Laser Cutting Machine Operation Safety Guide

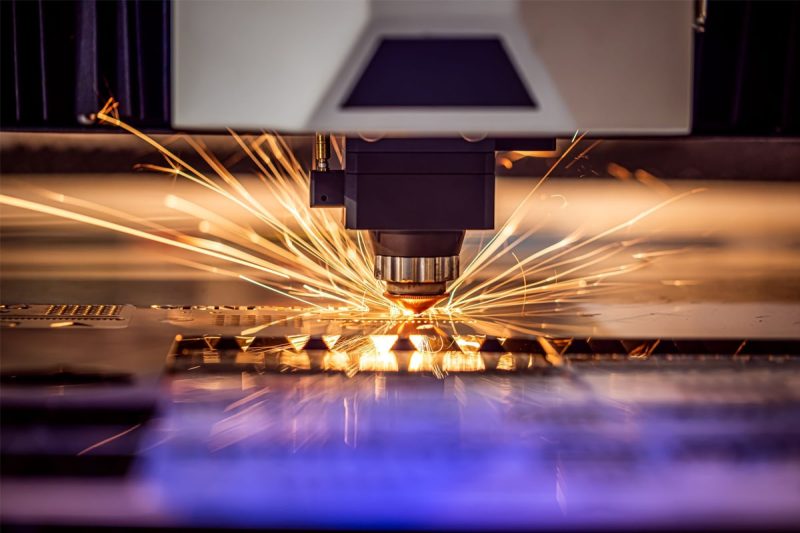

As an indispensable part of modern manufacturing, laser cutting technology provides efficient and precise material processing solutions for all walks of life. It has been widely used in industrial production. However, safety issues during operations have increasingly attracted people’s attention. The operation of laser cutting machines involves high-energy laser beams and complex mechanical systems. If appropriate safety measures are not taken, it may cause serious harm to operators and equipment, or even cause accidents. Therefore, when operating a laser cutting machine, a series of strict safety measures must be taken to ensure the safety of operators and equipment.

This article will introduce in detail the various safety measures that should be taken when operating a laser cutting machine, including the basic principles of laser cutting machines, the importance of operating laser cutting machines safely, and the development trends and application fields of laser cutting technology to ensure the safety of operations.

Table of Contents

Basic Principles Of Laser Cutting Machine

A laser cutting machine is a device that uses a high-energy laser beam to cut materials into desired shapes. Its basic principle involves the following key steps:

- Laser transmitter generates laser beams: Laser cutting machines usually use CO2 laser generators or fiber laser generators as laser sources to generate high-energy laser beams by exciting working materials, such as gas or optical fibers.

- Focusing of the laser beam: The generated laser beam is focused through optical elements, such as concave lenses or optical fibers. The focused laser beam can concentrate energy in a very small area, increasing cutting accuracy and efficiency.

- Material absorbs laser energy: When the laser beam is focused on the surface of the workpiece, it is absorbed by the cutting material and converted into heat energy. The energy of a high-energy laser beam causes the material to locally heat up, causing it to melt or vaporize.

- Assist gas to clear the melted area: Use an assist gas, such as nitrogen or oxygen, to purge the molten material and help cool the cutting area. Different assist gases can affect cutting quality and speed.

- The control system controls the cutting process: The control system can precisely control the intensity, focus position, and movement path of the laser beam. The operator can input the designed cutting pattern to make the machine cut according to the predetermined path.

Therefore, the laser cutting machine uses laser beam to locally heat and melt or vaporize the material, and then achieves precise cutting of the material by moving the laser beam and supplemented by auxiliary gas purge. This cutting method is efficient, precise, and suitable for a variety of materials, but improper operation can also cause serious injuries. The safe operation of laser-cutting machines is crucial to operators and equipment.

The Importance of Safe Operation of Laser Cutting Machines

The safe operation of laser-cutting machines is critical to both the operator and the equipment. Here are a few aspects of its importance:

Importance To Operators

- Personal safety: The operation of the laser cutting machine involves high-energy laser beams and complex mechanical systems. If not operated carefully, the operator may be injured by direct laser beams, hot melt splashing, etc.

- Occupational health protection: Long-term exposure to laser radiation and harmful gases may affect the health of operators, such as eye damage, respiratory diseases, etc., so safe operation can protect the occupational health of operators.

- Reduce accidents: The implementation of safe operating procedures and measures can effectively reduce the incidence of accidents and reduce injuries and losses at work.

- Improve work efficiency: Reasonable safe operating procedures and training can help operators better master equipment operation skills and improve work efficiency and production quality.

Importance To Equipment

Extend the life of the equipment: Safe operation can avoid equipment damage and failure caused by operating errors and extend the service life of the laser cutting machine.

Protect equipment integrity: Safe operating procedures and measures can reduce accidental damage and wear of equipment and protect the integrity and stability of equipment.

Save maintenance costs: Safe operation can reduce repair and replacement costs caused by operating errors and reduce the company’s production costs.

Maintain production continuity: Safe operations can avoid production interruptions caused by equipment failures or accidents and ensure production continuity and stability.

In short, the safe operation of laser cutting machines is of extremely important significance to ensure the safety and health of operators, extend the life of equipment, reduce production costs, and maintain production continuity. Therefore, enterprises and operators should attach great importance to safe operations and strictly implement safety regulations and measures.

What Safety Measures Should Be Taken When Operating A Laser Cutting Machine

When operating a laser cutting machine, it is crucial to take a series of safety measures to ensure the safety of both the operator and the equipment. The following will introduce in detail the security measures in various aspects:

Safety Training And Education

- All operators must receive comprehensive safety training and education before operating a laser-cutting machine. The training content should cover the basic principles, operating procedures, safety procedures, emergency handling procedures, etc. of the laser cutting machine. Through training, operators can understand the dangers of laser cutting machines and learn to properly use and maintain the equipment.

Equipment And Protective Measures

- Laser safety shield: must be installed on the laser cutting machine, which can effectively block the laser beam and prevent radiation damage.

- Personal protective equipment: Operators should be equipped with appropriate personal protective equipment, such as goggles, protective clothing, gloves, etc., to protect their safety.

- Safety interlock system: Ensure that the laser cutting machine can start working only when it is in a safe position and that all protective devices are intact to prevent unauthorized personnel from entering the operating area.

Environmental Safety

- Ventilation system: The operating area should be equipped with a good ventilation system to eliminate harmful gases generated by laser cutting promptly to protect the health of operators.

- Fire prevention measures: Fire extinguishers and other fire-fighting equipment should be installed around the equipment, and regular inspection and maintenance should be carried out to prevent fire accidents.

Laser Safety

- Do not look directly into the laser beam: Operators must not look directly into the laser beam and should always wear goggles to prevent eye damage from laser radiation and ensure that other personnel are not directly exposed to the laser beam.

- Pay attention to material compatibility: Some materials may release toxic and harmful gases during cutting. Protective measures and extraction measures should be taken to avoid harm to personnel.

Emergency Maintenance

- Develop emergency procedures: Establish and train operators in emergency procedures, including measures to deal with various emergencies such as machine failure and fire, to ensure that various emergencies can be responded to in a timely and effective manner.

Machine Maintenance

- Regular maintenance plan: Establish a regular maintenance plan, including cleaning, lubrication, inspection, and other items, replacement of worn parts, etc., to ensure that the equipment is in optimal working condition and reduce the incidence of failures.

- Equipment maintenance and cleaning training for operators: Train operators to perform basic equipment maintenance and cleaning to extend equipment life and ensure operational safety.

Access Restrictions

- Strict access restrictions are implemented and non-staff are prohibited from entering the operating area. At the same time, set safety signs at appropriate locations to remind personnel to pay attention to dangerous areas and operating processes.

Safety Signage And Safe Materials Handling

- Install safety signs: Set up visible safety signs in the operating area to remind personnel to pay attention to operating procedures and dangerous areas.

- Safe Material Handling: When loading and unloading materials, operators must be aware of safe material handling issues. Especially when handling toxic and hazardous materials, appropriate protective measures must be taken to avoid pollution and harm to personnel and the environment.

In summary, a series of safety measures should be taken when operating a laser cutting machine to fully ensure the safety of operators and equipment from the above aspects. Only by strictly implementing these safety measures can operational risks be effectively reduced and production safety ensured.

Development Trends And Application Areas Of Laser Cutting Technology

As an efficient and precise material processing method, laser cutting technology has been widely used in industrial production, and its development trend is still expanding. The following are the main aspects of the development trends of laser cutting technology:

- High-power and high-speed cutting: With the continuous advancement of laser generator technology, the power and cutting speed of laser cutting machines continue to increase, which can complete cutting tasks faster and improve production efficiency.

- Multi-wavelength laser technology: The application of multi-wavelength laser technology can achieve more precise cutting of different materials and expand the application scope of laser cutting.

- Intelligence and automation: Laser cutting machines are equipped with advanced control systems and sensor technologies, which can achieve automated control and intelligent operation, improving production efficiency and quality.

- Popularization of fiber laser technology: Fiber laser technology has the advantages of small size, high energy density, and good beam quality. It is gradually replacing traditional CO2 laser technology and becoming the mainstream laser cutting technology.

- Green and environmentally friendly cutting: Green and environmentally friendly cutting is an important trend in the current development of laser cutting technology. By optimizing the cutting process and material selection, environmental pollution and energy consumption are reduced.

- Customized and flexible production: As the trend of personalization and customization in consumer demand intensifies, laser cutting technology can flexibly respond to the customized production needs of different products.

Summarize

When operating a laser cutting machine, it is crucial to strictly adhere to safety measures. Through professional training and education, operators can become familiar with operating procedures and emergency procedures. Equipped with appropriate protective equipment and safety interlocking systems to ensure the safety of operators and equipment. Laser safety shields, ventilation systems, and fire protection equipment can effectively prevent accidents. It is forbidden to look directly into the laser beam, and attention to material compatibility and safe material handling are important measures to ensure operational safety. In addition, establishing emergency procedures and regular machine maintenance, as well as enforcing access restrictions and security signage, can help improve operational safety.

To sum up, safety factors must be fully considered when operating a laser cutting machine to ensure the safety of operators and equipment, to complete production tasks, and to achieve expected results. Contact AccTek Laser today and let’s embark on a journey to redefine precision in manufacturing and manufacturing processes. Increase your production capabilities with our laser-cutting solutions and see the transformative impact on your business.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions