How Does The Cooling System of The CO2 Laser Cutting Machine Work?

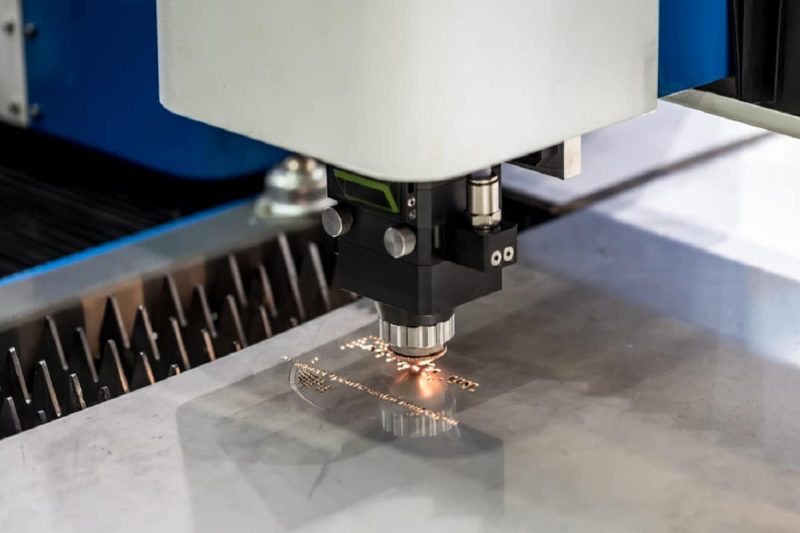

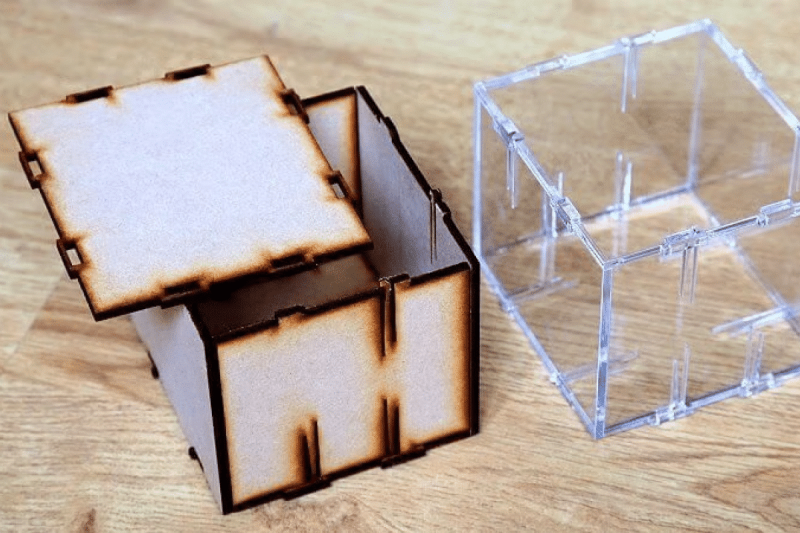

A CO2 laser cutter is an effective device for a wide variety of industrial engraving applications. CO2 lasers can be used on a variety of materials, including wood, glassware, acrylics, and leather. However, lasers generate a lot of heat, and if proper temperature regulation is not achieved, the laser system can be hampered by overheating and damage the components of the system, or even the finished product. Portable chillers are an effective means of achieving optimal temperature control when using industrial laser generators.

This article will deeply discuss the principle of the cooling system of the CO2 laser cutting machine, understand the components of the cooling system and its working process, and help improve the performance and durability of the CO2 laser cutting machine.

Table of Contents

Working principle of the CO2 laser generator

Before going deep into the cooling system of the CO2 laser cutting machine, let’s briefly review the working principle of the CO2 laser generator. The CO2 laser generator is a gas laser generator, and its laser medium is a mixed gas composed of carbon dioxide, nitrogen, and some rare gases. During the working process of the laser generator, electric energy is input into the laser medium, which excites the gas atoms to generate photon radiation transitions, and finally forms a high-energy laser beam.

During the working process of the CO2 laser generator, a large amount of electrical energy is converted into light energy, but part of the electrical energy is also converted into heat energy. This thermal energy will cause the internal temperature of the laser generator to rise rapidly, which will affect the performance and stability of the laser generator. To maintain a stable working temperature of the CO2 laser generator, the cooling system plays a vital role.

Cooling methods and differences

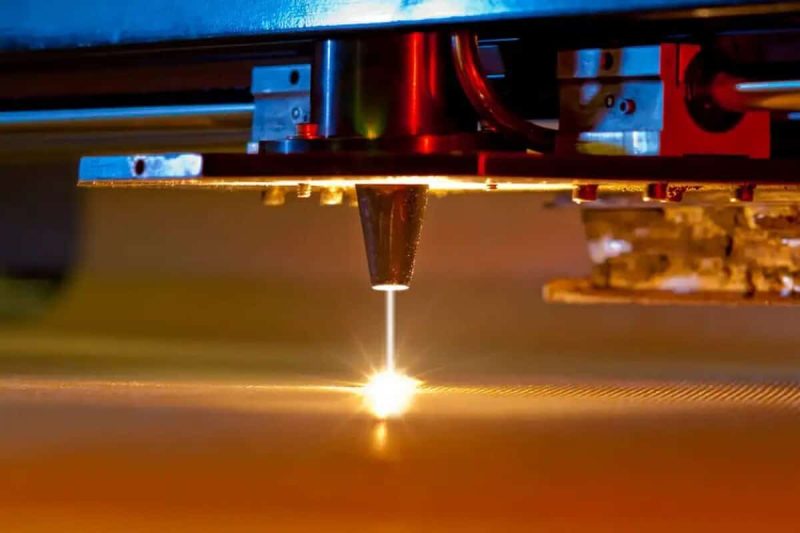

A key function of a CO2 laser cooling system is to cool the laser diode and other heat-generating system components such as transistors and resistors. The cooling system will keep reducing its temperature until it can keep the CO2 laser-cutting machine running normally. This means that the cooled laser diodes can perform optimally without being overstimulated, while also reducing the risk of damage.Common CO2 laser cooling methods are as follows:

Water cooling

Water cooling is the most commonly used cooling method for CO2 laser cutting machines. It involves circulating distilled or deionized water through a closed-loop system to dissipate the heat generated by the laser tube. Water cooling is relatively low cost, requires minimal maintenance, and is very efficient. Of course, water can also become polluted or stagnant if not properly maintained.

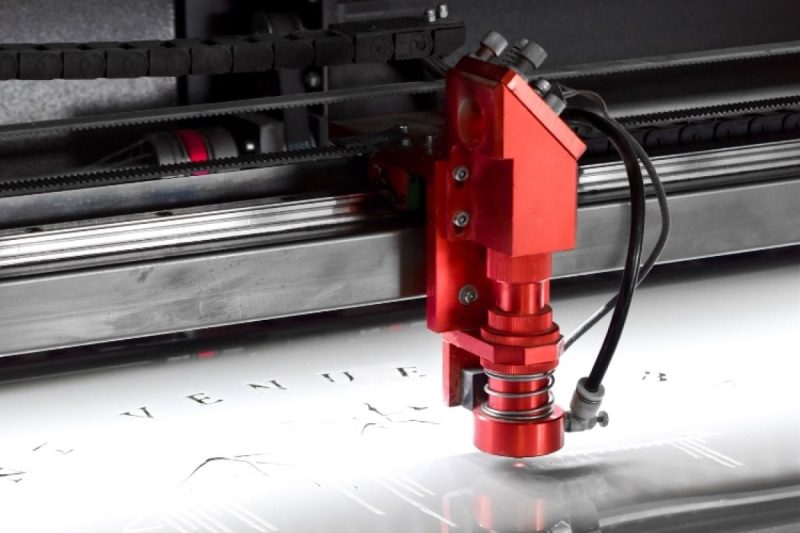

Air cooling

Air cooling works by blowing air through the laser tube to dissipate heat. While air cooling is less expensive and less maintenance than water cooling, it is less efficient and not adequate for high-powered CO2 laser cutting machines. Air cooling can also be noisy and lead to a dusty work environment.

Cooler cooling

Chiller cooling is also a type of water cooling that uses a separate cooling unit to cool the water before it circulates through the laser tube. Chillers cool efficiently and can provide precise temperature control, but they are more expensive and require more maintenance than other cooling methods.

Thermoelectric cooling

Thermoelectric cooling uses a Peltier cooler to cool the laser tube. While it can provide precise temperature control, it is not as effective as other cooling methods and may not be sufficient for high-power laser equipment. Thermoelectric cooling is also more expensive than other cooling methods.

Components of the cooling system

The laser machine chiller is composed of an external laser cooling system, which mainly uses water tanks, water pumps, water coolers, and cooling water pipes so that frozen water can be closed and circulated in the laser system.The following are the main components:

water tank

The water tank in the cooling system is an important component. The water tank is usually made of metal or plastic, and its capacity depends on the power and heat dissipation requirements of the laser generator. The water tank of the cooling system is responsible for containing the circulating water and sending the water to the laser generator and other cooling components through the water pump.

water pump

The water pump is one of the key equipment in the cooling system. It is responsible for pumping cooling water from the water tank and pipes it into the laser generator. The performance and stability of the water pump directly affect the operating efficiency of the cooling system and the heat dissipation effect of the laser generator.

water cooler

A water cooler is a self-contained cooling device, usually located near the laser generator. Its main function is to cool the circulating water through a forced fan or air cooler, thereby reducing the water temperature. The efficient operation of the water cooler ensures that the laser generator can be kept within the ideal operating temperature range.

cooling water pipe

Cooling water piping is the piping system that connects the various components of the cooling system. It is responsible for delivering cooling water from the water pump to the laser generator and sending hot water back to the tank for recirculation. The design and material selection of cooling water piping is critical to ensure that the water flow is free, leak-tight, and capable of withstanding high temperatures and pressures.

CO2 laser generator cooling process

When the CO2 laser generator starts to work, the electric energy in the laser medium is excited, and the generated laser beam is accompanied by a large amount of heat. This heat is quickly transferred to the housing of the laser generator and the surrounding environment. The working process of the cooling system is as follows:

pump work

The water pump in the cooling system starts to work, draws cooling water from the water tank, and sends it around the laser medium of the laser generator through the cooling water pipeline.

Cooling water absorbs heat

Cooling water flows around the laser medium of the laser generator to absorb the heat generated by the laser generator. This heat causes the temperature of the cooling water to gradually increase.

Cooling water enters the water cooler

The cooled water returns to the water tank and continues to circulate. This process is continuous to keep the operating temperature of the CO2 laser generator stable.

cooling water return

The cooled water returns to the water tank and continues to circulate. This process is continuous to keep the operating temperature of the CO2 laser generator stable.

The Importance of Cooling Systems

The performance and service life of a CO2 laser cutting machine usually depends on a variety of factors, such as frequency of use, daily cleaning, and maintenance. However, users often overlook a critical element of long-term machine functionality: effective cooling. The cooling system of the CO2 laser cutting machine is an integral part of the whole equipment. Its stability and efficiency directly affect the performance and life of the laser generator. Laser tubes produce high-temperature heat-absorbing light, if it is not removed from the air quickly, the laser generator will fail prematurely. The laser cooling system can be directly connected to your laser unit or integrated into the laser system as a whole. Reasonable design and operation of the cooling system can not only ensure the stable output of the laser generator but also prolong the service life of the laser generator and reduce maintenance costs.

Summarize

Through the introduction of this article, we have a deep understanding of the cooling system principle and working process of the CO2 laser cutting machine. As an important part of the CO2 laser generator, the cooling system can effectively control the temperature of the laser generator and ensure its stable operation, which is the key to efficient and accurate cutting.

With the continuous advancement of technology, the cooling system will continue to develop, bringing broader prospects for the application of CO2 laser cutting technology. If you are looking for a reliable CO2 laser cutting machine for your business, AccTek Laser is the one-stop solution for all your needs. Here you will find our range of CO2 laser engravers, accessories, and software to get the superior performance you need from your CO2 laser cutter.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions