Operating environment requirements

When using a laser welding machine, it is necessary to create a good operating environment for the machine. This is the prerequisite for the long-term stable use of the machine. The following are the requirements for the machine’s operating environment:

- The laser welding machine should be installed in a level and stable place and is not allowed to be used in an inclined place.

- Please use the laser welding machine in an environment with an ambient temperature of 5°C to 30°C and a humidity of ≤35%. At the same time, pay attention to the fact that the ambient temperature should not fluctuate too much.

- It is prohibited to use the laser welding machine in the following environments: an environment with oil pollution, an environment with vibration, an environment with corrosion, an environment with high-frequency noise, a humid environment, and an environment containing high concentrations of carbon, nitrogen, and sulfur oxides (CO2, NOX, SOX) environment.

- Laser welding machines have high requirements for environmental cleanliness. Please handle the laser welding head carefully when using or moving the machine to prevent dust or other contamination. Dust on the surface of the hand-held laser welding head may cause the lens to heat up and be damaged, resulting in the attenuation of the machine’s output power or failure to emit light.

- In winter, if the ambient temperature drops below 0°C, the water in the water tank will freeze and the water tank may freeze. Therefore, special attention should be paid to ensuring that the ambient temperature of the laser welding machine does not fall below 0°C in winter. If the ambient temperature drops below 0℃, please drain the water in the water tank first.

Laser welding machine maintenance

Many things need to be maintained during the use of laser welding machines, which is also the most important part of machine maintenance. Usually, before we start welding work, we need to check all components of the machine to ensure that the machine can operate normally. These maintenance items may take some time, but they are not complicated. By following these basic maintenance steps, you can extend the life of your machine components and save money. This is rewarding work. To keep your laser welding machine in good condition, the following maintenance items need to be performed.

- Clean the laser welding machine. Laser welding machines will accumulate dust during use. These substances will affect the stability of laser power output and welding efficiency, and will also accelerate the wear and tear of the machine. Therefore, regular cleaning of the machine is very necessary. Before cleaning the machine, you first need to cut off the power supply, wait for the machine to cool down, then wipe the areas with stains and dust, and place the machine in a dry and clean environment after cleaning.

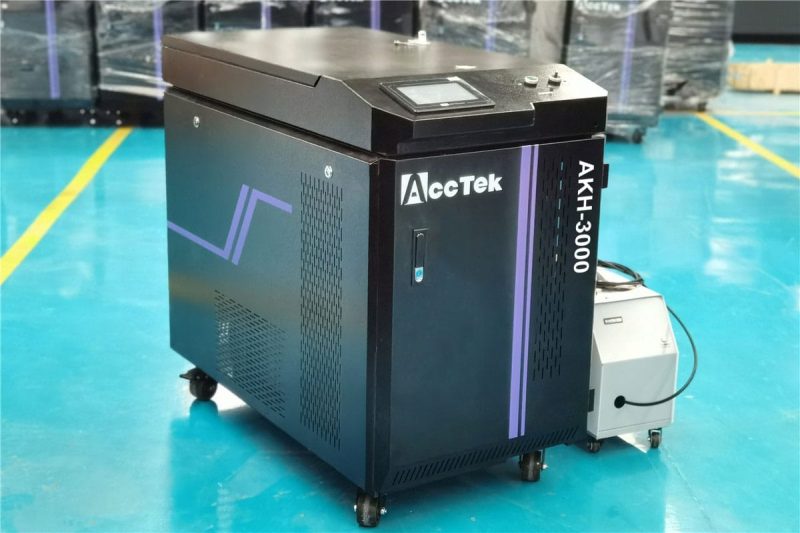

- Check the machine guard. Laser welding machine protective covers protect the laser generator and other key components inside the machine from dust and other debris. During long-term use of the machine, the outer shell will inevitably be deformed or rusted due to external collisions. In this case, the outer shell must be repaired or replaced in time.

- Check the cooling system. The cooling system is an important part of the laser welding machine and can ensure the normal operation of the laser welding machine. For water-cooled laser welding machines, you need to pay attention to the use of cooling water. When the amount of water is insufficient, it needs to be added to the appropriate water level. When the water quality becomes turbid, clean water sources should be replaced in time. For air-cooled laser welding machines, clean and dry compressed air should be used regularly to blow away the accumulated dust in the machine.

- Check machine consumables and replace them. Laser welding machines have a long service life, but during long-term use of the machine, parts will be consumed and worn, such as protective lenses, nozzles, and other conventional consumables. These components usually have a certain service life. After the service life is exceeded, it will hurt the performance of the machine. Therefore, when using a laser welding machine, you need to pay attention to checking the use of these components, and if any problematic components are found, repair or replace them in time to avoid affecting the welding quality.

- Check the laser beam quality. Laser welding machine operators can often use black paper to check the output spot of the laser generator. Once the spot is found to be uneven or the energy is reduced, the resonant cavity of the laser generator should be adjusted in time to ensure the beam quality of the laser output.

- Calibrate the machine regularly. The laser welding machine is a high-precision welding tool that requires regular calibration to ensure working accuracy and stability. Calibration matters include the position and angle of the equipment, laser power, zero point error, etc. Calibration can be done by instruments, or by manufacturers or professionals.

- Auxiliary gas check. Laser welding machines typically require auxiliary gases such as argon or nitrogen. Check gas supply and pressure regularly to ensure consistent and reliable flow during welding operations. During work, replace gas bottles as needed.

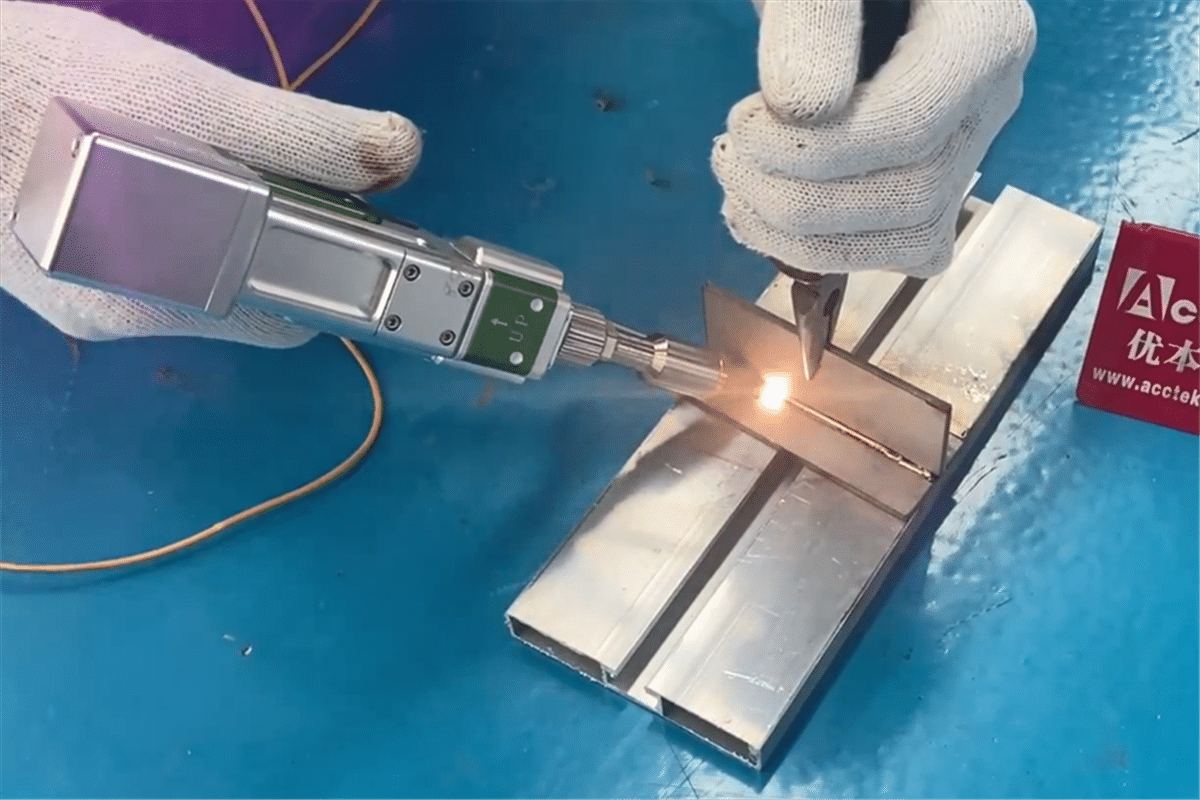

Laser welding gun maintenance

The laser welding gun is a component that directly performs welding work. The quality of welding has a great relationship with the use of the welding gun components. Therefore, before each use of the machine, the laser welding joint needs to be inspected to see if the components are contaminated or damaged. Laser welding can only be started after ensuring that all parts are clean and intact. There are the following points regarding the maintenance of laser welding guns.

- Pay attention to the laser welding gun temperature. The temperature of the laser welding gun will increase during long-term use, especially in hot summer, so it is best to start laser welding work in well-ventilated conditions.

- Check the contact tip. During the welding process, the contact tip will be worn or stuck with a spatter, which will affect the shape of the weld. If the contact tip is damaged, it needs to be replaced in time.

- Check protective lenses. The protective lens inside the laser welding gun can effectively protect the focusing lens from damage. When the laser energy suddenly weakens, you need to check whether the protective lens is contaminated or damaged, and clean or replace the lens according to the specific situation.

- Check the spring hose. Clean and replace spring hoses regularly. After the spring hose is used for a long time, a large amount of material waste will accumulate, and the oil stains on the hose must also be cleaned. If the spring hose is miswired or severely deformed, replace it with a new hose.

Summarize

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.