How to Start a Laser Cutting Business?

The laser cutting industry has huge market potential. With the growing demand for modern manufacturing and personalized design, laser cutting technology is increasingly used in all walks of life. Whether in industrial manufacturing, art design, or decoration processing, laser cutting technology has become an indispensable tool with its high precision, high efficiency and flexibility. Laser cutting can not only process a variety of materials such as metal, plastic, wood and composite materials, but also achieve complex pattern cutting and high-precision detail processing, meeting the needs from large-scale industrial production to personalized small-batch processing.

To succeed in this promising industry, it is essential to choose a high-quality laser cutting machine. The performance of the laser cutting machine directly affects the cutting accuracy, speed and work efficiency. High-quality equipment can not only ensure the accuracy and consistency of the product, but also reduce operating costs and improve production efficiency. In addition, the right laser equipment can meet your cutting needs in different materials and application scenarios, enhance your competitiveness and help you win more customers. Therefore, before entering the laser cutting business, investing in a high-performance laser cutting machine is not only the basis for the smooth development of the business, but also the key to the long-term development of the enterprise.

Table of Contents

What Is Laser Cutting?

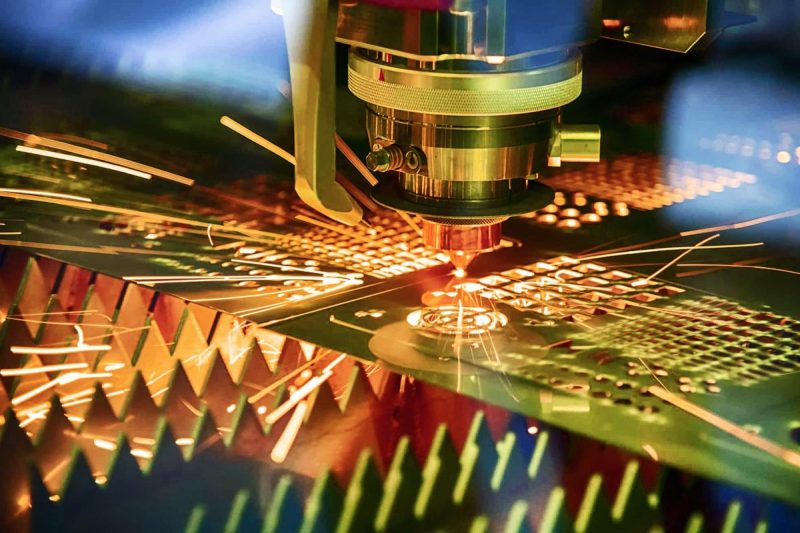

Laser cutting is a high-precision, non-contact processing technology that focuses a high-energy laser beam on the surface of a material, causing the local material to quickly heat up to melting, burning or vaporizing, thereby achieving processing techniques such as cutting, engraving, and punching. Its working principle is that a high-energy laser beam generated by a laser generator is focused by an optical device to form a very small high-temperature light spot on the material. This light spot can cut or engrave very fine patterns, lines or holes in the material with extremely high precision and repeatability.

Laser cutting technology is suitable for a variety of materials, including metals, plastics, wood, glass, ceramics, etc., and can process complex shapes and designs. Compared with traditional cutting processes, laser cutting has the advantage of non-contact operation and does not require mechanical contact with the material, so it will not cause mechanical stress or deformation to the material. In addition, the laser cutting kerf is very narrow, with less material loss, smooth cutting edges, and no need for subsequent processing, which improves processing efficiency.

The technology has been widely used in many industries. For example, in metal processing, laser cutting is used to precisely manufacture various metal parts; in the field of electronic component manufacturing, it can be used to cut and process complex circuit boards; and in advertising sign production, laser cutting can easily process acrylic, plastic and other materials to produce signboards and decorations with high precision and details.

The automation, flexibility and efficiency of laser cutting make it an indispensable part of modern manufacturing, and provide a reliable solution for personalized customized products and mass production.

Is There a Future for Laser Cutting?

The laser cutting industry has a bright future, especially in the context of growing automation and personalization in the manufacturing industry. As the global market’s requirements for efficient and precise processing technology continue to increase, laser cutting technology has become an indispensable part of industrial production and creative processing due to its excellent performance. Laser cutting not only has the advantages of high efficiency and high precision, but also can achieve cutting and engraving of complex shapes while maintaining low material loss, which has led to its rapid promotion in many industries.

In industrial processing, laser cutting is widely used in industries such as metal, automobile, aerospace, and electronic equipment, helping manufacturers increase production speed, reduce waste, and improve product quality. Its degree of automation enables it to be combined with a numerical control system (CNC) to achieve high-precision processing in mass production, thereby greatly reducing labor costs. The increasingly popular demand for customization in the manufacturing industry has also further promoted the application of laser cutting technology, especially in the processing of complex parts. Laser cutting provides a more flexible and economical solution than traditional mechanical cutting.

At the same time, laser cutting technology also shows strong growth potential in the creative handmade and personalized product market. Laser cutting can accurately process a variety of materials, such as wood, acrylic, leather and textiles, providing unlimited possibilities for small batch customized products and creative designs. From personalized gift customization to high-end home decoration, laser cutting meets consumers’ demand for unique and customized products. In addition, due to the continuous miniaturization and affordable prices of laser cutting equipment, more and more small businesses and individual entrepreneurs have begun to use laser cutting machines to create personalized products, which further promotes the expansion of this market.

The market demand for laser cutting is not limited to developed countries. With the rapid growth and technological innovation of the manufacturing industry in emerging markets, the application of laser cutting worldwide has also shown a significant upward trend. Manufacturing upgrades and automation processes in Asia-Pacific, Latin America, and the Middle East have accelerated the adoption of laser cutting machines, making them a key link in the global industrial chain.

Whether it is large-scale industrial manufacturing or creative workshops, laser cutting technology is a promising and profitable business direction with its diverse application scenarios, high production efficiency and low operating costs. For entrepreneurs who want to enter this field, the laser cutting industry is not only mature in technology, but also has a continuously growing market demand, making it an investment option with long-term development potential.

Is Laser Cutting Business Right for Me?

Whether the laser cutting and engraving business is right for you depends on whether you have a relevant technical background or a strong interest in the fields of manufacturing or creative design. If you have a certain understanding of engineering technology or are good at handling design software, then entering the laser cutting industry will bring you broad development opportunities. The core of laser cutting and engraving technology is precision and innovation. Whether in manufacturing, art design, or personalized product customization, the application of laser cutting machines can provide you with a highly automated and versatile platform. You can use this technology to transform your creativity into high-quality actual products.

For those who have entrepreneurial dreams, laser cutting business is a very promising option. The diversity of laser cutting equipment makes its application range wide, from metal processing, architectural model manufacturing, to gift customization, furniture engraving and other creative industries, and the market demand is strong. The affordability of small laser cutting machines also makes it easier for individuals to start their own businesses. You can quickly enter this field with a low initial investment.

In addition, if you already have an existing business, laser cutting and engraving can be used as an extension service to help you expand your business scope. For example, if you are engaged in the construction, decoration or advertising industry, laser cutting technology can allow you to provide more diversified products and services, enhance the competitiveness and innovation of your company. With laser cutting machines, you can provide customers with personalized and customized solutions, help them achieve unique designs, and improve customer satisfaction.

On the other hand, even if you don’t have a technical background, the laser cutting business is highly automated and relatively easy to operate. With some basic training, you can master the operation of the equipment and the use of design software and quickly enter this industry. Moreover, the accuracy and efficiency of the laser cutting machine can reduce human errors and help you produce high-quality products with fewer resources.

In general, the laser cutting and engraving business is not only suitable for those with a technical background or design experience, but also for individuals or companies who want to start a business with innovative technology. If you are interested in modern manufacturing technology and creative design, the laser cutting industry will provide you with a career development direction full of opportunities.

Is There Anything I Need to Pay Attention to When Starting a Laser Cutting Business?

What are the key factors to consider when starting a laser cutting business? Although the laser cutting business has huge market potential, there are still many aspects that need to be carefully considered during the startup and operation process. You need to ensure that everything from equipment selection to operating environment is up to standard, and have good business planning and legal awareness. Is necessary industry training required? How to ensure the correct operation and maintenance of the equipment? What safety regulations and environmental requirements need to be paid attention to when setting up the workspace? How to deal with material procurement and inventory management? Also, how to ensure that the product pricing is reasonable and can stand out in the highly competitive market? In addition to these basic operational elements, you also need to pay attention to details such as marketing strategies, customer needs, and after-sales service to ensure the smooth development of your business and win the trust of customers. These issues are important matters that must be considered when starting a laser cutting business.

How to Start a Laser Cutting Business?

There are so many things to pay attention to when developing laser cutting business, so how do we start the cutting business? Next, I have sorted out some routes for doing business, which can be used as a reference.

Create a Roadmap for Your Business

A clear business plan is the first step to success. You need to have a clear understanding of the market and customer groups you intend to serve. Are you focusing on large-scale industrial processing or small batches of customized products? Different market demands and customer types will directly affect the equipment, workflows, and marketing strategies you choose. For example, if your goal is to serve the supply chain of the manufacturing industry, you may need to invest in a high-power laser cutting machine and ensure production capacity and delivery efficiency. If you plan to enter the market for creative design or personalized products, flexibility and sophistication may be the performance indicators you need to focus on. In addition, you also need to develop a detailed business plan to clarify short-term and long-term goals, budgets, sources of funds, and potential market risks and opportunities. This will help you maintain a clear direction and response strategy during business development.

Obtain a Legal Entity for Your Laser Cutting Business

In order to conduct business legally, you need to register a legal business entity, such as a limited liability company (LLC) or a sole proprietorship. It is crucial to choose the form of legal entity that suits you. Registering a legal entity not only allows you to comply with national and local laws and regulations, but also protects your personal property in the event of a business dispute or accident. Different countries and regions have different legal requirements. It is recommended to understand local business regulations or seek help from legal counsel before registering. In addition, registering a legal entity can also enhance your business image and enhance customer trust in your business.

Get an EIN to Register for Taxes

Regardless of the size of your business, tax compliance is an important part that cannot be ignored. Before you officially start operations, make sure you have registered with the tax agency and obtained an employer identification number (EIN). EIN is not only a necessary document for employers to pay taxes, but also one of the necessary conditions for you to apply for a business bank account, apply for a business loan, and other financial operations. After registering for EIN, it is recommended to communicate with a tax advisor or accountant regularly to ensure that you comply with legal requirements in financial management and tax reporting to avoid possible tax problems in the future.

Choose a Machine and Set up the Appropriate Environment

The laser cutting machine is the core tool of your business, and it is crucial to choose the equipment that suits your business needs. You need to choose a suitable machine based on your product type, processing materials, precision requirements and production scale. For example, metal cutting may require a higher-power laser machine, while non-metallic materials such as wood and acrylic can choose a low-power model. AccTek offers a variety of laser cutting machine models, covering the needs of small and medium-sized enterprises to large-scale industrial production. When choosing a machine, you also need to consider the efficiency, service life, operating difficulty and maintenance cost of the equipment. The environment in which the laser cutting machine is installed must also meet relevant safety standards, ensure that the operating area has good ventilation and fire protection facilities, and provide employees with appropriate protective equipment.If you want to know how to choose a laser cutting machine that suits you, please read this article“How To Choose The Right Laser Cutting Machine?”

Learn to Use the Laser Cutter

Once the equipment is in place, mastering its use is the key to improving production efficiency and avoiding losses. Operating a laser cutting machine requires a certain technical background, so it is recommended to ensure that you can use the equipment skillfully and safely by participating in professional training or referring to the manufacturer’s operating manual. Especially when you are engaged in complex processing, understanding the equipment’s precision control, cutting path planning, and the characteristics of different materials will help you maximize the performance of the equipment. At the same time, regular equipment maintenance is also a necessary part of ensuring smooth production. AccTek usually provides technical support and training to customers to help you familiarize yourself with machine operation as soon as possible.

Purchase Materials and Design

Laser cutting business involves many different types of materials, such as metal, wood, plastic, acrylic, etc. Depending on the type of service you provide, sourcing the right materials is a crucial step. You need to establish a reliable supply chain to ensure the quality and stability of the materials. In addition, developing unique design solutions can also help you stand out from the competition. Design software such as CorelDRAW, AutoCAD, etc. are commonly used tools for laser cutting graphic design. Mastering these tools will help you improve design efficiency and provide more customized services.

Set Your Pricing

Reasonable pricing is key to ensuring a profitable business. When setting prices, you need to consider multiple factors, including production costs (materials, equipment depreciation, energy consumption, etc.), labor costs, market demand, and competitor pricing strategies. Your pricing must be able to cover operating costs and ensure profits while remaining competitive in the market. If you offer high value-added customized products or complex processing services, you may be able to set prices higher. For standard products produced on a large scale, prices may need to be more competitive. When developing a pricing strategy, it is recommended to work with industry experts or consultants to ensure that pricing is in line with market expectations.

Develop a Good Marketing Strategy

No matter how tech-savvy you are, lack of effective marketing will make it difficult for your business to be discovered by potential customers. First, you need to conduct market research to understand where your target customer base is active and what their needs are. Using social media platforms such as Facebook, Instagram, LinkedIn, etc. to publish your products and case studies will help you attract customers. Google Ads and search engine optimization (SEO) are also effective ways to increase online exposure. Especially in the B2B market, showing your technical capabilities and success stories will bring you more business cooperation opportunities.

Build Your Online Presence

Having a professional official website is the foundation for establishing a brand image. The website is not only a window for customers to understand your business, but also enhances customers’ trust in you by showcasing your equipment, technical strength and past project cases. When building a website, it is recommended to optimize SEO to improve the ranking in search engines such as Google. At the same time, you can publish industry-related articles through blogs to share the latest developments and application cases of laser cutting technology to further increase website traffic. The combined use of social media will help enhance the brand’s online influence.

Improve Management

In the process of business operation, it is crucial to maintain efficient management processes. You need to establish a customer management system (CRM) to track orders and maintain customer relationships. In addition, regular review of production processes, inventory management and financial status will help optimize resource allocation and improve business operation efficiency. Especially when the order volume increases, good management processes will help you avoid production delays and customer loss.

Increase Your Inventory (Extra Tips)

As your business gradually expands, increasing your inventory of raw materials and equipment in a timely manner is a necessary measure to cope with the growth of customer demand. Stocking up on commonly used materials in advance can not only ensure the continuity of production, but also reduce procurement costs when raw material prices fluctuate. At the same time, consider adding more advanced equipment to improve your production capacity and product diversity and further expand your market. In this way, you will be able to take on more orders and lay a solid foundation for future expansion.

By implementing the above steps, you will be able to effectively start and grow your laser cutting business. Although each stage requires careful planning and execution, as long as you maintain flexible market response capabilities and a solid management model, the laser cutting industry will bring you lasting success and profitability.

Profitable Laser Cutting Business Ideas

Metal Processing

Laser cutting demonstrates extremely high precision and efficiency in the field of metal processing. Whether it is used to manufacture mechanical parts, automotive components, or industrial tools, laser cutting can provide complex geometries and precise cutting effects. Compared with traditional mechanical cutting methods, laser cutting reduces material waste and can process a variety of metal materials such as steel, stainless steel, iron, and titanium. Especially today, with the increasing popularity of manufacturing automation, metal laser cutting has huge advantages in production speed, precision, and stability. Investing in metal laser cutting equipment can help you quickly enter the precision manufacturing industry and meet the market demand for high-quality parts.

Creative Customization

As the demand for personalized customization increases, creative laser cutting and engraving services are gradually becoming a profitable market. With laser technology, you can provide customers with personalized gifts, customized home decorations, fashion accessories and other products. For example, you can perform fine engraving on materials such as wood, leather, glass, and acrylic to create unique works of art and daily necessities. Whether it is wedding souvenirs, custom furniture or personalized signs, the sophistication and flexibility of laser cutting and engraving allow your business to cover multiple areas from creative design to daily life, meeting the personalized needs of customers while increasing your business revenue.

Advertising Sign Production

Advertising signage is another hot market for the laser cutting business. With laser cutting technology, you can easily customize signs of various sizes, shapes, and materials. Whether it is a store sign, indoor signage or a large outdoor billboard, laser cutting can provide high-precision design and seamless cutting effects. Metal and acrylic are the most common materials used in sign making. Laser technology can not only cut these materials, but also perform surface engraving to increase the three-dimensional sense and artistic effect of the sign. With the increasing market demand for customized signs, especially for high-end commercial projects, entering this field will bring you considerable profit margins.

Conclusion

The laser cutting business has a broad market potential, especially in the fields of metal processing, creative customization and advertising signage production. To stand out in this competitive market, the key to success lies in choosing the right equipment, developing a detailed business plan, and continuously improving technical capabilities and service quality. AccTek Laser offers a range of high-performance laser cutting machines to suit the needs of businesses of all sizes, from precision metal processing to personalized customization, we can provide you with reliable equipment and comprehensive technical support.

Start your laser business with AccTek Laser and choose high-quality laser cutting equipment to ensure you gain a competitive advantage in the laser industry. Whether you are a start-up or an existing business expansion, we will provide you with stable solutions and full support to help you achieve the success of your laser cutting business.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions