How to Extend The Service Life of a Laser Welding Machine?

As an important process in modern manufacturing, laser welding technology is widely used in automobiles, electronics, aerospace, and other fields. With the increasing popularity of laser welding technology, people have become interested in the service life of laser welding machines and the factors that affect their service life. As the core equipment for realizing this technology, laser welding machines not only ensure production efficiency but also face the test of service life.

This article will discuss the service life of the laser welding machine, analyze the working principle of the laser welding machine, the key factors that affect the life of the machine, and discuss methods to extend the life of the machine, to provide an effective guarantee for its reliable and stable w

Table Of Contents

Working principle of laser welding machine

The laser welding machine is a high-precision welding equipment that uses a laser beam to melt and connect workpieces. The specific working principle is as follows:

- Laser emission: Laser welding machines use laser generators to produce high-intensity laser beams. In a laser generator, laser energy is excited by a laser medium (such as a laser diode), causing its atoms or molecules to be at a high energy level and then releasing photons to form laser light.

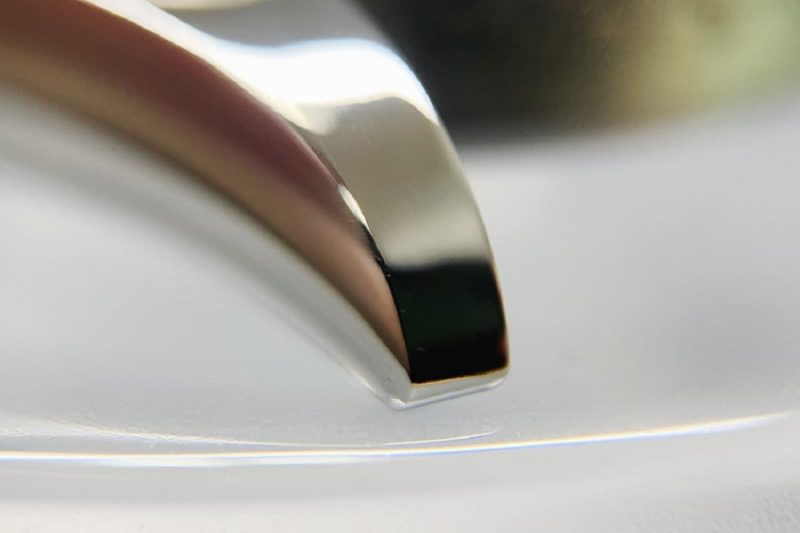

- Laser focusing: Focusing a laser beam to a very small focal point through optical components such as lenses or mirrors. This can increase the energy density of the laser energy and achieve the purpose of melting materials at high temperatures.

- Energy transfer: The focused laser beam irradiates the surface of the welding material with extremely high energy density. The energy is locally absorbed, causing the surface of the material to heat up rapidly and form a molten pool.

- Molten pool formation: The high-energy-density laser beam causes the material in the welding area to melt rapidly, forming a molten pool. Under the action of the laser beam, the material in the molten pool rapidly cools and solidifies to achieve welding. Laser welding is characterized by the small size of the molten pool and controllable melting depth, thereby achieving high-precision and high-efficiency welding.

The service life of a laser welding machine will be affected by many factors. The general service life can be between 10,000 and 30,000 hours. However, this is only an estimate, and a fixed life span cannot be given simply and clearly. However, through reasonable use and maintenance, the life of the laser welding machine can be extended to a certain extent.

What are the factors that affect the life of a laser welding machine?

The life of a laser welding machine is affected by many factors, including the stability of electronic components, working environment, frequency of use and load, as well as usage technology and operating level. The following is a detailed description of these factors:

Stability of electronic components

The stability of electronic components has a profound impact on machine performance and reliability. The following is the impact of electronic components on the life of laser welding machines:

- Heat and electromagnetic radiation: When the laser welding machine is working, the electronic components in the laser and control system are usually irradiated by a high-energy laser, generating a large amount of heat. This heat may cause an increase in the temperature of electronic components or the effects of electromagnetic radiation, affecting their performance and stability.

- Aging and failure: Long-time working and high-temperature environments may cause aging and damage to electronic components. The aging of electronic components may manifest itself as performance degradation, increased resistance, decreased capacitance, etc., which ultimately leads to reduced performance or even failure of the laser welding machine.

Working environment

The working environment of the laser welding machine directly affects its performance and life. Here are a few key aspects of how the work environment affects the life of your laser welding machine:

Temperature and humidity control

- High-temperature environment: Working in a high-temperature environment with a laser welding machine may cause the temperature of electronic components to rise, increasing the risk of failure. Long-term high-temperature operation may also cause expansion of mechanical components, exacerbating friction and wear.

- Low-temperature environment: Low-temperature environment may cause some mechanical parts to become brittle, making them more susceptible to impact and damage.

Cleanliness

- Dirt and Dust: Dust and particles in the air may adhere to the laser generator’s optical components and affect the transmission of the laser beam. This can lead to poor welding quality and increased wear on optical components, and may also affect heat dissipation and cooling.

Stable power supply

- An unstable power supply may cause fluctuations in laser generator power, affecting welding stability. Working under an unstable power supply for a long time may cause damage to electronic components.

Frequency of use and load

High-frequency use and overloaded working conditions are one of the main reasons for shortening the life of laser welding machines. Here is a detailed explanation of these two factors:

Frequency of use

- Excessive use: High-frequency use means that the laser welding machine is in working condition for a long time. Such overuse may cause the key components inside the machine, such as laser generators and other electronic components, to age, fatigue, and eventually fail.

Load

- Excessive loads: If the laser welding machine is used outside the designed load range, the mechanical components will be subject to additional stress and friction, increasing the possibility of loss and wear.

- Mechanical wear: Excessive load may cause mechanical components, such as welding guns, focus adjustment mechanisms, etc., to withstand forces exceeding design requirements during work, causing these components to wear out faster, thus affecting the overall lifespan.

Usage technology and operational level

The usage technology and operating level of the laser welding machine are directly related to the safety, efficiency, and life of the machine. The following is a detailed description of the impact of these two aspects on the life of the laser welding machine:

Precision operation technology

- Welding parameter settings: Laser welding involves the adjustment of multiple parameters, including power, focal length, scanning speed, etc. Reasonable parameter settings can ensure welding quality, reduce the burden on the machine, and extend the service life.

- Welding seam control: Skilled welding technology can achieve precise welding control and reduce the heating range of the welding area, thus reducing the thermal stress on the machine and helping to extend the service life.

Safe operation level

By considering these factors and formulating scientific maintenance plans and reasonable operating procedures, the service life of the laser welding machine can be effectively extended and its stability and work efficiency can be improved.

How to extend the service life of a laser welding machine?

To ensure stable operation and extend the service life of the laser welding machine, a series of scientific and reasonable maintenance and operation measures need to be taken. The following is a detailed description of how to extend the service life of a laser welding machine:

Provide an appropriate working environment

- Control temperature and humidity: Laser welding machines have higher requirements for temperature and humidity in the working environment. Temperatures that are too high or too low can have adverse effects on electronic components and optical components. Therefore, ensure that the temperature and humidity of the working environment are within the appropriate range.

- Keep the air clean: Avoid using the laser welding machine in an environment with too much dust and particulate matter to prevent these impurities from entering the machine and affecting the clarity of optical components and the stability of electronic components.

Reasonable planning of usage plan

- Avoid overuse: High-frequency use for a long time will increase the wear and heat stress of the machine, so the use plan should be planned reasonably to avoid overuse, especially under high-power operation.

- Reasonably arrange the load: avoid overload operation and ensure that the welding machine is within the normal working load range. Excessive loads may cause damage and excessive wear to mechanical components.

Regular maintenance and upkeep

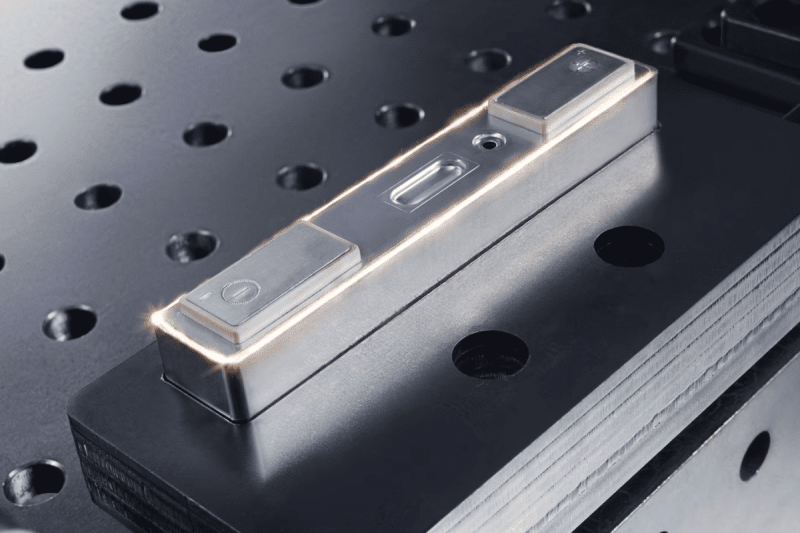

- Cleaning and lubrication: Clean the laser welding machine regularly to remove dust and impurities and keep the optical components clean. At the same time, the mechanical parts are lubricated to reduce friction losses.

- Component replacement and repair: Regularly check various components of the machine, such as electronic components, optical components, and mechanical structures, and promptly replace or repair worn or aging components if found.

Optimize the use of technology and level

- Training operators: Provide professional training to ensure that operators are proficient in the operating technology of laser welding machines and avoid machine failures caused by misoperation.

- High-level maintenance: Ensure you have high-level technicians performing maintenance and repairs who can quickly and accurately diagnose problems and take appropriate repair measures.

Regular monitoring and surveillance

- Performance monitoring: Use performance monitoring tools regularly to detect the operating status of the laser welding machine and promptly detect performance degradation or abnormalities for timely adjustment and repair.

- Fault diagnosis: Establish a complete fault diagnosis system, conduct regular comprehensive inspections of the laser welding machine, discover potential problems, and solve them in time.

Update and upgrade equipment

- Follow up on new technologies: Timely update the software and hardware of laser welding machines to adapt to new market demands and the development of new technologies.

- Equipment upgrade: When technical conditions permit, upgrade old equipment to improve its performance and service life.

Through the reasonable implementation of the above series of measures, the service life of the laser welding machine can be effectively extended, its work efficiency can be improved, and maintenance costs can be reduced, thereby better meeting the needs of modern manufacturing.

Summarize

As an important industrial technology, the service life of laser welding machines directly affects production efficiency and cost control. In actual production, only by comprehensively considering these factors can enterprises extend the service life of laser welding machines to the greatest extent, improve production efficiency, and reduce maintenance costs. Regular cleaning, lubrication, and inspection and replacement of worn parts can effectively prevent potential failures and keep the machine running efficiently.

Therefore, attention to and management of the service life of laser welding machines will play an increasingly important role in the manufacturing industry. If you are looking for a reliable way to join metals quickly and accurately, please feel free to contact AccTek Laser. We will answer any questions you have or provide professional advice on laser welding machine maintenance.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions