How to Achieve High Contrast in Laser Marking

As an efficient and accurate marking method, laser marking is widely used in many industries, especially in electronic manufacturing, medical devices, automotive parts, aerospace, jewelry, packaging and other fields. From product serial numbers, QR codes, brand logos to complex graphics, laser marking technology can achieve permanent marking on a variety of materials. This technology has become an indispensable part of the modern manufacturing industry with its non-contact, high speed, low cost and high precision. Contrast is a key factor affecting the quality of laser marking. High contrast not only improves the readability of the mark, but also directly affects the visual effect of the product and brand. Whether it is automatic barcode reading, clarity of brand logos, or complex industrial markings, good contrast is essential to ensure the quality of the mark. So, how to achieve high contrast in laser marking? This article will explore the relevant technologies and best practices in detail to help you achieve excellent laser marking effects in various application scenarios.

Table of Contents

Learn About Laser Marking Technology

Laser marking technology has been widely used in industry for its non-contact, high-precision, and diverse marking methods. Depending on the marking material and marking requirements, laser marking can be achieved in a variety of ways, including engraving, annealing, foaming, ablation, and carbon migration. Each technology has different working principles and marking effects, suitable for different application scenarios. Below we will explore each marking technology in depth to help you understand their advantages and application areas.

Engraving

Engraving is a technique that uses high-energy lasers to remove the surface layer of a material to create a mark. The high temperature of the laser causes the material to evaporate or melt, leaving a permanent recessed mark. This technique is often used to deeply or permanently mark materials and is suitable for applications that require long-term durability and resistance to wear.

- Applicable materials: metal, plastic, ceramic, wood, etc.

- Advantages: The engraving depth is controllable, the marking is very wear-resistant, and it is suitable for parts working in harsh environments, such as automotive parts and tools.

- Application industries: automotive manufacturing, electronic equipment, metal processing, jewelry, tool identification, etc.

Engraving technology is particularly suitable for marking hard materials such as stainless steel and aluminum alloys. It can create durable and clear marks, ensuring that the marks are still readable even under harsh conditions.

Annealing

Annealing technology is mainly used for metal materials. The laser heats the surface of the material, causing an oxidation reaction on the surface to form marks of different colors. Since the surface layer of the material only changes color without removing any material, the smooth surface of the annealing mark is suitable for applications that have high requirements on the material surface.

- Applicable materials: stainless steel, titanium alloy, chromium, and other metal materials.

- Advantages: no mechanical damage to the surface of the material, smooth surface, suitable for medical equipment and high-demand parts.

- Application industries: medical equipment, surgical tools, aerospace parts, etc.

The significant advantage of annealing marking technology is its ability to provide high-contrast marks while maintaining the integrity of the material surface, making it the first choice for industries with high requirements on material performance.

Foaming

Foaming technology is often used for plastic marking. The laser heats the surface of the material, causing it to vaporize locally and form tiny bubbles. These bubbles change the reflective properties of the material, creating a noticeable color difference. Foaming usually makes the surface of the material slightly raised, adding a three-dimensional effect to the mark.

- Applicable materials: non-metallic materials such as plastics and rubber.

- Advantages: The foaming mark is clear and has high contrast, especially suitable for dark plastic materials.

- Application industries: electronic components, plastic products, consumer product packaging, etc.

Foam marking can achieve obvious marking without changing the overall structure of the plastic. It is often used in the fields of electronic products, packaging materials, and consumer goods.

Ablation

Ablation technology uses high-energy lasers to precisely remove coatings or films from the surface of materials. Unlike engraving, ablation only removes the surface layer without affecting the underlying material. This technology is often used for high-precision marking of coated materials, removing the surface coating to expose the underlying material, thus creating a contrast.

- Applicable materials: coated metals, plastics, glass, etc.

- Advantages: High-precision marking, suitable for applications with high appearance requirements and fine marking.

- Application industries: electronic components, home appliance housings, instruments, etc.

Ablation marking is suitable for multi-layer materials, especially in applications where the underlying material needs to be revealed, such as electronic product housings, automotive components, and the marking of precision instruments.

Carbon migration

Carbon migration changes the carbon content of a material through lasers, causing the surface of the material to change color and form a permanent mark. Carbon migration is mainly used in metal materials, especially those containing carbon. It precisely controls the laser energy to redistribute or sublimate the carbon element in the material, forming a color change.

- Applicable materials: carbon steel, stainless steel, titanium, and other carbon-containing metal materials.

- Advantages: It can achieve extremely high contrast without damaging the surface finish, and is particularly suitable for products with high requirements for appearance.

- Application industries: medical devices, jewelry, consumer products, etc.

Carbon migration marking technology is widely used for marking stainless steel and titanium alloys, such as surgical tools and luxury goods because it does not damage the surface of the material.

Different laser marking technologies offer a wide range of options for diverse applications. Engraving technology provides deep and durable marks, annealing technology ensures a smooth metal surface while achieving color changes; foaming is suitable for plastic materials, ablation is good at processing coated materials, and carbon migration can provide unparalleled results for high-contrast metal marking. Depending on the type of material and marking requirements, choosing the appropriate marking method can greatly improve the quality and readability of product markings. In industrial production, it is crucial to understand these technologies and make choices based on specific application scenarios.

Understanding Contrast in Laser Marking

In the laser marking process, contrast is one of the important factors that determine the quality of the mark. High-contrast marks make information easier to identify and read, especially in industrial applications, where the quality of contrast directly affects production efficiency and product performance. The following will detail the definition of contrast in laser marking and its importance in various industries.

Definition of Contrast

In laser marking, contrast refers to the difference in light and dark between the marked part and the surrounding unmarked area. Specifically, the color, brightness or reflectivity of the marked area forms a sharp contrast with the unmarked area, producing a clear visual effect. The higher the contrast, the clearer the mark, which is crucial for reading or scanning the marked information.

The generation of contrast mainly depends on the following aspects:

- Properties of the material surface: The absorptivity and reflectivity of different materials affect the interaction of the laser with the material, thus affecting the color and clarity of the mark. For example, laser marking on black plastic will be significantly different than on white plastic.

- Laser parameters: Power, pulse frequency, scanning speed, and other parameters will affect the laser marking depth, color change, and gloss on the material, thus directly affecting the contrast of the mark.

- Environmental conditions: Temperature, humidity, and other factors may also affect the physical properties of the material and the effect of laser marking.

Whether it is a barcode, QR code, text, or pattern, clear marking depends on sufficient contrast. Especially in industrial production, whether the marking is clear is directly related to the traceability and readability of the product.

The Importance of High Contrast

High-contrast laser marking is not only more visually prominent but also significantly improves the efficiency of industrial automation and manual identification. This is particularly critical in the following aspects:

- Improved readability and recognition: High-contrast markings make information visible in different lights, angles, and distances. Especially in complex industrial environments, factors such as strong light, reflections, or dust can affect the visibility of low-contrast markings, while high contrast ensures easy recognition even in harsh conditions.

- Reading efficiency of automated equipment: In many industries, such as automobile manufacturing, electronic products, logistics, and medical equipment, information marks such as barcodes and QR codes are usually recognized by automated code reading equipment. If the contrast of the mark is insufficient, the code-reading device will be more likely to make recognition errors or require multiple scans, which will reduce production efficiency. High-contrast markings can reduce recognition errors and reading failures, significantly improving the efficiency of automated equipment.

- Ensure product traceability and compliance: In high-standard industries such as electronics, automobiles, and medical equipment, product traceability is an important part of ensuring safety and quality. Laser marking is widely used to mark parts in these industries. High-contrast markings not only help trace products during production, transportation, and use but also ensure that the requirements of industry regulations are met.

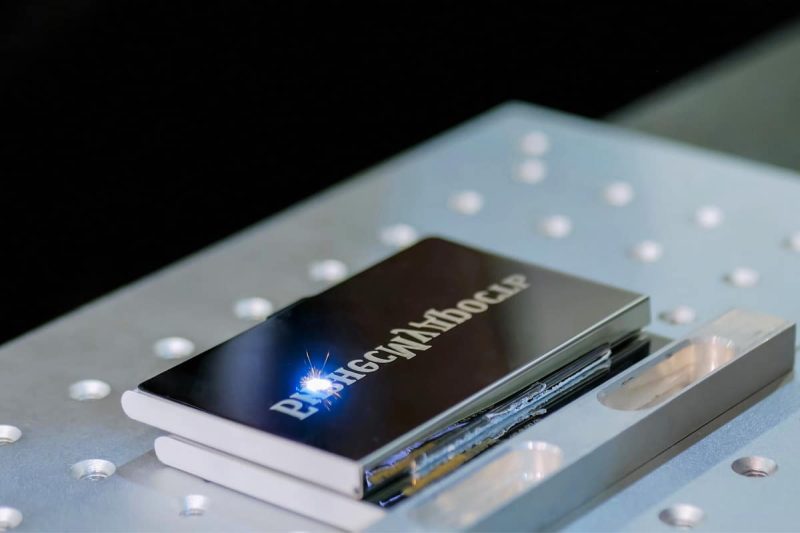

- Enhance brand and visual effects: In some consumer goods fields, such as jewelry, luxury goods, mobile phone cases, etc., laser marking is often used for brand identification. High-contrast markings not only increase the aesthetics of the product but also enhance brand recognition. Clear and durable markings not only highlight the brand image but also provide consumers with a good visual experience.

Application Examples in the Industry

- Automotive industry: High-contrast marking is used for serial numbers, production dates, and batch numbers of parts to ensure traceability on the production line and the accuracy of automated code reading.

- Electronics industry: Laser marking of components such as chips and printed circuit boards usually requires fineness and high contrast to ensure accurate reading of equipment on high-speed production lines.

- Medical device industry: For surgical instruments and medical devices, high-contrast laser marking ensures the uniqueness and traceability of products, ensuring that products meet strict hygiene and quality requirements.

- Aerospace: Due to special materials and harsh environments, high-contrast marking can ensure the clear legibility of parts during production, installation, and maintenance.

High contrast is not only a symbol of laser marking quality but also an important factor in ensuring industrial production efficiency and product traceability. In industries with strict requirements on marking clarity, achieving high-contrast marking plays an irreplaceable role in improving the performance of automated code reading equipment, reducing errors, and ensuring product compliance. Therefore, selecting appropriate laser parameters and materials and optimizing the marking process are important steps to achieve high contrast.

Factors Affecting Laser Marking Contrast

The contrast of laser marking is affected by multiple factors, among which the characteristics of the material, laser parameters, environmental conditions, and surface preparation all play a key role. Understanding these factors and making optimization adjustments accordingly can significantly improve the clarity and quality of your marks. Below we will discuss in detail how to achieve high-contrast laser marking by controlling these factors from various aspects.

Material Properties

The physical and chemical properties of the material have a direct impact on the effect of laser marking, especially when achieving high-contrast marking, the material’s absorption rate, reflectivity, surface color, and surface condition are all key factors.

- Absorption rate: The absorption rate of laser energy by a material is one of the main factors that determines the marking effect. Materials with high absorptivity can convert laser energy into heat energy more efficiently, resulting in more obvious changes on the material surface. For example, materials such as plastics, wood, and coated metals typically have high laser absorption rates and therefore produce sharper marks. Glass and some metals have lower absorption rates and may require higher power or special laser wavelengths to achieve the desired effect.

- Reflectivity: Materials with high reflectivity, such as aluminum, silver, and copper, tend to reflect most of the laser energy, causing the marking effect to be insignificant. When marking this type of material, it is usually necessary to use a laser of a specific wavelength (such as fiber laser or green laser) to ensure sufficient energy absorption and improve marking contrast. Proper surface treatment or pre-coating can also help reduce reflectivity and improve marking.

- Surface color and composition: The color of the material also has a significant impact on the contrast of laser marking. Dark-colored materials (such as black plastics, and black metal coatings) are more likely to produce significant contrast because dark-colored materials generally absorb laser energy more efficiently. Conversely, light-colored materials, such as white plastic or silver metal, may require higher laser power or finer parameter adjustments to achieve ideal contrast.

- Surface condition: The smoothness or roughness of the material surface directly affects the interaction between the laser and the material. Smooth surfaces usually reflect laser light more evenly, resulting in higher contrast, while surfaces that are too rough may cause laser energy to scatter, reducing the marking effect. However, a moderately rough surface may facilitate the absorption of laser energy, thereby improving marking effectiveness. This means that depending on the material and application requirements, choosing the right surface roughness can also have a positive impact on improving contrast.

Laser Parameters

During laser marking, the parameter settings of the laser equipment play an important role in the quality, accuracy, and contrast of the mark. By optimizing the laser power, speed, pulse frequency, and focus, the marking effect can be improved and the marked contrast can be increased.

- Power: The power of the laser determines the amount of energy it delivers to the surface of the material. Too low a power may result in unclear marking and insufficient contrast, while too high a power may cause excessive burning or melting of the material, or even damage the surface of the material. To achieve high-contrast marking, the power selection needs to be precisely adjusted to ensure that the laser energy matches the material characteristics, achieving clear marking without damaging the material.

- Speed: The speed at which the laser head moves affects the time the laser acts on the surface of the material. Slower speeds allow the laser to stay on the surface of the material longer, increasing the accumulation of heat energy, and thereby improving the depth and contrast of the marking. However, too slow a speed may also cause the material to overheat and affect the clarity of the mark. Therefore, the speed adjustment should be considered in conjunction with the power to achieve the best marking effect.

- Pulse frequency: The laser pulse frequency determines the laser repetition rate, that is, the number of laser pulses per unit time. High-frequency laser pulses are more suitable for delicate and complex pattern markings because they can cover more area in a short time; while low-frequency laser pulses are suitable for deep marking. To achieve high-contrast marking, choosing the appropriate pulse frequency can help produce more uniform and clear marks on the material surface.

- Focus: Accurate laser focusing ensures that the laser energy is concentrated on a specific area on the material surface, thereby achieving the most efficient energy transfer. Inaccurate focus may cause laser energy to disperse, affecting the clarity and contrast of the mark. By adjusting the laser focus, you can ensure that the marked area obtains maximum laser energy and improves contrast.

Environmental Conditions

Environmental conditions also affect the marking effect during laser marking. Temperature, humidity, and the cleanliness of the working environment will change the physical properties of the material and the efficiency of laser energy transmission, thus affecting the contrast.

- Temperature: Ambient temperature has a certain impact on the physical properties of materials and the transmission of laser energy. High-temperature environments may reduce the absorption rate of materials, especially in heat-sensitive materials such as plastics. High temperatures may cause the materials to soften or deform in advance, affecting the marking effect. Therefore, when laser marking is performed in a high-temperature environment, it may be necessary to reduce the laser power or optimize other parameters.

- Humidity: Humidity has a significant impact on the laser marking effect of certain materials, especially plastics and wood. A high-humidity environment may cause water vapor to condense on the material surface, affecting the transmission of laser energy and reducing mark clarity. To ensure mark contrast, in environments with high humidity, it is best to ensure that the surface of the material is dry.

- Cleanliness: Dust, grease, oxides and other pollutants on the surface of the material will interfere with the transmission of laser energy, causing energy dispersion and thus affecting the marking effect. Especially for laser marking with high precision requirements, it is crucial to ensure that the material surface is clean. Cleaning the material surface before laser marking can significantly improve the contrast of the mark.

Surface Preparation

Before laser marking, the surface preparation of the material will directly affect the final mark quality and contrast. Reasonable surface cleaning, roughness adjustment, and necessary pretreatment help ensure that the laser energy is efficiently transferred to the material surface and produces clear marks.

- Cleaning: The material surface should be thoroughly cleaned before marking to remove dust, grease, oxide layers, or other contaminants that may affect the laser marking effect. Using solvents, brushes or ultrasonic cleaning equipment can help ensure that the surface is free of any residue, thereby improving the contrast of the laser marking.

- Surface roughness: Appropriate surface roughness can help the material better absorb laser energy, especially on highly reflective materials. Increasing the surface roughness can reduce the reflectivity and thus improve the marking effect. However, for applications that require smooth surfaces, such as high-precision medical devices or electronic components, it is necessary to ensure surface smoothness for better marking results.

- Pretreatment: Some materials may require pretreatment to ensure the best performance of the laser marking effect. For example, metal materials can be polished or coated, and plastic materials can be treated with surface chemical treatment. These steps help improve the absorption of laser energy by the material surface, thereby achieving higher contrast.

The factors that affect the contrast of laser marking are complex and varied, including the characteristics of the material, the parameters of the laser equipment, the environmental conditions, and the surface preparation. By adjusting these factors in a targeted manner, the contrast of laser marking can be effectively improved to ensure that the marking effect is clear and durable. This can not only meet the traceability and identification requirements in industrial production but also achieve better visual effects in applications such as brand identification.

Seven Key Practices for Achieving High Contrast

To achieve high contrast in laser marking, a series of best practices need to be adopted, from the selection of laser type to environmental control to the application of post-processing technology. Through reasonable operation and adjustment, clear and durable marking effects can be obtained on different materials.

Choose the Right Laser Type

The wavelength of the laser has different absorption rates for different materials, so choosing the right laser type is crucial. Fiber laser generators are suitable for metal materials such as stainless steel, aluminum, and copper, and can produce clear marks. CO2 lasers are more suitable for plastics, organic materials, and some non-metallic materials such as wood, leather, etc. Choosing a laser generator that matches the material properties can ensure higher energy absorption, thereby improving the marking contrast.

Material Preparation

The preparation of the material surface has a direct impact on the marking results. The surface should be clean and flat so that the laser energy is evenly distributed and absorbed. Depending on the material, pre-treatment such as polishing, sandblasting, chemical cleaning, etc. may be required to remove any impurities that may interfere with the marking. This type of preparation helps to optimize the laser’s transmission effect and improve the contrast and clarity of the mark.

Laser Parameter Optimization

The setting of laser parameters is crucial to achieve high contrast. Parameters such as power, speed, pulse frequency, etc. need to be adjusted according to the characteristics of the material. Generally, higher power increases the depth of the mark, but too high power may cause material burning or over-processing. A slower marking speed helps increase the interaction between the laser and the material, thereby improving the contrast. Through a series of experimental tests, the laser settings that are most suitable for different materials can be found to ensure the best marking effect.

Controlled Environmental Conditions

The temperature, humidity, and cleanliness of the environment will affect the stability of laser marking. Excessive temperature or humidity may change the physical properties of the material, which in turn affects the absorption and conduction efficiency of the laser. Maintaining constant environmental conditions, especially when laser marking on moisture-sensitive materials, can ensure consistent marking results. Clean the work area regularly to avoid dust or impurities that interfere with the marking process to ensure high-contrast mark quality.

Fixtures and Material Handling

During the marking process, the material must remain stable and motionless. Any slight movement will result in unclear markings or errors. Using high-precision fixtures and material fixtures can ensure the stability and consistency of the marking position, avoiding repeated processing or blurred markings. Especially when marking large areas or complex patterns, a stable fixture can improve the overall marking quality.

Software and Control Systems

Modern laser marking systems are equipped with highly intelligent control software that can help accurately manage the laser’s output power, path, and marking speed. Proper use of these functions can achieve automatic parameter adjustment and improve operational efficiency. In addition, the software can also record the best parameter settings for different materials to facilitate subsequent operations and ensure that each marking can achieve the ideal contrast.

Post-Processing Technology

In some cases, post-processing after laser marking can further improve contrast. For example, metal surfaces can be oxidized or sprayed with a protective layer to enhance the marking effect. Sometimes, a post-marking cleaning step can also help remove residues from the marking process, making the mark clearer and more durable. These post-processing techniques can be flexibly used according to different materials and application scenarios to improve the overall quality of laser marking.

High-contrast laser marking can be achieved by selecting the right laser type, fine-tuning parameters, controlling environmental conditions, and using post-processing techniques. These best practices will help improve mark clarity and durability, and ensure that the mark performs well on a variety of materials.

Summarize

To achieve high-contrast laser marking, it is necessary to consider a variety of factors such as materials, laser parameters, and environment. By properly selecting the laser type, optimizing the marking settings, and maintaining the cleanliness of the material, companies can greatly improve the marking quality and bring more beautiful and practical marking effects.

In terms of material preparation, different materials have different absorption and reflectivity, so choosing the right laser generator is key. The fiber laser marking machine provided by AccTek is particularly suitable for metal materials, such as stainless steel and aluminum, while the CO2 laser marking machine is more suitable for plastics and organic materials. Proper pretreatment according to the material characteristics, such as polishing and cleaning, can ensure that the laser energy is evenly absorbed and the marking contrast is clearer.

Adjusting the laser parameters is equally important. When marking, our laser equipment supports flexible parameter adjustment and can find the most suitable settings based on power, speed, and frequency. Whether it is a deep mark on metal or a shallow mark on plastic, high-contrast effects can be guaranteed. Even for highly reflective materials, AccTek’s fiber laser marking machine can easily handle it.

Controlling environmental conditions is also a step that cannot be ignored. Keeping the marking environment dry and clean can effectively prevent dust or moisture from affecting the marking effect. Our equipment performs well in various industrial environments and has strong stability, helping companies achieve consistent marking results under different conditions. In daily operations, our laser marking machines are simple in design and easy to maintain. By using our laser marking machines reasonably, customers can achieve fast and accurate marking, and improve the overall quality and brand image of the product. Through these efforts, not only can the product be made more beautiful, but also customers can be interested in our laser marking solutions, thereby promoting order growth.

If you are interested in our laser marking machines, please feel free to contact us to learn more about customized solutions that are suitable for your business.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions