Is a Cheap Laser Cutting Machine Worth Buying?

When choosing a laser cutting machine, price is often the primary factor that many consumers focus on. Cheap laser cutting machines seem to be an attractive option, especially for businesses and hobbyists with limited budgets. However, are low-priced models worth the money? This article will explore the pros and cons of cheap laser cutting machines to help you make an informed choice before making a purchasing decision. I hope to provide valuable reference information for friends who are investing in the field of laser cutting.

Table of Contents

Learn About CO2 Laser Cutting Machine

Laser cutting machines are an indispensable tool in modern manufacturing, which uses precise laser beams to cut a variety of materials. This technology has been widely used in many fields such as metal processing, electronic manufacturing, and the automotive industry. To fully understand the advantages and applicability of laser cutting machines, you first need to understand their key components, various types, and their cost-influencing factors.

Laser Cutting Machine Parts and Functions Overview

The core of the laser cutting machine lies in its highly integrated technical components, which work together to achieve efficient and accurate material cutting. The main components include:

- Laser generator: This is the “heart” of the laser cutting machine, responsible for generating a high-energy laser beam. Common types of laser generators include CO2 laser generators and fiber laser generators. Different types of laser generators are suitable for different materials and cutting requirements.

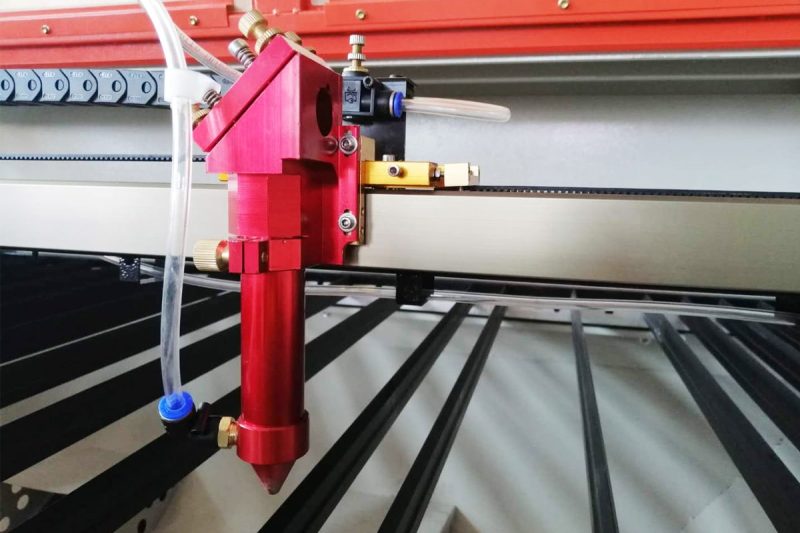

- Cutting head: The cutting head contains a focusing mirror and a reflector to accurately focus the laser beam on the surface of the material to ensure cutting accuracy. A high-quality cutting head can reduce the scattering of the laser beam and improve cutting efficiency and accuracy.

- Optical system: The function of the optical system is to transmit the laser beam to the cutting head. The design of this system directly affects the stability of the laser beam and the cutting quality.

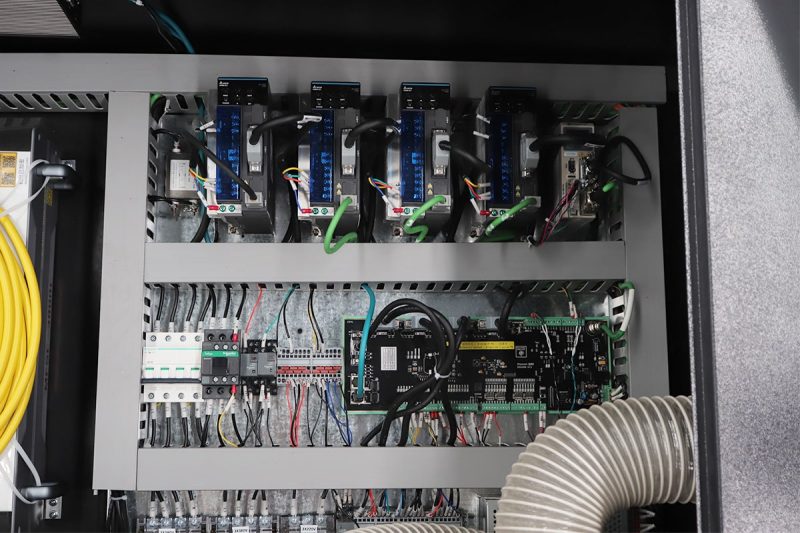

- Control system: This is the brain of the laser cutting machine, responsible for accurately controlling parameters such as cutting path, speed, and laser power. Modern laser cutting machines are usually equipped with advanced CNC systems to achieve automated cutting of complex graphics.

- Cooling device: The laser cutting machine generates a lot of heat during operation. The cooling system (such as water cooling or air cooling system) can effectively dissipate heat to prevent the laser generator and other key components from overheating, thereby extending the service life of the equipment.

The quality and performance of each component will directly affect the cutting effect and the overall service life of the machine. High-end laser cutting machines usually use high-quality materials and advanced technology, which makes them excel in precision, speed, and stability.

Types of Laser Cutting Machines

Laser cutting machines can be divided into many types according to the type of laser generator they use, each type has its own unique advantages and disadvantages and applicable scenarios:

- CO2 laser cutting machine: The CO2 laser cutting machine uses carbon dioxide as the laser medium and can effectively cut non-metallic materials such as wood, plastic, glass, etc. Due to its high energy density and good beam quality, CO2 laser generators perform well in cutting and engraving non-metallic materials and are often used in industries such as advertising production and furniture manufacturing.

- Fiber laser cutting machine: Fiber laser cutting machine uses optical fiber as the laser transmission medium and has the advantages of high efficiency and low maintenance cost. Fiber laser generators can produce short-wavelength laser beams, which are particularly suitable for cutting metal materials (such as stainless steel, aluminum alloy, etc.). Its high efficiency and fine-cutting capabilities make it an important position in precision manufacturing and heavy industry.

Different types of laser cutting machines have their advantages in terms of applicable materials, cutting thickness, precision, and speed. We need to choose the most suitable type according to specific needs.

Factors Affecting the Cost of Laser Cutting Machines

The cost of a laser cutting machine is determined by several factors, including the performance parameters of the equipment itself and external support services:

- Laser power: The power of the laser generator directly affects the cutting speed and cutting thickness. Higher-power laser generators are more expensive, but they can handle a wider range of materials and have higher cutting efficiency. Therefore, for companies that need to frequently cut thick materials, high-power laser cutting machines are worth investing in.

- Material handling capabilities: Different materials have different cutting difficulties and required technologies, which also affect the cost of laser cutting machines. For example, metal materials usually require higher-power laser generators and more sophisticated control systems, which will increase the overall cost of the equipment.

- Manufacturer’s brand and technical support: Well-known brands usually provide higher-quality products and more complete after-sales service, which is also part of the cost. Choosing a reputable manufacturer can not only ensure the quality of the equipment but also obtain long-term technical support and maintenance services, reducing losses caused by equipment failure.

- Additional functions and automation: Modern laser cutting machines are usually equipped with various automation functions, such as autofocus, automatic feeding, and remote monitoring systems. Although these additional functions improve production efficiency, they also increase the purchase cost of the equipment.

Although high-quality laser cutting machines are more expensive, their excellent performance, long service life, and perfect after-sales service make the total cost of ownership (TCO) more advantageous. Therefore, when choosing a laser cutting machine, in addition to paying attention to the initial investment, you should also consider the long-term return and maintenance cost of the equipment.

Pros and Cons of Investing in a Cheap laser cutting machine

When choosing a laser cutting machine, cheap models are often the first choice for small businesses and hobbyists due to their attractive prices. This type of equipment has obvious advantages, but some disadvantages cannot be ignored. Before making an investment decision, it is crucial to understand these advantages and disadvantages for the long-term development of the business.

Advantages of Investing in a Cheap laser cutting machine

- Low initial investment cost: The biggest advantage of cheap laser cutting machines is their low purchase cost, which is very attractive to businesses or individuals with limited budgets. The low initial investment allows small businesses, startups, and hobbyists to quickly enter the market and gain a certain competitiveness without the pressure of high capital.

- Accessibility for small businesses and hobbyists: Due to the low price, more small businesses and hobbyists can afford laser cutting equipment. This allows them to use laser cutting machines to achieve more complex and delicate cutting tasks, expand their business scope, and increase the diversity of their products.

- Basic functions for simple cutting tasks: Although cheap laser cutting machines may not be as capable as high-end models in terms of functions and performance, they are still capable of some basic cutting tasks. This is enough for users who do not need extremely high precision or handle complex materials to cope with daily work needs.

- Potential for cost-effective prototyping and experimentation: Cheap laser cutting machines can be used as an affordable tool for prototyping and experimentation. Although this type of equipment has limited performance, it is still quite valuable for testing new concepts, making preliminary samples, and conducting small-batch production.

Disadvantages of Investing in a Cheap laser cutting machine

- Limited cutting capacity and power: Cheap laser cutting machines are often equipped with low laser power, which limits their ability to cut heavy materials or high-speed production. Users may find that these machines are not able to achieve satisfactory speed and cutting results when processing harder or thicker materials.

- Lower-quality components and construction: To reduce costs, cheap laser cutting machines may use lower-quality components and materials. This not only affects the durability of the equipment but may also cause reliability issues in the long-term use of the machine, such as reduced precision or frequent mechanical failures.

- Reduced precision and accuracy: Compared with high-end laser cutting machines, cheap models tend to have lower precision and cutting accuracy. This is a significant disadvantage for applications that require high-precision cutting and may result in a finished product that does not meet the expected quality standards.

- Higher maintenance and repair costs in the long run: Although the initial cost of cheap laser cutting machines is low, their long-term maintenance and repair costs may be higher than expected. Due to the use of lower-quality components, the machine is more prone to failure and maintenance is more frequent, which ultimately increases the total cost of ownership (TCO).

In summary, cheap laser cutting machines are a good choice when the budget is tight and basic needs are met, but if long-term usage needs and performance requirements are taken into account, the return on investment needs must be carefully evaluated. Before purchasing, companies should fully understand their cutting needs and long-term development goals to ensure that the selected equipment can bring the greatest benefits.

Things to Consider Before Buying a Cheap laser cutting machine

Purchasing a cheap laser cutting machine is a decision that requires careful consideration. While these machines may be attractive in terms of price, several key factors need to be evaluated in detail before purchasing to ensure that they will meet your needs and provide the greatest return on your investment.

Understand Your Cutting Requirements and Materials

Before purchasing a laser cutting machine, first determine your specific cutting needs. This includes the type of material you need to process (such as metal, wood, plastic, etc.), the thickness range of the material, and the requirements for cutting accuracy and speed. Cheap laser cutting machines may be limited in power and performance, so they may not meet your needs for thick materials or complex cutting tasks. Understanding these requirements can help you avoid wasting money and time by purchasing equipment that is not suitable.

Expected Frequency and Quantity of Use

Frequency of use and workload are also important factors to consider. If your business requires frequent or prolonged use of the laser cutting machine, then a cheaper model may face durability and performance challenges. Cheap laser cutting machines are usually designed to handle lightweight tasks, and if they are operated in a high-intensity use environment, they may cause premature damage or frequent failures. Therefore, evaluating your expected frequency of use will help determine whether this type of equipment is suitable for your business needs.

Evaluate the Machine's Specifications and Capabilities

Before purchasing a cheap laser cutting machine, it is important to carefully review the specifications and features of the equipment. This includes key parameters such as laser power, cutting speed, maximum cutting thickness, cutting accuracy, etc. Lower-priced laser cutting machines may be weak in these aspects, so make sure the selected equipment can meet your minimum needs to avoid problems in subsequent use.

Research the Manufacturer’S Reputation and Reliability

It is crucial to choose a reputable manufacturer. The market for cheap laser cutting machines may be filled with many unknown brands or products of varying quality, so it is important to research the manufacturer’s history, customer feedback, and after-sales service. Reliable manufacturers usually provide better support services, and the quality of the equipment is relatively guaranteed, which can reduce future maintenance costs and operational risks.

Evaluate Long-Term Costs and Return on Investment (ROI)

The low initial cost of a cheap laser cutting machine may appeal to you, but you need to consider its long-term operating costs. This includes maintenance costs, parts replacement costs, energy costs, etc. Lower-quality equipment may require more frequent repairs or parts replacement during use, which will increase the long-term total cost of ownership (TCO). Therefore, when evaluating the total return on investment (ROI) of the equipment, these long-term costs should be taken into account to ensure that the selected equipment is financially sustainable.

Customer Support and Warranty Options

Finally, make sure you understand the customer support and warranty policies of the laser cutting machine you choose. Good after-sales service and warranty options can provide you with timely assistance when the equipment fails and reduce losses caused by downtime. Some cheap brands may not provide comprehensive after-sales support or warranty, so make sure you understand this information before purchasing to make an informed decision.

By carefully considering the above considerations, you can better evaluate whether a cheap laser cutting machine is suitable for your needs and make the best purchase decision for your business.

Alternatives and Considerations

When considering buying a cheap laser cutting machine, you can also explore other options to ensure that it meets your business needs and maximizes your return on investment. Here are some alternatives and considerations to help you make a more informed decision.

Renting or Leasing a High-Quality laser cutting machine

If your laser cutting machine needs are limited to short-term projects or occasional use, renting or leasing a high-quality laser cutting machine may be a more cost-effective option. Leasing allows you to get more advanced and powerful equipment without a large one-time investment. This method also avoids the problem of equipment depreciation and usually includes maintenance and technical support services to help ensure that the equipment is stable throughout the rental period. In addition, leasing equipment can give you more flexibility to adapt to changes in business needs, making it easier to upgrade equipment when you need to.

Explore Refurbished or Used Equipment Options

Purchasing a refurbished or used laser cutting machine is also an effective way to reduce costs. These devices are usually professionally inspected and tested to ensure that they can operate properly, and the price is usually much lower than that of new equipment. The benefit of buying refurbished equipment is that you can get a high-quality machine at a lower price while enjoying partial warranty or technical support. However, when purchasing used equipment, be sure to carefully examine the equipment’s history and condition to ensure it will meet your cutting needs and have sufficient life.

Nvest in Operator Training and Skill Development

Improving operator skills can go a long way toward making up for a lack of equipment performance. By investing in operator training, you can ensure better cutting results and productivity even with a lower-performing laser cutting machine. Skilled operators are better able to adjust and optimize the machine’s parameters to suit different materials and cutting tasks, thereby maximizing the equipment’s potential. In addition, trained operators are more efficient in maintaining and servicing the equipment, reducing downtime and repair costs.

Build Long-Term Relationships with Suppliers

Building long-term relationships with suppliers may result in better pricing, support, and service. AccTek Laser is willing to provide customized solutions, favorable pricing, and priority technical support to long-term customers. If you plan to continue to expand your business and increase the number of laser cutting equipment in the future, working with AccTek can save you a lot of money and ensure that you will receive ongoing support and training.

The above alternatives and considerations can help you find a laser cutting solution that better suits your business needs, rather than choosing a cheap laser cutting machine simply because of its lower initial cost.

Summarize

When buying a laser cutting machine, price is only one factor to consider. Although a cheap laser cutting machine is attractive in terms of initial investment, the long-term cost and performance issues it may bring should not be ignored. Before making a decision, fully evaluate your needs, budget, and long-term plans to choose the solution that best suits you. An investment in high-quality equipment will not only improve production efficiency but also bring higher returns to your business.

Get Laser Solutions

Whether you are investing in laser cutting technology for the first time or looking to upgrade your existing equipment, AccTek Laser can provide you with a tailor-made solution. Contact us for more information and let us help you achieve your business goals.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions