How Does The Cooling System Affect The CO2 Laser Cutting Machine’s Performance And Life?

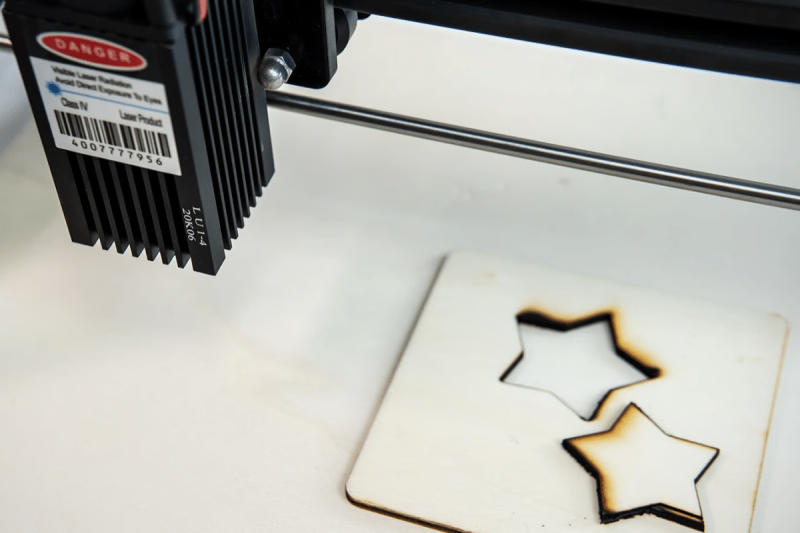

CO2 lasers are good for engraving most materials such as wood, glass, leather, and acrylic. Because of their versatility, CO2 laser cutting machines are an integral part of today’s production facilities and businesses large and small.

The performance and service life of a CO2 laser cutting machine depends on many factors, such as frequency of use, daily cleaning, and maintenance. But users often overlook a key element to ensure the long-term function of the machine: effective cooling, which plays a vital role in the performance and life of the CO2 laser cutting machine. This article will delve into the impact of the cooling system on the performance and life of the CO2 laser cutting machine.

Table of Contents

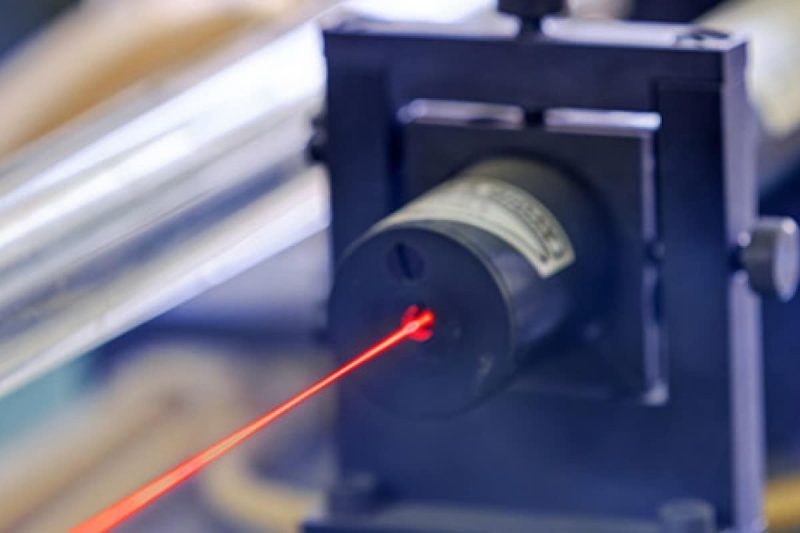

Working principle of CO2 laser cutting machine

Before going deep into the cooling system of the CO2 laser cutting machine, let’s briefly review the working principle of the CO2 laser generator. The CO2 laser generator is a gas laser generator, and its laser medium is a mixed gas composed of carbon dioxide, nitrogen, and some rare gases. During the working process of the CO2 laser generator, electric energy is input into the laser medium, which excites gas atoms to generate photon radiation transitions, and finally forms a high-energy laser beam. Realize the cutting of materials. But a part of the electrical energy is also converted into heat energy. This heat energy will cause the internal temperature of the laser generator to rise rapidly. If the heat cannot be removed in time and effectively, it will affect the performance and life of the CO2 laser cutting machine. To maintain a stable working temperature of the CO2 laser generator, the cooling system plays a vital role.

The Importance of Cooling Systems

The cooling system is a key component of a CO2 laser cutting machine and plays a vital role in ensuring the performance, efficiency, and overall life of the machine. A lot of heat will be generated during the laser cutting process, a reliable cooling system solves the problem of this heat accumulation, thereby improving the performance, life, and safety of the machine.

Prolonged exposure to high temperatures will accelerate the wear of laser components. Laser tubes, optics, and other sensitive components are designed to operate within specific temperature ranges. When you run the CO2 laser cutting machine for a long time and there is no corresponding cooling mechanism, excessive heat will be generated inside the components around the laser tube machine, causing the tube to break, the beam to produce arcs and other damage, which will reduce the cutting quality and reduce the use of the machine life.

The cooling system plays a vital role in maintaining the performance, life, and safety of the CO2 laser-cutting machine. It helps regulate temperature, prolongs the life of critical components, ensures consistent performance, enhances safety, reduces downtime, and helps improve the overall quality of finished products. A well-designed and properly maintained cooling system contributes to the success of various cutting applications and reduces the possibility of costly downtime and repairs.

Role of the cooling system

CO2 laser cutting technology plays an important role in modern manufacturing, however, its performance and life are closely related to the quality of the cooling system. As the core component of the CO2 laser cutting machine, the cooling system plays a key role.

Effect of Cooling System on Performance

During the laser cutting process, the huge heat generated by the CO2 laser cutting machine needs to be effectively removed to ensure the stable operation of the equipment and high-quality cutting results. Here are a few aspects of how the cooling system affects the performance of a CO2 laser-cutting machine:

- Stability and consistency: If the cooling system cannot maintain the optimal working temperature of the laser tube, the laser output will be affected by temperature fluctuations, resulting in unstable cutting results. The stable cooling system can ensure that the laser generator remains within the design temperature range, to achieve stable laser output and ensure the consistency of cutting results.

- Power output and cutting speed: Excessively high operating temperature will reduce the efficiency of the laser tube, thereby affecting the power output and cutting speed. A good cooling system can keep the laser tube working in a suitable temperature range, ensure the high-efficiency operation of the laser tube, and achieve higher power output and cutting speed.

- Stable beam quality: Temperature changes will distort the laser beam, which will affect the accuracy and smoothness of laser cutting. A good cooling system prevents the quality of the laser beam from deteriorating due to heat-related deformations in the optics. Stable beam quality ensures that the focused laser remains sharp and well-defined for precise cuts.

- Failure risk and maintenance: An unstable or poor cooling system can lead to an increased risk of equipment failure. Overheating may cause damage to key components and even cause serious equipment accidents. Improper maintenance can also cause blockage or water leakage in the cooling system, affecting the operation stability of the entire laser cutting machine.

- Maintain focus: Heat can cause thermal expansion and contraction of optical components, which can cause changes in laser focus. An effective cooling mechanism minimizes these fluctuations, ensuring that the laser’s focus remains on the target for precise cutting.

Effect of cooling system on life

The cooling system in a CO2 laser cutting machine plays a key role in extending the life of the machine by ensuring its components operate within an optimal temperature range and minimizing wear and tear caused by overheating. The following are the key influences of the cooling system on the service life of the CO2 laser cutting machine:

- Reduced component stress: Excessive heat can stress various components within a laser cutter, including the laser tube, optics, power supply, and control electronics. The cooling system helps dissipate heat and maintain a stable operating temperature, reducing stress on these components and extending component life.

- Prolong the service life of the laser tube: The laser tube is one of the core components of the CO2 laser cutting machine, and its working life is directly affected by the temperature. It is responsible for emitting the laser beam for cutting. The cooling system ensures that the laser tube operates within the recommended temperature range, preventing overheating from causing tube aging and premature failure. This extends the life of the laser tube and reduces the need for frequent replacement.

- Maintaining Optical Integrity: The optical components of a laser system, such as mirrors and lenses, are sensitive to temperature changes. Proper cooling minimizes thermal distortion of these components, which can cause misalignment and reduce cut quality. Maintaining the integrity of the optics contributes to consistent performance and longer life.

- Minimize wear and tear: Excessive heat will accelerate the wear and tear of moving parts, electrical components, and sensitive mechanisms within the machine. By providing a controlled and cool operating environment, the cooling system helps to minimize the degradation of these components, thereby extending the service life.

- Reduced maintenance costs: A properly functioning cooling system reduces the possibility of component failure due to overheating. As a result, maintenance costs associated with replacing or repairing components are reduced, contributing to cost savings throughout the life of the machine.

- Consistent performance over time: Adequate cooling maintains stable operating conditions for machines even as they age. As components naturally degrade, their sensitivity to temperature changes increases. The cooling system helps counteract this effect, ensuring consistent performance over the life of the machine.

- Enhanced overall reliability: The combined effect of reducing component stress, extending the life of critical components, and minimizing wear and tear contributes to an overall increase in machine reliability. More reliable machines require fewer repairs and experience fewer unplanned downtime events.

- Prevention of accidents: Overheating may cause accidents, such as laser bursts, damage to optical components, etc. This not only endangers the safety of the operator but also causes serious damage to the equipment. A stable cooling system can reduce the risk of these accidents, safeguarding the safety of operators and the integrity of equipment.

Optimization and Maintenance of Cooling Systems

The importance of the CO2 laser cutting machine cooling system cannot be ignored. To ensure the stability, high efficiency, and long-life operation of the CO2 laser cutting machine, extend the life of key components, and reduce maintenance costs. Optimizing and maintaining the cooling system is an essential measure.

Suitable coolant selection

Choosing the right coolant is the basis for cooling system optimization. The coolant should have good thermal conductivity, corrosion resistance, and stability to ensure efficient operation of the cooling system.

Regular cleaning and replacement of coolant

The coolant may be affected by impurities and deposits during circulation, reducing heat dissipation efficiency. Regularly clean the inside of the cooling system and replace the aging coolant regularly to ensure the smooth flow and efficiency of the system.

Regularly check cooling system performance

Controlling the circulation speed of the coolant can ensure that the heat can be dissipated quickly when working at high power. Establish a plan for regularly checking the performance of the cooling system, including checking the flow rate, temperature stability, and other indicators, to find and solve problems in time.

Regularly check lines and connections

Regularly check the cooling system pipes and connections for leaks, blockages, etc. Make sure that the coolant can flow unimpeded to ensure efficient cooling.

Install temperature sensor

Install temperature sensors near key components to monitor the temperature changes of lasers and other components in real-time. This data can help the cooling system automatically adjust its operating status as needed to keep the equipment within the appropriate operating temperature range.

Regularly maintain the radiator

The radiator is an important part of the cooling system. Check and clean the radiator regularly to prevent it from being blocked by dust and dirt, which will affect the cooling effect.

External Environmental Control

Try to place the CO2 laser cutting machine in a well-ventilated and moderate-temperature environment to avoid the influence of excessive ambient temperature on the cooling system.

Training operators

Train operators to use and maintain the cooling system correctly, and let them understand the working principle and maintenance process of the system, to avoid problems caused by incorrect operation. In case of complicated problems, it is best to seek professional technicians for maintenance and repair.

Summarize

The cooling system is an important factor in the performance and life of the CO2 laser-cutting machine. An excellent cooling system can maintain a stable working temperature of the laser generator, improve cutting efficiency, ensure cutting quality and prolong equipment life. When using a CO2 laser cutting machine, full attention must be paid to the optimization and maintenance of the cooling system to ensure its continuous and stable performance.

If you are looking for a reliable industrial chiller for your CO2 laser cutting machine, AccTek Laser is a one-stop solution for all your needs. Here you can find out about our entire range of CO2 laser cutting machines, accessories, software, and everything you need to get your laser cutter to perform at its best.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions