Laser cutting software

Computer-Aided Design (CAD) Software

Computer-aided design (CAD) software is the cornerstone of laser cutting. It enables designers and engineers to create detailed 2D and 3D models and convert them into machine-readable instructions for laser-cutting machines. Common CAD software includes:

- AutoCAD: AutoCAD is an industry-standard CAD software developed by Autodesk that excels at creating precise 2D and 3D designs. AutoCAD files are widely compatible with laser-cutting software and machines, making them the first choice for a variety of industries, including architecture and engineering.

- SolidWorks: SolidWorks is a powerful 3D CAD software ideal for modeling complex 3D parts and assemblies. It is compatible with various file formats used in laser-cutting workflows, including DXF and STL.

- Rhino: Rhino is a versatile 3D modeling software known for its ease of use and adaptability. It can export files in a variety of formats, suitable for laser-cutting projects with different needs.

Vector graphics software

2D vector graphics are an essential element for many laser-cutting projects. Vector graphics software is specifically designed to create precise, scalable 2D designs. Some popular options include:

- Adobe Illustrator: Adobe Illustrator is a leading vector graphics software widely used in many design industries. It excels at creating complex 2D vector graphics and designs. AI files created in Illustrator retain high-quality vector data, making them ideal for laser-cutting projects with intricate details.

- CorelDRAW: CorelDRAW is a user-friendly vector graphics software known for its versatility and ease of use. It is popular among designers for creating vector-based graphics.

- Inkscape: Inkscape is an open-source vector graphics software that provides a cost-effective alternative to proprietary options. It’s free and easy to use, and the SVG files it generates are compatible with many laser-cutting programs.

3D modeling software

In projects that require complex 3D shapes, 3D modeling software is essential. Some well-known options include:

- Blender: Blender is a versatile 3D modeling software widely used to create 3D models, animations, and visual effects. It is valued for its flexibility and adaptability. STL files commonly used in laser cutting can be easily exported from Blender for 3D laser cutting and engraving.

- Autodesk Maya: Autodesk Maya is a high-end 3D modeling and animation software commonly used for film and game development. It supports OBJ file format, which makes it compatible with laser cutting workflow.

- 3ds Max: 3ds Max is another product from Autodesk that specializes in 3D modeling and rendering. It is suitable for creating visualizations and animations. Like Maya, 3ds Max supports the OBJ file format for 3D laser cutting.

Common file formats

2D vector file format

- DXF (Drawing Exchange Format): DXF is one of the most popular file formats for laser cutting. It is a vector file format that stores 2D data and is highly compatible with various laser-cutting software and machines. DXF files offer versatility and accuracy in saving design data.

- DWG (AutoCAD Drawing): The DWG format is closely related to AutoCAD software. It is particularly prevalent in construction and engineering applications. When laser cutting machines are integrated with AutoCAD-based software, DWG files are typically used.

- AI (Adobe Illustrator): AI files are created in Adobe Illustrator, a well-known vector graphics software. It works with complex 2D vector graphics and maintains high-quality vector data.

- SVG (Scalable Vector Graphics): SVG is an open standard vector file format that enjoys widespread support in vector graphics software and laser cutters. It is an ideal format for 2D vector graphics that need to be resized without losing quality.

- EPS (Encapsulated PostScript): EPS files are often used in laser-cutting projects involving text and logos. These files can store vector and raster data and can be edited in a variety of software programs.

3D file format

- STL (Stereolithography): STL files are built specifically for 3D printing and 3D laser cutting. It uses a collection of triangles or polygons to describe the surface geometry of a 3D model. This format is the first choice for complex 3D laser cutting and engraving projects.

- OBJ (Wavefront OBJ): OBJ files are a common 3D file format used in 3D modeling and 3D laser cutting workflows. It stores 3D model information and is compatible with a variety of design software, including Blender, Maya, and 3ds Max.

Hybrid and universal formats

- PDF (Portable Document Format): PDF files are known for their versatility and portability. Although primarily document formats, they can contain vector and raster data. PDF files are also sometimes used for laser cutting, especially for simpler designs or when compatibility with various software is required.

- CDR (CorelDRAW): CDR files are proprietary files of the vector graphics software CorelDRAW. Although CDR files are closely related to CorelDRAW, they can be opened in other software that supports the format.

Choose the right software and format

Project complexity

Machine compatibility

Software familiarity

Project requirements

Interoperability

Laser cutting workflow

Now that we’ve explored the basics of laser cutting software and file formats, let’s put this knowledge into practice. Understanding the interaction between software and file formats can help ensure a successful laser-cutting project. Here is a simplified overview of the laser-cutting workflow:

- Design creation: Designers use CAD software, vector graphics software, or 3D modeling software to create 2D or 3D designs according to project requirements.

- File export: Designs are exported in appropriate file formats such as DXF, DWG, AI, SVG, STL, or OBJ, ensuring compatibility with design software and laser-cutting machines.

- File import: The exported design files are imported into the laser cutting software, which acts as an intermediary between the design and the machine. Laser-cutting software interprets the design and converts it into machine-readable instructions.

- Machine setup: Configuring the laser cutting machine, includes loading the material to be cut, configuring laser power and speed settings, and ensuring safety measures are in place.

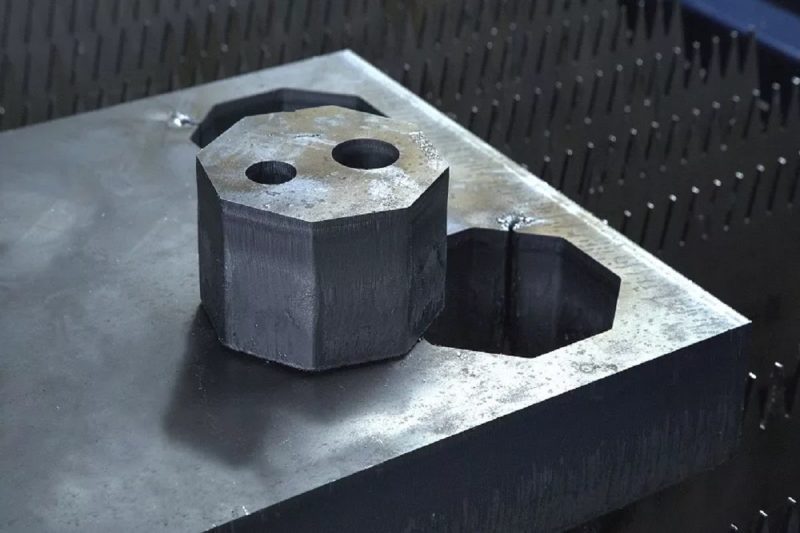

- Laser cutting: The laser cutting machine executes the design according to the instructions in the file. It cuts, engraves, or marks material in a specified manner.

- Quality control: After the cutting process is completed, quality control inspections will be conducted to ensure that the final product meets the design specifications.

- Post-processing: Depending on the project, post-processing tasks such as cleaning, assembly, or other processing may be required.

- Project completion: Once post-processing is complete, the project is considered complete and the finished product is ready for use, assembly, or distribution.

Summarize

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.