Effect Of Laser Power And Wavelength On Marking Ability

As a high-precision and high-efficiency material processing and marking method, laser marking technology has been widely used in industrial production and scientific research institutes. However, laser power and wavelength, as two key parameters, have an important impact on the efficiency and performance of the laser marking process. In practical applications, factors such as material characteristics, compliance requirements, and equipment performance need to be considered to reasonably select laser power and wavelength to achieve the best marking effect.

This article will discuss the effects of laser power and wavelength on marking capabilities, including the basic principles of laser marking technology, and the effects of laser power and wavelength on marking capabilities respectively. We will further explore its comprehensive role in providing reference and guidance for the optimization of the laser marking process.

Table of Contents

Basic Principles Of Laser Marking Technology

Laser marking technology is a high-precision processing method that uses a laser beam to mark, etch, or cut directly on the surface of a workpiece. The basic principle involves the generation, focusing, and interaction of laser light with materials. The specific steps are as follows:

- Laser generation: The inside of the laser generator excites the medium (such as gas, solid, or semiconductor) to an excited state, and then produces radiation of photons and releases them so that the photons are synchronized and amplified to form a high-energy laser beam.

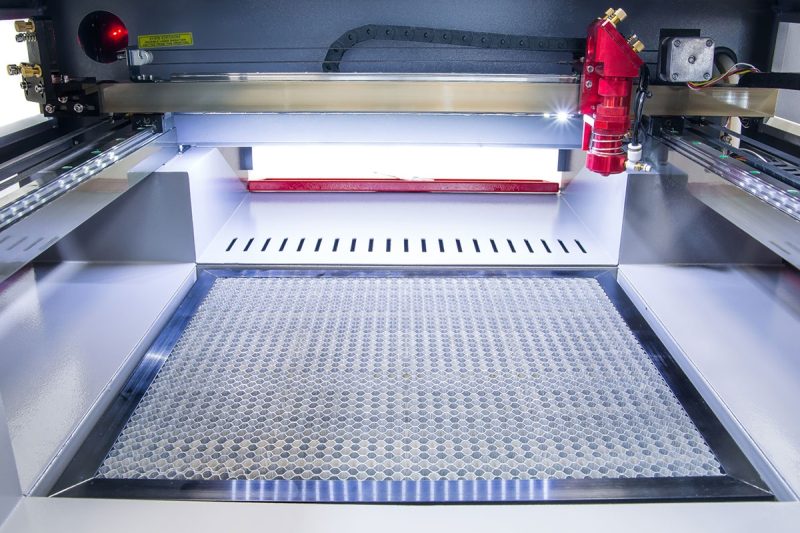

- Laser focusing: The generated laser beam is focused through an optical system (such as lenses, or mirrors) so that the beam can be focused in a very small area.

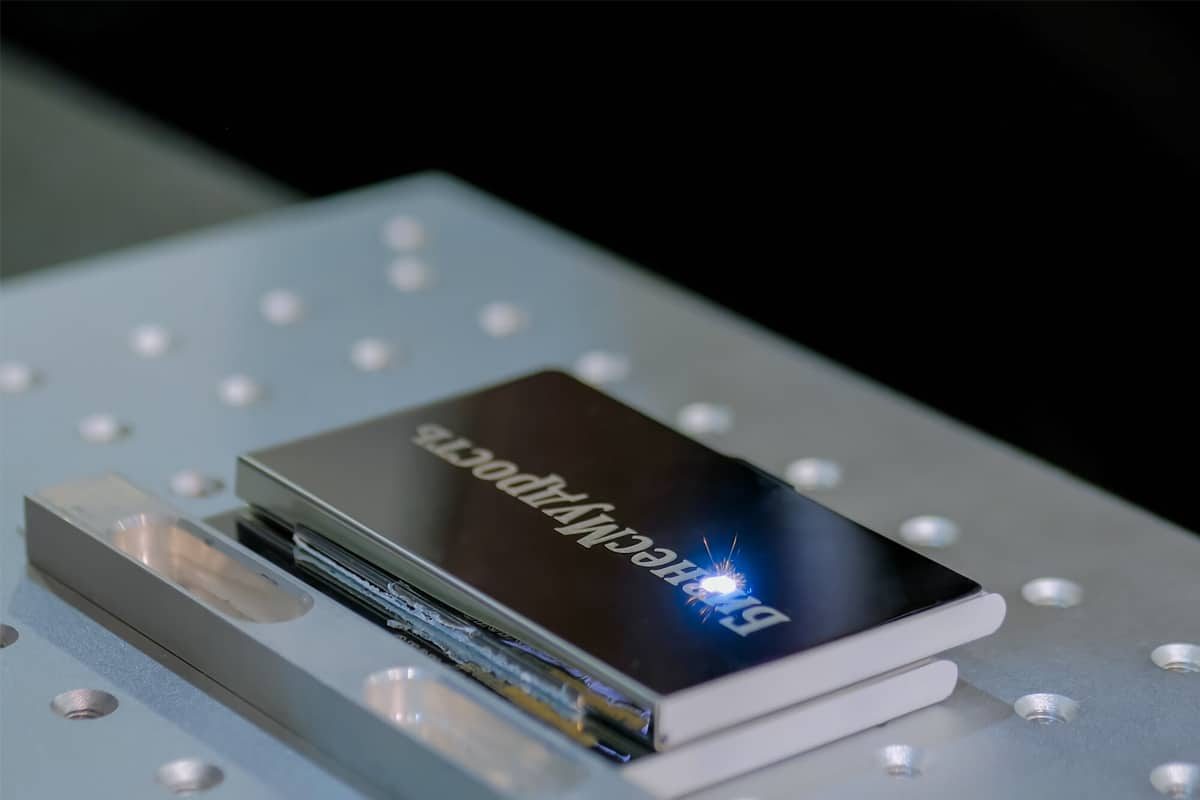

- Laser-material interaction: Once the laser beam is focused on the workpiece surface, the light energy interacts with the material. This interaction may lead to heating, melting, evaporation, or chemical changes of the material, thereby marking, etching, or cutting the workpiece surface.

- Control system: The laser marking system is also equipped with a control system to accurately control parameters such as laser power, wavelength, focus position, and marking speed. Through these controls, precise control of the marking process can be achieved to meet the processing needs of different materials, different shapes, and different accuracy requirements.

In general, the basic principle of laser marking technology is to use a high-energy, monochromatic, focused beam generated by a laser generator to achieve precise marking, etching, or cutting of the workpiece surface through the interaction of light and material.

Effect Of Laser Power On Marking Ability

The effect of laser power on marking ability is a crucial factor in the laser marking process. The following will describe the impact of laser power on marking ability from three aspects: marking speed, marking quality, and material processing effect.

Marking Speed

- The relationship between energy density and heating speed: Laser power directly determines the energy density of the laser beam, that is, the energy per unit area. The higher the power, the greater the energy density of the laser beam, so it can heat more of the material surface at the same time, thus speeding up marking.

- Advantages of high power: For applications that require high-volume production or have strict time requirements, high-power laser marking systems can complete the same marking task faster, thereby increasing production efficiency and throughput.

- Moderate selection: However, too high power may cause excessive ablation or melting of the material, affecting the marking quality, or even damaging the material surface. Therefore, the characteristics of the material and the required marking quality need to be appropriately considered when selecting power to balance speed and quality.

Marking Quality

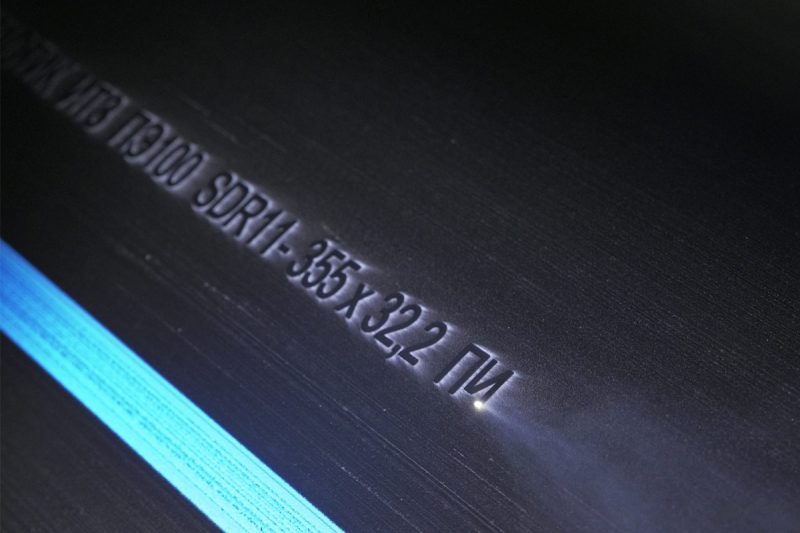

- Clarity and Depth: Proper laser power ensures stable and consistent marking quality. Within a certain range, increasing the power can improve the marking depth and clarity, making the marking pattern clearer and more precise.

- Risks of too high power: However, too high power may cause excessive ablation or melting of the material surface, causing unnecessary damage or affecting the accuracy and clarity of marking. This is especially important in applications where details are critical.

- Good control: Therefore, during the laser marking process, it is necessary to accurately control the laser power to ensure that the marking quality meets the requirements and avoid quality problems caused by excessive power.

Material Processing Effect

- Material characteristics: Different materials respond differently to laser power, so appropriate power selection will also affect the processing effect of the material. For example, in metal marking, appropriate power can achieve clear marks without damaging the surface.

- Applicability of marking: High-power lasers are usually more suitable for etching and cutting materials such as metals, while low-power lasers are more suitable for marking plastics, rubber, and other materials.

- Comprehensive consideration: Therefore, when selecting laser power, factors such as material characteristics, marking requirements, and equipment performance need to be comprehensively considered to achieve the best processing effect.

To sum up, the impact of laser power on marking ability is a complex process that requires comprehensive consideration of multiple factors such as marking speed, marking quality, and material processing effects. Appropriate power selection can improve marking speed, quality, and processing effect, thereby achieving more efficient and accurate laser marking processing.

Effect Of Laser Wavelength On Marking Ability

Laser wavelength is another crucial parameter in the laser marking process, which has a direct impact on marking capabilities. The following will describe the impact of laser wavelength on marking ability from three aspects: material selection, absorption capacity, and marking effect.

Material Selection

- Material absorption properties: The choice of laser wavelength is closely related to the material to be processed. Lasers of different wavelengths have different absorption capabilities on materials, so it is necessary to choose lasers with appropriate wavelengths for different materials. For example, some materials absorb laser light at red wavelengths better, while other materials are more sensitive to laser light at blue or ultraviolet wavelengths.

- Optimal wavelength selection: For a specific material, selecting the optimal laser wavelength can maximize marking efficiency and quality. For example, in metal marking, a shorter wavelength UV laser is usually chosen to achieve better etching results, while in plastic or organic material marking, a red laser may be preferred to achieve better absorption.

Absorptive Capacity

- Wavelength and material absorption: Different wavelengths of laser light have different absorption levels on materials. Typically, laser wavelengths that match the material are more effectively absorbed by the material, making the marking process more efficient.

- Light Absorption and Scattering: Additionally, wavelength affects how the laser interacts with the material. For example, some materials may be more sensitive to laser scattering and not absorb the laser sufficiently, thus affecting the quality and effect of marking.

Marking Effect

- Clarity and Depth: Choosing the right wavelength can affect the clarity and depth of your mark. In some applications that require high resolution and fineness, choosing a wavelength suitable for the material can result in clearer and finer marking results.

- Optical effects: Lasers of different wavelengths may also cause different optical effects, such as dispersion and refraction. These effects may affect the precision and accuracy of marking and therefore need to be considered when selecting a wavelength.

In short, the laser wavelength has a direct impact on the marking ability, and the influencing factors involve material selection, absorption capacity, and marking effect. Selecting the appropriate wavelength can maximize marking efficiency and quality. Therefore, in practical applications, the optimal laser wavelength needs to be selected based on specific material properties and marking requirements.

Discussion On The Combined Effects Of Power And Wavelength

Power and wavelength are two key parameters in the laser marking process, and their combined impact is of great significance to marking capabilities. The comprehensive effects of power and wavelength on laser marking will be discussed below.

The Balance Between Marking Speed And Quality

- Power vs. speed relationship: High-power lasers can usually speed up marking, but too high power may result in reduced marking quality, such as excessive ablation or melting. Therefore, it is necessary to balance the needs of speed and quality when selecting power and increase the power appropriately to speed up the speed without affecting the marking quality.

- Relationship between wavelength and quality: The choice of wavelength also affects the quality of marking. Lasers of different wavelengths have different absorption capabilities on materials, so choosing a wavelength suitable for the material can improve the marking quality. For example, some materials absorb laser light of specific wavelengths more fully, allowing for clearer and more precise marking results.

Balance of equipment performance and operational needs

- Equipment adaptability: Laser marking systems with different powers and wavelengths have different equipment performance and operating characteristics. Therefore, when selecting a laser marking system, it is necessary to comprehensively consider the adaptability and operational needs of the equipment and select the most appropriate system to meet the requirements of practical applications.

- Process optimization: For specific applications, the best marking results can be achieved by optimizing process parameters, such as adjusting power and wavelength. This may require trial and practice to determine the best combination of parameters to meet the marking requirements of different materials and needs.

Summarize

Through the discussion in this article, we can see that the appropriate selection of laser power and wavelength can increase the marking speed while ensuring the marking quality and processing effect. However, in practical applications. It is necessary to comprehensively consider factors such as material characteristics, marking requirements, and equipment performance, reasonably select power and wavelength, and optimize the process to achieve the best marking effect.

In short, the impact of laser power and wavelength on marking ability is a comprehensive topic, which requires comprehensive consideration of multiple factors for reasonable parameter selection and process optimization. With the continuous development of science and technology, laser marking technology will be applied in more fields and continuously improved and optimized. In the future, we look forward to the emergence of more intelligent and efficient laser marking systems, which will bring more possibilities to applications in industrial production and other fields. Whether it’s learning about the depths our machines can reach or purchasing a machine for your business, our team is dedicated to guiding you every step of the way. Contact us today to explore the huge potential of laser marking and experience the difference AccTek Laser can bring.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions