What is a Cooling System

Heat Generation

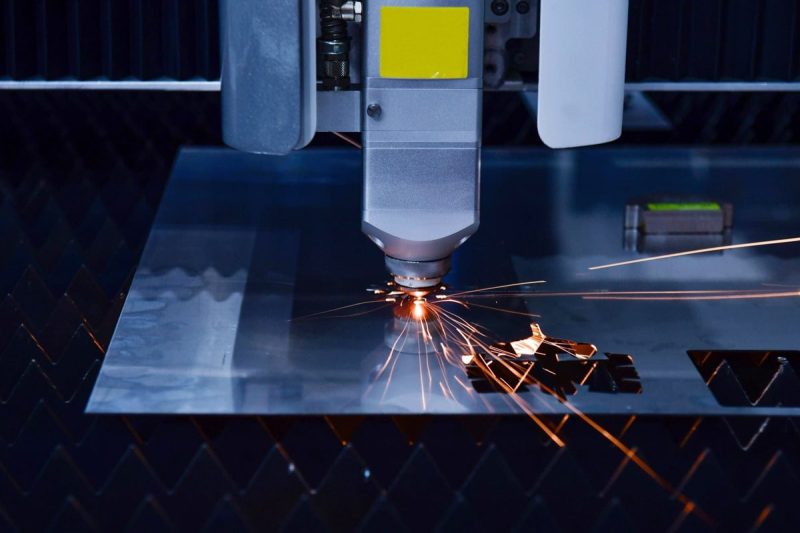

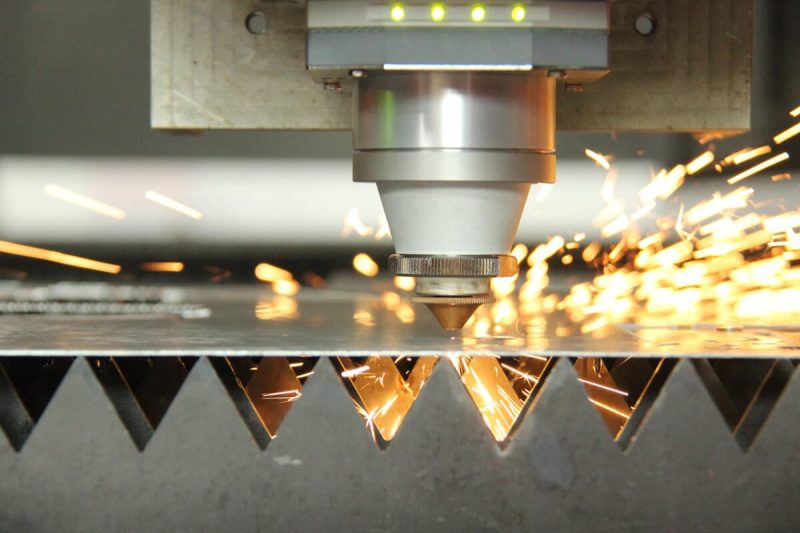

In laser-cutting machines, heat is generated primarily through two processes:

- Laser Operation: The laser source (whether it is a CO2 laser generator, fiber laser generator, or any other type) generates a lot of heat when it emits the high-energy beam used for cutting. The conversion of electrical energy into laser light is not very efficient, and the excess energy is released as heat.

- Material Interaction: When the laser beam interacts with the material being cut, it causes localized heating, resulting in melting, burning, or vaporization. This process not only affects the material but also generates additional heat that needs to be managed.

Without an effective cooling system, the built-up heat can cause a variety of problems, including:

- Thermal Deformation: Excessive heat can cause the laser beam to deform, resulting in poor cut quality.

- Degraded Component Performance: Continued exposure to high temperatures can degrade the performance of the laser source, optics, and other key components, shortening their lifespan.

- Safety Risks: Excessive heat poses safety hazards, including the risk of fire or equipment failure.

Components of a Cooling System

The typical cooling system in a laser cutting machine consists of several key components:

- Heat Exchangers: Devices that transfer heat from the laser cutting machine to a cooling medium (air or liquid). They remove excess heat and maintain a stable temperature.

- Fans: Fans are used in air-cooled systems to facilitate the flow of air between heat-generating components, helping to dissipate heat through convection.

- Heat Sinks: Heat sinks are usually made of materials with high thermal conductivity, such as aluminum or copper, and absorb heat from components and transfer it to the surrounding air.

- Pumps: In liquid-cooled systems, pumps circulate the coolant through the system, ensuring continuous heat absorption and transfer.

- Chillers: Active cooling devices that control the temperature of the coolant in a liquid-cooled system by removing heat from the coolant.

- Coolants: Usually liquids, such as water mixed with antifreeze, that absorb and carry away heat from the laser generator and other components.

- Reservoirs: They store the coolant and allow it to expand and contract due to temperature changes.

Importance of Laser Cutting Machine Cooling System

Maintaining Optimal Laser Temperature

Improving Cutting Quality

Extending Machine Life

Improved Operational Efficiency

Safety

Energy Efficiency

Supports Material Versatility

Reduce Downtime and Maintenance

Precision and Repeatability

Optimized for High-Power Applications

Types of Cooling Systems

Air Cooling Systems

Components and Mechanisms

- Fans: Fans are used to blow air over heat-generating components, such as the laser source and power supply. This process enhances convective heat transfer, helping to dissipate heat into the surrounding environment.

- Heat Sinks: Heat sinks are typically made from materials with high thermal conductivity, such as aluminum or copper. They absorb heat from the laser components and transfer it to the air passing over them.

Advantages of Air Cooling Systems

- Simplicity: Air cooling systems are straightforward to implement. They require fewer components and are less complex than liquid cooling systems.

- Lower Cost: The initial cost and maintenance expenses for air cooling systems are generally lower than those for liquid cooling systems.

- Low Maintenance: These systems have fewer parts that can fail or require regular maintenance, reducing the overall upkeep needed.

Disadvantages of Air Cooling Systems

- Limited Cooling Capacity: Air cooling is less effective for high-power lasers or applications that generate significant amounts of heat.

- Noise: Fans can generate noise, which might be disruptive in certain environments.

- Space Requirements: Effective air cooling often requires ample space for air circulation, which might not be feasible in compact machine designs.

Liquid Cooling Systems

Components and Mechanisms

- Coolant Circulation: A pump circulates the coolant through the system, ensuring continuous heat absorption from the laser and other heat-generating components. The coolant flows through channels or tubes that are in direct contact with these components.

- Heat Exchangers: Heat exchangers transfer heat from the coolant to another medium, typically air or another liquid. This process can involve radiators, where the heated coolant passes through coils and transfers heat to the air, or plate heat exchangers, which use a series of thin plates to facilitate heat transfer between the coolant and another fluid.

- Chillers: Chillers are active cooling devices that control the temperature of the coolant. They remove heat from the coolant and dissipate it externally, often using a refrigeration cycle to maintain the coolant at a specified temperature.

Advantages of Liquid Cooling Systems

- High Cooling Efficiency: Liquid cooling systems are highly effective at managing heat, making them suitable for high-power lasers and prolonged operation.

- Precise Temperature Control: These systems provide more accurate and stable temperature regulation, thereby maintaining consistent laser performance.

- Quieter Operation: Liquid cooling systems tend to be quieter than air cooling systems because they rely less on fans for heat dissipation.

Disadvantages of Liquid Cooling Systems

- Higher Initial Cost: The components and installation of liquid cooling systems are generally more expensive than those of air cooling systems.

- Complexity and Maintenance: Liquid cooling systems require regular maintenance to prevent leaks, coolant degradation, and other issues. The complexity of these systems can also lead to higher repair costs and downtime if problems arise.

- Potential for Leaks: Liquid cooling systems are prone to leaks, which can cause damage to the laser cutting machine and disrupt the operation.

Comparison and Applicability

The choice between air-cooling and liquid-cooling systems depends on several factors, including the power of the laser, the duration and intensity of the cutting operation, and the specific requirements of the application.

- Low-to Medium-Power Applications: For laser cutting machines with lower power requirements, an air-cooling system is usually sufficient. It provides a cost-effective and simple solution for heat management without complex components or extensive maintenance.

- High-Power and High-Precision Applications: For applications that require high power or where precision is critical, liquid-cooling systems are the preferred choice. Their superior cooling capabilities and precise temperature control ensure that the laser generator operates at its best, providing consistent performance and high-quality cutting.

- Operating Environment: The operating environment of the laser cutting machine can also affect the choice of cooling system. In noisy or space-constrained environments, liquid cooling systems may be more advantageous despite their higher cost and maintenance requirements.

Key Parameters Affecting Cooling System Performance

Cooling Capacity

Cooling capacity refers to the amount of heat that the cooling system can remove in a given time frame. It is usually measured in kilowatts (kW) or British thermal units per hour (BTU/hr). The cooling capacity must equal or exceed the heat generated by the laser and other components to prevent overheating. Factors that affect cooling capacity include:

- Size and type of Heat Exchanger: Larger or more efficient heat exchangers can dissipate more heat.

- Coolant Flow Rate: Higher flow rates increase the amount of heat that can be removed from the components.

Coolant Type and Properties

The type and properties of the coolant used in a liquid cooling system can significantly affect performance. Important coolant properties include:

- Thermal Conductivity: Higher thermal conductivity enables the coolant to absorb and transfer heat more efficiently.

- Viscosity: Lower viscosity reduces flow resistance, enhancing the coolant’s ability to circulate and dissipate heat.

- Specific Heat Capacity: A higher specific heat capacity means that the coolant can absorb more heat before the temperature rises significantly.

Flow Rate and Pressure

Ambient Temperature and Environmental Conditions

Heat Exchanger Efficiency

The efficiency of heat exchangers such as radiators, plate heat exchangers, and cooling coils determines how efficiently heat is transferred from the coolant to the environment. Factors that influence heat exchanger efficiency include:

- Surface Area: The larger the surface area, the more room there is for heat transfer, and the higher the efficiency.

- Material: Materials with high thermal conductivity, such as copper or aluminum, enhance heat transfer.

- Design: Efficient designs, such as finned surfaces or corrugated plates, increase turbulence in the coolant flow, which improves heat exchange.

Fan and Pump Performance

In air-cooled systems, the performance of the fan helps achieve effective heat dissipation. Parameters that influence fan performance include:

- Airflow Rate: Higher airflow rates improve convective heat transfer to the heat sink.

- Fan Speed: Adjustable fan speed optimizes cooling based on the machine’s operating conditions.

In liquid-cooled systems, pump performance is equally important. Key parameters include:

- Flow rate: The volume of coolant circulated per unit time affects heat dissipation efficiency.

- Pressure head: The pressure differential that the pump can maintain affects the flow rate and the system’s ability to overcome coolant circuit resistance.

Control Systems and Sensors

Advanced control systems and sensors improve cooling system performance by providing real-time monitoring and adjustments. Important control parameters include:

- Temperature Sensors: Monitoring temperatures at critical points allows precise control of cooling operations.

- Flow Sensors: Ensuring adequate coolant flow prevents overheating and improves efficiency.

- Feedback Loops: Automated systems that adjust fan speeds, pump speeds, and cooler settings based on real-time data optimize cooling performance and energy efficiency.

Maintenance and Cleaning

Regular maintenance and cleaning of cooling systems help achieve continuous, consistent performance. Key maintenance tasks include:

- Cleaning Heat Exchangers and Filters: Removing dust and debris from heat exchangers and filters ensures efficient airflow and heat transfer.

- Checking Coolant Levels and Quality: Maintaining proper coolant levels and replacing deteriorated coolant prevents overheating and corrosion.

- Inspecting and Replacing Worn Parts: Regular inspection and timely replacement of worn fans, pumps, and seals prevent failures and ensure continued cooling efficiency.

How to Choose a Suitable Cooling System

Assess the Laser Power and Heat Load

The first step in choosing a suitable cooling system is to assess the laser power and the associated heat load. Higher-power lasers generate more heat, requiring more robust cooling solutions.

- Laser Power Rating: Determine the power rating of the laser source, typically measured in watts (W). Higher-power lasers (e.g., 1 kW and above) generate more heat and require more efficient cooling systems.

- Operational Intensity: Consider the machine’s operational intensity and duty cycle. Machines operating continuously or at high speeds produce more heat, necessitating a cooling system that can handle prolonged heat loads.

Determine the Cooling Capacity Required

Once the laser power and heat load are assessed, calculate the cooling capacity required to maintain optimal operating temperatures.

- Heat Load Calculation: Estimate the total heat load generated by the laser and other components. This includes the laser generator, power supply, motion systems, and any auxiliary equipment.

- Cooling Capacity Matching: Ensure that the cooling system’s capacity, measured in kilowatts (kW) or British Thermal Units per hour (BTU/hr), matches or exceeds the calculated heat load. A safety margin of 10-20% is often recommended to account for variations in operating conditions.

Evaluate Cooling System Types

Air Cooling Systems

Air cooling systems use fans and heat sinks to dissipate heat from the laser and other components.

- Simplicity and Cost: Air cooling systems are simpler and less expensive to install and maintain. They are suitable for low to moderate-power lasers.

- Space and Noise Considerations: Consider the available space for airflow and the noise generated by fans. Air cooling systems can be noisy and may require ample space for effective heat dissipation.

Liquid Cooling Systems

Liquid cooling systems use a coolant, typically a mixture of water and antifreeze, to absorb heat from the laser and transfer it away.

- Cooling Efficiency: Liquid cooling systems are more efficient and effective for high-power laser generators, providing precise temperature control and higher cooling capacity.

- Complexity and Maintenance: These systems are more complex and require regular maintenance to prevent issues like leaks and coolant degradation. Consider the availability of maintenance resources and expertise.

Consider Environmental and Operational Factors

Environmental and operational factors play a significant role in selecting the appropriate cooling system.

- Ambient Temperature: High ambient temperatures reduce the efficiency of air cooling systems. In such environments, liquid cooling systems may be more effective.

- Dust and Contaminants: Dusty or contaminated environments can clog air filters and heat exchangers, reducing cooling efficiency. Liquid cooling systems are generally more resistant to such conditions.

- Space Constraints: Evaluate the available space for installing the cooling system. Liquid cooling systems may require more space for components like reservoirs, pumps, and chillers.

Analyze Total Cost of Ownership

When choosing a cooling system, consider the total cost of ownership, including initial costs, operational expenses, and maintenance requirements.

- Initial Costs: Compare the initial costs of air and liquid cooling systems, including installation and setup.

- Operational Costs: Evaluate the energy consumption of the cooling system. Liquid cooling systems are generally more energy-efficient but may have higher initial costs.

- Maintenance Costs: Consider the maintenance requirements and associated costs for each type of cooling system. Regular maintenance is essential for both air and liquid cooling systems to ensure long-term performance.

Review Manufacturer Specifications and Recommendations

Consult the laser cutting machine’s manufacturer specifications and recommendations for cooling systems. Manufacturers often provide guidelines on the optimal cooling solutions for their equipment.

- Compatibility: Ensure the cooling system is compatible with the specific make and model of the laser cutting machine.

- Performance Guarantees: Some manufacturers offer performance guarantees or warranties when their recommended cooling systems are used.

Consider Future Scalability

Consider the potential for future upgrades or changes in operational requirements. Choose a cooling system that can accommodate increased heat loads or higher-power laser generators if needed.

- Modular Systems: Look for modular cooling systems that can be expanded or upgraded as needed.

- Flexible Design: Ensure the cooling system can adapt to changes in operational conditions or machine configurations.

Seek Expert Consultation

Summary

Get Laser Cutting Solutions

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.