Fiber Laser Cleaning Machine

- Brand: AccTek

- Model: AKQ

- Laser Power: 1000W/1500W/2000W/3000W

- Laser Genertor: Raycus/JPT/Reci/Max/IPG

- Fiber Length: Standard 10m, maximum support 20m

- Price Range: $4100-$8300/Set

- After Sale: 3 Years

- Lead Time: 15-17 Working Day

| Model | AKQ-1000 | AKQ-1500 | AKQ-2000 | AKQ-3000 |

|---|---|---|---|---|

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Fiber Laser | |||

| Laser Generator | JPT / Raycus / Reci / IPG / Max | |||

| Pulse Formation | Q-Switched (Quality factor) | |||

| Cleaning Efficiency | 12㎡/h | |||

| Scanning Width | 10-80mm | |||

| Expected Focal Distance | 160mm | |||

| Fiber Cable Length | 10m | |||

| Cooling Type | Water cooling | |||

Product Configuration

Famous Fiber Laser Generator

Interactive Touch Screen Control System

Industrial Water Chiller

The industrial water cooler ensures the heat dissipation of the core optical path components, allowing the welding machine to provide consistent welding quality and helping to improve the overall quality of the weld itself. It can also increase welding output by reducing the downtime of fiber laser welding machines. In addition, an excellent industrial water cooler can also prolong the service life of the laser welding machine.

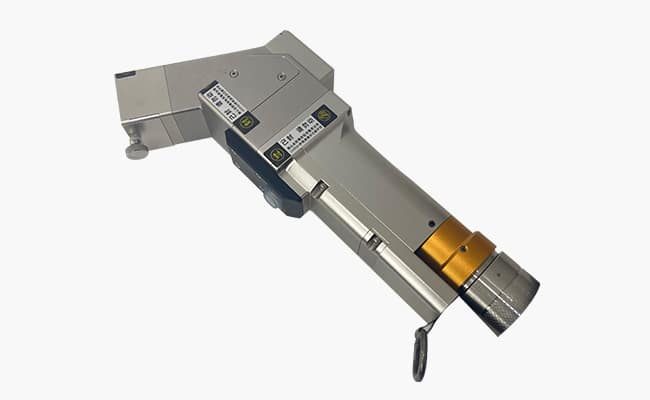

Laser Cleaning Head

Product Features

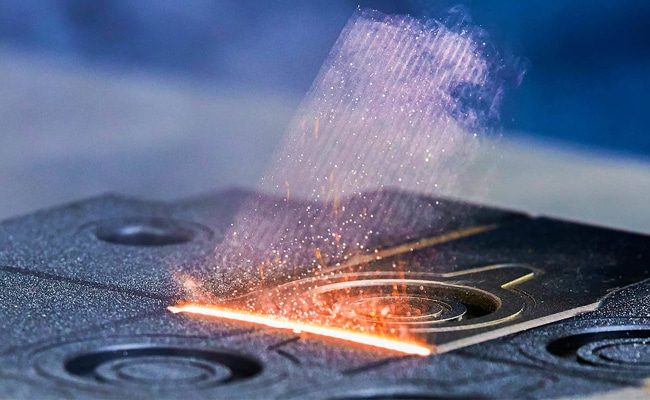

- Laser cleaning is a “green” cleaning method that does not need to use any chemicals or cleaning fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, and can easily solve the Environmental Pollution problems caused by chemical cleaning;

- The traditional cleaning method is often contact cleaning. The surface of the object to be cleaned has mechanical force, and the surface of the object that will be damaged or the cleaning medium adheres to the surface of the object to be cleaned and cannot be removed, causing secondary pollution. The non-abrasive and non-contact laser cleaning solves these problems;

- Laser cleaning can be transmitted through optical fiber, cooperate with robots to realize long-distance operation, and can clean parts that are difficult to reach by traditional methods;

- Laser cleaning can remove all kinds of pollutants on the surface of various materials, and achieve cleanliness that cannot be achieved by conventional cleaning. In addition, it can selectively clean the contaminants on the surface of the material without damaging the surface of the material;

- High efficiency of laser cleaning, saving time and effort;

Product Advantages

- No consumables, no chemical pollution, saving energy and electricity.

- No contact, no friction, and no stress can protect the surface of brittle materials, and minimize damage to the substrate.

- It can remove pollution particles below the nanometer level, and the cleanliness is high.

- Optical fiber transmission can be moved and operated, precisely positioned for cleaning, and can also clean areas that are not easily accessible.

- Synchronous cleaning and synchronous processing to achieve zero discharge during the cleaning process.

- It can realize fast cleaning of heavy pollutants and high-speed cleaning of light pollutants.

- Laser cleaning can solve problems that cannot be solved by traditional cleaning methods.

- Wide range of applicable materials for laser cleaning.

Product Application

Why Choose AccTek?

Factory Preset Cleaning Parameters

- Simple preset selection ensures consistent high-quality laser cleaning results.

- Operators can instantly switch between different presets to facilitate the cleaning of multiple materials;

- Advanced operators can make custom presets, and save them for future use, and novice operators can use them to produce the same results;

- Novice operators need less training to get started, reducing labor costs while maintaining cleaning quality;

Quick And Easy Setup

- Clear identification on the rear of the machine makes connection easy and fast.

- A single cable from the unit carries laser power, gas, and control connections to the laser gun.

- The ethernet computer connection provides access to advanced parameter settings for fine-tuning and saving cleaning process parameters.

Easy To Operate And Maintain

- The machine is ergonomic, compact, and proven to be the most comfortable and easy-to-use laser gun, and has a built-in adjustment wash width setting.

- Equipped with an intuitive user interface that allows you to quickly and easily adjust settings and monitor the progress of the cleaning process.

- The machine is designed to be energy efficient and requires very little maintenance.

Operator Safety Features

- Key switch control to protect the system from unauthorized cleaning operations.

- The emergency stop button can ensure that the machine can be shut down immediately when there is a problem.

- The safety interlock device verifies the integrity of laser delivery to the cleaning gun.

- Laser triggering requires 2 steps of operation (1: Laser Ready; 2: Laser Emission) to ensure the safety of cleaning operations.

- If anyone other than the operator accidentally enters the cleaning area, the door switch interlock circuit shuts off the laser.

Frequently Asked Questions

Choosing the right fiber laser cleaning machine is a critical decision for any business that requires precision cleaning of a variety of materials. Choosing the right fiber laser cleaning machine for your specific needs requires careful consideration of several key factors. Here are some important factors to consider when choosing a fiber laser cleaning machine:

- Laser power and capacity output: The power and energy output of the laser are key factors in determining the effectiveness of the cleaning process. Higher power and energy output generally result in faster, more efficient cleaning. However, higher-powered lasers may also have higher costs and require additional safety precautions. Consider the type of contaminants and surfaces you need to clean, and choose a machine with the proper power and energy output to meet your requirements.

- Wavelength: The wavelength of the beam determines the type of material that can be effectively cleaned. Different wavelengths are better suited for different materials, so choosing the right machine for the material you are cleaning is critical. Consider the type of contamination and surface you need to clean, and choose a machine with the right wavelength for the best cleaning results.

- Spot size and scanning speed: The spot size and scanning speed of the laser beam will affect the cleaning area and cleaning time. Larger spot sizes and higher scan speeds can clean larger areas in less time but may reduce cleaning accuracy and lead to poor cleaning results.

- Pulse duration: The pulse duration of the laser beam affects cleaning efficiency and surface quality. Shorter pulse durations are generally better for removing tough contaminants, while longer pulse durations may be better for removing delicate surfaces.

- Pulse width and frequency: The pulse width and frequency of the laser beam can also affect the cleaning ability of the machine. Shorter pulse widths and higher frequencies are generally more effective at removing contaminants from metals, while longer pulse widths and lower frequencies may be more suitable for cleaning organic materials.

- Scanning system: The scanning system is responsible for controlling the movement of the laser beam on the surface to be cleaned. It determines the cleaning speed, accuracy, and coverage area, so a good scanning system is only important to achieve accurate cleaning results. Try to choose a machine with a high-quality scanning system that can be easily adjusted to optimize the cleaning process for different surfaces and contaminants.

- Cleaning head and optics: The cleaning head and optics play a vital role in focusing the laser beam onto the surface and controlling the spot size. High-quality cleaning heads with good optics ensure consistent and effective cleaning results. Try to choose a machine with cleaning heads that are durable, easy to adjust, and compatible with different types of lenses or nozzles to suit a variety of cleaning requirements.

- Safety features: The high-powered laser beam produced by the fiber laser cleaning machine can cause injury to the operator and bystanders. Try to choose a fiber laser cleaning machine with appropriate safety features, such as interlock switches, emergency stop buttons, and laser safety shields, to protect the operator and the surrounding environment from accidental laser exposure.

- Brand and technical support: The brand and technical support of the fiber laser cleaning machine manufacturer need to be considered. A good manufacturer will produce reliable and high-quality products and will provide adequate technical support. This can guarantee the smooth operation and maintenance of the machine.

- Control unit and user interface: The control unit and user interface of the fiber laser cleaning machine should be user-friendly, allowing easy control of various settings such as laser power, scanning speed, and spot size. A machine with a clear and intuitive interface simplifies the operation and optimization of the cleaning process.

- Cost: The cost of a fiber laser cleaning machine can vary greatly depending on the features and capabilities of the machine. While pricier machines may have more advanced features, they may not be necessary for your specific cleaning needs. Therefore, when choosing a suitable fiber laser cleaning machine, it is necessary to balance cost, expected use, and expected benefits.

The above factors need to be carefully considered when choosing a fiber laser cleaning machine. By carefully considering these factors, you can purchase a fiber laser cleaning machine that meets your specific needs. If you are looking for a suitable fiber laser cleaning machine, please feel free to contact us. Our engineers will combine your purpose, budget, and other factors to help you choose a suitable fiber laser cleaning machine.

- Rust removal: The fiber laser cleaning machine can effectively remove the rust and corrosion of the metal surface, leaving a clean and corrosion-free surface. This makes it ideal for use in the automotive, marine, and aerospace industries where metal parts are prone to rust and clothing.

- Paint and coating removal: It effectively removes paint and coatings from metal, wood, and plastic surfaces. Laser beams can ablate paint or coatings without damaging the underlying surface, making them a viable option for surface preparation in industries such as automotive, aerospace, and shipbuilding.

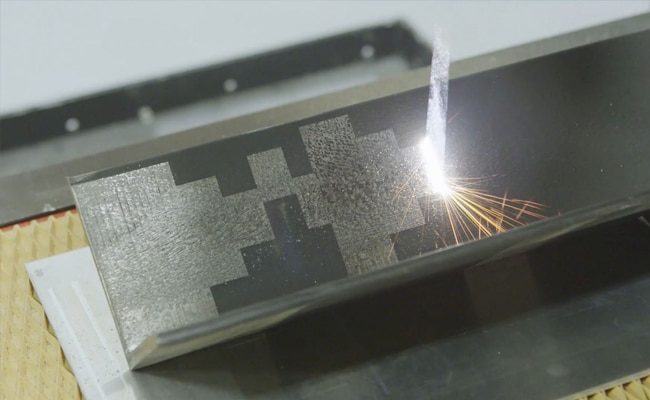

- Surface preparation: It is also used for surface preparation before bonding, welding, or painting. Removing contaminants, oxides, and other debris from the surface, improves the adhesion and quality of subsequent processes, ensuring optimum bonding or coating results.

- Welding cleaning: Welding will leave pollutants and debris on the metal surface, which can be easily removed by using a fiber laser cleaning machine to ensure high-quality welds and no defects.

- Restoration of historic artifacts: Historic artifacts, such as statues and monuments, may discolor over time. It safely removes these stains and restores the workpiece to its original condition without causing any damage.

- Mold and grease removal: Mold and grease can be difficult to remove from surfaces, but it effectively removes these contaminants, keeping surfaces clean and safe.

Fiber laser cleaning machines are versatile and can be used to clean a variety of materials. The type of material and type of contamination will determine the laser beam power and wavelength required for effective cleaning. Here are some examples of materials that can be cleaned with a fiber laser cleaning machine:

- Metals: It is especially effective for removing contaminants from metals including copper, aluminum, steel, brass, and titanium. It removes rust, paint, grease, and other types of contaminants from metal surfaces. Laser cleaning technology can clean metals of different thicknesses, shapes, and sizes.

- Plastics: It removes contaminants from plastics including polypropylene, polyethylene, and ABS. It removes adhesives, release agents, and other types of contaminants from plastic surfaces, making it suitable for applications in the automotive, electronics, and consumer goods industries.

- Ceramic: It removes contaminants from ceramic surfaces, including porcelain, tile, and other ceramic items. Contaminants that can be removed include grease, dirt, and other types of contaminants.

- Glass: It cleans glass surfaces such as windows, optical lenses, and glass molds. It removes dirt, coatings, and other contaminants from the glass surface without causing damage to the glass.

- Composites: It cleans composite materials, including carbon fiber and fiberglass, to remove contaminants from the composite surface without damaging the underlying material.

It is worth noting that the effectiveness of fiber laser cleaning machines may vary depending on the type of material and the nature of the contaminants being removed. Different laser parameters such as laser power, pulse width, and scan speed may need to be adjusted for different materials and contaminants to achieve optimal cleaning results. Therefore, fiber laser cleaning processes must be tested and optimized for specific materials and applications to ensure the best results. Additionally, proper safety precautions should be taken when operating a fiber laser cleaning machine, including personal protective equipment and proper ventilation.

Fiber laser cleaners offer several advantages over traditional cleaning methods. Here are some key advantages:

- Non-contact, non-abrasive cleaning: Fiber laser cleaning is a non-contact, non-abrasive cleaning method, meaning it does not require physical contact with the surface being cleaned, thus reducing the risk of damaging delicate components or surfaces. This is especially important with delicate or sensitive materials.

- Precision cleaning: The fiber laser can be precisely controlled and adjusted, allowing for precise cleaning of a specific area without affecting the surrounding area. This is especially useful for intricate surfaces that are difficult to clean using traditional cleaning methods.

- Eco-friendly: It is an environmentally friendly way of cleaning that does not require the use of chemicals or abrasive materials, reduces the generation of hazardous waste, and minimizes the impact on the environment.

- Reduced labor costs: It cleans surfaces quickly and efficiently, reducing manual labor requirements and lowering overall project cleaning costs.

- Versatile: It can be used to clean a wide variety of materials and surfaces, including metals, plastics, ceramics, and composites, making it a versatile cleaning solution for a variety of industries.

- Faster and more efficient: Fiber laser cleaning machines can clean large areas quickly and efficiently. Compared with traditional cleaning methods, cleaning time and labor costs are reduced. It also removes stubborn contaminants like rust or paints more effectively, increasing cleaning efficiency.

While fiber laser cleaning has many advantages, like many other cleaning methods, it has some disadvantages. Here are some major disadvantages:

- High cost: Fiber laser cleaning machines can be expensive compared to traditional cleaning methods and may not be a practical solution for all businesses or industries.

- Certain materials only: It is not suitable for all materials, such as certain types of glass or highly reflective surfaces, which may not be suitable for fiber laser cleaning due to their optical properties. Such surfaces may require specialized laser equipment or alternative cleaning methods.

- Surface damage: While a laser beam is very precise, it can damage certain types of surfaces if used incorrectly. The power and wavelength of the laser must be carefully controlled to avoid damaging delicate surfaces.

- Limited range: Laser beams have a limited cleaning range and may not be suitable for cleaning large or hard-to-reach areas.

- Safety concerns: It emits a high-intensity laser beam that can be dangerous if used incorrectly. Appropriate safety measures, such as wearing proper protective equipment and following safety guidelines, must be followed to ensure safe operation.

- Limited effectiveness on certain contaminants: While it can effectively remove certain types of contaminants, it may not work as well on others, such as stubborn stains or heavy grease buildup.

- Maintenance: Fiber laser cleaning machines require regular maintenance to ensure their performance and longevity. Maintenance includes cleaning and aligning optics, replacing consumables, and aligning the system, which may require additional time and cost.

Fiber laser cleaning offers several advantages over traditional cleaning methods, including precision, speed, and environmental friendliness. However, there are also some disadvantages to consider, such as safety concerns and maintenance requirements. When deciding whether a fiber laser cleaning machine is right for your business, it is important to carefully evaluate your specific cleaning needs and budget. AccTek Laser is a factory specializing in the production and manufacture of fiber laser cleaning machines, we provide perfect services and competitive prices. If you are planning to purchase a fiber laser cleaning machine, you can contact us at any time.