How Can Laser Cleaning Help Reduce Waste and Improve Sustainability?

As an advanced surface treatment method, laser cleaning technology has attracted widespread attention in modern industry and science and technology for its environmental protection, high efficiency, energy saving, multi-function, and non-contact characteristics. This technology uses the precise interaction of high-energy laser beams with the surface of materials to quickly and safely remove pollutants, rust layers, or coatings. It has not only completely changed the traditional cleaning methods, but also significantly reduced the environmental impact and resource consumption in the production process. Compared with traditional cleaning methods that rely on chemical agents or mechanical methods, laser cleaning is easier to operate, has a more targeted cleaning effect, and is particularly ideal for the treatment of precision equipment and complex-shaped surfaces.

In today’s global trend of pursuing green manufacturing and sustainable development, laser cleaning technology has become one of the important tools for industrial transformation due to its advantages of zero emissions and low energy consumption. From reducing waste emissions to protecting natural resources, from improving energy efficiency to extending the service life of equipment, laser cleaning provides a cost-effective and environmentally friendly solution for various industries. Whether it is manufacturing, the automotive industry, or cultural heritage protection and medical equipment manufacturing, laser cleaning has shown great potential. By deeply exploring the applications and advantages of this technology, we will further understand how it can help achieve global sustainable development goals.

Table of Contents

Learn About Laser Cleaning Technology

Laser cleaning technology is an advanced surface treatment method that uses the interaction between high-energy laser beams and the surface of materials to quickly remove contaminants. The laser beam is focused on the target area and removes contaminants such as dirt, oxide layers, grease, etc. from the surface of the object by pyrolysis, vaporization, or stripping. This technology not only has unparalleled efficiency and precision compared to traditional cleaning methods, but is also highly regarded for its environmental friendliness.

Main Features of Laser Cleaning

- Environmental protection: Laser cleaning does not require the use of any chemical agents or cleaning fluids, and relies entirely on laser beams for operation. This not only avoids the emission of harmful substances during chemical cleaning but also reduces wastewater treatment costs and water resource consumption. For industries pursuing green manufacturing, laser cleaning is an extremely attractive environmental solution.

- High efficiency and energy saving: Laser cleaning has extremely high cleaning efficiency and can complete the cleaning task of large areas or complex surfaces in a short time. At the same time, its energy consumption is relatively low, which is in line with the current industrial development trend of energy conservation and emission reduction. Compared with traditional cleaning methods such as sandblasting and chemical cleaning, laser cleaning is faster and more economical, saving time and cost for enterprises.

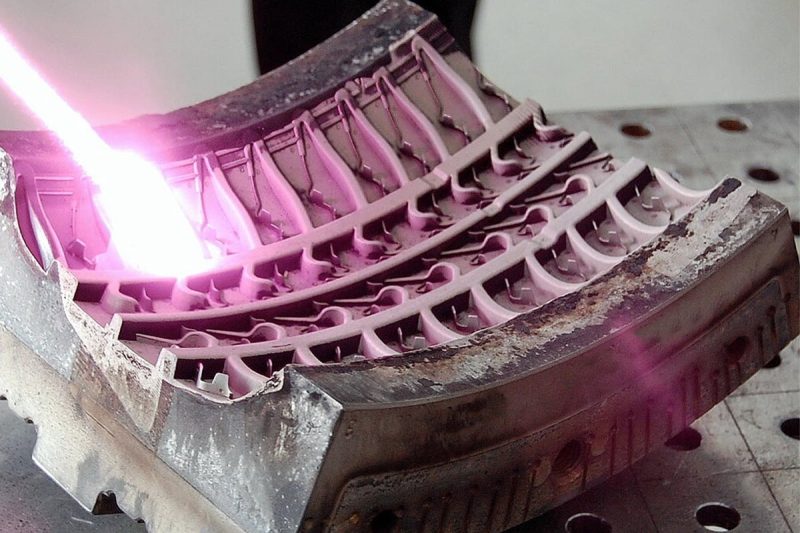

- Versatility: Laser cleaning technology applies to a variety of materials and industries. Whether it is metal, stone, wood, or composite surface, precise cleaning can be achieved by adjusting the laser power and wavelength. Its wide range of applications covers precision parts cleaning in the electronics industry, surface treatment in mold manufacturing, and cultural relics protection in building cleaning.

- Non-contact process: Laser cleaning is a non-contact cleaning process that removes dirt or rust by applying a high-energy laser beam to the surface of the workpiece. No external force is required during the entire process, thus avoiding mechanical damage to the surface of the object. This feature is particularly suitable for cleaning precision instruments, fragile surfaces, or workpieces with complex shapes, ensuring the cleaning effect while maintaining the integrity of the workpiece.

Laser cleaning technology has become an important technical means in the field of modern industrial cleaning due to its environmental protection, high efficiency, energy saving, multi-function, and non-contact characteristics. Driven by green manufacturing and sustainable development goals, laser cleaning can not only meet the high-demand cleaning needs but also provide a safer and more economical solution for industrial production. Its application will continue to expand and become the core cleaning technology in the future industrial field.

Benefits of Laser Cleaning for Waste Reduction and Sustainability

As the world pays more attention to environmental protection and resource conservation, enterprises and industrial fields are seeking greener and more environmentally friendly production processes. Laser cleaning technology, as an efficient, energy-saving, and environmentally friendly cleaning method, not only meets high standards of cleaning needs but also plays an important role in reducing waste, saving resources, and promoting sustainable development. The following are several significant benefits of laser cleaning technology in reducing waste and promoting sustainable development.

- Minimize waste generation: During the laser cleaning process, most of the waste generated is solid powder, which is small in size and easy to store and handle. Compared with liquid waste and bulk waste generated by traditional cleaning methods such as chemical cleaning and mechanical cleaning, the volume and difficulty of waste treatment are greatly reduced. In addition, the waste generated by laser cleaning can usually be recycled, further reducing the complexity of waste treatment and the environmental burden. In this way, laser cleaning not only improves production efficiency but also brings sustainable cleaning solutions to enterprises.

- Chemical-free cleaning: Traditional cleaning methods usually rely on chemical agents, which often release harmful substances during the cleaning process, polluting the air, water, and soil. In contrast, laser cleaning technology does not use chemical cleaning agents at all. The energy of the laser beam directly acts on the pollutants to peel them off or vaporize them from the surface of the object. This chemical-free cleaning feature effectively reduces environmental pollution, reduces the generation of harmful waste, and greatly reduces the negative impact on the ecological environment. Therefore, laser cleaning is particularly important in the pursuit of environmental protection and sustainable development.

- Energy efficiency: The energy consumption of laser cleaning technology is relatively low, which makes it more economical when performing cleaning tasks. Compared with traditional cleaning methods such as high-pressure water flow, chemical cleaning or sandblasting, laser cleaning consumes significantly less energy. Its efficient working principle and precise energy concentration enable laser cleaning to not only complete a large amount of cleaning work in a short period but also reduce the adverse effects on the environment caused by excessive energy consumption. In the green transformation of industrial production, laser cleaning has shown significant energy-saving advantages.

- Resource protection: In traditional cleaning methods, water consumption is an issue that cannot be ignored, especially in the cleaning process that requires a large amount of clean water and chemical solvents. Laser cleaning, due to its non-contact process, basically does not require any water or chemical solvents. In this way, laser cleaning effectively reduces the consumption of water resources and avoids the generation of a large amount of wastewater, which meets the current urgent need for water resource protection. For regions or industries with tight resources, laser cleaning technology is undoubtedly an ideal solution.

- Reduce maintenance downtime: The high efficiency of laser cleaning means that it can complete cleaning tasks in a very short time, saving a lot of time compared to traditional cleaning methods. This is of great significance for industrial production lines, because the cleaning process is usually accompanied by equipment downtime, and excessive cleaning time directly affects production efficiency and business operations. The fast processing characteristics of laser cleaning can reduce downtime and improve overall production efficiency, thereby helping companies reduce production costs and ensure the continuity and stability of the production process.

Laser cleaning technology is not only impeccable in cleaning effect but also greatly promotes waste reduction and resource protection through its advantages of environmental protection, high efficiency, energy saving, and chemical-free cleaning. In the process of promoting sustainable development and green manufacturing, laser cleaning, as an advanced cleaning technology, provides a solution that meets environmental standards. It reduces waste, saves energy and water resources, and improves production efficiency. It is one of the key technologies for various industries to pursue sustainable development.

Environmental Benefits of Laser Cleaning

As global awareness of environmental protection increases, the industrial sector is paying more and more attention to green and sustainable solutions when conducting production and processing. As an environmentally friendly and efficient cleaning method, laser cleaning technology has a positive impact on the environment in many aspects due to its unique advantages. Its energy efficiency, improvement of air quality, water-saving effect, and protection of natural resources all demonstrate its great potential as a green technology. The following are several major advantages of laser cleaning in terms of environmental benefits.

- Energy efficiency: Laser cleaning is an energy-efficient process that does not require additional cleaning media or chemicals during the cleaning process. Compared with traditional cleaning methods (such as chemical cleaning or high-pressure water cleaning), it greatly reduces the need for material handling and energy consumption. This low energy consumption makes laser cleaning an ideal choice for green manufacturing processes. Through precise laser energy transmission, laser cleaning can efficiently complete cleaning tasks while reducing unnecessary energy waste, which is in line with the global trend of energy conservation and emission reduction.

- Improved air quality: Traditional chemical cleaning methods are often accompanied by the generation of harmful gases, which not only threaten the health of operators but also pollute the surrounding environment. Laser cleaning removes pollutants by directly irradiating the surface of objects, avoiding the use of chemical agents, so no harmful gases are released, which significantly improves the air quality of the working environment. For people who need to work in closed or poorly ventilated spaces for a long time, laser cleaning technology undoubtedly provides a safer and healthier working environment.

- Save water: In traditional cleaning methods, water is an indispensable resource in the cleaning process, especially in high-pressure water flow and chemical cleaning, the consumption of water resources is very large. Laser cleaning does not require the use of water or chemical solvents at all, which not only reduces dependence on water resources but also avoids the generation of wastewater. This water-saving feature makes laser cleaning a cleaning process particularly suitable for areas with tight water resources or strict environmental protection requirements. Through this technology, industrial production can significantly reduce water consumption and promote sustainable development.

- Protecting natural resources: Laser cleaning plays a particularly significant role in reducing environmental pollution. Traditional cleaning methods often rely on chemicals and other cleaning media, which may pollute water, soil, and air during the process. In contrast, laser cleaning removes pollutants in a non-contact manner, reducing the emission of harmful substances. This not only effectively avoids the consumption of natural resources, but also reduces the pressure of waste disposal and helps protect the ecosystem. By reducing the demand for resources and reducing pollution, laser cleaning technology has made a positive contribution to environmental protection and the sustainable use of natural resources.

As an efficient and environmentally friendly cleaning method, laser cleaning technology has a significant positive effect on the environment while improving industrial cleaning efficiency. From energy conservation and emission reduction to improving air quality, from saving water resources to protecting natural resources, laser cleaning provides a green and sustainable solution for global industrial production. With the continuous improvement of environmental protection awareness, the application of laser cleaning in various industries will be further deepened, helping companies achieve green manufacturing goals while promoting global sustainable development.

Laser Cleaning for Sustainable Development

As a green and efficient surface treatment method, laser cleaning technology has been widely used in many industries. Its environmental protection, non-contact, low energy consumption, and precise control characteristics enable it to not only improve production efficiency but also play an important role in promoting sustainable development. The following are the innovative applications of laser cleaning in some key industries and how to promote sustainable development.

- Manufacturing and automotive industries: In the manufacturing and automotive industries, laser cleaning technology is widely used to remove unwanted surface materials such as coatings, paints, rust, and oil stains. Traditional cleaning methods often require the use of chemical cleaning agents or mechanical equipment, which not only consume a lot of resources but may also pollute the environment. Laser cleaning technology uses high-energy laser beams to directly act on the surface of objects, which can efficiently and accurately remove dirt or oxides without the use of any chemicals. This not only improves cleaning efficiency but also greatly reduces waste and exhaust emissions, helping to promote the green transformation of the manufacturing and automotive industries.

- Aerospace and Defense: In the aerospace and defense sector, laser cleaning is used to clean the surfaces of aircraft, spacecraft, and military equipment to ensure the performance and safety of these high-end equipment. Laser cleaning technology can remove coatings, oils, and rust from aviation parts without damaging the material itself. This is essential to ensure the long-term use and performance of equipment, especially in maintaining component accuracy and surface quality. The non-contact nature of laser cleaning technology protects these sensitive materials and reduces the risk of damage that may be caused by traditional mechanical cleaning. In addition, by reducing waste generation and the use of chemical agents, laser cleaning helps reduce negative impacts on the environment, in line with the aerospace and defense industry’s demand for sustainable development.

- Cultural Heritage Protection: The application of laser cleaning technology is particularly important in the field of cultural heritage protection. Traditional cleaning methods may cause damage to cultural relics, sculptures, and historical buildings, while laser cleaning, with its non-contact characteristics, can accurately remove dirt, mildew, and pollutants on the surface without causing any physical damage to the items. This makes laser cleaning an ideal choice for cultural heritage restoration and protection, especially when dealing with fragile materials such as stone, metal, wood, and ceramics. Laser cleaning not only protects the integrity of historical heritage but also provides a reliable means for the long-term preservation of cultural relics, promoting the sustainable protection of cultural heritage.

- Electronics and semiconductor manufacturing: In the electronics and semiconductor manufacturing process, laser cleaning is widely used to clean precision parts to ensure the cleanliness of the surface before processes such as lithography, welding, and coating. Laser cleaning technology can remove tiny contaminants and residues to maintain the high quality and precision of electronic components. Since laser cleaning can accurately control energy and will not damage microstructures, its application in the electronics and semiconductor fields is particularly important. As electronic products develop towards more precision and complexity, laser cleaning technology provides a more environmentally friendly and efficient solution for these manufacturing processes, promoting green manufacturing in the electronics industry.

- Medical device manufacturing: In medical device manufacturing, laser cleaning technology is widely used for cleaning and sterilizing equipment, tools, and surfaces. Laser cleaning can remove biological contaminants, residue, and coatings on medical devices without the use of any harsh chemicals. This makes laser cleaning a safe and environmentally friendly alternative, especially when it comes to the disinfection and cleaning of medical devices, which can effectively avoid the side effects of chemical cleaners or potential threats to human health. In addition, the high efficiency and non-contact nature of laser cleaning ensure the precision and integrity of the equipment during the manufacturing process, helping to improve the quality and performance of medical devices.

Laser cleaning technology has been widely used in many industries due to its high efficiency, precision, and environmental protection. In the fields of manufacturing, automobiles, aerospace, national defense, cultural heritage protection, electronic semiconductor manufacturing, and medical devices, laser cleaning not only improves production efficiency and product quality but also greatly reduces environmental pollution, resource consumption, and waste emissions. As a green technology that promotes sustainable development, laser cleaning provides strong support for the green transformation and sustainable development of all walks of life. With the continuous advancement of technology, laser cleaning will play an important role in more fields and help the world achieve more environmentally friendly and sustainable industrial development.

Summarize

Laser cleaning technology has gradually become one of the core technologies for promoting sustainable development in all walks of life due to its environmental protection, high efficiency, energy saving, and multifunctional characteristics. Compared with traditional cleaning methods, laser cleaning can not only significantly reduce the generation of waste, but also avoid chemical pollution, reduce the consumption of water resources and energy, and provide a green alternative for enterprises and industries. Through this technology, manufacturers can improve production efficiency while reducing the negative impact on the environment, thereby promoting the protection and recycling of resources.

In addition, the high energy efficiency and non-contact process characteristics of laser cleaning make it an important innovative tool in modern industry, especially in the fields of precision equipment, cultural heritage protection, and medical devices, which further proves its great potential in promoting green manufacturing, improving production quality and reducing the environmental burden. By reducing the use of chemical cleaning agents and exhaust emissions, laser cleaning provides technical support for building a more environmentally friendly industrial environment and a healthier workspace.

In general, laser cleaning is not only a tool to improve industrial cleaning efficiency, but also a key driving force for achieving global sustainable development goals. With the continuous advancement of technology and the expansion of application areas, laser cleaning will contribute more important forces to future green manufacturing, environmental innovation, and resource conservation, and help global companies develop in a more environmentally friendly, energy-saving, and sustainable direction.

Get Laser Solutions

If you are looking for an efficient and environmentally friendly cleaning and surface treatment solution, our laser cleaning machine will be your ideal choice. With its advanced laser technology, AccTek Laser’s equipment can provide excellent cleaning results for a variety of industries while reducing environmental impact and lowering operating costs. If you want to improve production efficiency, reduce waste emissions, and promote sustainable development, understanding our laser cleaning equipment is your first step toward green manufacturing. Contact us now to get a customized laser solution and start a more environmentally friendly and efficient production journey.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions