Understanding CO2 Laser Cutting Machines

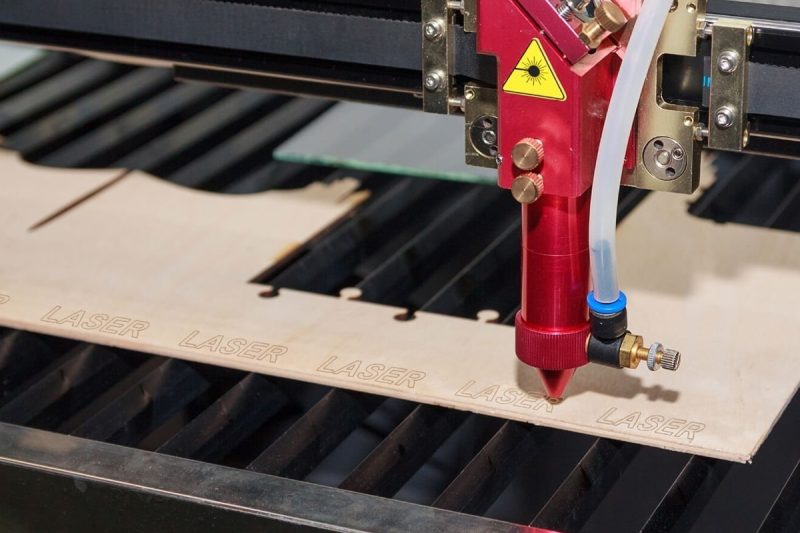

What Is a CO2 Laser Cutting Machine?

How Does It Work?

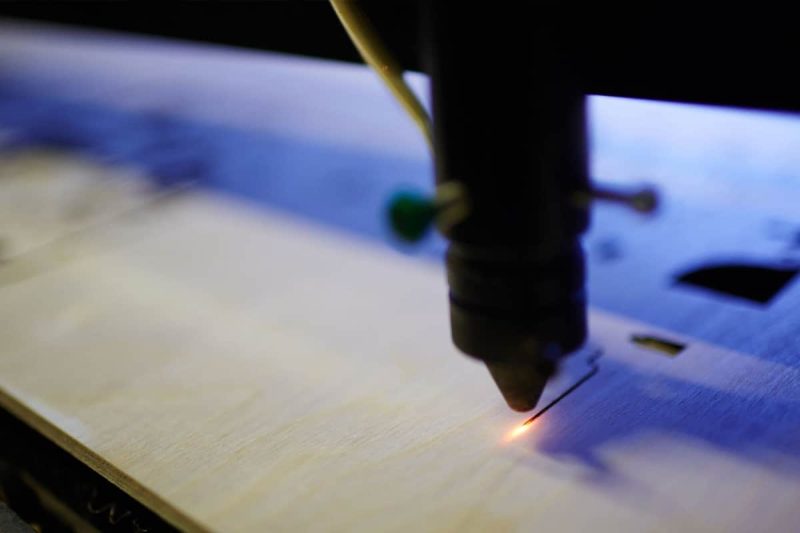

The operation of a CO2 laser-cutting machine involves a few key steps:

- Laser Generation: An electrical current is applied to a gas mixture (typically carbon dioxide, nitrogen, hydrogen, and helium), creating a powerful laser beam.

- Beam Focusing: This beam is then directed through mirrors and focused through lenses, achieving a narrow, intense spot of energy.

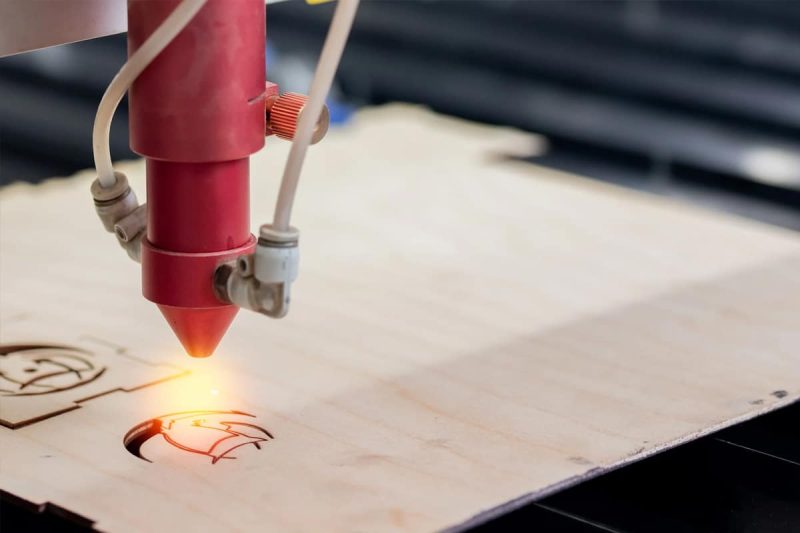

- Material Interaction: When the focused laser beam hits the surface, it rapidly heats the material to its melting or vaporization point, allowing precise cuts and engravings.

- Computer Numerical Control (CNC): CO2 laser machines are typically operated through CNC systems, which direct the laser head’s movement, ensuring intricate designs are accurately replicated.

Advantages of CO2 Laser Cutting Machines

CO2 laser cutting machines offer several benefits that make them an appealing choice for businesses and hobbyists alike:

- Precision and Accuracy: CO2 lasers can achieve extremely fine cuts with tolerances as low as 0.1 mm, making them ideal for detailed work and complex designs.

- Versatility: These machines are capable of working on various non-metal materials, including wood, acrylic, leather, glass, and certain plastics, which broadens their range of applications.

- Efficiency: CO2 lasers have relatively high cutting speeds, which increases productivity and allows for higher output, especially valuable in mass production.

- Quality of Finish: The laser’s non-contact nature means it cuts without physically touching the material, reducing the likelihood of warping or deformation. This process also leaves smooth, precise edges that often require minimal post-processing.

- Non-Contact Cutting: The laser beam’s non-contact nature reduces wear and tear on the machine itself and minimizes the physical stress on the material.

Materials Suitable for CO2 Laser Cutting

CO2 laser cutting machines are known for their adaptability, especially when working with non-metallic materials. The most common materials that can be effectively cut or engraved with a CO2 laser include:

- Wood: Ideal for cutting and engraving wooden items such as signs, furniture, and art pieces.

- Acrylic: Popular for creating signage, display pieces, and decorations, thanks to its clean, polished edges after laser cutting.

- Plastics: Certain plastics, such as ABS and polycarbonate, can be cut with CO2 lasers, although testing is recommended for compatibility.

- Leather and Fabrics: CO2 lasers are widely used for customizing leather products, including accessories and apparel.

- Glass (for Engraving): While not suitable for cutting, CO2 lasers can engrave glass surfaces to create decorative designs or personalized items.

- Paper and Cardboard: Perfect for intricate cuts, CO2 lasers are used to create custom invitations, packaging, and other paper goods.

Potential Business Opportunities

Custom Fabrication Services

Offering custom laser cutting and engraving services caters to a growing market that demands unique, one-off parts and designs.

- Applications: CO2 laser cutting machines are ideal for prototyping, short-run production, and custom parts manufacturing. Designers, engineers, and makers frequently need bespoke components that can’t be mass-produced.

- Clients: Clients may include hobbyists, inventors, local businesses, and startups seeking specialized parts for product development.

- Opportunities: By offering on-demand fabrication, you can serve a diverse range of customers, from creating prototypes for startups to fabricating custom designs for artists and DIY enthusiasts.

Signage and Advertising

Signage is a lucrative field where customizability and precision are highly valued. CO2 laser cutting machines can produce eye-catching signs and advertising materials, helping businesses attract more customers.

- Products: Create high-quality, custom-made signs, dimensional letters, storefront displays, and exhibition materials.

- Materials: Popular materials for laser-cut signage include acrylic, wood, and MDF, which can be cut into various shapes and engraved with logos and designs.

- Clients: Small businesses, event planners, retail stores, and large corporations often need unique, branded signage to stand out.

- Opportunities: Signage and advertising materials are in constant demand across industries. Offering tailored signage solutions can lead to repeat clients and referrals, making it a stable revenue stream.

Personalized Gifts and Products

With customization becoming a popular consumer trend, CO2 laser cutting machines allow you to create unique, personalized products that add value and appeal to gift buyers.

- Products: Customized plaques, engraved glassware, personalized wooden items, keychains, coasters, jewelry, and custom phone cases.

- Marketplaces: Selling on online platforms like Etsy, and Amazon Handmade, and your website can reach a broad audience looking for one-of-a-kind items.

- Occasions: Personalized gifts are especially popular for weddings, birthdays, corporate events, and holidays, providing seasonal spikes in demand.

- Opportunities: Customization not only enhances the value of everyday items but also appeals to consumers seeking unique gifts. By creating personalized products, you can tap into the lucrative custom gift market.

Architectural Models and Prototypes

Architects, designers, and engineers frequently need detailed models and prototypes to demonstrate their concepts. A CO2 laser cutting machine allows you to produce these components with high precision.

- Services: Cut and engrave intricate model components, landscape features, and prototype parts to showcase designs in 3D.

- Materials: Ideal materials for architectural models include acrylic, wood, and cardboard, which can be laser-cut to capture fine details.

- Clients: Architectural firms, construction companies, real estate developers, and design students are potential clients who require these models for project presentations.

- Opportunities: By specializing in architectural models, you can carve out a niche that offers consistent demand and often allows for higher margins due to the level of detail required.

Educational and Hobbyist Market

Educational institutions, maker spaces, and hobbyists are increasingly using laser cutting machines for hands-on learning and project work. CO2 laser-cutting machines can be used to create educational kits and offer workshops, meeting the needs of this growing market.

- Products and Services: Create DIY project kits for students, offer training classes or workshops, and provide project space access.

- Clients: Schools, universities, maker spaces, libraries, and individual hobbyists interested in learning laser cutting and engraving techniques.

- Benefits: Building partnerships with educational institutions and maker communities can lead to long-term relationships and consistent business.

- Opportunities: By offering courses and project kits, you can diversify your income beyond products alone, creating additional revenue through education and community engagement.

Industrial Applications

For those with access to larger markets, CO2 laser-cutting machines can also cater to industrial applications. While industrial cutting typically requires higher-power lasers for metals, certain components, fixtures, and small parts in non-metal materials are suited to CO2 laser cutting.

- Services: Produce components for machinery, OEM parts, gaskets, or packaging solutions.

- Clients: Automotive, electronics, medical devices, and packaging industries often require custom components that CO2 lasers can manufacture.

- Opportunities: Serving industrial clients often involves repeat orders and larger-scale projects. Establishing a reputation as a reliable supplier can lead to steady contracts and significant revenue growth.

Art and Design Collaborations

Artists and designers are increasingly turning to laser cutting for unique projects. By offering your services to this creative market, you can participate in collaborative and innovative work, helping bring artistic visions to life.

- Collaborative Projects: Work on projects such as custom sculptures, installations, textile patterns, and interior design elements.

- Clients: Artists, interior designers, fashion designers, and art galleries are ideal clients who seek high levels of customization.

- Advantages: Art and design projects allow you to experiment with materials and techniques, potentially leading to unique and high-profile projects.

- Opportunities: Building relationships in the art and design world can lead to exciting and unique projects that enhance your portfolio and reputation. Creative work often allows for higher pricing due to its specialized nature.

Setting Up Your Laser Cutting Business

Market Research and Identifying Niches

The foundation of any successful business starts with thorough market research. Understanding your target market and identifying profitable niches can help you tailor your offerings and stand out from competitors.

- Analyze Demand: Look at the current demand for laser-cut products in your area and online. Check out popular marketplaces, such as Etsy, Amazon Handmade, and local business directories, to see what kinds of laser-cut products are in demand.

- Identify Potential Clients: Clients could range from local businesses needing signage to individuals seeking custom gifts or architects needing scale models. Determine who is most likely to benefit from your services.

- Assess Competition: Research other laser-cutting businesses in your area or niche. Study their product offerings, pricing, and customer reviews to find gaps in the market.

- Define Your Niche: Based on your research, decide which specific area you want to focus on—custom signage, personalized gifts, industrial parts, or another niche. Specializing can help you target a specific client base more effectively and build expertise in a particular area.

Developing a Business Plan

A comprehensive business plan is critical for guiding your business and securing funding if necessary. This document will outline your business strategy, goals, and financial projections.

- Executive Summary: Briefly describe your business concept, products or services offered, and target market.

- Market Analysis: Summarize your research findings, including details on your target audience, market demand, and competition. Highlight any niches you plan to fill and your business’s competitive advantage.

- Products and Services: Clearly outline the specific products or services you’ll provide with your CO2 laser cutting machine. For example, include details about any custom fabrication services, signage, or personalized products you plan to offer.

- Marketing Strategy: Describe how you plan to attract customers. This could include building an online presence, social media marketing, networking with local businesses, or participating in trade shows and craft fairs.

- Financial Projections: Estimate your startup costs, such as purchasing the laser machine, workspace setup, materials, and marketing expenses. Include revenue forecasts based on your target market and pricing strategy to determine when you expect to break even and achieve profitability.

- Operational Plan: Define how your day-to-day operations will run, from production to customer service and order fulfillment. This section also includes details on necessary equipment, workspace setup, and production timelines.

Legal Requirements and Compliance

To ensure your business operates legally and avoids potential issues, familiarize yourself with the legal requirements and compliance standards for a laser-cutting business.

- Business Registration: Register your business according to local laws. This could involve obtaining a business license, registering a business name, and choosing a legal structure (such as a sole proprietorship, LLC, or corporation).

- Tax Registration: Apply for an employer identification number (EIN) or a tax identification number if required in your region. This will enable you to handle sales tax, payroll taxes, and other financial obligations.

- Safety Standards and Permits: Laser cutting involves high-powered equipment, so it’s essential to follow safety regulations. In some areas, you may need additional permits or safety inspections for the commercial use of laser equipment.

- Insurance: Consider purchasing business insurance, which may include general liability insurance, product liability, and property insurance. Insurance can protect your business from unexpected events, such as equipment damage or accidents, that could otherwise disrupt your operations.

- Intellectual Property Rights: If you’re producing custom designs or artwork, familiarize yourself with intellectual property laws. This knowledge will help you protect your designs and avoid infringing on others’ rights.

Setting Up Your Workspace

Creating an efficient, safe, and comfortable workspace is crucial for running a successful laser-cutting business. Here are some key considerations:

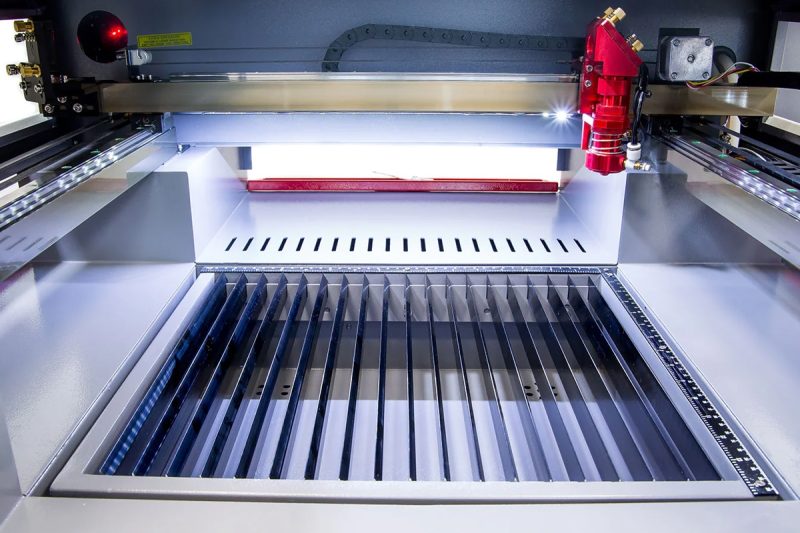

- Space Requirements: Your workspace needs sufficient room to house the CO2 laser cutting machine, materials, and finished products. Allocate space for storage, work tables, and a safe area around the machine for movement.

- Ventilation and Air Filtration: CO2 laser cutting produces fumes, especially when working with certain materials like acrylic or plastics. Install an exhaust system or air filtration unit to remove fumes and ensure a safe work environment.

- Electrical Setup: Make sure your workspace has the necessary power capacity and outlets to support your laser machine’s electrical requirements. Consult an electrician if needed to ensure safe and stable electrical connections.

- Safety Equipment: Equip your workspace with essential safety gear, such as fire extinguishers, first aid kits, and laser safety goggles. Clear safety instructions and emergency protocols should be posted and followed rigorously.

- Storage and Organization: Efficient storage for raw materials, finished products, and machine components will improve productivity. Use shelving units, cabinets, or bins to keep everything organized and within easy reach.

- Clean Work Area: Maintain a clean and orderly workspace to prevent dust accumulation, which can interfere with the laser’s optics and reduce machine performance. Regularly clean the laser machine, lenses, mirrors, and the surrounding area.

Choosing the Right CO2 Laser Cutting Machine

Key Features to Consider

Laser Power

- The power of the laser is measured in watts and determines the types and thicknesses of materials you can cut. For instance, lower-power lasers (80W-150W) are suitable for engraving and cutting thin materials like paper and leather. Higher-power lasers (180W-600W) can cut thicker materials like wood and acrylic with ease. For more versatile applications, consider a machine with adjustable power settings.

- Tip: Choosing the right laser power based on your target materials will help you maximize productivity and avoid unnecessary energy costs.

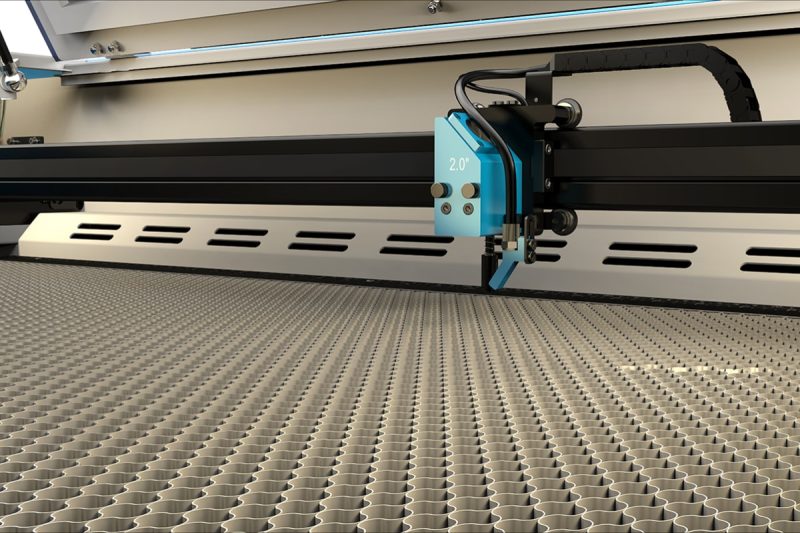

Bed Size (Working Area)

- The bed size, or working area, dictates the maximum dimensions of material that the machine can accommodate. Larger bed sizes allow you to work on bigger projects or batch-process multiple items simultaneously.

- Typical sizes range from 600×400 mm for smaller machines to 1500×3000 mm for larger ones, with additional custom-size options available.

- Tip: If you plan to cut large signs, architectural models, or multiple products in one run, a larger bed size can greatly improve efficiency.

Precision and Speed

- Precision, usually defined in terms of resolution (e.g., dots per inch, DPI), and cutting speed affect the machine’s ability to produce fine details and quickly complete projects. High-precision machines can create intricate designs, while high-speed machines increase productivity.

- Tip: For intricate designs and detailed engravings, choose a machine with a higher resolution. If high throughput is a priority, consider a machine with optimized speed settings.

Software Compatibility

- Most CO2 laser cutting machines require design software to create and send files to the machine. Make sure your machine is compatible with popular design programs like AutoCAD, CorelDRAW, and Adobe Illustrator, or offers its user-friendly software.

- Tip: Look for machines with intuitive software or compatibility with the design programs you’re already familiar with to avoid a steep learning curve.

Cooling System

- CO2 lasers generate heat during operation, so an efficient cooling system is essential to prevent overheating and ensure consistent performance. Many machines use water cooling systems, which are highly effective for keeping the laser tube at an optimal temperature.

- Tip: Consider a machine with a built-in cooling system to maintain safe operating conditions and extend the lifespan of your laser tube.

Maintenance and Support

- Regular maintenance is necessary for the longevity of a CO2 laser cutting machine, including cleaning lenses, mirrors, and the laser tube. Some models are designed for easy maintenance, with accessible components and straightforward assembly.

- Additionally, check whether the manufacturer or supplier offers technical support, warranties, and spare parts availability.

- Tip: Choose a machine with strong manufacturer support, ideally from a reputable provider like AccTek Laser, which offers robust after-sales support to help keep your machine in optimal condition.

Cost Considerations and ROI Analysis

Initial Investment

- Machine Cost: The cost of a CO2 laser cutting machine varies widely based on features and power, with entry-level models starting around $2,000 and high-end machines reaching up to $20,000 or more. Consider the machine’s capabilities and reliability as you evaluate prices.

- Installation and Setup: Installation fees, if applicable, and workspace setup costs (such as electrical upgrades or ventilation) should be factored into your budget.

- Software and Training: Depending on the machine, you may need additional software or training, which can also incur costs.

Operational Costs

- Electricity: Laser-cutting machines consume power during operation. The more powerful the machine, the higher the energy consumption, so consider electricity costs for regular use.

- Materials: Include the cost of raw materials, such as wood, acrylic, or leather, for your products. Efficient nesting and planning can help reduce material waste and control costs.

- Maintenance and Consumables: Routine maintenance includes cleaning and replacing parts such as lenses, mirrors, and laser tubes. The laser tube is a major component, and replacement costs vary based on power and quality. Regular cleaning supplies, protective eyewear, and other consumables are also part of ongoing expenses.

Revenue Projections

- Estimate your potential earnings based on your business plan and pricing strategy. For example, if you’re producing custom signs, calculate the price per unit and assess the monthly sales volume you anticipate.

- Consider potential seasonal demand for items like holiday-themed products, wedding decor, or back-to-school supplies that may impact your revenue.

Break-Even Analysis

- Calculate how long it will take to recover your initial investment by comparing total costs to projected monthly profits. Divide your startup costs (machine, setup, and initial inventory) by your monthly revenue minus operational costs to determine the break-even point.

- Example: If your total startup investment is $10,000 and your estimated monthly profit is $1,000, you’ll reach your break-even point in approximately 10 months. Factoring in potential demand increases and additional product offerings can help refine this timeline.

ROI Analysis

- Assess ROI by calculating how much profit your business can generate beyond the break-even point. A CO2 laser cutting machine can have a long lifespan with proper maintenance, meaning that after covering initial costs, ongoing profits are relatively high.

- Diversifying your product range can further increase ROI. By offering custom products, seasonal items, and services for both individuals and businesses, you can build multiple revenue streams that maximize your machine’s value.

Marketing Your Services

Building an Online Presence

A strong online presence is crucial for making your business accessible and professional. Your website acts as your storefront, showcasing your services, portfolio, and contact information.

- Create a Professional Website: Invest in a visually appealing, user-friendly website that represents your brand. Include clear descriptions of the services you offer, a portfolio of past projects, customer testimonials, and an easy-to-find contact form.

- SEO Optimization: Search engine optimization (SEO) helps your website rank higher on search engines, increasing visibility to potential clients. Use relevant keywords such as “CO2 laser cutting services” and “custom laser engraving” throughout your site, particularly in headers, service descriptions, and blog posts.

- Online Portfolio and Product Catalog: Showcase high-quality images of your laser-cut products, from custom signage to personalized gifts. A comprehensive portfolio helps clients visualize your work and builds credibility.

- E-commerce Integration: If you plan to sell products directly, consider integrating e-commerce features into your website, allowing customers to browse and purchase online. Offer customization options, if applicable, and ensure secure payment options.

Networking and Partnerships

Building relationships with local businesses and industry professionals can open doors to new opportunities and increase your client base.

- Collaborate with Local Businesses: Partner with businesses that complement your services, such as interior designers, event planners, and sign-making companies. For instance, offer to supply custom signage or decorative pieces to local retail stores, restaurants, or offices.

- Industry Associations and Groups: Join industry-related associations and groups in your area or online. Participating in these groups provides networking opportunities and keeps you updated on trends and innovations.

- Referral Programs: Encourage satisfied clients to refer others by offering discounts or small incentives. Word-of-mouth recommendations from trusted clients can be one of the most effective marketing strategies, helping you reach new clients without additional advertising costs.

- B2B (Business-to-Business) Relationships: Form partnerships with other businesses to provide B2B laser-cutting services. Manufacturing companies, product designers, and engineering firms may need custom-cut parts, making them ideal partners for ongoing contracts.

Utilizing Social Media and Online Marketplaces

Social media is a powerful tool for showcasing your work, reaching customers, and engaging with your audience. Platforms like Instagram and Facebook, as well as online marketplaces, help you reach a larger audience.

- Instagram and Facebook: These platforms are particularly useful for visually showcasing your laser-cut products. Post high-quality images, share process videos, and show behind-the-scenes shots of your workspace.

- Engaging Content: Create posts that go beyond simple promotions. Share tips, DIY ideas, and insights into the laser-cutting process to educate and engage your audience. Stories and live videos are also effective ways to show off new projects or interact with followers in real-time.

- LinkedIn for B2B Marketing: LinkedIn is valuable for reaching professional clients in industries like manufacturing, architecture, and design. Post examples of recent projects, connect with industry professionals and join LinkedIn groups related to laser cutting or design.

- Online Marketplaces: Selling products on online marketplaces like Etsy, Amazon Handmade, or eBay can expand your reach to a global audience. List your laser-cut items, such as personalized gifts or home décor, and ensure your product descriptions are SEO-friendly to increase visibility on these platforms.

- Customer Reviews and Testimonials: Encourage satisfied customers to leave reviews on social media, Google, and your website. Positive reviews build trust and attract new clients by showcasing your reliability and quality of work.

Attending Trade Shows and Local Events

In-person events allow you to connect with potential customers, showcase your products, and build brand awareness within the community.

- Trade Shows: Industry-specific trade shows, such as those focused on manufacturing, design, or arts and crafts, offer excellent opportunities to present your services to a concentrated audience. Prepare marketing materials, business cards, and sample products to leave a lasting impression.

- Craft Fairs and Farmer’s Markets: Local markets allow you to interact with customers and receive immediate feedback on your products. These events can be particularly effective for selling personalized items, custom gifts, and home décor.

- Live Demonstrations: Set up a small display with your CO2 laser cutting machine (if feasible) or bring pre-made samples to show customers how the laser cutting process works. Demonstrations captivate audiences, provide insight into the level of craftsmanship involved, and make your products stand out.

- Networking at Events: Events are also an opportunity to network with other creators and business owners. By exchanging contact information and building relationships, you may find new partnership opportunities or collaborative projects.

- Follow-Up: After events, follow up with contacts you’ve made, either through email or social media. This reinforces connections, keeps you fresh in people’s minds, and can lead to future collaborations or sales.

Pricing Your Services

Calculating Costs

Accurate cost calculation ensures that your pricing covers expenses and generates profit. Here are the primary costs to account for:

- Material Costs: Start by calculating the cost of the materials used in each project. This includes raw materials such as wood, acrylic, leather, or other materials required for cutting and engraving. Minimizing waste and efficiently nesting designs can help reduce material costs.

- Machine Operating Costs: CO2 laser cutting machines consume electricity, and higher-powered models may incur greater energy costs. Calculate operating costs based on power consumption and average run times.

- Labor Costs: Include the time you spend designing, setting up, cutting, and finishing each project. Decide on an hourly rate for your time, ensuring that it reflects both your skill level and the time spent on production.

- Maintenance and Consumables: Regular maintenance, like replacing lenses or cleaning the machine, incurs costs that should be included in your pricing structure. Consumables like protective eyewear, filters, and cleaning supplies are also essential for smooth operation.

- Overhead Expenses: Overhead expenses include indirect costs like rent, utilities, insurance, and software subscriptions. Allocate a portion of these expenses to each project based on your average output.

Competitive Pricing Strategies

Setting competitive prices helps attract customers while ensuring your business remains profitable. Here are some common strategies:

- Cost-Plus Pricing: This method involves adding a markup to your total costs. For example, if a project costs you $50 in materials, machine time, and labor, you might add a 50% markup, charging the customer $75. Cost-plus pricing ensures that all expenses are covered, with a predictable profit margin.

- Market-Based Pricing: Look at the going rates for similar laser-cut products or services in your market, both locally and online. Research what other providers charge for comparable work, and adjust your prices to remain competitive while offering unique value.

- Value-Based Pricing: With value-based pricing, you set prices based on the perceived value of your product or service to the customer. For instance, highly customized items or unique artistic pieces can often command higher prices than standard products because of their exclusivity and craftsmanship.

- Tiered Pricing: Offer multiple pricing tiers to give customers options that suit different budgets. For example, you might have basic, premium, and deluxe versions of a product or service, each with increasing levels of customization or quality. This strategy can attract a wider range of customers and maximize sales.

Offering Discounts and Promotions

Discounts and promotions can attract new customers, encourage repeat business, and increase sales during slower periods. Here are a few effective options:

- Bulk Discounts: Offer a discount for clients who order in larger quantities, which can help secure more substantial, consistent orders. This approach is ideal for customers who need multiples of the same product or for businesses ordering supplies or promotional items.

- Seasonal Promotions: Holiday seasons often see a rise in demand for personalized gifts and decorations. Offer special holiday discounts or limited-time promotions to boost sales during peak shopping periods.

- Introductory Offers: To attract new clients, consider offering a discount on their first order. This can incentivize potential customers to try your services and build loyalty.

- Loyalty Discounts: Reward repeat customers with a loyalty discount or special offers after a certain number of orders. Not only does this encourage customer retention, but it also builds goodwill.

- Referral Discounts: Encourage existing customers to refer new clients by offering them a discount on their next order for every successful referral. Word-of-mouth marketing is powerful, and referral discounts incentivize clients to promote your business.

Quotation and Invoicing

Quotations

- Itemized Breakdown: An itemized quotation shows clients exactly what they’re paying for, including material costs, labor, and any additional fees. Transparent pricing builds trust and helps clients understand the value of your work.

- Terms and Conditions: Include relevant terms and conditions, such as payment methods, deadlines, return policies, and any additional fees for rush orders or last-minute changes.

- Expiration Date: Setting an expiration date for quotes creates a sense of urgency and encourages clients to decide within a specific timeframe.

- Custom Options: If applicable, offer clients a few different options at various price points, especially if you offer customizations. This lets clients choose what best fits their needs and budget.

Invoicing

- Professional Format: Use a professional, organized format for your invoices, including your business name, contact information, and client details.

- Detailed Descriptions: List each item or service provided, along with the price, quantity, and total cost. Clear and concise invoices reduce confusion and potential disputes.

- Payment Terms: State payment terms, such as due dates and any penalties for late payments. Most invoices are net 30 (due within 30 days), but choose terms that work for your business.

- Automation Options: Consider using invoicing software or platforms that offer automation. These tools can track unpaid invoices, send payment reminders, and streamline financial management.

Maximizing Efficiency and Profitability

Streamlining Production

Optimizing your production process will help you save time, reduce waste, and complete more orders. By improving your workflow, you’ll increase efficiency and profitability.

- Batch Processing: If you frequently handle similar jobs, group them into batches to minimize setup time and maximize productivity. By preparing multiple items for cutting at once, you can reduce the number of machine resets and re-alignments needed, which saves time.

- Efficient Material Usage: Use nesting software to arrange multiple items on a single sheet of material, optimizing space and minimizing waste. This approach is particularly effective when working with expensive materials like acrylic or wood, as it helps you get the most out of each sheet.

- Automation Tools: Invest in software tools that automate repetitive tasks, such as file preparation or laser setup. Some laser-cutting machines support software integrations that enable automation, reducing manual intervention and minimizing errors.

- Standardized Templates: If you produce common items, like custom signage or gift items, create standardized templates that can be quickly modified. Templates speed up the design process and ensure consistency across projects.

- Scheduling and Workflow Management: Use project management tools or software to schedule jobs, track progress, and ensure deadlines are met. This helps prioritize orders, avoid bottlenecks, and maintain an efficient workflow, especially when managing multiple projects.

Regular Maintenance

Regular maintenance is essential for the longevity and performance of your CO2 laser cutting machine. By keeping your machine in peak condition, you can avoid costly downtime and maintain consistent cutting quality.

- Routine Cleaning: Dust, debris, and residue can accumulate on lenses, mirrors, and laser tubes, affecting performance. Clean these components regularly to prevent build-up and ensure accurate cuts. Use the cleaning solutions recommended by your machine manufacturer for the best results.

- Inspect and Replace Parts: Periodically check components like lenses, belts, and filters, which can wear out over time. Promptly replacing worn parts keeps the machine running smoothly and prevents potential breakdowns during operation.

- Cooling System Check: The cooling system prevents the laser tube from overheating, so check for leaks or temperature inconsistencies. If your machine uses a water cooling system, ensure that the water is replaced periodically and that no contaminants are present.

- Software and Firmware Updates: Stay current with software and firmware updates for your laser cutting machine. Manufacturers like AccTek Laser frequently release updates that improve performance, add features, or fix bugs. Keeping your system up-to-date enhances efficiency and reduces compatibility issues.

- Scheduled Maintenance: Follow the manufacturer’s recommended maintenance schedule to perform in-depth inspections and tune-ups. Scheduled maintenance extends the life of your machine and prevents unexpected interruptions in production.

Continuous Learning

Investing in continuous learning helps you stay up-to-date with new techniques, materials, and industry trends. Ongoing skill development enables you to expand your service offerings and improve the quality of your work.

- Technical Skills: Advance your knowledge of laser cutting techniques, such as adjusting settings for different materials, optimizing cut quality, and troubleshooting common issues. Understanding these details ensures you can work with a wider range of materials and offer diverse products.

- Design Software Proficiency: Proficiency in design software like Adobe Illustrator, CorelDRAW, or AutoCAD is crucial for creating intricate designs and meeting client specifications. As new tools or features become available, enhance your skills to streamline design work and reduce time spent on revisions.

- Material Expertise: Different materials require specific laser settings and handling techniques. Learning the nuances of materials like wood, acrylic, leather, and glass allows you to deliver higher-quality results and avoid damage or wasted materials.

- Industry Trends and Market Research: Follow industry blogs, attend workshops, or participate in trade shows to keep up with trends in laser cutting, customer preferences, and competitor offerings. Knowing what’s in demand allows you to adjust your product range and capture new market segments.

- Workshops and Online Courses: Many online platforms offer laser cutting tutorials and courses, from beginner to advanced levels. Consider joining workshops or courses that cover new techniques, design ideas, and business strategies, keeping your skills current and versatile.

Customer Service Excellence

Providing exceptional customer service builds trust, increases repeat business and enhances your reputation. Excellent customer service can set your business apart in a competitive market and drive long-term profitability.

- Clear Communication: Keep clients informed throughout the process, from initial quotes to delivery timelines. Communicate any changes, delays, or design adjustments promptly, and address questions promptly. Clear communication prevents misunderstandings and strengthens client relationships.

- Quality Assurance: Prioritize quality by carefully inspecting each item before delivery. Quality control ensures that each product meets the client’s specifications and reflects well on your business. If possible, send photos of the finished item to the client for confirmation before shipping.

- Personalized Service: Go the extra mile to meet client requests for customization. Offering personalized service can lead to word-of-mouth referrals and repeat clients, particularly for custom or one-of-a-kind items like gifts and décor.

- After-Sales Support: Offer support even after the sale is complete. This could include answering questions about product care, providing guidance on maintenance for clients who bought machinery or assisting with any issues they encounter post-purchase. Reliable after-sales support fosters loyalty and encourages positive reviews.

- Customer Feedback and Testimonials: Request feedback from clients and display positive reviews on your website and social media. Testimonials act as social proof, building trust with potential customers and boosting your credibility in the marketplace. If you receive constructive feedback, use it to improve your processes or product offerings.

Summary

Get Laser Cutting Solutions

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.