienced technicians who are familiar with the machine’s specific requirements and safety protocols. This includes properly connecting the machine to the power source, setting up the cooling system, and verifying that safety interlocks are operating as expected.

Routine maintenance for optimal power supply

Ongoing maintenance helps ensure that your laser cleaning machine continues to operate at peak efficiency. This includes checking and cleaning cooling systems, ensuring power supply stability, and performing regular safety checks on interlocks and safety mechanisms.

Summarize

Laser cleaning machines revolutionize various industries by providing an environmentally friendly and efficient method of surface preparation and cleaning. However, there is a critical aspect behind its powerful laser beam that is often overlooked: power requirements. The correct power supply is critical to the safe and efficient operation of these machines. Understanding the specific power requirements of laser cleaning machines, including voltage and frequency, power consumption, cooling systems, laser safety measures, and power supply stability, is critical for both manufacturers and users. Ignoring these requirements can result in reduced machine performance, reduced component life, and safety risks.

Manufacturers provide detailed specifications for laser cleaning machines, and users should follow these guidelines closely to ensure the machine is operating at its best. Additionally, consulting with a qualified electrician or technician during installation and maintenance can help ensure the long-term reliability and safety of your laser-cleaning machine.

To summarize, laser cleaning machines do have specific power requirements that play a vital role in their overall performance and safety. As technology continues to evolve, understanding and adhering to these requirements can still help reap the benefits of laser cleaning in various industries.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions