How Does Laser Cutting Improve The Efficiency And Productivity of Manufacturing?

In the evolving manufacturing landscape, productivity and efficiency are increasingly becoming the cornerstones of manufacturing. As industries strive to meet growing demands for precision and speed, innovative technologies are constantly revolutionizing production processes. Among these advancements, laser cutting technology has emerged as a transformative force, reshaping the manufacturing landscape with its high precision and efficiency. Through an in-depth study of the principles behind laser cutting and its diverse applications, from complex designs to high-volume production, the mechanism by which this technology optimizes manufacturing operations is revealed. In this article, we will explore the efficiency of laser cutting in the manufacturing process and measures to improve productivity and efficiency, so that laser cutting not only allows manufacturers to easily meet various challenges but also contributes to a more sustainable manufacturing ecosystem.

Table of Contents

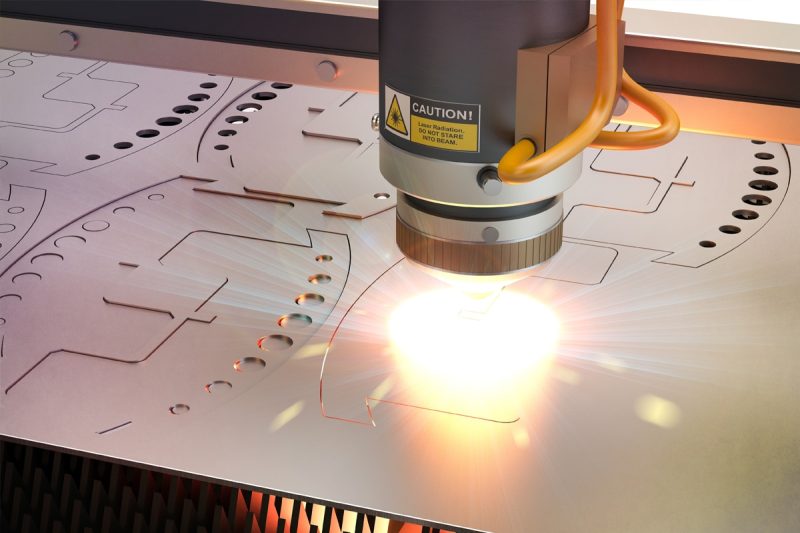

Learn About Laser Cutting Technology

Laser cutting technology utilizes highly focused beams of light energy to precisely cut a variety of materials with exceptional accuracy and precision. The technology relies on an intense laser beam to vaporize, melt or burn away material along a predetermined path, resulting in clean, precise cuts.

Precision And Accuracy

Laser cutting’s extremely narrow laser beam can be precisely controlled, ensuring clean edges and minimal material distortion. Enables manufacturers to achieve complex designs and tight tolerances that would be difficult or impossible to replicate using traditional cutting methods. This level of precision makes laser cutting ideal for applications requiring complex shapes, fine details, and high-quality surfaces.

Versatility

Laser-cutting machines can effectively process a variety of materials, including metal, plastic, wood, glass, ceramics, and composites. This versatility allows manufacturers to tackle different projects and meet a variety of customer requirements without having to use multiple specialized cutting tools. In addition, laser cutting can handle materials of different thicknesses, making it suitable for both thin and thick plates.

Speed And Efficiency

The concentrated heat of the laser beam removes material quickly, reducing processing time and increasing throughput. The non-contact nature of laser cutting reduces wear on cutting tools, minimizing downtime for maintenance and tool changes. In addition, the laser cutting machine can complete multiple operations such as cutting, engraving, and marking at one time, further improving efficiency.

Cost-Effectiveness

While the initial investment in laser cutting equipment can be significant, the long-term cost benefits of the technology are undeniable. Laser cutting offers several cost-saving benefits, including reduced material waste, lower labor costs and increased productivity. The precision of laser cutting minimizes material waste by optimizing nesting layout and minimizing kerf width.

In summary, laser cutting is able to deliver complex designs with exceptional precision, handle a variety of materials, achieve fast processing speeds, and minimize production costs, making it an indispensable tool for modern manufacturers looking to increase efficiency and productivity.

How To Improve Manufacturing Efficiency With Laser Cutting

Laser cutting technology can serve as a catalyst to improve manufacturing efficiency in various production processes, with transformative advantages in simplifying operations and improving quality standards. Measures to improve manufacturing efficiency through laser cutting are as follows:

Simplified Production Process

Laser cutting enables precise, fast and repeatable material cuts, streamlining the production process. Laser cutting can easily handle complex designs and tight tolerances, minimizing the need for secondary finishing operations such as deburring or machining, thereby reducing overall production time and labor costs. Additionally, the versatility of laser cutting allows manufacturers to consolidate multiple manufacturing steps into a single operation, further streamlining workflows and increasing throughput.

Rapid Prototyping And Iterative Design

Laser cutting technology accelerates the prototyping and design iteration process by providing fast and cost-effective prototyping and low-volume production runs. Design changes can be quickly implemented and tested, allowing for rapid iteration and improvement of product designs without the need for expensive tooling or lengthy lead times. This agility enables manufacturers to respond quickly to market demands, innovate more freely, and bring new products to market faster, thereby gaining a competitive advantage in a dynamic industry.

Just-In-Time Production

Laser cutting facilitates just-in-time (JIT) production strategies by enabling parts to be manufactured on demand with minimal lead time. By harnessing the speed and flexibility of laser cutting technology, manufacturers can produce parts precisely when they are needed, eliminating the need for large inventories and reducing shipping costs. JIT production not only optimizes inventory management, but also improves overall operational efficiency by minimizing waste, reducing storage space requirements and improving cash flow.

Customization And Personalization

Laser cutting enables manufacturers to offer customization and personalization options to meet individual customer preferences and market demands. Whether engraving a logo, cutting intricate patterns or creating custom designs, laser cutting technology provides unparalleled flexibility for product customization. By catering to niche markets and offering unique, personalized products, manufacturers can increase customer satisfaction, foster brand loyalty, and command premium prices that drive revenue growth and market differentiation.

Reduce Waste And Environmental Impact

Laser cutting technology minimizes material waste and environmental impact through its precise cutting capabilities and efficient material utilization. The narrow kerf width of the laser beam minimizes material loss, optimizing material utilization and reducing scrap. Additionally, laser cutting produces clean, burr-free edges, minimizing the need for additional machining and reducing energy consumption. By adopting laser cutting technology, manufacturers can achieve sustainability goals, minimize their carbon footprint, and contribute to a greener, more environmentally friendly manufacturing ecosystem.

In summary, laser cutting technology has revolutionized manufacturing efficiency by streamlining production processes, accelerating prototyping and design iterations, facilitating just-in-time production, enabling customization and personalization, and reducing waste and environmental impact. By harnessing the power of laser cutting, manufacturers can achieve greater flexibility, competitiveness and sustainability in today’s rapidly evolving market.

How To Increase Productivity With Laser Cutting

In the dynamic manufacturing landscape, optimizing production capacity is the primary goal for companies to meet growing demand and remain competitive in the market. Laser cutting technology becomes a key tool to achieve this goal, providing a multifaceted solution to increase productivity.

High Speed Cutting

Laser cutting technology enables high-speed cutting processes, thereby significantly increasing production capacity. By harnessing the power of a focused laser beam, manufacturers can achieve rapid material removal rates without compromising accuracy or quality. Advanced laser cutting systems equipped with high-power lasers and optimized cutting parameters enable superior cutting speeds, resulting in faster throughput and higher productivity. Increased cutting speeds mean shorter production cycles, reduced lead times and greater overall efficiency.

Batch Processing

Batch processing is a common strategy to maximize the throughput of laser cutting operations. Manufacturers can optimize efficiency by grouping similar parts together and processing them in batches, rather than cutting them one at a time. Laser cutters equipped with advanced nesting software can automatically arrange parts within sheets of material to minimize waste and maximize material utilization. By batching similar parts together, manufacturers can reduce setup time, streamline workflows and achieve higher productivity, ultimately increasing throughput while minimizing costs.

Integrate With Automation

Integration with automation systems represents a transformative approach to increasing production capabilities with laser cutting technology. Automated material handling systems, robotic arms, and CNC controllers can be seamlessly integrated with laser cutters to create fully automated production lines. This integration enables continuous operations with minimal human intervention, enabling 24/7 manufacturing and maximizing uptime. Additionally, automation increases precision, repeatability and consistency, ensuring uniform quality across all parts while reducing labor costs and reliance on manual labor. By leveraging the synergy between laser cutting technology and automation, manufacturers can achieve unparalleled production capabilities, scalability and competitiveness in today’s fast-paced manufacturing environment.

To sum up, laser cutting technology provides many of the above strategies to improve production capacity. By leveraging the speed, precision and flexibility of laser cutting technology along with advanced production methods, manufacturers can achieve new levels of efficiency, scalability and profitability to succeed in an increasingly competitive market.

How to Improve Quality and Consistency with Laser Cutting

Improving quality and consistency are top manufacturing goals, and laser-cutting technology offers a variety of strategies to achieve these goals. Here’s how laser cutting improves quality and consistency:

Clean And Burr-Free Cuts

Laser cutting produces clean, precise cuts with virtually no burrs, resulting in high-quality finished parts. Unlike traditional cutting methods like milling or stamping, which leave burrs or rough edges, laser cutting cleanly vaporizes or melts the material along the cutting path. This ensures smooth edges without the need for additional finishing operations, reducing post-processing time and increasing overall efficiency. The absence of burrs also enhances the aesthetics of the finished product, helping to create a professional and polished look.

Minimal Material Deformation

Laser cutting minimizes material distortion, especially heat-sensitive materials like plastic or thin metal. The localized heating provided by the laser beam allows precise control of the cutting process, minimizing the heat-affected zone and reducing the risk of warping or deformation. , which ensures dimensional accuracy and maintains tight tolerances. By minimizing material distortion, laser cutting technology ensures consistent quality across all parts, regardless of material type or thickness.

Quality Assurance

Laser cutting technology incorporates advanced features and quality control measures to ensure consistent and accurate cutting results. The laser cutting machine is equipped with an advanced motion control system and real-time monitoring functions to maintain precise beam positioning and cutting parameters throughout the production process. In addition, integrated quality assurance systems, such as vision inspection cameras and laser power monitoring sensors, enable operators to promptly detect and correct any deviations from required cutting specifications. By implementing strong quality assurance measures, manufacturers can adhere to strict quality standards, minimize defects, and consistently deliver reliable, high-quality products to customers.

In summary, by leveraging the precision, control, and advanced capabilities of laser cutting systems, manufacturers can achieve superior cutting results, ensure dimensional accuracy, and maintain tight tolerances on all parts, ultimately delivering high-quality products that meet or exceed customer expectations.

How to Maximize Productivity with Laser Cutting Automation

Maximizing productivity through laser cutting automation involves utilizing a variety of technologies and strategies to streamline the process, reduce downtime, and optimize workflow efficiency. Here’s how automation can improve the productivity of laser-cutting operations:

CNC Control And Programming

Computer numerical control (CNC) technology forms the backbone of laser cutting automation, enabling precise control of the cutting process. CNC systems utilize advanced software to convert design specifications into machine-readable instructions that direct the movement of laser cutting heads and other components with high precision. By automating cutting parameters, tool paths, and material handling sequences, CNC controls minimize human error, ensure consistency, and maximize throughput. In addition, CNC programming allows for quick setup and switching between different jobs, reducing idle time and increasing overall productivity.

Robot Integration And Material Handling

Robotic integration increases the productivity of laser cutting operations by automating material handling, part loading and unloading, and other ancillary tasks. Robotic arms equipped with grippers or suction cups can efficiently handle raw materials, transfer workpieces between processing stations, and stack finished parts on pallets or conveyors. By automating material handling tasks, robotic integration reduces manual labor requirements, increases throughput, and enables continuous operations to maximize overall productivity and efficiency.

Artificial Intelligence And Machine Learning

Artificial intelligence (AI) and machine learning (ML) technologies provide advanced capabilities to optimize the laser cutting process and maximize productivity. Artificial intelligence algorithms can analyze large amounts of data collected from sensors, cameras, and other sources to identify patterns, optimize cutting parameters, and predict potential problems before they occur. Machine learning models can learn from historical data to refine cutting strategies, improve material utilization, and optimize nesting layouts for maximum efficiency. By harnessing the power of artificial intelligence and machine learning, manufacturers can achieve higher yields, reduce scrap, and increase the overall productivity of their laser-cutting operations.

Remote Monitoring And Maintenance

Remote monitoring and maintenance solutions provide real-time supervision of laser cutting systems, allowing operators to monitor performance, diagnose issues, and perform troubleshooting remotely. Remote monitoring platforms provide insights into machine status, production metrics, and predictive maintenance alerts, allowing proactive intervention to prevent downtime and optimize uptime. Additionally, remote access capabilities facilitate remote software updates, diagnostics, and maintenance tasks, reducing the need for on-site service visits and minimizing disruption to production. By implementing remote monitoring and maintenance solutions, manufacturers can ensure continuous operations, maximize productivity, and minimize unplanned downtime in laser cutting operations.

In summary, by leveraging the synergies between these automation technologies, manufacturers can optimize workflow efficiency, reduce labor costs, and achieve higher productivity in laser cutting operations, ultimately increasing overall productivity and competitiveness.

Summarize

In today’s fast-paced manufacturing environment, optimizing efficiency and productivity is critical to staying competitive. Laser cutting technology has become a key enabler in achieving these goals, offering a range of advantages that simplify operations and increase quality standards. By leveraging the speed, precision and flexibility of laser cutting technology, manufacturers can achieve faster throughput, reduce lead times and maximize production capacity. In summary, by adopting laser cutting technology and leveraging its transformative capabilities, manufacturers can achieve operational excellence, drive innovation, maintain a competitive advantage in today’s dynamic marketplace, and promote a greener manufacturing ecosystem.

Laser cutting is capable of cutting a variety of materials and thicknesses at high speeds, resulting in extremely precise cuts. AccTek Laser is proud to offer a range of laser cutting machines for your business, whether it includes prototypes, components or final components. We firmly believe that quality results can only be achieved by using quality equipment.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions