High-Configuration Pipe Fiber Laser Cutting Machine

- Brand: AccTek

- Model: AKJ60F

- Laser Head: Raytools

- Laser Genertor: Raycus

- Servo Motor: Japanese Yaskawa

- Price Range: $23400-$73800/Set

- After Sale: 3 Years

- Lead Time: 15-17 Working Day

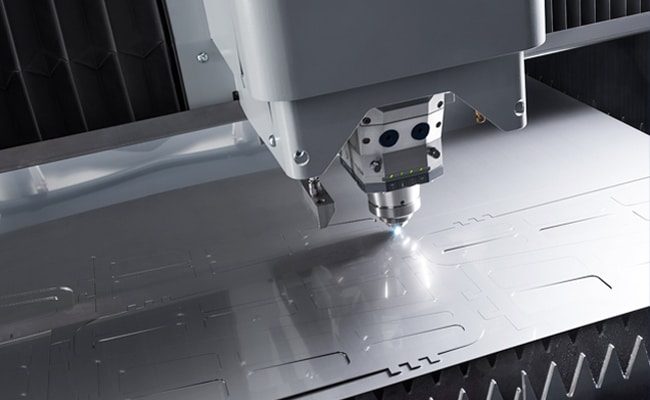

AKJ60F laser cutting machine is a professional pipe fiber laser cutting machine. It can cut any programmed shape on metal pipe, and the laser can achieve perfect cutting in any direction. Through computer programming design, the processed shape can be changed flexibly and quickly. The high flexibility of the laser tube cutting machine provides strong technical support for increasingly personalized metal processing, thereby reducing the number of molds used.

AccTek has 10 years of experience in laser-cutting machine production and is committed to providing professional laser solutions to global customers. As a professional manufacturer of fiber laser cutting machines, we have designed fiber laser cutting machines with different powers and models to meet the needs of different customers. AccTek implements strict assembly processes and world-class branded parts to ensure high cutting accuracy and powerful cutting ability, thus maximizing the productivity and profitability of sheet metal fabricators.

| Model | AKJ60F | Working Area | 200*6000mm |

|---|---|---|---|

| Min Line Width | 0.1mm | Power Requirement | 380V, 50/60Hz, 3PH |

| Control System | Cypcut controller system | Transmission | Y axis gear and pinion; Z axis ball screw |

| Max Cutting Speed | 35m/min | X Axis Max Speed | 65m/min |

| Y Axis Max Speed | 100m/min | Z Axis Max Speed | 30m/min |

| Cooling Way | Water cooling, industrial water chiler | Laser Generator | Reci / Raycus / IPG |

| Electronic Components | French Schneider | Motor | YASKAWA / Panasonic |

Product Configuration

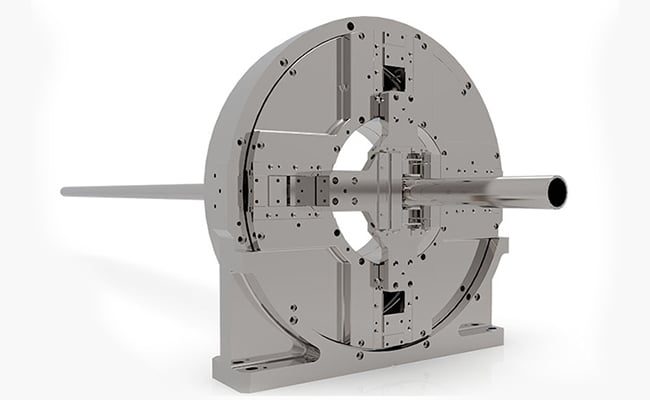

Self-Centering Chuck

The two sides are designed with pneumatic clamps, which can automatically adjust the center, and the speed is 3 times that of the electric chuck. The clamping force of the self-centering chuck is large and constant, which can effectively maintain the precision of pipe cutting. In addition, it also has a professional pipe support function to avoid pipe sagging and deformation, precise and durable.

Tube Welding Bed

The internal structure of the bed is welded by multiple rectangular tubes, and there are reinforced rectangular tubes inside the bed to enhance the strength and stability of the body. The solid body structure not only increases the stability of the guide rail but also effectively prevents the deformation of the body. The service life of the body is as long as 25 years.

Raycus Laser Generator

The Raycus laser generator not only has higher photoelectric conversion efficiency but also provides more stable optical quality to ensure a more stable and finer cutting effect.

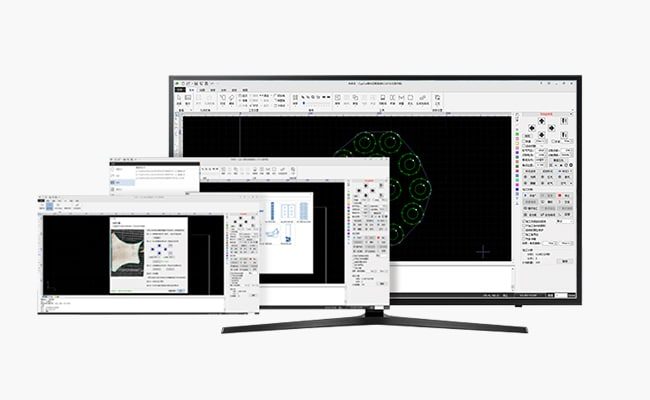

Professional Pipe Cutting System

Adopt the Cypcut 3000S laser cutting system, which is simple, economical, practical, and convenient for human-computer interaction. The cutting system has a rich built-in fiber laser cutting process and parameters and supports advanced functions such as workpiece edge finding, autofocus control, and breakpoint positioning. The cutting system is highly integrated and intelligent, integrating file reading, design, output, and processing control.

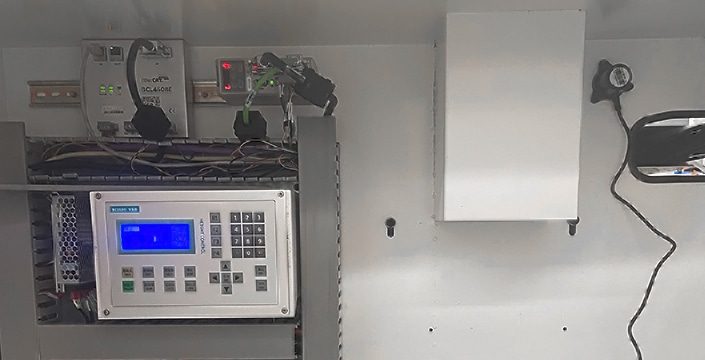

Operation Screen

The operation screen adopts a vertical screen design, which is different from the traditional horizontal screen display, with fast response speed, higher contrast, wider field of view, low power consumption, and high resolution. In addition, the operating screen features high brightness and low reflectivity, as well as a durable solid glass panel.

Hiwin Guide Rail

Hiwin Guide Rails provide high-precision and reliable linear motion for laser cutting machines, allowing accurate and efficient cutting of materials. It is manufactured from advanced materials that can withstand the high temperatures and pressures of laser cutting. In addition, Hiwin rails can be installed and maintained quickly and easily.

Japan Yaskawa Servo Motor

Yaskawa servo motor has the highest amplifier response in the same industry, which greatly shortens the settling time, realizes high-speed acceleration and deceleration, and has a fast response.

It has the function of resonance suppression to ensure the smooth operation of the machine at high speed.

Strong anti-interference ability and strong anti-overload ability.

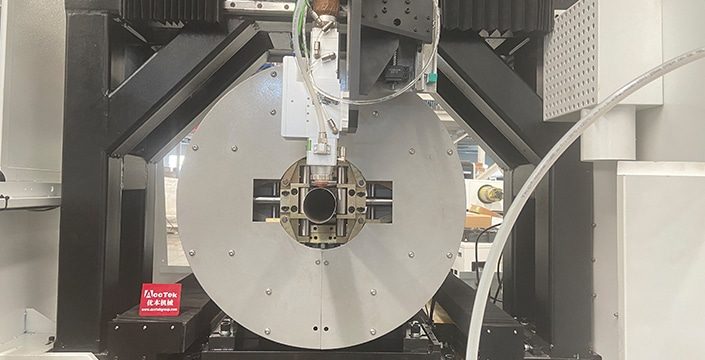

Auto Focus Laser Cutting Head

No Manual Focus Required

The software automatically adjusts the focusing lens to realize automatic perforation and cutting of plates with different thicknesses. Autofocus lenses are ten times faster than manual focus.

Wider Adjustment Range

Adjustment range -10mm~+10mm, precision 0.01mm, suitable for different types of 0~20mm plates.

Long Lasting

The collimating mirror and the focusing mirror are equipped with water-cooling fins, which can reduce the laser cutting head’s temperature and improve the laser cutting head’s service life.

Product Features

- The pipe fiber laser cutting machine can cut round pipes, square pipes, oval pipes, D-shaped pipes, and other conventional and special-shaped pipes.

- The pipe fiber laser cutting machine can realize the precision cutting of various complex graphics that are difficult to realize by conventional methods.

- The pipe fiber laser cutting machine has the advantages of high flexibility, high precision, high efficiency, and a short production cycle. The use of fully automatic processing methods can greatly improve the production efficiency of pipe workpieces.

Product Advantages

- The pipe fiber laser cutting machine can cut any pattern on the metal pipe, and the laser can cut in any direction and at any angle, providing favorable technical support for personalized processing. And the pipe fiber laser cutting machine does not need to open the mold, which greatly saves the mold opening cost and improves the processing efficiency.

- The cutting precision of the pipe fiber laser cutting machine is higher. Different materials may undergo slight expansion and contraction deformation during processing, and they can be flexibly adjusted according to these deformations, which is impossible for many traditional processes.

- The pipe fiber laser cutting machine is finished after annealing to eliminate stress, which can better solve the stress generated by welding and processing, thereby improving the rigidity and stability of the equipment. Reliable stability brings longer service life to the machine.

Product Application

AKJ60F fiber laser cutting machine is a professional pipe fiber laser cutting machine, which is widely used in electronics, electrical, mechanical hardware, new energy, packaging, solar energy, LED, automobile, and other industries. The fiber laser cutting machine is used to cut various metal pipes of different materials, such as stainless steel, carbon steel, galvanized sheet, electrolytic sheet, brass, aluminum, various alloy sheets, rare metals, etc.

Cutting Samples

AKJ60F fiber laser cutting machine can cut all types of metal pipes, from mild steel to stainless steel and non-ferrous metals. But some highly reflective metals, such as aluminum and copper, are more difficult to cut. The maximum thickness of metal a laser can cut is determined by the laser source. Theoretically, the greater the laser power, the greater the thickness that can be cut. In addition, the expertise of the machine operator also affects the thickness of the laser cut.

Why Choose AccTek?

Productivity

- Advanced motion systems and one-piece frame design increase motion stability and accuracy over the full range of speeds.

- Fiber laser technology significantly increases cutting speeds while simultaneously reducing power consumption and overall operating costs.

- Ultra jump and scan cut functions minimize positioning time and maximize beam on time.

- Intelligent autofocus and automatic gas pressure control reduce setup times.

Quality

- Proven databases for a range of materials.

- Zoom head with autofocus offers automatic beam magnification of up to 4x for the best combination of speed and quality over a wide range of material thicknesses.

- Fast, clean, and more consistent perforation even in thick materials.

- The water-cooling feature adds stability to the material being processed.

Reliability

- Cypcut Cutting systems deliver proven reliability.

- Fiber lasers offer maximum efficiency and reliability.

- The high-performance cutting head offers a completely dustproof beam path for long lens life and maximum reliability.

- Remote service with online diagnostics.

Get Laser Solutions

We can customize the design according to your requirements. You only need to tell us your requirements, and our engineers will provide you with turnkey solutions in the shortest possible time. Our laser equipment prices are very competitive, please contact us for a free quote. If you need other laser equipment-related services, you can also contact us.