Laser Cleaning: Eco-Friendly Assessment

The growing popularity of environmental responsibility is challenging traditional industrial processes around the world to come up with newer, greener business models. As an emerging cleaning technology, laser cleaning has received widespread attention in recent years. It is considered to have many advantages in the cleaning field, but it also raises doubts about its environmental protection. This article will delve into the working principles and advantages of laser cleaning, the potential impacts on the environment caused by the use of laser cleaning machines, and environmentally friendly measures.

Table Of Contents

What is laser cleaning?

Laser cleaning is a high-tech cleaning technology that uses laser beams to remove surface dirt, grease, coatings, and other impurities from the surface of objects with high precision. Its working principle is based on the selective absorption and thermal effect of laser energy on target substances. The basic working principle is as follows:

- Absorption of light energy: Laser cleaning uses a high-energy beam of light produced by a laser generator, usually a laser pulse. This beam is aimed at the surface that needs cleaning. When a laser beam strikes a target surface, dirt and impurities absorb the light energy.

- Thermal Expansion and Cooling: Dirt that absorbs laser energy undergoes thermal expansion. Due to the instantaneous nature of the laser pulse, the dirt heats up rapidly in a very short period, causing instantaneous expansion of its surface. The dirt then cools rapidly and shrinks due to the thermal conductivity of the material.

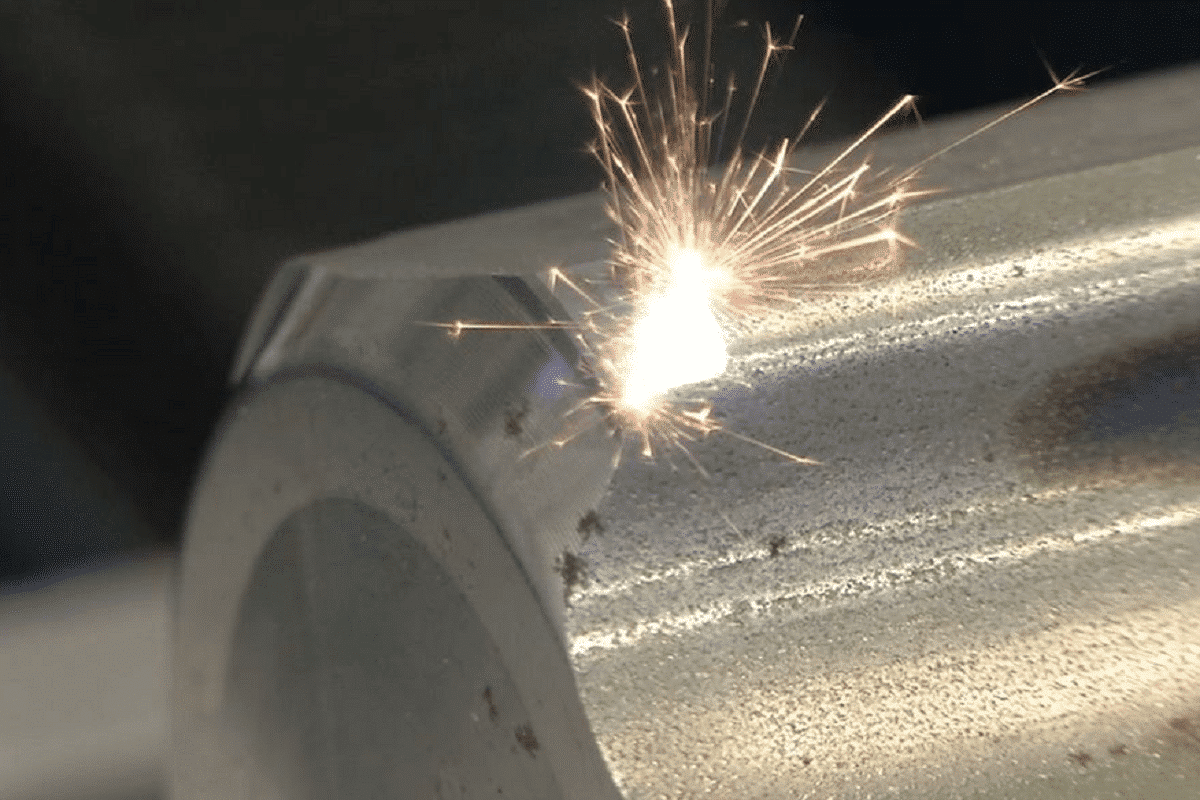

- Blasting and Removal: The process of thermal expansion and cooling causes tiny cracks between the dirt and the substrate. At this moment, the laser cleaning system uses the power of laser pulses to blast the dirt at the cracks and make it fall off the substrate.

- Laser parameter control: The effect of laser cleaning can be controlled by adjusting parameters such as laser energy, pulse width, frequency, and focus diameter. This height-adjustable system makes laser cleaning suitable for different types and sizes of surfaces.

Advantages of laser cleaning

As an advanced cleaning method, laser cleaning technology has many advantages and shows unique characteristics in many aspects, ranging from efficiency, and accuracy to environmental protection. The following are the main advantages of laser cleaning technology:

Efficient and fast

Laser cleaning technology has very high cleaning efficiency and can complete the cleaning process in a very short time. This is particularly important in industrial production lines, which can greatly improve production efficiency, reduce cleaning time, and reduce production costs.

No chemicals required

Compared with traditional cleaning methods, laser cleaning does not require the use of chemicals. Traditional cleaning methods may require a large amount of cleaning agents and solvents, but laser cleaning uses laser energy to directly act on the surface, avoiding chemical pollution to the environment and conforming to the concept of green environmental protection.

High precision

Laser cleaning technology has extremely high precision and can precisely control the focus and intensity of the laser beam, so it can remove surface dirt without damaging the substrate. This is particularly important for application fields that have strict requirements on cleaning results, such as electronic component manufacturing, precision instruments, etc.

No mechanical wear

Compared with some mechanical cleaning methods, laser cleaning does not involve physical contact, so there is no secondary contamination problem caused by mechanical wear. This helps protect the surface quality of the object being cleaned and prolongs its service life.

Multi-material applicability

Laser cleaning technology is suitable for a variety of materials, including metals, plastics, ceramics, and more. This makes it widely applicable in different industries and application fields and can cope with the cleaning needs of various surface characteristics.

No residue

Since laser cleaning does not involve chemicals and the dirt removed during the cleaning process is in the form of fine powder, no residue is produced. This has advantages in certain industries that require high purity, such as semiconductor manufacturing, medical device production, etc.

Strong controllability

The laser cleaning system is highly adjustable. Operators can adjust laser parameters according to specific needs, including energy, pulse width, frequency, etc., to achieve precise control of different materials and cleaning requirements.

Suitable for complex structures

Laser cleaning can use beam focusing and aiming technology, which is suitable for various complex structures and curved surfaces, and can clean areas that are difficult to reach with traditional methods.

Energy saving and emission reduction

Compared with some traditional cleaning methods, laser cleaning is more efficient in energy use, can reduce energy consumption, and reduces negative impacts on the environment.

Therefore, the many advantages of laser cleaning technology make it widely used in industrial, cultural heritage, and other protection fields.

Environmental protection characteristics of laser cleaning

Laser cleaning has several environmentally friendly features that make it more environmentally friendly than some traditional cleaning methods. The following are the environmentally friendly features of laser cleaning.

No chemicals required

There is no need to use any chemical cleaners or solvents during the laser cleaning process. Traditional cleaning methods often require large amounts of chemicals that can have negative impacts on the environment, including the generation of chemical waste and contamination of water sources. The chemical-free use of laser cleaning reduces these environmental concerns.

Low energy consumption

Compared with some traditional cleaning methods with high energy consumption, laser cleaning can usually use energy more efficiently. Its efficient cleaning process and adjustable laser parameters help reduce overall energy consumption, thereby reducing energy dependence.

Waste reduction

Laser cleaning produces relatively little waste, which is usually in the form of a fine powder of the dirt being removed. Compared with the large amounts of wastewater and waste solvents produced by some traditional cleaning methods, this helps reduce waste treatment and disposal costs and reduces the burden on the environment.

No secondary pollution

Since laser cleaning does not involve mechanical wear, no additional contaminants will be produced during the cleaning process, thus avoiding secondary contamination problems caused by mechanical wear.

Recyclable

Because laser cleaning does not introduce harmful chemicals, cleaned surfaces can often be recycled more easily. This has a positive significance for promoting sustainable development and resource conservation.

Potential environmental issues with laser cleaning

Although laser cleaning technology has many advantages, there are still some potential environmental issues that need to be considered in practical applications. Here are some environmental issues that may arise from using laser cleaning:

Energy consumption

- Equipment energy consumption: The operation of laser cleaning equipment usually requires a considerable amount of electrical energy. Especially for large-scale production lines or long-running cleaning tasks, the high energy consumption of the equipment may cause a certain burden on the power grid.

- Laser energy consumption: The high energy requirements of pulsed lasers can result in greater energy consumption of the device. While pursuing cleaning effects, efforts need to be made to improve the utilization efficiency of laser energy to reduce energy dependence.

Waste Disposal

- Removal of waste from objects: Dirt and coatings removed by laser cleaning are usually in the form of fine powders. Although the waste liquid and waste solvent produced by some traditional methods are reduced, these fine powders still need to be handled properly to avoid potential pollution to the environment.

Environmental impacts of laser equipment manufacturing and maintenance

- Production and Disposal: Manufacturing laser cleaning equipment involves the collection, processing, and manufacturing of resources, which in itself may have some negative impacts on the environment. In addition, the equipment needs to be disposed of properly to reduce the impact on the environment.

Possible gas emissions

- Gases produced by the laser process: Some gases may be produced during laser cleaning, especially when working with certain types of materials. These gases may contain harmful substances and require appropriate treatment in cleaning equipment to prevent negative impacts on air quality.

Impact on the working environment

- Laser radiation: High-energy lasers may produce radiation, and it is necessary to ensure that both the operator and the surrounding environment are adequately protected when using laser cleaning equipment. This includes adopting appropriate protective measures and equipment safety standards.

Maintenance requirements

- Waste generated by equipment maintenance: Maintenance of laser cleaning equipment may involve cleaning optical components, replacing parts, etc. The waste generated from these maintenance activities needs to be disposed of properly to prevent potential impact on the environment.

Environmentally Friendly Measures for Laser Cleaning

To improve the environmental friendliness of laser cleaning technology, a series of measures can be taken, involving many aspects such as equipment design, operation management, waste treatment, and sustainable development. Here are some friendliness measures:

Equipment technology improvement

- Energy efficiency improvement: Develop more efficient laser cleaning equipment to reduce energy consumption and optimize beam utilization efficiency to reduce the burden on the power grid.

- Radiation control: Design equipment and working environment for the radiation generated by a laser to ensure that operators and the surrounding environment are adequately protected and comply with relevant safety standards.

Waste Management and Disposal

- Micropowder handling: Developing effective waste treatment technologies, specifically for micropowders generated by laser cleaning. This can include methods such as filtration, recycling, and reuse to minimize waste discharge.

- Disposal of discarded equipment: Develop a recycling and disposal plan for discarded equipment to ensure that discarded equipment does not negatively impact the environment.

Industry standards and regulations

- Develop environmental standards: Industry organizations, governments, and businesses can work together to develop environmental standards and regulations for laser cleaning equipment. This helps standardize the application of laser cleaning technology and ensure its environmental friendliness.

- Promote technological innovation: Promote the development of the entire industry in a more environmentally friendly direction by encouraging technological innovation in laser cleaning technology, such as the development of more environmentally friendly laser sources and optical components.

Training and Education

- Operation training: Provide operation training for laser cleaning equipment to ensure that operators understand safe operating procedures and environmental awareness, and reduce risks during operation.

- Environmental education: educate practitioners, managers, and the public to strengthen their understanding of the environmental protection characteristics and sustainability of laser cleaning technology and promote its correct application.

Circular economy principles

- Sustainability by design: Consider the sustainability and recyclability of materials during the design phase of laser cleaning equipment to promote the principles of a circular economy.

- Product life cycle management: Focus on promoting product life cycle management of laser cleaning equipment, including extending the service life of equipment, providing maintenance and update services, and reducing the number of discarded equipment.

Public participation

- Information transparency: Promote public participation and social supervision by providing information and transparency about laser cleaning technology and environmental protection characteristics to ensure the rational use and management of technology.

Summarize

As an advanced cleaning technology, laser cleaning brings the advantages of high efficiency, precision, and no chemical substances. It has shown its wide application prospects from industrial manufacturing to cultural relic protection. However, we cannot take the environmental issues of laser cleaning lightly. This requires us to continue to innovate in technology and minimize the potential impact of laser cleaning on the environment by reducing energy consumption, improving waste treatment technology, and other measures.

AccTek Laser focuses on the expertise and application of laser cleaning solutions. We offer laser cleaning machines in a variety of power ranges and provide training (including laser safety procedures, equipment operation, maintenance, and troubleshooting) to ensure your employees get the most from their laser cleaning solutions. Contact us today to find the laser cleaning solution that’s right for you.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions