How to Choose The Right Laser Cutting Machine Manufacturer

If you are planning to buy a laser cutting machine, it is very important to choose a reliable machine manufacturer. Professional laser cutting machine manufacturers have rich manufacturing experience and can provide various types of machine products. By cooperating with a reliable laser cutting machine manufacturer, users can save a lot of time and effort, and get high-quality services and products. Facts have proved that a reliable laser cutting machine manufacturer can become a trustworthy long-term partner. So how can we choose the right laser cutting machine manufacturer? This article discusses many factors that should be considered when choosing a laser cutting machine manufacturer, and I hope it can provide a reference for you.

Table of Contents

Know what kind of laser cutting machine you need

As a user, you must consider your own business scope: what kind of material do you need to cut? What is the thickness of the material? What are the dimensions of the material? Factors like these. Choose the laser power of the machine and the size of the worktable according to these needs. At present, the power of CO2 laser cutting machines on the market is between 60W-600W, and the power of fiber laser cutting machines is between 1000W-40000W. As for the size of the worktable, it can be customized according to user needs.

Choose the correct laser cutting machine according to the cutting material

Different laser cutting machines have their own fields of application. If you want to process non-metallic materials, you need to choose a CO2 laser cutting machine. If you want to process metal materials, you need to choose a fiber laser cutting machine. If you have processing needs for both materials, then you can choose a mixed laser cutting machine. At present, many laser cutting machine manufacturers can customize the production of fiber and CO2 combined laser cutting machines.

Select the appropriate laser power according to the material thickness

First, you need to understand what the cutting range of the laser generator represents. The max cutting thickness provided by the laser cutting machine manufacturer can only be used to cut some samples. Normal cutting thickness refers to general processing scenarios. Hi-speed processing thickness means that plates of the same thickness can be mass-produced.

For cutting of non-metallic materials, 60W-100W low-power CO2 laser cutting machine can be selected for plates below 10mm; 130W-180W medium-power CO2 laser cutting machine can be selected for plates of 10-25mm; 220W-600W high-power CO2 laser cutting machine can be selected for plates above 25mm. For metal material cutting, different metal materials require different power. For example, a 2000W fiber laser cutting machine can cut carbon steel below 14mm and stainless steel below 6mm. To choose which power laser generator to choose, you can consult the laser cutting machine manufacturer.

Laser power has a great influence on cutting speed. When the laser power is increased for the same thickness of material, the cutting speed will also increase accordingly. Therefore, if you want to obtain a faster cutting speed, it is best to choose a laser generator with a surplus of power.

Select the machine worktable size according to the max processed size of the material

For the CO2 laser cutting machine, the small size machine is 600*900mm; 1300*900mm, the big size machine is 1300*2500mm and 1500*3000mm, which can meet the cutting needs of various sizes of plates; the standard size of the fiber laser cutting machine is 1500*3000mm, which can meet the common plate cutting needs. If you need to cut larger materials, there are options for custom machines.

Select machine additional configuration according to the special needs of processing

For CO2 laser cutting machines, you can add a rotary axis for processing cylindrical materials; add a honeycomb table for processing soft materials such as cloth. For fiber laser cutting machines, you can add a rotary axis for cutting tubes; add a second worktable to increase feeding speed; add a fully enclosed structure to improve environmental performance. Reliable laser cutting machine manufacturers often recommend machine accessories suitable for processing needs according to user needs.

Preliminary selection for laser cutting machine manufacturers

After determining the machine to be purchased according to the cutting needs, the user needs to find a reliable laser cutting machine manufacturer. When making the initial selection of machine manufacturers, the following points can be used for reference.

Which channels are used to find laser cutting machine manufacturers

Now e-commerce is very developed, you can learn about laser cutting machine manufacturers all over the world on the Internet. At present, the more popular platforms include online markets such as Made in China, Alibaba, and European Express. Of course, each country also has its own domestic online platform market. You can learn about the price and performance of the machine from multiple website platforms for a comprehensive comparison.

Compare prices and configurations of laser cutting machine Manufacturers

The price of a laser cutting machine will vary greatly depending on the power of the laser generator, the brand of the laser generator, the size of the machine, and the specifications and configurations of the laser cutting head. The price range of a CO2 laser cutting machine is usually 3000-6000 US dollars, and the price range of a fiber laser cutting machine is from 10,000 to hundreds of thousands of US dollars. The price of the machine increases or decreases according to the configuration and requirements.

It is recommended to communicate with several powerful laser-cutting machine manufacturers with favorable prices first. In the process of communication, buyers should not only pay attention to the price but also know what kind of machine configuration the price can provide, whether to provide after-sales service, etc.

Read laser cutting machine manufacturer reviews

A good way to find out if a manufacturer is reliable is to check its public reviews. You can Google and social media and ask what other people think about the company. If the manufacturer has a lot of loyal customers, then its machines are worth considering. In addition, you can also ask the manufacturer if there are buyers in your city, so that you can actually find out.

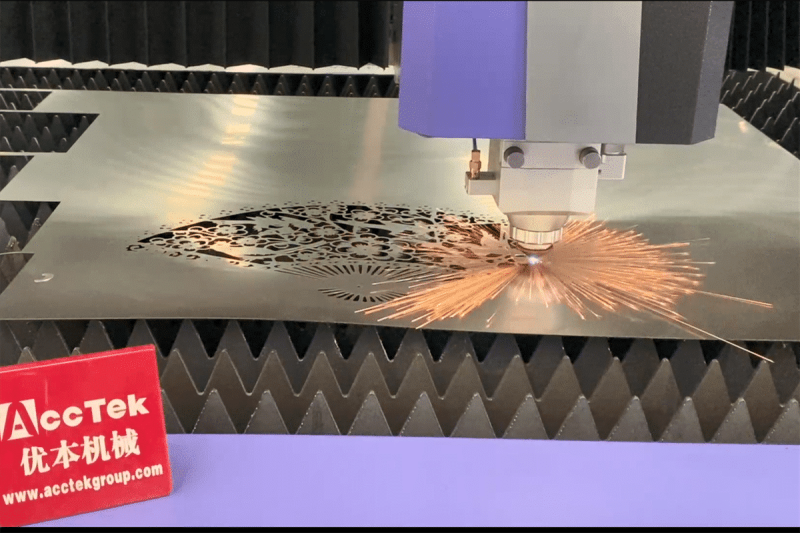

Understand the actual effect of laser cutting machine

You can view the actual processing effect of their machines through various channels such as the official website of the laser cutting machine manufacturer, YouTube videos, etc. In addition, you can also send samples to laser cutting machine manufacturers for staff to make samples. The manufacturer will provide you with a video of the sample processing process, so that you can understand the actual effect of the laser cutting machine, so as to judge whether the machine meets your processing needs.

Check machine offerings from laser cutting machine manufacturers

From the buyer’s point of view, the reliability of a laser cutting machine manufacturer is first reflected in the quality assurance of the products it provides. Powerful machine manufacturers usually cooperate closely with the world’s high-end parts suppliers, such as Japan Yaskawa, Germany Schneider, Japan Shimpo, etc. The use of high-end components makes the machine have higher cutting accuracy, efficiency and longer service life. When choosing a laser cutting machine manufacturer, you need to look at these main components to determine machine quality.

Cast aluminum beam

Most laser cutting machine manufacturers usually choose aviation aluminum to make the beam part. Cast aluminum beams have good toughness, corrosion resistance, and oxidation resistance. High-quality beams can increase processing speed and improve machine stability and durability.

Laser cutting head

At present, most laser cutting machine manufacturers choose auto-focus laser cutting head for their machines. The commonly used brands are CypCut, Raytools, WSX, Au3tech. The auto-focus function of the laser cutting head can shorten the punching time and improve the cutting quality. The high-quality laser cutting head has a smooth, efficient airflow design, is protected from dust.

Laser generator

The performance and quality of a laser cutting machine largely depends on the quality of its optical components, so the laser generator is a very important part of the machine. Professional laser cutting machine manufacturers have strict requirements on the selection of laser generators. The best fiber laser generators on the market include German IPG, British SPI, American n-light, and Chinese Raycus and Max laser generator.

Control system

Manufacturers of professional laser cutting machines prefer a visual control system that can support the import of various types of files. And only the control system has automatic typesetting function, which is very user-friendly. Therefore, when purchasing a laser cutting machine, you need to check whether the control system supports your file. Usually, the salesperson will introduce the supporting file types of different control systems, so that users can choose the appropriate control system.

Drives and Motors

Professional fiber laser cutting machine manufacturers usually cooperate with international leading driver and motor manufacturers. High-end drivers and motors effectively guarantee the high precision, high speed and high stability of the whole machine during laser cutting. So when you buy a machine, ask the manufacturer what drives and motors the machine uses. The configuration of different brands leads to different prices. So I suggest that you compare multiple sources and choose the most suitable driver and motor.

Transmission system

The quality of the transmission system affects the cutting accuracy of the laser cutting machine. When assembling the machine, the manufacturer needs to ensure the accuracy of the guide rail and rack, including the screw point of each rack, the splicing point of two racks, the straightness and horizontal accuracy of the guide rail, and the accuracy of the rack.

Drives and Motors

Professional fiber laser cutting machine manufacturers usually cooperate with international leading driver and motor manufacturers. High-end drivers and motors effectively guarantee the high precision, high speed and high stability of the whole machine during laser cutting. So when you buy a machine, ask the manufacturer what drives and motors the machine uses. The configuration of different brands leads to different prices. So I suggest that you compare multiple sources and choose the most suitable driver and motor.

Transmission system

The quality of the transmission system affects the cutting accuracy of the laser cutting machine. When assembling the machine, the manufacturer needs to ensure the accuracy of the guide rail and rack, including the screw point of each rack, the splicing point of two racks, the straightness and horizontal accuracy of the guide rail, and the accuracy of the rack.

Inspection of laser cutting machine manufacturer's factory

A formalized factory is the foundation of a laser cutting machine manufacturer. Generally speaking, a reliable laser machine manufacturer usually has more than 10 years of machine manufacturing experience. As a buyer, you need to investigate the factory scale and manufacturing standards of the laser cutting machine manufacturer to understand the professionalism of the manufacturer. If a factory follows strict production standards to manufacture the machine, then its laser cutting machine is worth buying.

Factory scale

A powerful laser cutting machine manufacturer will have its own design and development team and production team. Mechanical designers can redesign customized machines to ensure the optimal use of each component, and the production workshop is arranged in an orderly manner according to machine types and production schedules.

Assembly technology

Even with the same accessories, the running speed and cutting accuracy of the machine assembled by different skilled workers will be different. Therefore, a reliable laser cutting machine manufacturer will spend a lot of money to recruit excellent technical teams to assemble laser cutting equipment. These excellent technicians will assemble the machine completely in accordance with production standards to ensure that the machine has a better cutting effect.

Quality inspection and cutting commissioning

After the factory completes the assembly of the laser cutting machine, it needs to conduct strict quality inspection and debugging on each part of the machine before it can be officially delivered. Important components such as the bed, beams, guide rails, motors, drives, and lead screws need to undergo multiple inspections. In addition, engineers will debug the cutting effect and parameter settings to set the most suitable parameters for users.

Machine shipment

After a strict quality inspection stage, the factory will custom pack wooden boxes according to the size of the machine, and then ship the machine to the buyer’s location. Before delivery, the manufacturer will remind the buyer to prepare the required customs declaration documents, and provide the buyer with detailed logistics information and packing list at the time of delivery.

Learn about the services that laser cutting machine manufacturers can provide

When choosing a laser cutting machine manufacturer, people tend to prioritize price over service. But good service is as important as machine quality, especially after-sales service. No matter how advanced the laser cutting machine is, users will encounter various problems during use. In this case, it is very important for manufacturers to provide solutions to users in a timely manner. A powerful laser cutting machine manufacturer should provide one-stop service, including training during machine operation, as well as machine maintenance and debugging.

Pre-sale service

Professional laser cutting machine manufacturers will provide users with pre-sales consultation and guidance. The sales manager will provide users with machine selection plans based on various factors such as the thickness, size, use, and cutting speed requirements of the material to be processed by the customer. The content of the purchase plan will involve detailed information on all aspects of the machine, including configuration, price, parameter selection, payment method, delivery process, etc. In addition, customers can also mail samples to the manufacturer for cutting test, so as to accurately understand the cutting effect of the material.

In-sale service

After the customer pays the deposit and chooses the machine configuration, the manufacturer starts to produce the machine according to the customer’s requirements. The production workshop must be clean and orderly, and the factory can receive customers to visit the factory at any time. After the machine is assembled, the engineer conducts a cutting test on the machine and completes the adjustment of the parameters.

After-sales service

Users can only know the quality of the machine when it is in use. Therefore, when purchasing a laser cutting machine, be sure to choose a machine manufacturer that provides a warranty period. Under normal circumstances, 3 years for machinery warranty; 2 years for fiber laser generator; 1.5 years for core components, including controllers, cutting heads, motors, drives, transformers, chillers, switching power supplies, exhaust fan etc.

In addition to the warranty of the machine, when the user encounters a machine failure, the manufacturer’s engineer can also provide a quick response and solution. In addition, laser cutting machine manufacturers also provide on-site training and maintenance services, which often require paying engineers a certain fee.

Customized service

Different users have different processing needs and budget plans, professional laser cutting machine manufacturers can provide users with customized services. For example, if the user needs to cut both metal plates and metal tubes, the manufacturer can customize a laser cutting machine with rotary axis for the user. This not only satisfies the needs of the user, but also reduces the cost of purchasing multiple devices for the user. Custom-made machines can often complete the user’s cutting task within the best budget.

Free training

For users, especially those who are using laser cutting machines for the first time, technical guidance is very important. Professional technical guidance can help users save time in learning to operate the machine, and can effectively improve the quality of cutting workpieces. After the user receives the machine, the manufacturer’s engineers help the user to become an experienced laser cutting machine operator faster through remote guidance.

Summarize

AccTek Laser is a laser cutting machine manufacturer integrating R&D, production, sales and after-sales. We have mature machine manufacturing technology and professional engineers, before buying the machine, we will show you the cutting test video. Through sample testing, you can clearly know whether the machine can meet the processing needs. After receiving the machine, our engineers will promptly provide solutions to any technical problems encountered by users. At present, AccTek Laser has provided satisfactory metal laser cutting solutions for users in more than 100 countries.

AccTek will always be committed to providing customers with the most cost-effective machines and the best customer service. If you need us to recommend any laser cutting machine for your business, please feel free to contact us.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions