What is the difference between CO2 and fiber laser welding machines?

With the widespread application of laser technology in industrial manufacturing, laser welding, as an efficient and precise welding technology, is gradually becoming an important process in metal processing, automobile, aerospace, medical equipment, electronics, and other industries. This article will analyzeCO2 and fiber laser welding machines in detail, covering their principles, advantages, applications, and limitations. It will help you make scientific and reasonable judgments when choosing laser welding equipment and improve enterprises’ production efficiency and product quality.

Tartalomjegyzék

CO2 Laser Welding Machine Overview

As a relatively mature device in the field of laser processing, the CO2 laser welding machine has played an important role in metal processing, automobile manufacturing, aerospace, and electronics industries after years of technological accumulation and continuous innovation. With its high power output and excellent beam quality, it meets the strict requirements of large-scale production for welding stability and precision. However, the limitations of its complex equipment maintenance, relatively low efficiency, and large size have also prompted the industry to continuously explore more advanced and efficient laser welding solutions.

CO2 laser welding principle

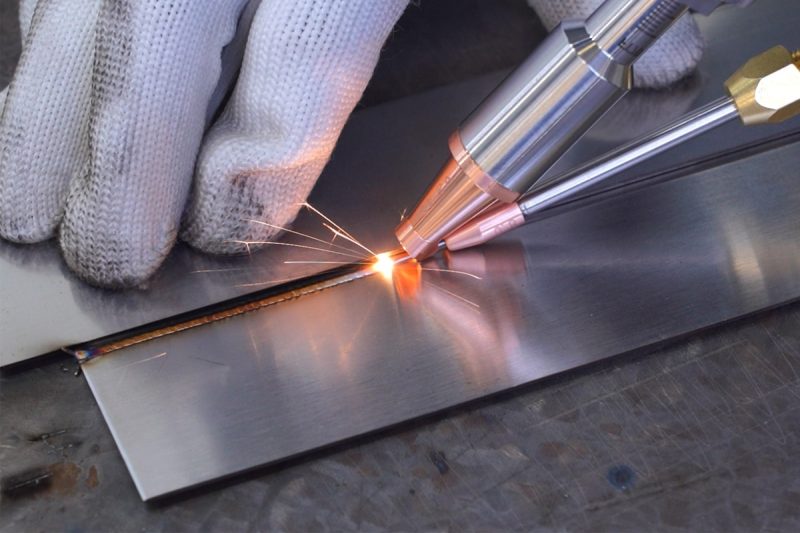

CO2 laser welding machines mainly use CO2 gas as a laser medium to generate a high-energy laser beam through excitation. Inside the laser generator, CO2 molecules emit continuous and stable lasers through stimulated radiation under specific excitation conditions. After being shaped and focused by a series of optical elements, the laser irradiates the surface of the workpiece with extremely high energy density, causing the material to melt locally in an instant, and then quickly solidify in the area where the laser beam stops irradiating, thus forming a strong and precise weld. This principle has been fully verified in industrial applications for many years, proving the great advantages ofCO2 laser welding technology in ensuring welding quality and stability.

The main advantages ofCO2 laser welding machine

- High power output: the CO2laser welding machine can provide a high-power laser beam, which makes it perform particularly well in high-power welding scenarios. Whether it is thick plates or large-sized workpieces, it can rely on its high energy density to achieve fast and effective welding, thereby greatly improving production efficiency.

- Excellent beam quality: Under suitable focusing conditions, the laser beam generated by the CO2laser has very good stability and uniformity. Precise beam focusing enables the welding area to quickly reach the melting point, ensuring consistent weld depth and a stable and reliable welding effect. This is an extremely important technical indicator for manufacturing companies that pursue welding accuracy and high-quality products.

- Versatility: the CO2laser welding machine is suitable for the processing of a variety of metal materials, such as stainless steel, aluminum alloy, copper, etc. Its diverse application capabilities enable it to play a key role in industrial production in different fields and meet the requirements of large-scale continuous production.

- Mature technology: After years of industrial application and technical verification,CO2laser welding technology has become mature. Mature process flow and perfect system design not only ensure welding quality but also provide enterprises with long-term and stable production guarantees and reduce process risks.

Application ofCO2 laser welding machine

CO2 laser welding machines have been widely used in industrial manufacturing, and their main areas include:

- Metal processing: In processes such as metal cutting, welding, and surface treatment,CO2laser welding machines achieve high-quality welding with their high energy density and fine processing capabilities.

- Automobile manufacturing: In the production process of automobile bodies, chassis, and various parts, laser welding technology can provide high-efficiency and high-consistency welding solutions.

- Aerospace: The demanding aerospace industry has strict requirements for welding accuracy and material integrity.CO2laser welding technology meets these requirements with its stability and precision.

- Electronic industry: In the assembly process of precision electronic components, laser welding technology ensures a stable connection between tiny components and improves the overall quality of the product.

Limitations ofCO2 Laser Welding

AlthoughCO2 laser welding machines excel in many aspects, they still have some limitations that cannot be ignored:

- High maintenance cost: Due to the complex system structure, the daily maintenance and adjustment of the equipment requires professional technicians to operate, which increases the operating costs of the enterprise.

- Low efficiency: On some high-speed production lines, the processing efficiency ofCO2laser welding may not be as good as that of new laser welding equipment, thus affecting the overall production rhythm.

- Large volume: Compared with other laser welding technologies, the overall volume ofCO2laser welding machines is larger, making it difficult to achieve flexible layout and integration in compact automated production lines.

- Limited flexibility: Faced with changing production needs and complex workpiece shapes,CO2laser welding machines have relatively poor adaptability and flexibility, and require special debugging and configuration for different working conditions.

In summary,CO2 laser welding machines have played an irreplaceable role in large-scale metal processing and high-demand manufacturing fields with their high power output, excellent beam quality, and mature technology applications. However, its limitations such as high maintenance costs, low production efficiency, and large equipment size also require companies to comprehensively consider actual production needs and economic benefits when selecting models. For companies pursuing high-precision and high-stability welding,CO2 laser welding machines are still a trustworthy choice. At the same time, companies can also consider combining with other advanced laser welding technologies according to their own production scale and process requirements to achieve more efficient production processes and higher-quality product output.

Fiber Laser Welding Machine Overview

Szállézeres hegesztőgépek have become the mainstream welding equipment in the precision manufacturing industry due to their excellent beam quality, efficient energy conversion, compact design, and low maintenance costs. Their high stability and flexibility have made them widely used in many high-end manufacturing fields such as automobiles, aerospace, electronics, and medical. Compared with traditional welding technology, fiber laser welding machines can not only achieve high-precision and high-efficiency welding but also have stronger adaptability and lower operating costs. However, despite its significant advantages, the high initial investment and adaptability to specific materials are still factors that need to be considered. Overall, fiber laser welding technology is gradually driving modern manufacturing in a more efficient and intelligent direction.

Fiber Laser Welding Principle

- High beam quality: The fiber laser welding machine has extremely high beam stability and focusing performance, which can achieve extremely small spot diameters and make the welds more delicate. This high-quality beam is particularly suitable for micro-welding and high-precision welding, such as microcircuit welding in the electronics industry and precision assembly of medical devices.

- High welding efficiency: The photoelectric conversion efficiency of the fiber laser welding machine is much higher than that of the CO2laser welding machine, usually up to 30%-50%. This advantage not only increases the welding speed but also reduces the overall energy consumption, greatly improving production efficiency. In a mass-production manufacturing environment, this efficient welding capability can reduce cycle time and increase overall output.

- Low maintenance cost: Compared with the CO2laser welding machine, the system structure of the fiber laser welding machine is simpler, and the laser generator does not require complex gas systems and optical lens maintenance, which greatly reduces maintenance costs. In addition, the fiber laser generator has a longer service life, generally up to 100,000 hours or more, reducing the cost of equipment replacement and downtime maintenance.

- Compact design, easy to integrate: The fiber laser welding machine adopts a compact design and occupies a small area, which is easy to integrate into the automated production line. Its lightweight structure enables it to adapt to a variety of production environments, whether it is the automated production of large factories or the high-precision welding needs of small workshops.

- Versatility: Fiber laser welding machines can be used in a variety of application scenarios from thick plate welding to tiny parts welding. Whether it is the welding of high-strength metal materials or the need for precision micro-welding, this equipment can provide a reliable solution. Therefore, it is widely used in many high-end manufacturing industries.

Applications of Fiber Laser Welding

Fiber laser welding machines are widely used in many industries due to their high precision, high stability, and high efficiency:

- Automotive industry: used for body welding, battery pack welding, exhaust system welding, etc., to ensure the high strength and durability of welds.

- Aerospace industry: widely used in high-demand welding tasks such as aerospace engine components and spacecraft structural parts to ensure lightweight and high reliability of products.

- Medical device industry: such as the welding of high-precision medical equipment such as pacemakers, surgical instruments, and micro-catheters, to ensure that the welding parts are pollution-free, high-strength, and corrosion-resistant.

- Electronics industry: such as microcircuits, battery connection welding, assembly of precision sensors, etc., can achieve high-precision processing without contact and heat-affected zones.

- Jewelry and watchmaking industry: excellent performance in the precision welding of precious metals such as gold, platinum, and titanium alloys, which can achieve seamless welding and improve product quality.

Limitations of Fiber Laser Welding

Although fiber laser welding machines excel in many applications, they still have some limitations:

- High initial cost: The core components of fiber laser welding machines, such as high-quality fiber laser generators and precision optical systems, are expensive, resulting in a large initial investment in the equipment. For small and medium-sized enterprises with limited funds, purchasing such equipment may face certain pressure.

- Material absorption rate problem: The laser wavelength of fiber laser welding machines is usually around 1μm. For some highly reflective materials (such as copper, aluminum, etc.), their energy absorption rate is relatively low, which may affect the welding quality. For these materials, special pretreatment methods or adjustment of laser parameters may be required to improve the welding effect.

- Limited welding thickness: Compared with CO2 laser welding machines, fiber laser welding machines may have certain limitations in welding extremely thick materials (such as metal plates over 10mm). For specific large-thickness welding needs, other auxiliary technologies, such as wire welding or multiple welding, may be required to improve welding quality.

In general, fiber laser welding machines are becoming an ideal choice for high-precision welding in various industries due to their excellent beam quality, high welding efficiency, low maintenance cost and compact equipment design. Despite the high initial cost, their long service life and low operating costs give them obvious economic advantages in the field of high-end manufacturing. With the continuous advancement of fiber laser technology, future fiber laser welding machines will further improve welding quality and scope of application. For example, by optimizing wavelength design to increase the absorption rate of highly reflective materials; combining AI technology to achieve intelligent welding monitoring and adaptive parameter adjustment; and using higher-power fiber laser generators to expand its application in thick plate welding.

The main differences between CO2 and fiber laser welding machines

CO2 laser welding machines and fiber laser welding machines are two advanced technologies widely used in the field of industrial welding. Although they both use the principle of laser welding, there are significant differences in wavelength, beam quality, power efficiency, maintenance requirements, flexibility, and cost. These differences directly affect their application selection in different production environments. Next, we will compare the key differences between the two welding machines in depth to help companies make wise decisions when choosing welding equipment.

- Wavelength and material absorption rate: CO2 laser wavelength is about 10.6 microns, which is suitable for materials with high laser energy absorption rates, but the adaptability to different materials varies. The fiber laser wavelength is about 1.06 microns, which is more advantageous in metal processing and can achieve higher energy utilization and better welding effects.

- Beam quality and focusing: Fiber laser welding machines usually have higher beam quality and higher focusing accuracy, which can meet the application scenarios with high requirements for weld fineness; while CO2 laser may be difficult to achieve the same focusing effect under certain conditions.

- Power efficiency: The overall power conversion rate of the fiber laser system is higher, which can achieve a faster welding process and reduce energy consumption; relatively speaking, the CO2 laser system is slightly inferior in energy efficiency.

- Maintenance requirements: The CO2 laser welding machine has a complex structure and high maintenance and daily adjustment requirements; the fiber laser welding machine is more compact in design, with a long maintenance cycle and low cost, which helps to improve the overall service life of the equipment.

- Flexibility and integration: Fiber laser equipment is small in size and light in weight, making it easy to integrate into modern automated production lines; while CO2 laser equipment, although it has its unique advantages in large-scale production, has certain limitations in flexibility and modular integration.

- Cost: In terms of initial investment, fiber laser equipment has relatively high costs due to its advanced technology; but from the perspective of long-term operation and maintenance, its low maintenance cost and high efficiency often bring higher return on investment. Relatively speaking, the initial investment of CO2 laser welding machines may be more competitive, but the subsequent maintenance costs and energy consumption cannot be ignored.

CO2 laser welding machines and fiber laser welding machines each have their advantages. The choice of which equipment to use should be based on the specific application scenario, material properties, and the company’s production needs. CO2 laser welding machines have advantages in mature stability and high-power output, while fiber laser machines excel in beam quality, efficiency, maintenance, and flexibility. Understanding the main differences between the two will help companies make more scientific equipment selections in the field of laser welding and improve product quality and production efficiency.

Összesít

CO2 laser welding machines and fiber laser welding machines each have their advantages and limitations. Choosing the right equipment should be determined based on specific production requirements, material types, processing accuracy, and budget. CO2 laser welding machines are suitable for large-scale production and have good adaptability to certain highly reflective materials, but they have low energy efficiency and high maintenance costs. Fiber laser welding machines, with their high energy efficiency, excellent beam quality, and low maintenance requirements, show unique advantages in precision welding and high-efficiency production. By deeply understanding the differences between the two, companies can choose the most appropriate welding technology according to their own needs and optimize production costs and welding effects.

Szerezzen lézeres megoldásokat

If you are looking for laser welding solutions that suit your production needs, AccTek Laser is committed to providing professional, customized laser welding equipment and technical support to customers in various industries. With rich industry experience and a deep understanding of the latest laser technology, we can not only meet the high requirements for welding accuracy and efficiency in the fields of automobiles, aviation, medical devices, etc. but also provide personalized services according to your specific application scenarios to help you gain greater competitive advantages in the market. Lépjen kapcsolatba velünk now to get more professional advice on laser processing equipment optimization, so that your production line can achieve more efficient and accurate welding operations.

Through the detailed analysis of this article, we hope to provide you with a practical reference when choosing a CO2 or fiber laser welding machine. AccTek Laser always takes technological innovation and customer first as its core, providing you with the best laser solutions to help your company achieve higher value and benefits in the field of laser processing.

Elérhetőség

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 A zóna, Lunzhen ipari zóna, Yucheng város, Shandong tartomány.

Szerezzen lézeres megoldásokat