How to Choose The Right Laser Marking Machine For Your Business

Laser marking technology has become an integral part of various industries, offering precise and permanent marking solutions on a wide range of materials. Whether you’re in manufacturing, electronics, automotive, or any other industry, choosing the right laser marking machine is crucial for achieving optimal results. In this comprehensive guide, we’ll delve into the key factors to consider when selecting a laser marking machine, ensuring that your investment meets your specific needs and delivers the desired outcomes.

Table of Contents

Understanding laser marking technology

Laser marking is a process that can leave permanent marks on the surface of materials. It can leave permanent traceable marks on the surface of a series of materials such as stainless steel, carbon steel, plastic, wood, and rubber. These markings include serial numbers, barcodes, QR data matrix codes, or graphics and are primarily used to identify parts and products.

How laser marking works

Laser marking works by using a focused beam of light to mark the surface of a material. When a beam of light interacts with a material’s surface, it changes the material’s properties and appearance. This concentrated beam is targeted only at a designated area, allowing laser marking to create precise, high-quality, high-contrast marks. This feature makes laser marking machines ideal for high-precision and permanent marking applications.

Types of laser marking processes

There are several laser marking systems applicable in part manufacturing processes. Here are the four most common laser marking processes.

- Laser Engraving: Laser engraving is the most common marking method in part manufacturing and prototyping, suitable for working on materials like metals, ceramics, and plastics. Like any laser marking method, it delivers permanent marking, but it has less clarity than others. Laser engraving is a subtractive process, i.e., it involves using the laser beam to remove part of the material surface. The laser beam focusing on the surface turns the removed material into plasma or vapor removed by the fume extractor. On removal, it leaves an engraved marking that is easily felt by the fingers.

- Laser Etching: Laser etching is another marking method for making permanent marks on a workpiece. It commonly applies to metals such as etching aluminum, steel, stainless steel, lead, etc. The laser marking machine etches the workpiece by releasing pulsed laser beams on the workpiece surface. On hitting the surface, the material absorbs the beam and converts it to heat to melt the surface and raise it. The laser-etched surface requires less energy as it does not have depth, unlike laser engraving. Additionally, they are more visible, for example, laser etched aluminum is more visible than laser engraved aluminum.

- Laser Annealing: Laser annealing is a non-subtractive process commonly used for products with important dimensional accuracy. It involves using laser beams to slowly heat and cool metal surfaces to modify their color (yellow, red, or green) depending on the temperature of the metal’s surface. The laser annealing process is not suitable for non-ferrous metals and aluminum because their colors are not affected by the influence of heat and oxide.

- Laser Ablation: Laser ablation is the process of marking by removing coatings. Laser ablation creates marks by removing something other than material from a surface, usually paint, and can be used to remove portions of paint to mark identifiers such as barcodes. Laser ablation is the same as laser cleaning, the only difference is the application: the purpose of laser ablation is to mark, not to clean. In some cases, laser ablation is the fastest laser marking solution, such as removing paint faster than marking steel.

Different types of laser marking machines and their applications

There are several types of laser marking machines, each utilizing different laser sources and mechanisms to achieve specific marking effects. To obtain good marking results, you need to choose the correct laser marking machine according to the type of material. The following are different types of laser marking machines and their application scenarios.

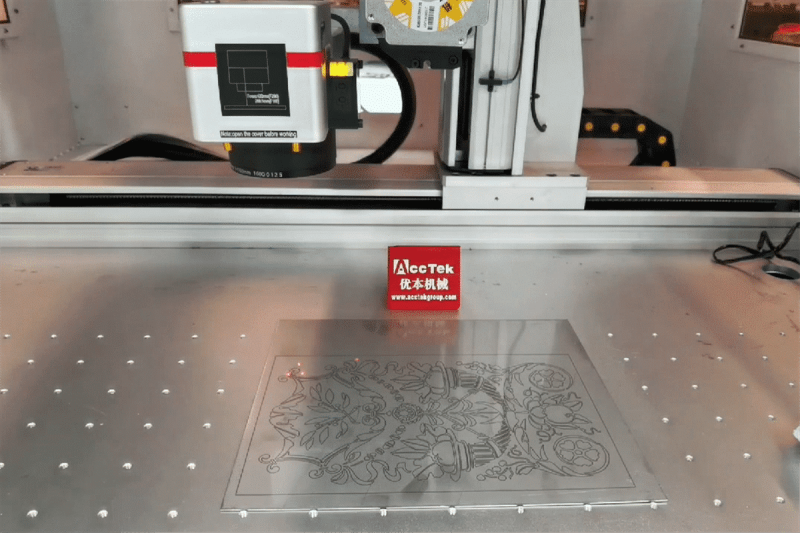

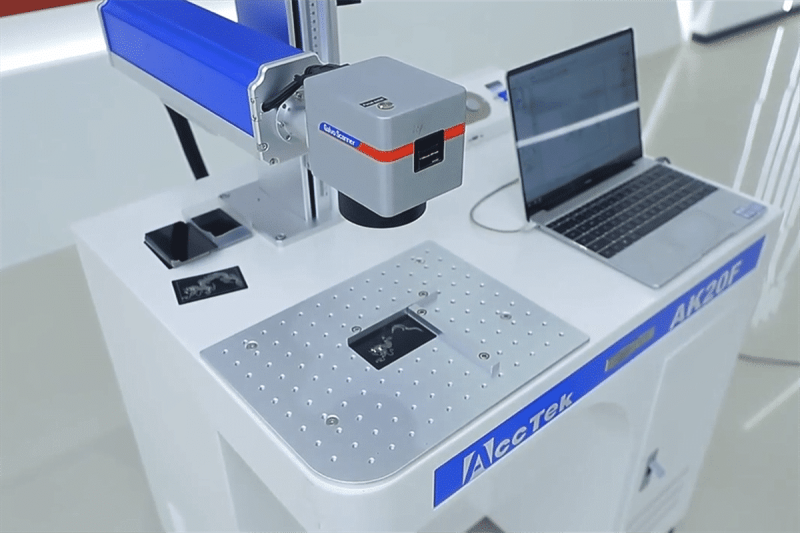

Fiber laser marking machine

- Metal Marking: A fiber laser marking machine is highly effective for marking metals such as stainless steel, aluminum, copper, and alloys. They are widely used in industries like automotive, aerospace, and electronics for part identification and traceability.

- Plastic Marking: Fiber laser marking machine can also mark certain types of plastics, providing a permanent and high-contrast mark. This is useful in the production of electronic components and consumer goods.

CO2 laser marking machine

- Organic Materials: The CO2 laser marking machine is suitable for marking organic materials like wood, leather, glass, and certain types of plastics. They are commonly used in the packaging, arts and crafts, and promotional products industries.

- Paper and Cardboard: CO2 lasers are used for marking expiration dates, serial numbers, or other information on paper and cardboard packaging.

UV laser marking machine

- High-Contrast Marking on Plastics: UV lasers are effective for marking plastics, especially in applications where a high-contrast mark is required. This is often used in the medical device and electronics industries.

- Semiconductor Marking: UV lasers are used for marking semiconductor materials, providing precise and high-resolution marks without damaging the sensitive components.

Green laser marking machine

- Sensitive Materials: Green lasers are suitable for marking sensitive materials such as plastics and certain types of ceramics. They are used in applications where heat generation needs to be minimized.

- High-Speed Marking: Green lasers are often chosen for high-speed marking applications due to their shorter wavelength.

YAG laser marking machine

- Deep Engraving on Metals: YAG lasers are capable of deep engraving on metals, making them suitable for applications where a more pronounced mark is required. This is often used in the tool and die industry.

- Ceramic Marking: YAG lasers can mark ceramics effectively, making them useful in industries like electronics and medical devices.

Diode-Pumped laser marking machine

- Plastic and Metal Marking: Diode-pumped lasers are versatile and can be used for marking both plastics and metals. They are chosen for applications where a compact and efficient solution is required.

Q-Switched laser marking machine

- High-Speed Marking: Q-switched lasers are capable of producing short bursts of energy, making them suitable for high-speed marking applications. This is useful in industries where production efficiency is a key consideration.

Key factors in choosing the right laser marking machine

Choosing the right laser marking machine involves considering several factors to ensure it meets your specific needs and applications. Here are some key factors to consider:

- Laser Type: Fiber, CO2, or UV: Different lasers are suitable for different materials. Fiber lasers are excellent for metals, CO2 lasers for organic materials like wood and plastics, and UV lasers for certain plastics and sensitive materials.

- Power Output: The power of the laser determines its capability to mark different materials and the speed of marking. Choose a power level based on the materials you will be working with.

- Wavelength: The wavelength of the laser affects its absorption by materials. Make sure the wavelength is appropriate for the materials you intend to mark.

- Marking Speed and Precision: Consider the required marking speed and precision for your applications. Higher power lasers may offer faster marking speeds, but this can also depend on the specific machine and its features.

- Marking Area Size: Ensure that the marking area size is sufficient for your specific applications. Consider both the maximum and minimum sizes needed, considering scalability for future needs.

- Software and Control System: The software that comes with the laser marking machine should be user-friendly and provide the necessary features for your applications. Check if it supports vector and raster marking.

- Integration and Connectivity: Check if the laser marking machine can easily integrate into your existing workflow. Consider factors such as compatibility with design software and whether it supports file formats commonly used in your industry.

- Ease of Use and Maintenance: Look for a machine that is easy to set up and operate. Consider the maintenance requirements and how easy it is to replace consumables like laser lenses.

- Cooling System: Laser marking machines generate heat, so a reliable cooling system is essential. Ensure that the machine has an efficient cooling system to maintain stable operation.

- Safety Features: Check for safety features such as interlocks, fume extraction systems, and compliance with safety standards to ensure the well-being of operators.

- Budget: Consider your budget constraints. Laser marking machines vary in price based on their features and capabilities. Make sure to balance your requirements with the available budget.

- Customer Support and Training: Look for a manufacturer that provides good customer support, training, and documentation. This is crucial for troubleshooting and maximizing the capabilities of your laser marking machine.

- Reviews and References: Read reviews from other users and seek references from the manufacturer. This can provide insights into the real-world performance and reliability of the laser marking machine.

By carefully evaluating these factors, you can choose a laser marking machine that aligns with your specific needs and ensures successful and efficient marking for your applications.

Summarize

The choice of the laser marking machine depends on the material to be marked, the desired marking effect, production volume, and other specific requirements. Each type of machine has its advantages and limitations, and selecting the right laser marking machine is crucial for achieving the desired results in a particular application. It will directly affect the efficiency and quality of your marking process. By considering the factors outlined in this comprehensive guide, you can make an informed decision that aligns with your specific application requirements and business goals. If you want to get more information about laser marking machines, you can contact us at any time. AccTek Laser engineers will provide a matching solution based on your specific application and provide you with detailed pricing information.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions