Is the Smoke Produced by Laser Cutting Machines Toxic?

Laser cutting machine machines are widely used in modern industrial manufacturing. With their efficient and precise cutting capabilities, they have become an important tool for processing various materials. However, the large amount of smoke generated during laser cutting is often easily overlooked. These fumes may contain substances that are harmful to the human body. Inhalation of these fumes may pose a potential risk to the health of operators, especially when working in closed or poorly ventilated environments. Therefore, understanding the composition of laser-cutting fumes, the health hazards they may bring, and effective mitigation strategies are essential to ensure safe production.

Table of Contents

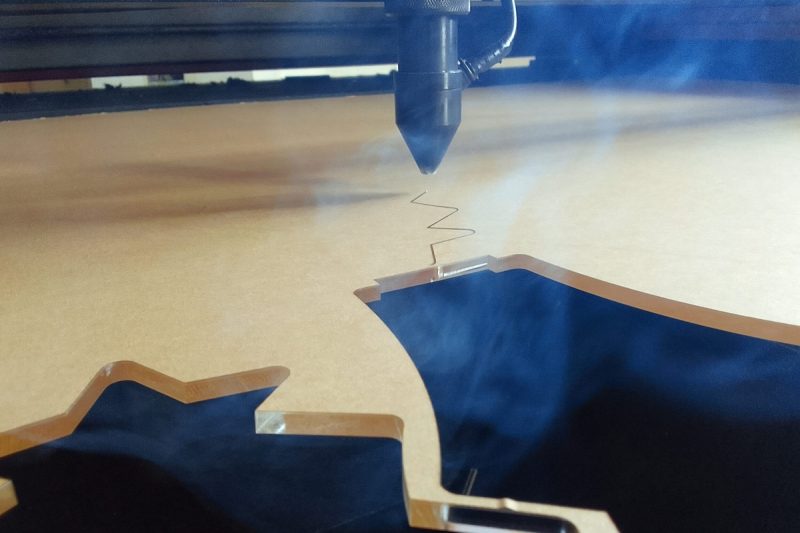

Learn About the Laser Cutting Process

How Laser Cutting Works

Laser cutting machines use a high-energy laser beam to locally heat the material to the melting point or vaporization point through a focused optical path, and remove the molten or vaporized material through an auxiliary gas to achieve precise cutting. This process varies depending on the characteristics of the material and the type and settings of the cutting machine. For example, higher laser power and faster cutting speeds tend to result in more smoke, and the burning or vaporization of different materials (such as metal, plastic, and wood) will also result in different smoke compositions. Therefore, when using a laser cutting machine, it is important to understand the impact of these variables on smoke production to develop appropriate protective measures.

Factors That Affect Smoke Generation

Factors that affect the generation of laser cutting smoke include the type of material, laser power, cutting speed, cutting thickness, and the auxiliary gas used. By adjusting these parameters, the generation and composition of smoke can be controlled to a certain extent.

Type of Material

Different materials will produce different types and amounts of smoke when laser cutting. For example, when cutting metals, especially steel and aluminum, a large amount of metal oxide particles are usually produced. These particles are usually generated by the high-temperature reaction of the laser with the metal surface, especially when oxygen is used as an auxiliary gas, which will intensify the oxidation reaction and produce more particulate smoke. On the other hand, when cutting plastics or other organic materials, volatile organic compounds (VOCs) and other harmful gases may be released. These smoke components are easy to volatilize at high temperatures, which poses potential risks to health and the environment.

Laser Power and Cutting Speed

High-power lasers can melt or evaporate materials quickly, but they also cause more material to vaporize, which increases smoke generation. Although higher cutting speeds can reduce the heat exposure time of the material, they may also lead to incomplete cutting and more smoke generation at higher power. On the contrary, slower cutting speeds may cause excessive burning of the material, which also increases smoke generation.

Cutting Thickness

Cutting thicker materials usually requires higher laser power and slower cutting speed, resulting in more material being evaporated or melted, thus generating more smoke. Cutting thinner materials usually generates less smoke, but if the cutting parameters are not appropriate, it may still cause a lot of smoke to be generated.

Auxiliary Gas

The use of auxiliary gas has a significant impact on the composition and quantity of smoke. Commonly used auxiliary gases include oxygen, nitrogen, and air. Oxygen is often used to improve cutting efficiency, but it promotes oxidation reactions, producing more smoke and oxide particles. Nitrogen can inhibit oxidation reactions and reduce smoke, but it may result in higher laser power consumption when cutting certain materials. When air is used as an auxiliary gas because it contains oxygen, a certain amount of smoke will also be generated.

Laser Beam Settings

Adjusting the focal length of the laser beam affects the size and energy density of the spot, thus affecting the melting and vaporization efficiency of the material. Shorter focal lengths usually produce higher power density, resulting in more material being vaporized, which in turn produces more smoke. By precisely adjusting these parameters, the cutting process can be optimized, smoke generation can be controlled, and its impact on the environment and health can be reduced.

In summary, the generation of smoke in laser cutting is the result of the combined effect of multiple factors. Understanding these factors and controlling them can reduce the generation of smoke to a certain extent and improve the environmental protection and safety of the cutting process.

Laser Generator Type

Common types of laser generators used in laser cutting machines include CO2 laser generators and fiber laser generators. CO2 laser generators are often used to cut non-metallic materials, while fiber laser generators are known for their high efficiency and suitability for metal cutting. These different types of laser generators produce different smoke compositions during the cutting process. For example, when cutting with a fiber laser, due to the shorter wavelength of the laser, it usually results in less heat-affected zone, but more metal particles may be produced when cutting metal. Understanding the working principles and application scenarios of different laser generators will help you choose the most suitable protective equipment and strategies.

Composition of Laser Cutting Smoke

The composition of laser-cutting smoke is quite complex, and the specific composition depends on the type of material being cut, the cutting process parameters, and the auxiliary gas used. These components may include the following substances, each of which has different degrees of harm to the environment and human health.

Small Particles (Such as PM2.5)

Tiny particles, especially those with a diameter of less than 2.5 microns (PM2.5), are common components in laser cutting smoke. These particles are small in size and light in weight, easily suspended in the air and enter the human lungs through the respiratory system. Long-term exposure may cause respiratory inflammation, decreased lung function, and even increase the risk of cardiovascular disease.

Volatile Organic Compounds (VOCs)

Volatile organic compounds (VOCs) are common smoke components when cutting organic materials such as plastics, wood, rubber, etc. These substances include formaldehyde, benzene, toluene, etc., which are highly toxic. Inhalation of these compounds may cause headaches, dizziness, respiratory irritation, and even the risk of cancer at high exposure concentrations.

Metal Oxides

When laser cutting metal materials, various metal oxides are generated. For example, iron oxide may be generated when cutting steel, and aluminum oxide may be generated when cutting aluminum. These oxides are mostly in the form of particles, which can be easily inhaled into the body and cause lung diseases. Long-term exposure may lead to chronic obstructive pulmonary disease (COPD) and other respiratory diseases.

Heavy Metal Particles

Heavy metal particles are another type of laser cutting fume component that needs attention, especially when cutting materials containing heavy metals such as lead and cadmium. These heavy metal particles are highly toxic to the human body and may cause damage to the nervous system, kidney damage, and even be carcinogenic.

Other Harmful Substances

Depending on the cutting material, other harmful substances may also be produced. For example, when cutting plastic materials containing chlorine (such as PVC), hydrogen chloride gas will be released. This gas will form hydrochloric acid when combined with water. It is highly corrosive and has a strong irritating effect on the respiratory system and eyes.The smoke produced by laser cutting has complex components and is very harmful. Understanding its composition is crucial to formulating safety protection measures. Enterprises should deploy efficient ventilation and filtration systems, require operators to wear personal protective equipment, and regularly monitor the concentration of harmful substances in the environment to effectively reduce the impact of smoke on the environment and health.

Health Hazards Associated with Laser Cutting Fumes

The harmful substances in laser cutting machine smoke can have a variety of adverse effects on human health. First, tiny particles (PM2.5) can penetrate deep into the respiratory tract and cause respiratory diseases such as asthma, bronchitis, and even lung cancer. In addition, long-term exposure to toxic organic volatiles (such as formaldehyde, benzene, etc.) may cause chronic poisoning and affect the nervous system and endocrine systems. Heavy metal particles, such as lead and cadmium, may enter the human body through the respiratory tract or skin contact, causing poisoning symptoms and even leading to the occurrence of chronic diseases. Direct contact or high-concentration exposure to the eyes and skin may cause severe irritation reactions, including conjunctivitis, dermatitis, etc. Therefore, in laser-cutting operations, effective protective measures must be taken to avoid the occurrence of these health hazards.

Regulatory Standards and Guidelines

To protect the health of operators, many countries and regions have formulated regulatory standards and guidelines for workplace air quality. For example, the Occupational Safety and Health Administration (OSHA) of the United States has established concentration limits for hazardous substances in workplace air to control the risk of workers being exposed to laser-cutting fumes. International and domestic standard organizations such as ISO and EPA have also formulated corresponding regulations requiring companies to monitor air quality during the laser cutting process to ensure that the operating environment meets safety standards. These standards not only limit the concentration of fumes but also put forward specific requirements for the use of ventilation equipment and personal protective equipment (PPE). When performing laser cutting operations, companies should strictly abide by these standards to protect the health and safety of workers.

Laser Cutting Smoke Mitigation Strategies

To effectively mitigate the health effects of laser cutting fumes, the following are a variety of strategies that can be adopted, each of which helps to reduce the risk of fume exposure and thus protect the health of operators:

Efficient Ventilation System

- Local exhaust ventilation (LEV): Installing efficient local exhaust ventilation is a key measure to control laser cutting smoke. These devices prevent smoke from accumulating in the work area by capturing smoke at the source and exhausting it to the outside or through a filtration system. LEV systems usually include capture hoods, ducts, and fans to quickly remove pollutants.

- Overall ventilation system: In large-area factories or workshops, in addition to local exhaust, an overall ventilation system should be installed to maintain indoor air circulation and reduce smoke concentration.

Smoke Purifier

- Filtering equipment: Installing a smoke purifier, such as a HEPA filter or activated carbon filter, can effectively capture and filter the tiny particles and harmful gases generated during the laser cutting process. HEPA filters mainly target particulate matter, while activated carbon filters are used to absorb gaseous pollutants such as volatile organic compounds (VOCs).

- Regular maintenance: Ensure regular maintenance and filter replacement of smoke purification equipment to ensure its efficient operation, thereby reducing the emission of harmful substances.

Personal Protective Equipment (PPE)

- N95 mask: Operators should wear N95 masks that meet the standards, which can effectively filter tiny particles in the air and reduce the inhalation of harmful substances. This mask is designed for filtering particulate matter and has a high protective effect against particles generated by laser cutting.

- Goggles: To protect the eyes from the irritation of harmful fumes, operators should wear protective goggles. Goggles can prevent particles and volatile compounds in the fumes from entering the eyes, reducing the risk of eye health problems.

- Protective clothing: Wearing protective clothing can prevent particles and chemicals generated during laser cutting from direct contact with the skin, reducing the risk of skin allergies and chemical burns.

Operating Environment and Equipment Adjustment

- Optimize laser parameters: Reduce the generation of smoke during cutting by adjusting laser power, cutting speed, focal length, and other parameters. Reducing laser power or increasing cutting speed can reduce the excessive burning of materials, thereby reducing the generation of smoke.

- Choose the right auxiliary gas: Using the right auxiliary gas (such as nitrogen or oxygen) can reduce the formation of harmful smoke. For example, nitrogen can reduce oxidation reactions when cutting metals, thereby reducing the generation of metal oxide particles.

Through the comprehensive application of the above strategies, the impact of laser cutting smoke on operator health can be significantly reduced, while ensuring that the factory or workshop meets environmental protection and safety standards.

Operator Education and Training

Educating and training operators about the hazards of laser-cutting fumes is a key step in reducing risks. Training should include the composition of laser cutting fumes, potential health risks, and how to properly use protective equipment and exhaust systems. Operators should understand how to recognize danger signs, such as increased smoke concentrations or equipment failures, and how to take quick action to protect themselves and their colleagues in an emergency. Regular education and training will not only increase operators’ safety awareness but also ensure that they follow best practices in actual operations to minimize health risks.

Addressing Common Misconceptions

Myth 1: Laser Cutting Smoke Is Just Ordinary Dust

- Misconception: Many people think that laser cutting smoke is just ordinary dust.

- Reality: In fact, smoke contains harmful tiny particles and organic volatiles, which are potential threats to human health.

- Solution: Improve the understanding of the composition of laser cutting smoke and take corresponding protective measures, such as using high-efficiency filtering equipment.

Myth 2: Ventilation Systems Are Sufficient to Handle Smoke

- Myth: Some people believe that ventilation systems can solve all smoke problems.

- Reality: Ventilation can only dilute smoke, but it cannot remove the toxic substances in it.

- Solution: Use a combination of local exhaust devices and high-efficiency filtration equipment to ensure that harmful substances in the air are effectively removed.

Myth 3: The Impact of Smog Is Only Short-Term

- Myth: Many people underestimate the risks of long-term exposure to laser-cutting fumes.

- Reality: Prolonged exposure to these fumes can lead to chronic health problems.

- Solution: Wear personal protective equipment (such as N95 masks) and regularly maintain ventilation and filtration equipment to reduce long-term health risks.

Correcting common misunderstandings about laser cutting fumes taking appropriate protective measures and education and training can effectively reduce health risks.

Summarize

The smoke generated during the laser cutting process does contain a variety of harmful substances that pose potential risks to the health of operators. Therefore, understanding the composition of these fumes and their health hazards and taking effective protective measures are important steps to ensure safe production. These risks can be effectively reduced by installing efficient ventilation systems, using smoke purifiers, wearing personal protective equipment, and conducting regular training for operators. Enterprises should strictly abide by relevant safety standards and guidelines to ensure the environmental safety of laser cutting operations, and should also continuously update protective equipment and technology to cope with new risks that may arise. In short, only by fully understanding and responding to the hazards of laser cutting smoke can the health of operators and the safety of the workplace be ensured.

Get Laser Solutions

Whether you are investing in laser cutting technology for the first time or looking to upgrade your existing equipment, AccTek Laser can provide you with a tailor-made solution. Contact us for more information and let us help you achieve your business goals.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions