How Can The Life Expectancy of a Laser Cleaning Machine Be Improved

As a professional cleaning tool in modern industries, laser cleaning machines have stable performance and environmental protection features. However, as an expensive piece of industrial equipment, the service life of laser cleaning machines has always been a focus of interest for companies and users, which has a direct impact on the sustainability of the equipment and the economy. This article takes an in-depth look at steps you can take to extend the life expectancy of your laser cleaning machine.

Table of Contents

Working principle of laser cleaning machine

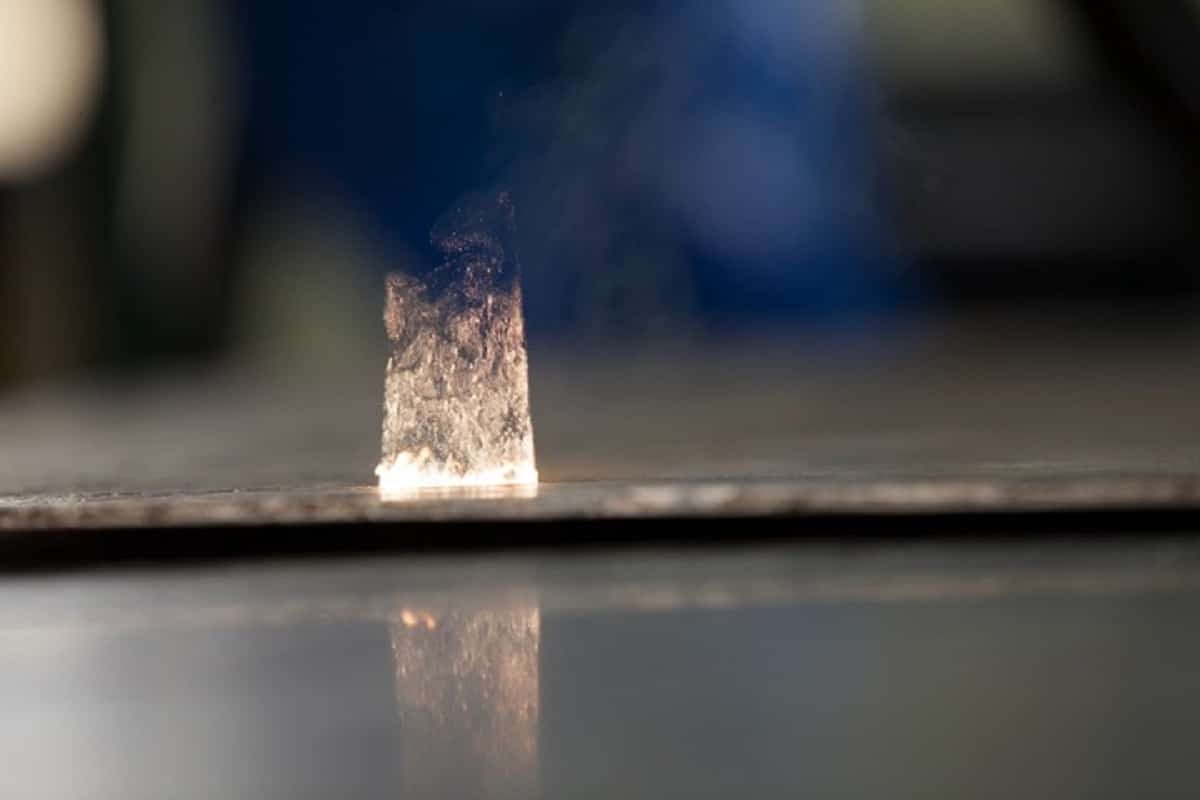

Laser cleaning machines utilize laser technology to remove contaminants, coatings, rust, and other unwanted materials from various surfaces. The laser cleaning process is non-contact and highly precise, making it ideal for a variety of cleaning and surface preparation applications.

Laser cleaning machines work by using a high-power laser beam to remove contaminants and unwanted surface layers from materials. The laser beam is focused on the target surface and interacts with the contaminants, causing the contaminants to be moved and removed. The process may involve vaporization, shock wave generation, and material ablation. The removed contaminants are then collected, allowing the surface to be cleaned and restored. Appropriate safety measures need to be taken when using laser cleaning machines to protect the operator from the laser beam and to control and monitor the parameters of the machine to achieve precise cleaning.

Laser cleaning technology is a “green” cleaning method because it does not require the use of sandblasting or chemical solvents and only involves the interaction between a high-intensity laser beam and the target surface. Basically, the waste generated after cleaning is very small and easy to store and recycle. Laser cleaning does not involve the environmental pollution problems caused by chemical cleaning methods, so it has become an ideal solution to replace traditional cleaning methods.

What are the factors that affect the life expectancy of a laser cleaning machine?

The laser cleaning machine is an advanced cleaning equipment widely used in modern industry. It uses laser technology to clean surfaces and remove dirt and impurities. The performance and life of the laser cleaning machine directly affect the return on production efficiency and equipment investment. Let’s take a look at the factors that affect the service life of laser cleaning machines.

working environment

- Temperature and humidity: Extreme temperature changes and humidity conditions can cause damage to electronic components and mechanical parts in laser cleaning machines. High-temperature conditions may cause electronic components to overheat, while high-humidity conditions may cause machine corrosion, so a stable environment needs to be maintained within a specific range.

- Dust and particles: Dust and particles may enter the interior of the laser cleaning machine, causing wear and tear on the mechanical parts, and may even damage the laser optical system. Therefore, maintaining a clean working environment helps extend the life of your laser cleaning machine.

Accessory quality and manufacturing process

- Accessory quality: The quality of the accessories used to manufacture the machine will affect the durability and life of the laser cleaning machine. High-quality accessories tend to last longer and are more resistant to wear and tear.

- Manufacturing process: The precision and quality control measures of the manufacturing process used to build the machine also affect its service life. A well-constructed machine is more likely to have a longer service life.

Cleaning process parameters

- Optimal settings: It is critical to adjust cleaning process parameters (such as laser power, pulse duration, and spot size) to match the specific material and surface to be cleaned. Using inappropriate settings can cause unnecessary wear and tear on the machine.

Laser generator life

- Laser generator quality: The service life of the laser generator will significantly affect the overall service life of the laser cleaning machine. The type of laser source (continuous laser generator, pulsed laser generator), its quality, and maintenance can significantly affect the service life of the machine.

Frequency of use and workload

- Frequency of use: The frequency of use of the machine will affect its service life. Machines that are used frequently may require more maintenance and have a shorter lifespan than machines that are used infrequently.

- Workload: Workload or intensity of use (including the duration and type of tasks performed) affects wear and tear on a machine. Heavy workloads can cause components to break down faster.

Care and maintenance

- Regular maintenance: Consistent and correct maintenance is crucial to extending the life of your laser cleaning machine. This includes cleaning optics, checking for loose parts, lubricating moving parts, and replacing consumables as needed.

- Preventative maintenance: Performing regular preventive maintenance as recommended by your laser cleaning machine manufacturer can identify and resolve problems before they become major problems.

- Component replacement: Replacing consumables such as cleaning nozzles, protective windows, and filters as needed helps maintain optimal performance.

The service life of a laser cleaning machine is comprehensively affected by factors such as the working environment, material quality, and manufacturing, cleaning process parameters, laser generator quality and maintenance, frequency of use and workload, and regular maintenance. By paying attention to these factors, operators can maximize the life and efficiency of their laser cleaning equipment.

How to Improve the Life Expectancy of Laser Cleaning Machines

Improving the life expectancy of your laser cleaning machine can help you maintain the performance of your equipment for longer, reducing repair and replacement costs. Here are some ways to help extend the life of your laser cleaner:

Regular cleaning and maintenance

- Regularly clean and inspect optical components such as lenses and mirrors to prevent the accumulation of contaminants that could affect laser generator performance.

- Lubricate moving parts according to the manufacturer’s specifications to reduce friction and wear.

- Check the machine for loose or damaged parts and resolve any problems promptly.

- Use appropriate tools and detergents when cleaning to prevent scratches and corrosion.

Environmental control

- Maintain a clean and controlled environment for the laser cleaning machine. Prevent overheating and contamination by controlling temperature, humidity, and ventilation.

- Implement effective dust and particle control measures to minimize the accumulation of contaminants on optical components.

Operator training

- Properly train operators to ensure they understand the correct operating methods and safe operating procedures of laser cleaning machines. Improper operation may cause excessive wear or damage to the equipment.

use correctly

- Use laser cleaning machine within specified limits and guidelines. Avoid overloading the machine or exceeding its capabilities.

- Avoid unnecessary overuse of equipment. Use your laser cleaner only when cleaning is required to prolong its life.

Optimize cleaning parameters

- Depending on the type of laser used and the material to be cleaned, laser cleaning may require the use of consumable materials, such as protective coatings or solvents, which add to operating costs.

Cooling system maintenance

- Regularly maintain the cooling system to prevent the laser generator from overheating and maintain laser efficiency.

- Clean or replace filters and coolant as needed.

Power supply and electrical systems

- Use a surge protector or voltage regulator to protect your machine from power surges and fluctuations.

- Regularly check electrical connections for loose or corroded contacts.

Premium consumables and components

- Use high-quality consumables such as cleaning nozzles, lenses, and protective windows as recommended by the manufacturer. Replace consumables when they show signs of wear or damage.

Software update

- Keep your machine’s software up to date with the latest firmware or software version provided by the manufacturer. Updates may include bug fixes and performance improvements.

Safety measures

- Ensure the machine is equipped with appropriate safety features (e.g. interlocks, enclosures, and safety sensors.) to protect operators from laser exposure. Follow safety protocols to prevent accidents.

Documents and records

- Keep detailed records of maintenance activities, repairs, and parts replacement. This helps track the machine’s history and identify patterns of wear or problems.

By consistently implementing these practices, you can significantly increase the life of your laser cleaning machine, reduce downtime, and ensure that it continues to operate efficiently and effectively for a longer period of time. Regular maintenance and careful operation are key to achieving optimal results and extending service life

Summarize

Taking these factors into account, the life expectancy of a laser cleaning machine can range from a few years to a decade or more. Therefore, when purchasing and using a laser cleaning machine, it is important to carefully consider the maintenance, working environment, and operation methods of the equipment. Maximize its life and get the best performance. If you are interested in laser cleaning, please contact an AccTek Laser specialist. We can provide you with customized laser cleaning solutions based on your specific situation.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions