Exploring the Efficacy of Laser Cleaning: A Comprehensive Analysis

Among the ever-evolving industrial cleaning methods, laser cleaning has become a revolutionary technology, providing a precise, environmentally friendly and efficient solution for removing contaminants from various surfaces. From rust and paint to oil and residue, laser cleaning has captured the attention of industries for its ability to achieve perfect results without the use of chemicals or abrasive materials. But just how efficient is laser cleaning? In this article, we take an in-depth exploration of laser cleaning technology. We examine how laser cleaning technology works, explore its advantages, limitations and applications, evaluate its efficiency compared to traditional cleaning methods, and explore the factors that influence laser cleaning efficiency. Join us on a journey into the complex world of laser cleaning, where precision combines with productivity and sustainability.

Table of Contents

What Is Laser Cleaning?

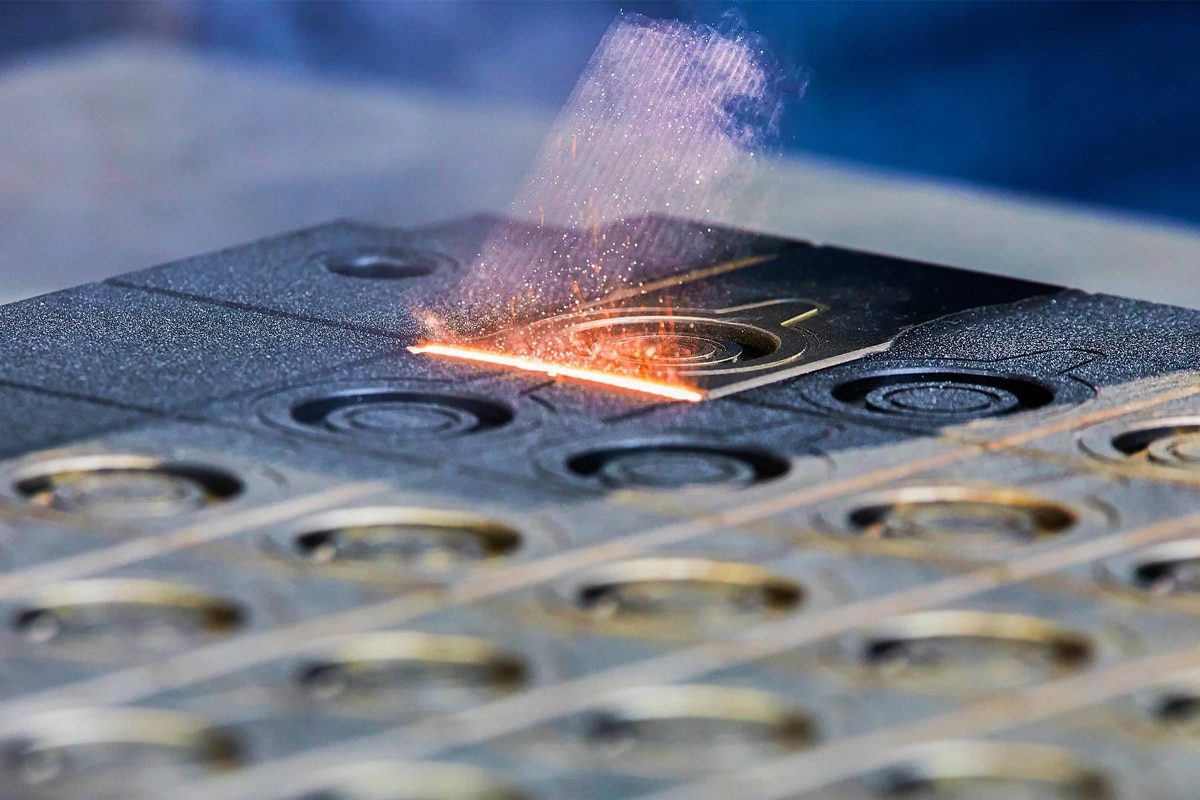

Pulsed laser cleaning is an efficient and precise surface cleaning technology. The basic principle of pulsed laser cleaning involves the interaction between intense pulses of laser light and the material to be cleaned. When a laser beam strikes a surface, it rapidly heats contaminants or coatings to vaporization or sublimation temperatures. The rapid expansion of steam creates shock waves that effectively remove unwanted material from the surface, leaving a clean substrate.

Types of laser generators used for cleaning

Laser cleaning applications typically utilize several types of laser generators, each with unique advantages and characteristics suitable for specific cleaning tasks:

- Fiber laser generators: These laser generators use optical fibers to deliver high-energy laser pulses. Fiber laser generators are known for their compact size, high beam quality, and excellent reliability, making them ideal for precision cleaning applications.

- Q-switched laser generator: Q-switched laser generator uses a Q-switched mechanism to control the release of energy stored in the laser cavity, thereby generating short pulses with high peak power. Q-switched laser generators deliver intense bursts of energy in a controlled manner, making them ideal for removing stubborn contaminants and coatings.

- Nd: YAG Laser Generator: The Nd: YAG (Neodymium-doped Yttrium Aluminum Garnet) laser is a general-purpose laser generator commonly used in industrial cleaning applications. They can operate in pulsed and continuous wave modes, providing flexibility and adaptability for a variety of cleaning requirements.

- Excimer laser generator: Excimer laser generators produce pulsed ultraviolet (UV) light by exciting a mixture of rare gases and halogens. Due to their short wavelength and minimal heat-affected zone, these lasers are particularly effective at cleaning surfaces that are sensitive to thermal damage, such as semiconductor materials.

Applications of Laser Cleaning

- Metalworking: Removing rust, paint, and oxides from metal surfaces in the automotive, aerospace, and manufacturing industries.

- Historic Restoration: Clean delicate artifacts, statues, and historical monuments without causing damage to the underlying materials.

- Electronics Manufacturing: Removal of residues, oxides, and coatings from semiconductor wafers, printed circuit boards (PCBs), and electronic components.

- Precision Cleaning: Preparing surfaces for bonding, welding, or coating in applications requiring a high level of cleanliness and surface quality.

- Paint Stripping: Precisely and efficiently remove paint and coatings from aircraft, automobiles, and industrial equipment.

Overall, laser cleaning provides a versatile, efficient and environmentally friendly solution for surface cleaning and preparation tasks across industries, capable of precisely removing contaminants while maintaining the integrity of the substrate.

How Does Laser Cleaning Work?

Laser cleaning works by using a powerful laser beam to remove contaminants, coatings, oxides and other unwanted materials from surfaces. The process involves several key steps to achieve precise, efficient cleaning:

Interaction between laser and materials

When a laser beam hits a surface, it interacts with the materials present, whether they are contaminants, coatings or substrates. This interaction mainly involves the absorption of laser energy by the material. The degree of absorption depends on factors such as the optical properties of the material, the wavelength of the laser, and the presence of any coatings or surface treatments.

Pollutant removal mechanism

Once the laser energy is absorbed, it rapidly heats the material to vaporization or sublimation temperatures. This rapid heating causes material to be expelled from the surface through various mechanisms:

- Ablative: For solid contaminants or coatings, intense heat causes them to evaporate or break down into small particles that are then ejected from the surface.

- Thermal stress cracking: In some cases, rapid heating and expansion of a material can create thermal stress, causing cracks to form and subsequently detach from the surface.

- Shock wave formation: The rapid expansion of vaporized material creates shock waves that help remove nearby contaminants or coatings, further facilitating their removal.

Surface treatment

When unwanted material is removed from the surface, what remains is a clean substrate ready for further processing or application. Laser cleaning leaves minimal residue and does not introduce additional contaminants, making it ideal for precision cleaning and surface preparation tasks.

Selective cleaning

One of the main advantages of laser cleaning is its ability to selectively remove specific materials while leaving the underlying substrate intact. This selectivity is achieved by adjusting parameters such as laser power, pulse duration and spot size to target the desired contaminants or coatings without damaging the underlying surface.

Overall, laser cleaning provides a precise, efficient and environmentally friendly solution for removing contaminants and preparing surfaces for a variety of applications and industries. Its versatility, selectivity and minimal impact on the substrate make it the first choice for tasks requiring high cleanliness and surface quality.

What Are The Factors That Affect Laser Cleaning Efficiency?

Laser cleaning efficiency hinges on a delicate interplay of various factors, ranging from laser parameters to material and contaminant properties. Understanding these factors is essential for optimizing cleaning processes across a wide range of applications. In this introduction, we will explore three main categories of factors that influence laser cleaning efficiency: laser parameters, material properties, and contaminant characteristics.

Laser Parameters

- Wavelength: The wavelength of the laser beam determines its interaction with the material surface. Different materials have varying absorption characteristics at different wavelengths. Selecting the appropriate wavelength ensures efficient energy absorption and thus effective cleaning. For example, metals often absorb well in the near-infrared range, while organic materials may require shorter wavelengths in the visible or ultraviolet spectrum.

- Pulse Duration: The duration of each laser pulse, often measured in nanoseconds or picoseconds, impacts the amount of energy delivered to the surface. Shorter pulse durations are typically more effective for precise cleaning tasks, as they minimize heat transfer and reduce the risk of substrate damage.

- Power: The power of the laser beam dictates the intensity of energy delivered to the surface. Higher power levels can enhance cleaning speed and effectiveness, but excessive power may lead to substrate damage or excessive material removal. Balancing power with other parameters is crucial for achieving optimal cleaning results.

Material Properties

- Absorptivity: The absorptivity of the material determines how efficiently it absorbs laser energy. Materials with high absorptivity are more effectively cleaned, as they absorb a larger portion of the incident laser light. Surface treatments or coatings can alter a material’s absorptivity, influencing its response to laser cleaning.

- Thermal Conductivity: Materials with high thermal conductivity dissipate heat more rapidly, which can affect the effectiveness of laser cleaning. Substrates with low thermal conductivity may experience localized heating, leading to thermal damage or incomplete cleaning. Understanding the thermal properties of the material is crucial for optimizing cleaning parameters.

Contaminant Characteristics

- Type: The type of contaminant present on the surface dictates its response to laser cleaning. Different contaminants may require specific laser parameters or cleaning strategies for effective removal. For example, organic contaminants such as grease or paint may respond differently to laser cleaning compared to inorganic materials like rust or oxides.

- Thickness: The thickness of the contaminant layer influences the amount of energy required for removal. Thicker layers may require higher laser power or multiple cleaning passes to achieve complete removal. Understanding the thickness of the contaminant layer is essential for selecting appropriate cleaning parameters.

- Adhesion Factors: The adhesion strength between the contaminant and the substrate affects the ease of removal during laser cleaning. Contaminants with strong adhesion may require higher energy levels or additional surface preparation techniques to facilitate detachment. Assessing adhesion factors helps determine the most effective cleaning approach.

By considering these factors comprehensively and tailoring laser cleaning parameters accordingly, practitioners can optimize efficiency, minimize substrate damage, and achieve superior cleaning results across diverse applications and materials.

Advantages of Laser Cleaning

Laser cleaning offers a multitude of benefits that significantly impact its effectiveness and appeal across various industries. Here are some of the key advantages:

Non-Contact Cleaning

Laser cleaning is a non-contact process, meaning there is no physical contact between the cleaning tool and the surface being treated. This eliminates the risk of mechanical damage to delicate substrates, such as scratches or distortion, which can occur with abrasive cleaning methods like sandblasting or grinding. Non-contact cleaning also allows for the treatment of intricate or irregularly shaped surfaces without compromising their integrity.

Non-Abrasive

Unlike traditional cleaning methods that rely on abrasive materials to remove contaminants, laser cleaning does not require any physical abrasion. Instead, it utilizes the energy of focused laser beams to dislodge and vaporize unwanted materials from the surface. This non-abrasive nature preserves the integrity and finish of the substrate, making laser cleaning particularly suitable for sensitive materials or surfaces prone to damage.

Environmentally Friendly

Laser cleaning is an environmentally friendly cleaning solution that eliminates the need for harsh chemicals, solvents, or abrasive materials. It produces minimal waste and does not generate harmful by-products or emissions, making it a sustainable alternative to traditional cleaning methods. Additionally, laser cleaning can be performed without the use of water, reducing water consumption and wastewater treatment requirements.

Precise and Controlled Cleaning

Laser cleaning offers unparalleled precision and control over the cleaning process. Operators can adjust parameters such as laser power, pulse duration, and spot size to tailor the cleaning operation to specific requirements. This precision allows for selective removal of contaminants while leaving the underlying substrate intact, ensuring consistent and uniform cleaning results across the entire surface.

Reduced Need for Consumables and Waste

Unlike abrasive cleaning methods that require the continual replenishment of consumable materials such as abrasives or blasting media, laser cleaning is a consumable-free process. There are no abrasive materials to purchase, handle, or dispose of, resulting in cost savings and reduced waste generation. Additionally, since laser cleaning produces minimal residue or secondary waste, there is less need for post-cleaning cleanup or disposal efforts.

Overall, the advantages of laser cleaning, such as non-contact operation, non-abrasive cleaning action, environmental sustainability, precise control, and reduced consumables and waste, make it an attractive and versatile solution. It is suitable for a variety of cleaning applications in a variety of industries, from automotive and aerospace to electronics manufacturing and historic restoration.

Laser Cleaning Limitations and Challenges

Laser cleaning undoubtedly has many advantages, but like any technology, it has limitations and challenges that must be considered. Here are some key factors to keep in mind:

Material damage and discoloratin

While laser cleaning is generally non-abrasive and non-contact, there is still a risk of material damage or discoloration, especially with sensitive substrates. High laser intensity or prolonged exposure can cause thermal damage, alter surface properties, or cause color or texture changes. Careful selection of laser parameters and testing of representative samples can help mitigate these risks.

Security considerations

Laser cleaning involves high-intensity laser beams, which can be potentially dangerous to operators and bystanders if appropriate safety measures are not taken. Preventing eye exposure to harmful laser radiation can protect your eyes, and operators should wear appropriate laser safety goggles or glasses suitable for the specific wavelength used. Additionally, a fume extraction system may be required to remove any evaporated contaminants or particles produced during the cleaning process to ensure a safe working environment.

Equipment and operating costs

Implementing laser cleaning technology requires investment in specialized equipment, including laser systems, optics and control systems. The initial capital outlay can be significant, and ongoing maintenance and operating costs should also be considered. While laser cleaning offers long-term benefits such as reduced supplies and waste and increased efficiency, organizations must weigh these benefits against the upfront costs.

Limited effectiveness against certain pollutants

While laser cleaning is very effective at removing many types of contaminants, it may be less suitable for certain materials and substances. For example, highly reflective or transparent materials may not absorb laser energy effectively, reducing cleaning effectiveness. Likewise, thick or heavily adhered contaminants may require multiple cleaning or refill methods to be completely removed. Understanding the limitations of laser cleaning and its suitability for a specific application makes it easier to achieve satisfactory results.

Despite these limitations and challenges, laser cleaning remains a versatile and valuable cleaning technology, providing precise, environmentally friendly, and efficient solutions for a wide range of applications. By addressing these challenges with careful planning, risk assessment, and implementing appropriate safety measures, organizations can leverage the full potential of laser cleaning while minimizing potential drawbacks.

Comparative Analysis of Laser Cleaning And Traditional Cleaning Methods

Laser cleaning is compared to traditional cleaning methods based on different criteria, including cleaning efficiency, surface damage, environmental impact, safety, cost and efficiency, versatility and more:

Cleaning Efficiency

- Laser Cleaning: Laser cleaning offers high precision and effectiveness in removing contaminants, coatings, and oxides from surfaces. It can achieve thorough cleaning even in hard-to-reach areas and on complex geometries.

- Traditional Methods: Traditional methods such as abrasive blasting, chemical cleaning, or mechanical scrubbing may be effective but can be labor-intensive and less precise. They may also generate secondary waste or require multiple steps for thorough cleaning.

Surface Damage

- Laser Cleaning: Laser cleaning is non-contact and non-abrasive, minimizing the risk of surface damage or distortion. It can be used on delicate materials without compromising their integrity.

- Traditional Methods: Some traditional methods, such as abrasive blasting or mechanical scrubbing, can cause surface damage, scratches, or distortion, particularly on softer or more delicate substrates.

Environmental Impact

- Laser Cleaning: Laser cleaning is environmentally friendly, as it does not involve the use of chemicals or abrasive materials. It produces minimal waste and does not generate harmful emissions.

- Traditional Methods: Traditional cleaning methods may involve the use of chemicals, solvents, or abrasive materials that can be harmful to the environment. They may also generate wastewater or air emissions requiring treatment.

Safety

- Laser Cleaning: Laser cleaning requires proper safety measures to protect against exposure to laser radiation. Operators must wear appropriate eye protection, and fume extraction may be necessary to remove vapors or particulates.

- Traditional Methods: Traditional methods may pose safety risks such as exposure to hazardous chemicals, inhalation of dust or fumes, or injuries from abrasive materials or equipment.

Cost and Efficiency

- Laser Cleaning: While laser cleaning technology involves higher initial capital investment, it offers long-term cost savings through reduced labor, consumables, and waste disposal costs. It also offers higher efficiency and productivity.

- Traditional Methods: Traditional cleaning methods may have lower upfront costs but can be labor-intensive and time-consuming. They may also require frequent replenishment of consumables or disposal of waste, leading to higher operational costs over time.

Versatility

- Laser Cleaning: Laser cleaning is versatile and can be adapted to various materials, surfaces, and contaminants. It offers precise control over cleaning parameters, making it suitable for a wide range of applications.

- Traditional Methods: Traditional cleaning methods vary in their versatility and effectiveness depending on the type of material and contaminant. Some methods may be limited in their applicability to specific surfaces or conditions.

In conclusion, while traditional cleaning methods have their merits, laser cleaning offers several advantages in terms of efficiency, precision, environmental friendliness, and long-term cost savings. However, the choice between laser cleaning and traditional methods ultimately depends on factors such as the specific cleaning requirements, the nature of the surface and contaminants, and the available resources and expertise.

Summarize

In summary, laser cleaning demonstrates excellent cleaning efficiency, providing a precise, environmentally friendly, and cost-effective solution to surface cleaning tasks. Its ability to achieve thorough cleaning while maintaining surface integrity and minimizing environmental impact makes it the first choice for industries looking for optimal cleaning performance and sustainability.

In this article, we take an in-depth look at the cleaning efficiency of laser cleaning, exploring its effectiveness across various criteria. Discussing the cleaning efficiency of laser cleaning machines is not only for efficient cleaning but also to promote the sustainable development of laser cleaning. AccTek Laser not only provides cutting-edge laser cleaning machines but also tailor-made solutions to ensure a safe working environment. Consult us today and see how our expertise can transform your workspace into a productive and safe space.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions