How to Choose a Suitable CO2 Laser Cutting Machine?

In modern industrial production, CO2 laser cutting machines have become an indispensable processing tool in the manufacturing industry due to their advantages such as high precision, high efficiency, and wide range of applicable materials. However, there are many types of CO2 laser-cutting machines on the market, and how to choose a suitable device has become the focus of attention for enterprises. This article will analyze in detail the principles of the equipment, application fields, key purchase factors, etc., to help you find the CO2 laser-cutting machine that best suits your needs.

CO2 laser cutting machines are widely used in the processing of metal and non-metal materials, such as stainless steel, carbon steel, wood, plastic, acrylic, etc. With the development of intelligent manufacturing, CO2 laser cutting technology is upgrading towards automation, high precision, energy saving, and environmental protection. The market search demand for products such as “CO2 laser cutting machines”, “laser cutting technology”, and “industrial laser equipment” continues to rise, and choosing high-performance equipment has become an important means for enterprises to improve productivity.

Table of Contents

CO2 Laser Cutting Machine Overview

Working principle and technical advantages

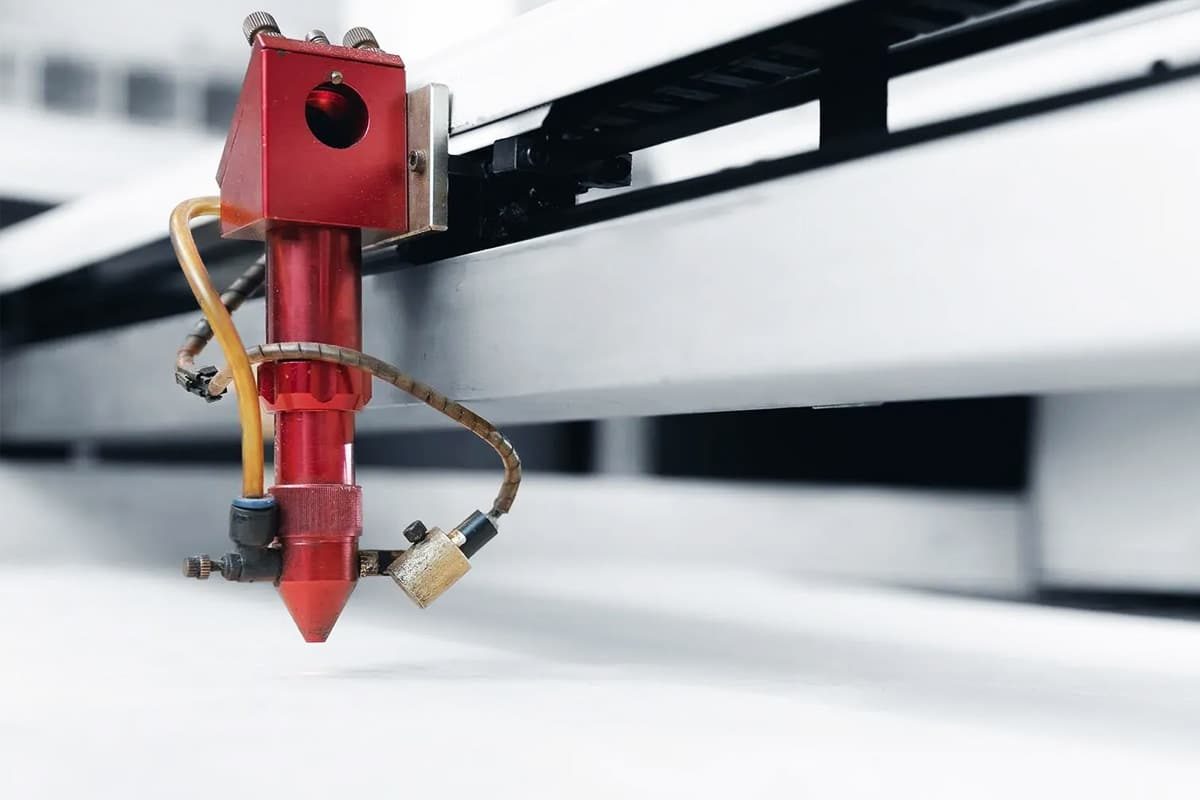

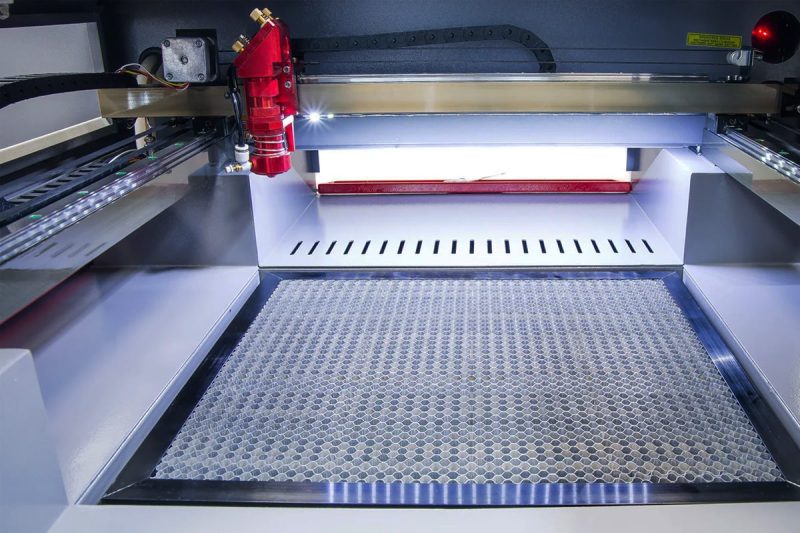

CO2 laser cutting machine uses a carbon dioxide laser generator as a light source, focusing the laser beam on the surface of the material to produce high-temperature melting or gasification, thus achieving high-precision cutting. Its main advantages include:

- High-precision cutting: can achieve delicate, burr-free cutting effects

- Wide application range: can process metal and non-metal materials

- High stability: CO2 laser generator has a long service life

- Environmental protection and energy saving: compared with traditional mechanical cutting, laser cutting consumes less energy

Main application areas

CO2 laser cutting machines are widely used in many industries, including:

With the development of technologies such as “laser processing” and “precision cutting”, CO2 laser cutting machines have become an ideal choice for efficient production.

Key factors for choosing a suitable CO2 laser cutting machine

When purchasing a CO2 laser cutting machine, companies need to consider multiple factors to ensure that the equipment meets their production needs, cost budget, and long-term return on investment. The following is a detailed analysis of six key purchasing factors:

Material and thickness matching

The power of a CO2 laser cutting machine directly determines the types and thickness of materials it can cut. Therefore, when choosing equipment, you first need to identify the main processing materials and select the appropriate laser power according to the cutting requirements of different materials. For example:

- 150W-300W: Suitable for non-metallic materials such as wood, acrylic, plastic, cardboard, leather, cloth, etc., mainly used in the advertising industry, handicraft production, packaging industry, etc. This type of equipment is generally used in small and medium-sized enterprises and the DIY market, suitable for fine engraving and light cutting.

- 600W-1500W: Suitable for cutting thin sheet metals such as stainless steel, carbon steel, aluminum alloy, and thicker acrylic and wood can also be processed. Suitable for medium-sized manufacturing companies, such as mechanical processing, electronic manufacturing, home decoration, and other industries, AccTek Laser has hybrid laser cutting machines that can adapt to multi-material cutting of metals and non-metals.

- >1500W: Suitable for thicker metal sheets, such as stainless steel above 5mm, carbon steel above 10mm, etc., but it is recommended to use a fiber laser cutting machine for cutting thick metal sheets.

When choosing a laser cutting machine, in addition to power matching, you also need to consider the following factors:

- Reflectivity of materials: Some highly reflective materials (such as copper and aluminum) have low absorption rates for CO2 lasers and may require higher power equipment or fiber laser cutting machines.

- Cutting quality requirements: Different materials may produce different degrees of burrs and heat-affected zones after laser cutting. Appropriate equipment should be selected based on subsequent processing requirements.

Cutting accuracy and speed requirements

Different industries have different requirements for cutting accuracy and speed, so when choosing a CO2 laser cutting machine, you need to weigh it according to your own needs.If you pursue high precision (such as electronic components, jewelry, and handicraft industries), you need to choose a high-precision laser cutting machine and pay attention to the following parameters:

- Minimum focal diameter: determines the fineness of the cutting line.

- Repeat positioning accuracy: usually controlled within ±02mm to ensure the consistency of mass production.

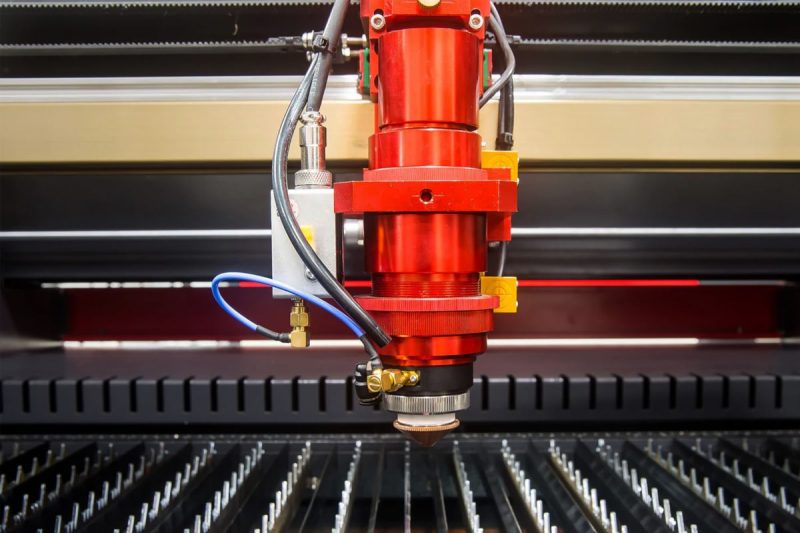

- Motion control system: high-end laser cutting machines usually use servo motors and precision guide rails to improve positioning accuracy and cutting stability.

If you are pursuing high-speed production (such as sheet metal processing, advertising production, and packaging industries), you need to choose equipment with high-speed cutting capabilities and pay attention to the following factors:

- Laser power and cutting speed: The higher the power, the faster the cutting speed. For example, a 600W laser cutting machine can be about 50%-80% faster than a 300W model.

- Optimized motion control system: The use of high-speed CNC systems (such as gantry structures, and linear motor drives) can improve overall processing efficiency.

- Gas-assisted cutting: The rational use of oxygen, nitrogen, or air-assisted cutting can improve cutting efficiency and optimize cutting quality.

Equipment power and energy efficiency ratio

Power selection not only affects cutting capacity but also directly affects energy consumption and long-term operating costs. Choosing the right power can achieve energy conservation and emission reduction while ensuring production efficiency.

When choosing a CO2 laser cutting machine, different powers are suitable for different application scenarios:

- Low power (<500W): suitable for light industry, DIY processing, low energy consumption, suitable for cutting thin materials.

- Medium power (500W-1500W): suitable for small and medium-sized enterprise production, can balance cutting capacity and energy consumption, suitable for a variety of materials.

- High power (>1500W): suitable for large-scale industrial production, can cut thick materials, suitable for mass production, but the operating cost is higher.

In addition to power selection, the following energy efficiency factors should also be considered:

- Laser generator efficiency: High-quality CO2 laser generator have high conversion efficiency and reduce power waste.

- Cooling system design: Advanced water cooling or air cooling systems can optimize energy consumption and reduce operating costs.

- Standby power consumption: Some laser cutting machines still consume a lot of electricity when in standby mode. Choosing equipment with intelligent energy-saving modes can reduce energy loss.

Control system and intelligence level

Modern CO2 laser cutting machines are becoming more and more intelligent, improving processing efficiency and operating convenience. The main intelligence functions include:

- Intelligent path optimization: reduce idle time and improve cutting efficiency.

- Automatic focus system: can automatically adjust the focus according to different thickness materials to improve cutting quality.

- Remote monitoring and operation: the Internet of Things connection, allows users to remotely monitor the status of the equipment and improve management efficiency.

- Intelligent typesetting software: optimize material utilization, reduce waste, and improve production efficiency.

Choosing advanced control systems (such as Ruida, and DSP control systems) can improve the stability of the equipment and the convenience of operation.

After-sales service and technical support

CO2 laser cutting machine is a long-term investment, and high-quality after-sales service and technical support are essential for the stable operation of the equipment. When choosing a brand, the following after-sales support factors should be considered:

- Warranty period: High-quality brands usually provide at least 1-2 years of warranty, and some high-end equipment even provides longer warranty period.

- Repair response speed: For production-oriented enterprises, equipment failure may cause production losses, so it is crucial to choose a supplier with fast response.

- Remote technical support: Some manufacturers provide technical support such as online diagnosis and remote debugging, which can effectively reduce maintenance costs and downtime.

Cost and cost-effectiveness considerations

In addition to the acquisition cost of the equipment, you also need to evaluate the long-term operating costs, including:

- Consumables cost: The main consumables of CO2 laser cutting machines include laser tubes, reflective lenses, lenses, etc., which need to be replaced regularly. For example, the life of CO2 glass tubes is generally between 3000-10000 hours, and metal laser tubes have a longer life but higher costs.

- Maintenance cost: Equipment optical path adjustment, cooling system maintenance, etc. will also affect long-term costs.

- Power consumption: High-power laser generators consume more power, but may improve production efficiency, so the energy efficiency ratio needs to be considered comprehensively.

When choosing equipment, cost-effective equipment can reduce long-term use costs and improve return on investment while ensuring quality. To choose a suitable CO2 laser cutting machine, you need to consider factors such as material adaptation, power selection, cutting accuracy, control system, after-sales service, and long-term cost. Enterprises should choose the most suitable equipment according to their own production needs, budge, and future development plans.

Comparison of mainstream brands and products in the market

Analysis of domestic and foreign brand advantages

In the CO2 laser cutting machine market, brand selection is crucial. The main brands include international high-end brands and domestic brands:

- International brands: such as TRUMPF, Amada, etc., these brands of CO2 laser cutting machines are widely used in high-end manufacturing, and have a place in the global market with their high precision and innovative technology. Although their equipment has advantages in performance and quality, the high price limits its application in small businesses and companies with limited budgets.

- Domestic brands: such as AccTek Laser, with its cost-effectiveness, has won the favor of global customers. While providing high-quality laser cutting machines, domestic brands also provide customers with more flexible price options and comprehensive after-sales service support. With the continuous advancement of technology, brands such as AccTek Laser have gradually occupied a place in the global market, especially in small and medium-sized enterprises and customer groups with limited budgets.

User Reviews and Success Stories

When purchasing a CO2 laser cutting machine, it is very important to refer to real user feedback and success stories. Customers’ word of mouth and success stories can not only help you understand the actual performance of the equipment, but also reflect its performance in different application scenarios. For example, AccTek Laser has helped many manufacturing companies improve production efficiency and reduce operating costs by providing flexible customization solutions and perfect after-sales services. Success stories can often provide a more realistic reference for your purchase decision.

Purchase suggestions and future trends

In the CO2 laser cutting machine market, brand selection is crucial. The main brands include international high-end brands and domestic brands:

How to make a purchasing plan based on demand?

Each industry and enterprise has different requirements when choosing a CO2 laser cutting machine. The following are purchase suggestions based on the characteristics of different industries, processing requirements, and budgets:

- Advertising industry: It is recommended to choose a low-power CO2 laser cutting machine (such as 150W-300W), which is suitable for processing materials such as acrylic, wood and paper, and can meet the needs of fine cutting and engraving.

- Metal processing industry: It is recommended to choose medium and high power (500W-1500W) models, which are suitable for cutting metal materials such as stainless steel, carbon steel, and aluminum, and pay attention to the energy efficiency ratio of the equipment to reduce production costs.

- Intelligent manufacturing enterprises: With the development of intelligent manufacturing and Industry 4.0, you can consider choosing high-end models with intelligent control, automatic cutting path planning, remote monitoring and other functions to improve production efficiency and reduce human errors.

CO2 laser cutting machine technology development trend

With the continuous advancement of laser cutting technology, CO2 laser cutting machines will gradually develop in the following directions:

- Automation technology: Future CO2 laser cutting machines will be equipped with more advanced intelligent control systems, supporting functions such as automated cutting path optimization, intelligent focusing, and remote monitoring, to improve operating efficiency and cutting accuracy.

- Energy saving and environmental protection: With increasingly stringent environmental protection policies, laser cutting equipment will pay more attention to improving energy efficiency, reducing energy consumption, and promoting green manufacturing. High-efficiency CO2 laser generators will become an industry trend.

- Intelligent manufacturing: Combined with Industry 4.0, CO2 laser cutting machines will gradually achieve interconnection with other intelligent devices, further improve production efficiency, and reduce the need for manual intervention.

When choosing a CO2 laser cutting machine, companies should make comprehensive considerations based on their own industry needs, processing materials, budgets, and production scale. The advertising industry is suitable for low-power models, the metal processing industry requires high-power equipment, and smart manufacturing companies should focus on automation and intelligent functions. In the future, CO2 laser cutting technology will develop in the direction of higher precision, greater intelligence, and more environmentally friendly and energy-saving. Technologies such as automated control, remote monitoring, and intelligent path optimization will improve production efficiency, while more energy-efficient laser technology will also reduce corporate operating costs. At the same time, with the development of Industry 4.0, the combination of intelligent manufacturing and laser cutting will further promote industry upgrades. When purchasing, companies should comprehensively consider factors such as equipment performance, energy efficiency ratio, intelligence level, and after-sales service to ensure that they choose a laser cutting machine that meets their own production needs to improve processing efficiency and market competitiveness.

Summarize

When choosing a suitable CO2 laser cutting machine, companies should focus on the following factors:

- Power and material matching: Choose a laser cutting machine with appropriate power according to the type and thickness of the cutting material.

- Equipment accuracy and speed: High-precision and high-speed cutting are crucial for enterprises with different needs. When choosing, make a reasonable choice based on the production scale and accuracy requirements.

- Cost-effectiveness and energy efficiency ratio: Under the premise of ensuring quality, choose equipment with high cost-effectiveness and excellent energy efficiency ratio.

- After-sales service and technical support: Choose a brand with a complete after-sales service system to ensure long-term stable operation of the equipment and timely support.

As a well-known brand in the field of laser cutting equipment, AccTek Laser provides customers with high-performance and cost-effective CO2 laser cutting machines with its many years of industry experience and technical accumulation. Our laser cutting machines have the following advantages:

- High-quality equipment: Using advanced laser technology, the equipment undergoes strict quality control to ensure high-precision cutting and high-efficiency production.

- Intelligent control: The laser cutting machine is equipped with the latest CNC system, supports automatic path planning and remote monitoring, and improves operational convenience and production efficiency.

- Perfect after-sales service: Provide global technical support and timely after-sales service to ensure that customers have no worries and help companies improve production stability and long-term benefits.

If you are looking for a CO2 laser cutting machine with excellent performance and cost-effectiveness, AccTek Laser will be your ideal choice. We will provide professional laser processing solutions based on your specific needs to help your company stand out in the fiercely competitive market.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions