How to Achieve Minimum Weld Width in Laser Welding

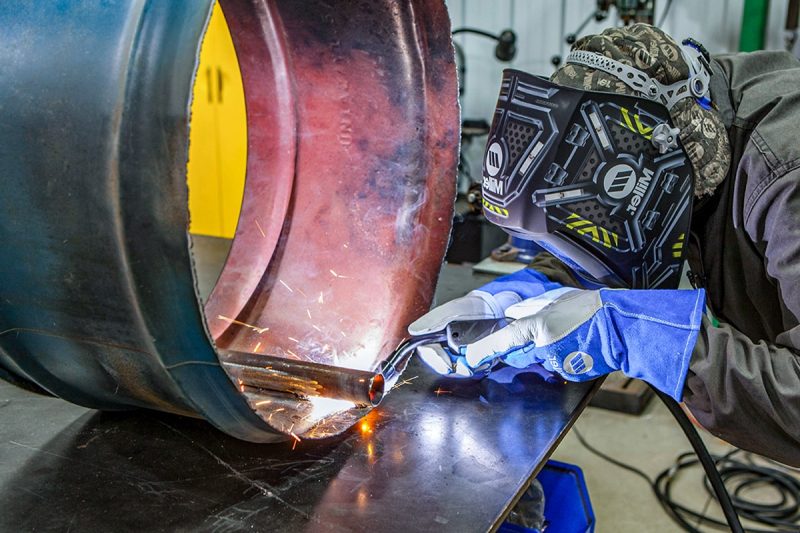

As a precision welding technology, laser welding has been widely used in aerospace, automobile manufacturing, electronic components, and medical equipment due to its high efficiency, precision, and controllability. By using a high-energy-density laser beam for local heating and melting, laser welding can achieve highly precise welding operations, especially in scenarios with strict requirements on weld size.

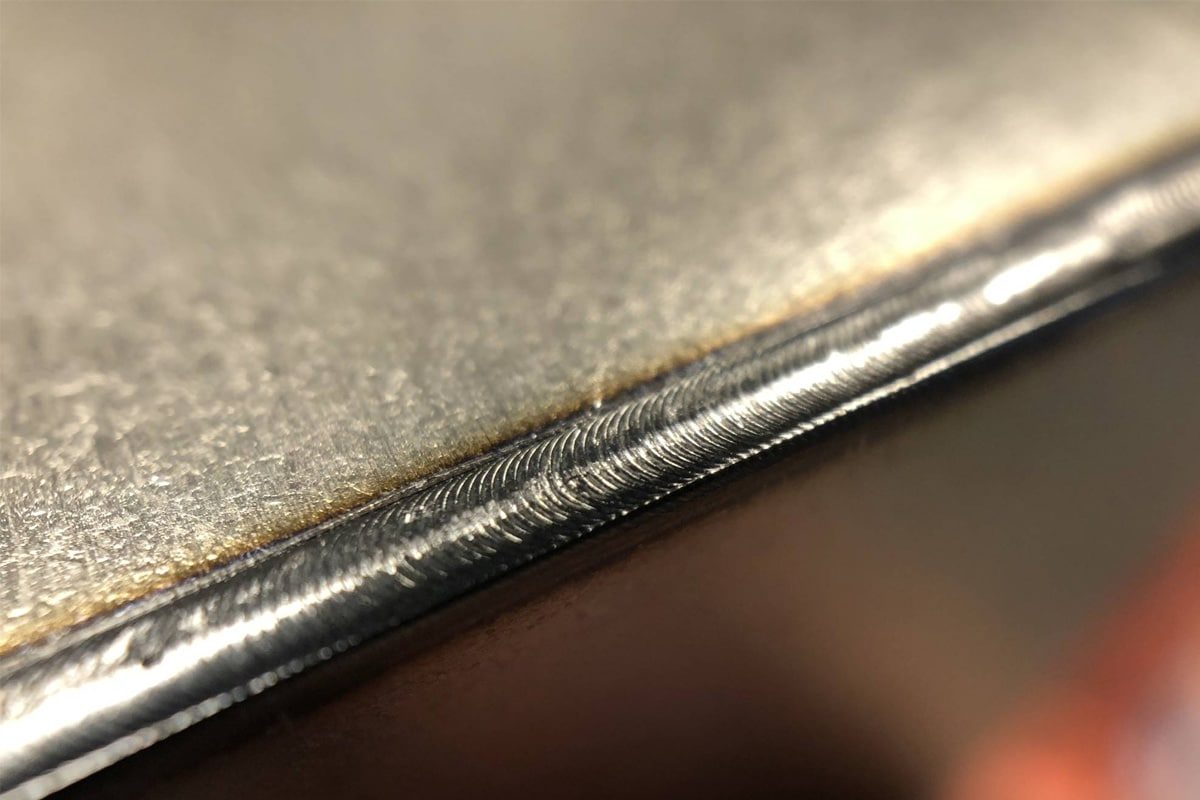

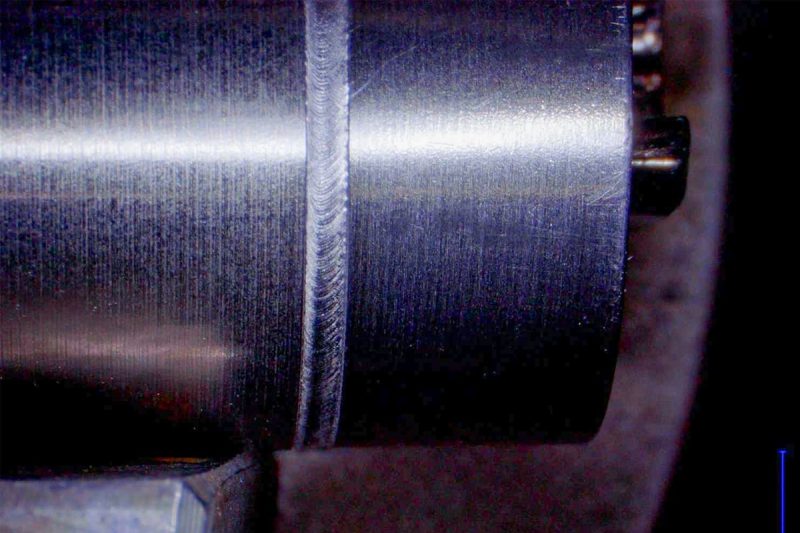

In the field of precision manufacturing, the control of weld width is crucial. Minimizing the weld width can reduce the range of the heat-affected zone, thereby reducing the risk of material deformation, while improving welding strength and appearance quality. In addition, narrower welds also mean less material loss and higher welding efficiency, which meets the needs of modern industry for high-quality and low-cost production.

Table of Contents

Understanding Laser Welding

Basics of Laser Welding

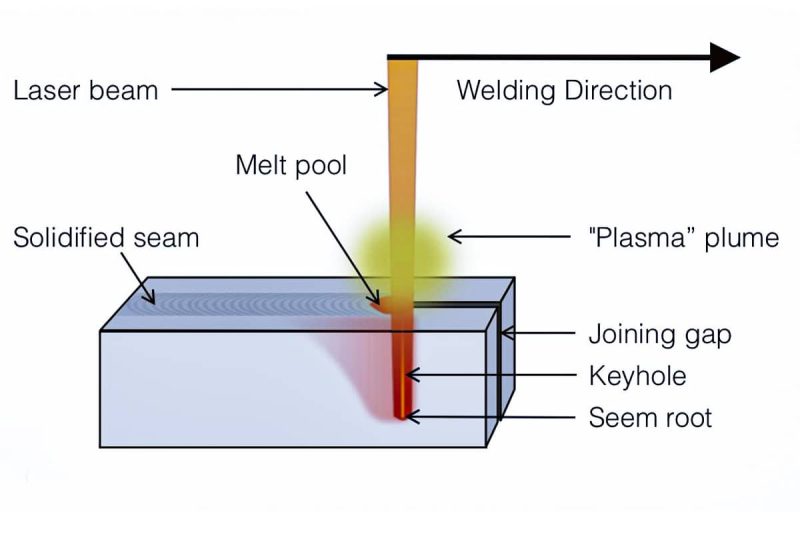

Laser welding is an advanced welding technology that uses a high-energy-density laser beam to locally heat the material, causing the surface of the material to melt and quickly combine with adjacent areas. Due to the high power density and high precision of the laser beam, energy can be concentrated in a very small area, thereby achieving precise and efficient welding.

This technology is particularly suitable for welding thin-walled structures and precision parts because its heat-affected zone is small, it is not easy to cause material deformation, and it can well preserve the original properties of the parent material.

Laser Welding Type

Laser welding can be divided into continuous laser welding and pulsed laser welding. Continuous laser welding is suitable for thicker materials, while pulsed laser welding is suitable for thin materials and welding tasks with higher precision requirements.

- Continuous wave laser welding: suitable for long-term, high-intensity welding needs, widely used for the connection and sealing of thick metal plates.

- Pulse laser welding: heats the material through short-term high-energy pulses, more suitable for welding thin plates or micro components, with higher control accuracy.

In addition, by adjusting the laser parameters (such as power, speed, focus position, etc.), the heat input of the welding area can be flexibly controlled to meet different materials and welding requirements, thereby affecting the weld size and welding quality. This high adaptability makes laser welding widely used in aerospace, automotive manufacturing, and electronics industries.

Factors Affecting Weld Width

Weld width is one of the important indicators of laser welding quality, and its size is directly related to the accuracy, strength, and appearance of welding. The control of weld width involves multiple factors, mainly including laser parameters, material properties, and welding environment. The following is a detailed analysis of how each factor affects weld width:

Laser Parameters

- Laser power: Laser power is one of the most critical parameters affecting welding results. The greater the laser power, the more heat is generated, and the volume of the heat-affected zone and the molten pool also increases, which increases the weld width. Conversely, if the power is too low, it cannot provide enough energy to melt the material, and the weld joint may be insufficient, resulting in a narrow weld or incomplete welding. Therefore, the laser power needs to be reasonably selected according to the thickness, type, and welding speed of the material to achieve the optimal width of the weld.

- Welding speed: The welding speed has an important influence on the heat input. When the welding speed is slow, the laser stays in the welding area for a longer time, resulting in more heat transfer to the base material, forming a larger molten pool and heat-affected zone, thereby increasing the weld width. Conversely, too fast a welding speed will reduce the heat input, resulting in incomplete welding, too narrow welds, and possibly weak welds. Therefore, reasonable control of the welding speed is the key to ensuring the appropriate weld width.

- Wavelength: The wavelength of the laser determines how the laser interacts with the material. Short-wavelength lasers (such as those emitted by fiber laser generators) can be better absorbed by metal materials because they have a higher energy concentration and can provide more energy in a smaller area, thereby improving welding efficiency and making the weld narrower. Relatively speaking, long-wavelength lasers (such as those emitted by CO2 laser tubes) have poor absorption of metal materials, and the energy distribution during welding is relatively wide, which easily leads to a larger weld width. Therefore, short-wavelength lasers are more suitable for high-precision welding.

- Pulse duration: Pulsed laser welding has the unique advantage of optimizing welding by adjusting the pulse duration. The shorter the pulse duration, the shorter the heat input time of the laser, which helps to reduce the expansion of the heat-affected zone and form a smaller weld. Longer pulse durations result in more heat input and a wider weld. Through pulse shaping technology, the pulse width and interval of the laser can be precisely controlled to optimize the heat distribution and weld morphology during welding.

- Beam quality: The quality and focus control of the laser beam are critical to welding accuracy. Lasers with better beam quality have smaller focus sizes and more concentrated energy, which can achieve higher-precision welding. Higher beam quality helps reduce heat diffusion so that heat is more concentrated in the welding area and the weld width becomes smaller. If the beam quality is poor, it will cause uneven distribution of laser energy, thereby increasing the width of the weld.

Material Properties

- Absorption rate: The absorption rate of the material to the laser directly affects the welding effect. The absorption rate of metal materials is usually high, especially when the short-wavelength laser is matched with the metal, the absorption rate is further improved. In the laser welding process, a higher absorption rate means that the laser energy can be effectively converted into heat energy, resulting in a smaller weld. Conversely, if the absorption rate of the material is low, the effective utilization rate of the laser energy is poor, which may cause the weld to be too wide or incomplete.

- Thermal conductivity: The thermal conductivity of the material affects the diffusion rate of heat in the substrate. Materials with higher thermal conductivity (such as copper and aluminum) will quickly disperse heat, resulting in excessive heat dispersion in the welding area and wider welds. In contrast, materials with lower thermal conductivity (such as stainless steel) can keep more heat concentrated in the welding area, forming a narrower weld. Therefore, when welding materials with different thermal conductivities, it is necessary to adjust the welding parameters according to their thermal properties to ensure that the weld width is appropriate.

- Reflectivity: Materials with high reflectivity (such as aluminum and copper) will produce greater reflection of the laser, and reduce the absorption efficiency of the laser energy, thereby affecting the welding quality and may cause the weld width to increase. To overcome this problem, you can choose a laser type that is suitable for highly reflective materials (such as using a short wavelength laser), or increase the laser power to compensate for the reflection loss. In addition, using a focused beam and an appropriate laser wavelength can also help increase the laser absorption rate of reflective materials.

Welding Environment

- Shielding gas: Shielding gas plays an important role in laser welding. It not only prevents oxidation and contamination during welding but also affects heat conduction and weld width by controlling the flow of gas. For example, argon and nitrogen are often used as shielding gases in laser welding. They can effectively reduce the range of the heat-affected zone and avoid the generation of excessive welds. The selection and control of shielding gas needs to be adjusted according to the specific materials and welding requirements.

- Environmental conditions: Environmental factors such as temperature and humidity also have a certain impact on the effect of laser welding. In low-temperature environments, the thermal conductivity of metal materials may change, which affects the thermal management during welding. In addition, high humidity environments may cause scattering of laser energy and affect welding quality. Stable environmental conditions help maintain the stability of the laser beam and ensure the consistency of weld width during welding.

The control of weld width in laser welding involves the combined effect of multiple factors such as laser parameters, material properties, and welding environment. To obtain the minimum weld width, these factors need to be finely adjusted and reasonably selected according to the actual application. By reasonably optimizing parameters such as laser power, welding speed, and beam quality, and considering the absorptivity, thermal conductivity, and reflectivity of the material, the welding accuracy can be effectively improved to ensure the narrowness and quality of the weld. In practical applications, solving problems such as high reflectivity and difficult thermal management is the key to achieving high-precision welding.

Technology to Achieve Minimum Weld Width

To achieve the minimum weld width in laser welding, optimization, and adjustment must be made in many aspects, including laser type selection, laser parameter optimization, material preparation advanced welding technology, etc. These technologies can effectively control heat input, reduce heat-affected zones, and ensure weld accuracy and narrowness.

Laser Type Selection

Choosing the right laser type is the basis for achieving the minimum weld width. Different types of laser generators perform differently when welding metals and are suitable for different welding tasks.

- Fiber laser generator: Fiber laser generator is one of the most widely used laser sources in laser welding. It has high power, high beam quality, and excellent focusing ability. The beam of the fiber laser generator can be precisely focused on a very small area, making the weld width smaller and able to process thin plate materials efficiently. Fiber laser generators are very suitable for high-precision and fast welding tasks and can achieve high-quality small welds and reduce the expansion of the material’s heat-affected zone (HAZ).

- CO2 laser tube: CO2 laser tube is another laser source commonly used for metal welding. Although the beam quality of CO2 laser tubes is generally not as good as that of fiber laser generators, it can provide greater power and deeper penetration depth, which is suitable for welding thicker materials. Although it is not as accurate as fiber laser, relatively small weld widths can be achieved through reasonable power regulation and optimized welding speed.

Laser Wavelength Selection

Different laser generator wavelengths have different absorption rates for different materials. CO2 lasers have longer wavelengths and are generally less efficient at absorbing non-ferrous metals (such as aluminum and copper). Fiber lasers have shorter wavelengths and are generally better absorbed by metal materials, providing higher welding efficiency and narrower welds. Therefore, when selecting a laser generator, in addition to considering the power and material thickness, the optical properties of the material and the wavelength matching of the laser should also be considered.

Laser Parameter Optimization

- Laser power adjustment: Laser power is the main factor affecting welding heat input. Excessive power will cause excessive heat to spread to the surrounding area, thereby widening the weld and even causing welding defects. Appropriately reducing power can help reduce heat input and narrow the weld width, especially when welding thin plate materials. However, too low power may result in inadequate welding. Therefore, reasonable adjustment of laser power to match it with material properties, welding speed, and welding requirements can achieve precise welding and effectively control the weld width.

- Pulse shaping technology: Pulse laser welding technology can accurately control the heat input during welding by adjusting the frequency, duration, and energy of the laser pulse. The shorter the pulse width, the shorter the heat input time, and the less heat accumulation in the welding area, making the weld narrower. In addition, by adjusting the pulse frequency and energy, the welding speed and molten pool morphology can be controlled, which in turn affects the width of the weld. Using pulse shaping technology, especially in micro welding, the heat distribution of each pulse can be accurately controlled to effectively achieve the minimum weld width.

- Beam focus control: The accuracy and weld width of laser welding is closely related to the focal position of the beam. The smaller the laser beam focus, the higher the energy density, which can be concentrated in the welding area, thus producing a narrow and fine weld. Therefore, laser focus control is very important. By adjusting the focus position, the energy of the laser beam can be more concentrated in the welding area, avoiding heat diffusion to the surrounding area, and thereby reducing the width of the weld.

Material Preparation

- Surface cleanliness: The surface cleanliness of the welding material directly affects the effect of laser welding. Oxides, oil, rust, and other contaminants on the surface will affect the absorption rate of the laser, resulting in the inability to effectively concentrate the heat in the welding area, thus affecting the welding quality and increasing the weld width. Ensuring that the welding surface is clean and free of contamination is a prerequisite for optimizing welding quality. Surface contaminants can usually be removed by chemical cleaning, mechanical cleaning, or laser cleaning.

- Surface coating: In some cases, especially for materials that are difficult to weld, surface coating can significantly improve the absorption efficiency of the laser. Coating materials (such as copper plating, zinc plating, etc.) can improve the interaction between the laser and the material and enhance the heat accumulation in the welding area, thereby helping to accurately control the weld width during the welding process. In addition, special coatings can also improve the stability of the molten pool during welding and reduce defects during welding.

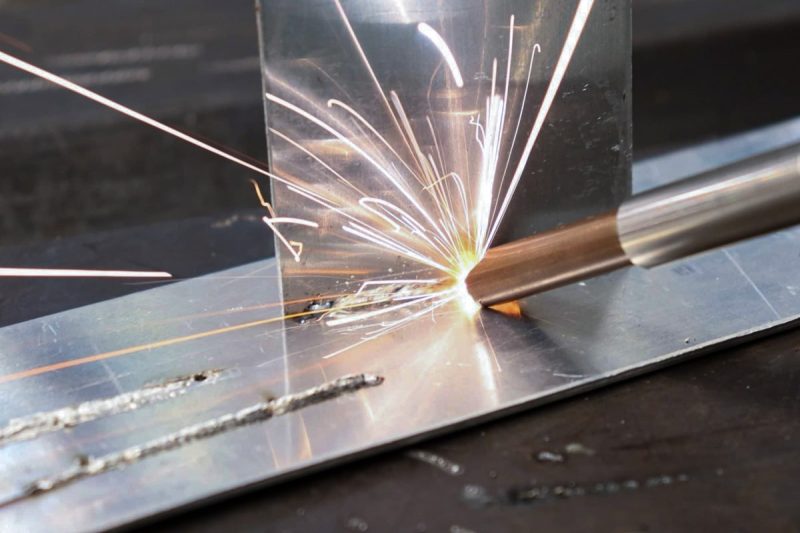

Advanced Welding Technology

- Hybrid laser welding: Hybrid laser welding technology combines the advantages of laser and traditional welding methods (such as TIG welding or MIG welding), and improves heat input and welding accuracy by combining the advantages of different heat sources. The combination of laser and traditional welding methods can effectively reduce the weld width, especially when welding thicker materials. Hybrid laser welding technology can provide higher molten pool stability and smaller heat-affected zones, thereby achieving more refined welding effects.

- Micro welding technology: Micro laser welding is a high-precision welding technology for processing ultra-small welds, especially suitable for connecting small parts. Micro-welding technology uses finely controlled laser pulses to achieve efficient energy transfer in a very small welding area, ensuring the formation of very narrow welds. Micro welding is commonly used in industries such as electronics, precision instruments, and medical devices, and can achieve high welding accuracy and minimize the thermal impact of the welding area.

The key to achieving the minimum weld width lies in the comprehensive regulation of multiple factors, from laser type, laser parameters, material preparation to advanced welding technology, each link requires fine design and adjustment. By selecting the appropriate laser type, optimizing laser power and pulse shape, controlling the beam focus position, and improving material preparation and surface treatment, the weld width can be significantly reduced. At the same time, the application of hybrid laser welding and micro-welding technology provides more possibilities for achieving high-precision and narrow welds. Through the combination and innovation of these technologies, laser welding can improve welding efficiency and quality while meeting high-precision requirements.

Challenges and Solutions

The challenges in the laser welding process are mainly reflected in thermal management, material reflectivity, and process stability. Given these problems, taking corresponding solutions can effectively improve welding quality, reduce weld width, and ensure the controllability and consistency of the welding process.

Thermal Management

Challenge

In laser welding, excessive heat input can cause overheating of the welding area, resulting in excessive weld width, and may cause a series of welding defects such as thermal cracks and deformation. In addition, a large heat-affected zone (HAZ) can also have a negative impact on material properties. How to reasonably control heat input and avoid excessive heat diffusion has become an important challenge in achieving precise welding.

Solution

- Use auxiliary gas cooling: Using appropriate shielding gas or auxiliary gas (such as argon, nitrogen, or oxygen), can not only prevent oxidation of the welding area but also effectively remove excess heat generated during welding, thereby reducing the expansion of the heat-affected zone. The flow rate and pressure of the auxiliary gas need to be optimized according to the welding material, welding speed, and laser power to ensure the best cooling effect.

- Welding speed optimization: Properly increasing the welding speed can reduce the heat input per unit time and reduce the heating time of the material, thereby effectively avoiding overheating of the welding area. Higher welding speeds can cause heat to spread rapidly to a larger area, reduce local temperature rise, and thus control the weld width and heat-affected zone.

- Heat source regulation: By adjusting the laser power or using a pulsed laser, the heat input can be precisely controlled during the welding process. Especially in pulse welding, short pulses, and higher pulse frequencies can ensure that the heat is quickly focused and distributed in the welding area to avoid heat diffusion.

Material Reflectivity

Challenge

Many metal materials, especially non-ferrous metals (such as aluminum, copper, etc.), have high light reflectivity. High reflectivity materials will cause a large amount of laser energy to be reflected, which will reduce the effective utilization of energy, limit welding efficiency, and may cause incomplete welding and increased weld width during welding.

Solution

- Use short-wavelength lasers: Short-wavelength lasers (such as those produced by fiber laser generators) have a higher absorption rate for highly reflective materials. Short-wavelength lasers can be better absorbed by materials, reduce reflections, and ensure that more laser energy is effectively used in the welding process, thereby improving welding efficiency and reducing weld width. Compared with long-wavelength CO2 lasers, fiber laser generators are more suitable for processing materials with higher reflectivity.

- Laser power adjustment: For materials with high reflectivity, appropriately reducing the laser power can avoid excessive energy reflection. Lower power settings help reduce reflections and avoid energy waste, thereby effectively controlling weld width and optimizing welding quality.

- Use coated materials: Some highly reflective metal materials, such as aluminum and copper, can use coating technology, such as coating aluminum plating, copper plating, and other surface treatment methods. These coatings have lower reflectivity, which can improve the absorption efficiency of the laser and reduce the interference of reflection on the welding process, thereby better controlling the weld width.

Process Stability

Challenge

Stability during laser welding is a key factor. Any process instability may lead to fluctuations in welding quality, changes in weld width, and even welding defects (such as pores, weld offset, etc.). To achieve consistent welding results, the stability of the laser welding process must be ensured to avoid welding quality problems caused by parameter fluctuations.

Solution

- Advanced laser control system: By using advanced laser control systems, key parameters such as laser power, welding speed, beam focus, etc. can be monitored and adjusted in real-time to ensure the consistency of laser parameters during each welding process. Modern laser welding systems are usually equipped with high-precision sensors and automatic adjustment functions, which can detect the temperature of the welding area, the molten pool morphology, and the beam position in real-time, and automatically adjust the laser output to maintain the stability of the welding process.

- Real-time feedback and closed-loop control: The use of real-time feedback and closed-loop control technology can adjust parameters in real-time during the welding process to cope with changes in material properties and the welding environment. For example, sensors can monitor the size, shape, and temperature of the molten pool, and the system can automatically adjust the laser power and welding speed to maintain the consistency of welding quality. This technology can significantly improve the reliability of the welding process and avoid welding problems caused by process fluctuations.

- Welding path optimization: During the welding process, optimizing laser path planning is another important way to improve process stability. By accurately controlling the welding path and welding sequence, material deformation and changes in the heat-affected zone can be reduced, ensuring consistent temperature distribution during each welding process, and thereby achieving stable welding results.

Thermal management, material reflectivity, and process stability are the three major challenges in laser welding, which affect the weld width, welding quality, and production efficiency. These challenges can be effectively solved by adopting appropriate cooling methods, short-wavelength lasers, laser power regulation, advanced laser control systems optimized welding paths, and other technologies to improve the accuracy and stability of the welding process. These solutions not only help to achieve the minimum weld width but also provide strong support for the widespread application of laser welding technology.

Summarize

Achieving the minimum weld width in laser welding is not only the key to improving welding quality, but also an important step to reduce material waste, improve production efficiency and reduce costs. With the increasing demand for precision welding technology in the manufacturing industry, more and more companies are beginning to pay attention to how to accurately control the heat input, weld width and welding quality during the welding process. In laser welding, by accurately controlling laser parameters (such as power, welding speed, pulse shaping and beam focus, etc.), selecting appropriate materials and welding technology, the welding effect can be effectively optimized, the ideal weld quality can be achieved, unnecessary material waste can be reduced, and the consistency and reliability of the product can be improved.

However, in actual production applications, laser welding still faces a series of technical challenges. For example, excessive heat input may cause the weld to be too wide, and the reflectivity of the material will also affect the effective transmission of laser energy. These challenges need to be solved through advanced technical means and process improvements. For example, using appropriate cooling methods, selecting short-wavelength lasers, optimizing laser power, and using efficient laser control systems can solve these problems to a certain extent. With the continuous advancement of technology, the accuracy and stability of laser welding will continue to improve, enabling it to meet the needs of wider and more sophisticated industrial applications.

In this process, our laser welding machines have become the leaders in the industry with their superior technology and innovative design. Our company’s laser welding machines use the latest fiber laser technology, which can achieve efficient welding while ensuring accurate temperature control during the welding process, thereby effectively controlling the weld width and reducing the heat-affected zone. Our welding equipment not only has high-precision laser beam adjustment capabilities but is also equipped with an advanced temperature control system that can automatically adjust the parameters during the welding process, thereby optimizing the welding effect and ensuring stable and consistent quality at each welding point.

In addition, AccTek Laser’s welding machines are widely applicable to various metal materials and complex processes and can meet the needs of different industries for high-precision, narrow welds. Whether in electronic manufacturing, the automotive industry, or precision instrument production, our laser welding equipment can provide reliable solutions. With excellent product quality and stability, we have won the trust of many customers in the field of laser welding. With the continuous evolution of laser welding technology, AccTek Laser will continue to be committed to innovation and technology optimization, continuously improve product performance, and provide customers with more efficient, more accurate, and more reliable welding solutions, helping customers to occupy a favorable position in the fierce market competition.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions