How to Maintain The Cooling System of The Laser Cleaning Machine?

In the normal operation of laser cleaning machines, the cooling system plays a vital role. It not only effectively dissipates the heat generated by the laser generator and keeps the laser generator within the appropriate operating temperature range, but also helps maintain the stability and performance of the equipment. Therefore, regular maintenance of the cooling system of the laser cleaning machine is a key part of ensuring long-term and efficient operation of the equipment.

This article will explain the working principle of laser cleaning machines, several common cooling system types, specific maintenance methods of laser cleaning machine cooling systems, and the importance of cooling systems, so as to ensure the efficient performance of laser cleaning machines during operation.

Table Of Contents

How does the laser cleaning machine work?

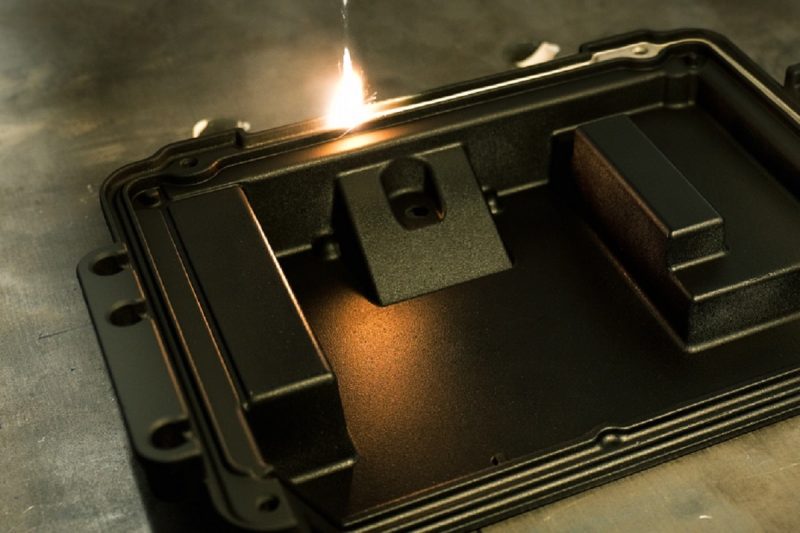

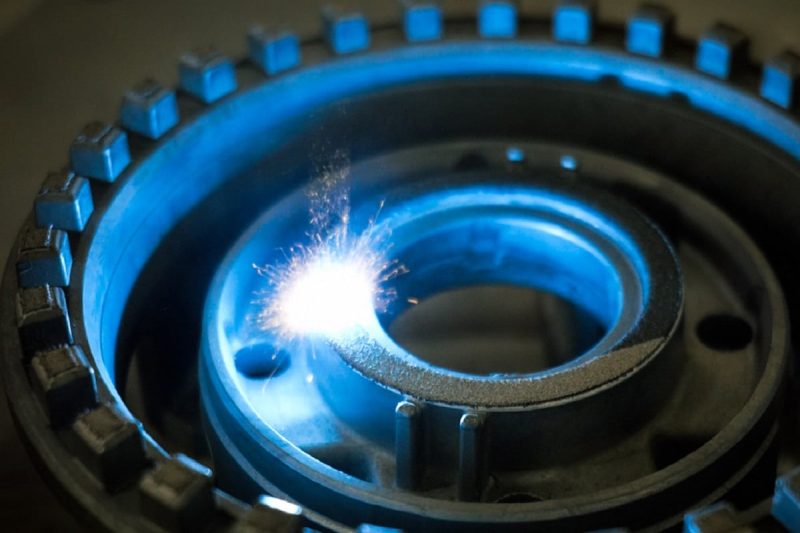

The importance of cooling systems in equipment performance and stability cannot be ignored, especially in high-power equipment such as laser cleaning. Understanding how a laser cleaning machine works can help you better understand the critical role of the cooling system. The working principle of laser cleaning machines is based on the application of laser technology. Its core component is the laser generator, which generates a high-energy laser beam. In operation, the laser beam is focused through an optical system and aimed at the target surface. When the laser beam intersects the target surface, light-matter interaction occurs. This process includes the following key steps:

- Absorption: The material on the target surface absorbs the energy of the laser beam.

- Conduction: The absorbed energy causes an increase in the temperature of the target surface, causing the target surface material to conduct heat.

- Evaporation or removal: Under the action of a high-power laser beam, dirt, coatings, or other contaminants on the target surface may evaporate, sinter, or decompose, thereby being cleaned or removed.

Because this process involves the concentrated release of energy, laser generators, and optical components generate large amounts of heat when operating. To maintain the normal operation of the equipment and ensure the stability of the laser beam, the cooling system has become a crucial component.

Common types of laser cleaning machine cooling systems

Before we start discussing the maintenance of the cooling system, let’s review the common types of laser-cleaning machine cooling systems, including water cooling systems, air cooling systems, liquid nitrogen cooling systems, and refrigerator cooling systems. Each type has its unique working principle and applicable scenarios.

Water cooling system

A water cooling system is one of the most common cooling systems for laser cleaning machines. It uses water to cool laser generators and other heat-sensitive components. Water cooling systems usually include a cooling water tank, water pump, cooler, and cooling water pipes. The heat generated by the laser generator is dissipated through the cooling water circulation through the cooler and then is taken away by the cooling water. The advantages of this system include good heat dissipation and high stability, but it requires regular maintenance of water quality and prevention of cooling water freezing.

Air cooling system

The air cooling systems use air to cool laser generators and other heat-sensitive components. Such systems typically include fans and heat sinks that move air to achieve a cooling effect. The advantage of the air cooling system is that it is relatively simple and does not require the maintenance of the water cooling system, but the heat dissipation effect is not as good as that of the water cooling system, so it is suitable for lower power laser cleaning machines.

Liquid nitrogen cooling system

The liquid nitrogen cooling system uses liquid nitrogen to cool the laser generator. The low temperature of the liquid nitrogen can quickly reduce the temperature of the laser generator. The advantage of this system is that the cooling effect is very good and can be used in high-power laser cleaning machines. However, the cost of liquid nitrogen is relatively high, and special equipment is required to handle liquid nitrogen.

Refrigerant cooling system

Refrigerator cooling systems use refrigerators to reduce the temperature of laser generators and other heat-sensitive components. Refrigerators absorb and reject heat by circulating refrigerant to keep the temperature of the system stable. The advantage of this system is that it has high stability and is not affected by the ambient temperature, but it requires additional energy supply and maintenance of the refrigerator.

The importance of regular maintenance of the cooling system of laser cleaning machines

The cooling system is very important to the laser cleaning machine. The importance of regular maintenance is mainly reflected in the following aspects:

Stability and performance

Laser cleaning machines generate a lot of heat when working, especially the laser generator and optical components. If these parts overheat, it will cause the device’s performance to degrade and possibly even cause malfunction. The cooling system maintains these key components within a suitable temperature range by dissipating heat to ensure the stability and high-performance operation of the laser cleaning machine.

prevent damage

Overheating can cause damage to critical components of the equipment. Laser generators and optical components are temperature sensitive, and if overheating is not handled properly, it can result in shortened equipment life, reduced performance, or even equipment failure, requiring expensive repair or replacement.

extend your life

Cooling systems help extend the life of your laser cleaning machine. By effectively controlling the temperature and reducing the loss caused by the heating of the equipment, the durability of the equipment can be improved, maintenance costs can be reduced, and the service life of the entire system can be extended.

maintain cleaning effect

During the cleaning process, the laser cleaning machine applies a high-energy laser beam to the target surface. The stability of the cooling system is directly related to the stability of the laser beam, thus affecting the consistency and accuracy of the cleaning effect. A good cooling system helps ensure precise aiming of the laser beam and reliable cleaning results.

safety

Overheating may not only affect the performance of the equipment but may also cause the equipment to overheat and cause safety hazards. The normal operation of the cooling system helps avoid safety issues caused by equipment overheating and ensures the safety of operators and equipment.

How to maintain the cooling system of the laser cleaning machine?

Regular maintenance of the cooling system of the laser cleaning machine is an important step to ensure the stable operation of the equipment and extend its life. Here are some suggestions for maintaining the cooling system of your laser cleaning machine:

Check your water cooling system regularly

- Check the quality of the cooling water: Check the quality of the cooling water regularly to ensure that the water is clean and free of impurities and pollution. If the water quality is found to be poor, replace the cooling water in time to avoid adverse effects on the system.

- Clean your cooler: Clean your cooler regularly to prevent the build-up of dirt and scale. Use a suitable cleaning agent and follow the manufacturer’s recommendations. Cleaning the cooler helps improve heat dissipation and ensures proper system operation.

- Check the operating status of the water pump: Check the operating status of the water pump regularly to ensure that the water pump can supply water normally. Lubricate the water pump bearings and check that the seals are intact. If any abnormality is found in the water pump, replace or repair it in time.

- Prevent freezing: In cold environments, measures need to be taken to prevent cooling water pipes from freezing. Consider using antifreeze or draining the water cooling system when the equipment is shut down.

Clean and maintain air cooling systems

- Clean the fans and heat sinks: Regularly clean the dust and debris on the fans and heat sinks in the air cooling system. It is recommended to use compressed air or a soft brush for cleaning to ensure good heat dissipation.

- Check the operating status of the fan: Check the operating status of the fan regularly to ensure that the fan can operate normally and there is no abnormal sound or vibration. When abnormalities are found, replace or repair the fan promptly.

- Maintain clear air ducts: Check the air circulation channels to ensure that air flows smoothly through the cooling components. Maintain ventilation by clearing obstructions that may block passageways.

Maintenance of liquid nitrogen cooling system

- Ensure liquid nitrogen supply: Regularly check the supply of liquid nitrogen to ensure safe storage of liquid nitrogen tanks and replenish them as needed. In addition, the stability of the liquid nitrogen supply also needs to be ensured.

- Clean the system regularly: The pipes and components in the liquid nitrogen cooling system need to be cleaned regularly to prevent the accumulation of dirt from affecting the normal operation of the system. It is recommended to use appropriate methods for cleaning.

- Check the cooling effect: By monitoring the temperature and cooling effect of the laser generator, abnormalities in the liquid nitrogen cooling system can be discovered in time and dealt with to ensure that the cooling effect is within the expected range.

Maintenance of refrigerant cooling systems

- Check the status of the refrigerator: Check the operating status of the refrigerator regularly to ensure that it can operate normally. Clean the dust and dirt on the refrigerator in time to maintain good heat dissipation.

- Check the refrigerant: Make sure there is enough refrigerant in the refrigerator and add or replace as needed. The stability of the refrigerant contributes to the long-term operation of the machine.

- Maintenance of cooling pipes: Check the cooling pipes for leaks and repair leaks in time to ensure the sealing of the cooling system. In addition, the tightness of pipe connections needs to be checked regularly.

Preventative maintenance cooling system

- Train operators: Make sure laser cleaning machine operators have the necessary training and understand how to properly operate and monitor the cooling system. They should understand how to identify potential problems and know what actions to take if needed.

- Regularly replace key components: According to the manufacturer’s recommendations, regularly replace key components in the cooling system, such as water pumps, fans, refrigerants in refrigerators, etc. This can help prevent failures caused by component aging.

- Establish maintenance records: Establish detailed maintenance records, including maintenance dates, maintenance content, replaced parts, and other information. Through the establishment of maintenance records, we can better understand the operating status of the equipment and detect potential problems promptly.

Summarize

The cooling system of the laser cleaning machine is a key component to ensure the normal operation of the equipment and increase the life of the equipment. Different types of cooling systems have their advantages, disadvantages, and applicable scenarios. Therefore, when selecting a cooling system, you need to fully consider the power, working environment, and budget of the laser cleaning machine. By properly selecting and maintaining the cooling system, you can ensure the efficient operation of your laser cleaning machine, providing cleaning solutions for a variety of industrial applications.

At AccTek Laser, we understand the importance of a well-maintained cooling system to keep your laser cleaning machine functioning. Our state-of-the-art equipment is designed with durability and efficiency in mind. As a leading provider of laser cleaning solutions, we can provide you with high-quality products that exceed industry standards. Our team of experts is dedicated to providing unparalleled customer support, ensuring you can contact us for advice or assistance at any time. Boost your cleaning capabilities with AccTek Laser, combining innovation and reliability. Contact us today to experience the future of laser cleaning technology.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions