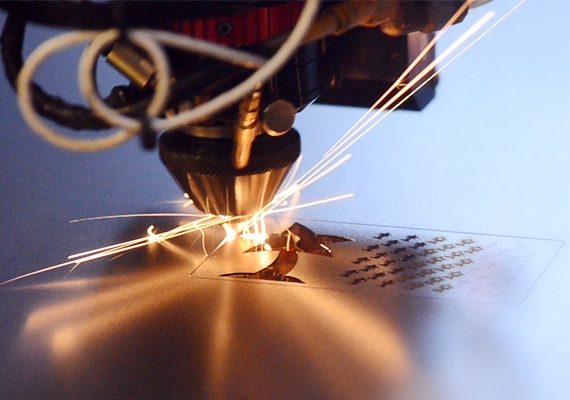

The high-quality laser cutting head delivers precision and efficiency, featuring advanced optics for superior beam focus and accuracy. Designed for durability and versatility, it ensures clean cuts on various materials, minimizing waste. With user-friendly adjustments and high-speed performance, it’s the perfect component for professional-grade laser cutting applications.

The ultra-stable laser generator is the heart of cutting-edge performance, delivering consistent power output for flawless cutting and engraving. Engineered for reliability, it ensures precision even during extended operations. Its advanced design minimizes fluctuations, enhances efficiency, and maximizes material compatibility, making it essential for professional-grade laser cutting applications.

The aviation aluminum beam combines lightweight design with exceptional strength, ensuring stability and precision during high-speed operations. Crafted from aerospace-grade aluminum, it enhances cutting accuracy while resisting deformation. Its corrosion-resistant and durable structure reduces vibration, enabling smooth, efficient performance, making it a cornerstone of advanced laser cutting technology.

The Sturdy Cutting Bed is built for durability and precision, providing a stable platform for flawless laser cutting. Its robust construction resists wear and deformation, ensuring long-term reliability. Designed to support heavy workloads and various materials, it enhances cutting accuracy and efficiency, making it indispensable for industrial-grade performance.

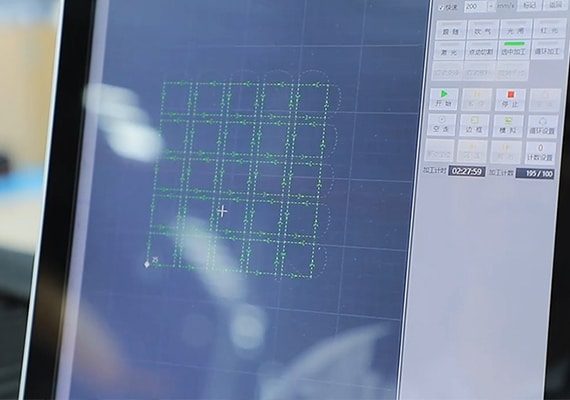

The friendly CNC control system offers intuitive operation with a user-focused interface, simplifying laser cutting processes. Equipped with advanced programming capabilities, it ensures precise control and seamless execution of complex designs. Compatible with various file formats, it boosts productivity while providing an effortless experience for professionals and beginners alike.

The high-precision servo motor ensures unmatched accuracy and smooth motion control for laser cutting operations. Its advanced design delivers rapid response and stable performance, enabling intricate cuts with exceptional detail. Built for durability and efficiency, it minimizes errors and enhances speed, making it essential for professional-grade cutting precision.

The high-performance reducer optimizes torque transmission for smooth and efficient laser-cutting operations. Engineered for durability, it minimizes vibration and ensures stable performance under high workloads. Its precision design enhances cutting accuracy and extends machine life, making it an indispensable component for achieving consistent, high-quality results.

The high-efficiency water chillers provide reliable cooling to maintain optimal laser performance during intensive operations. Designed for energy efficiency, they regulate temperature precisely, preventing overheating and ensuring consistent output. With a durable build and user-friendly controls, these chillers enhance system longevity and productivity, making them essential for peak laser-cutting efficiency.

| Model | AKJ-1325F | AKJ-1530F | AKJ-1545F | AKJ-2040F | AKJ-2560F |

|---|---|---|---|---|---|

| Cutting Range | 1300*2500mm | 1500*3000mm | 1500*4500mm | 2000*4000mm | 2500*6000mm |

| Laser Type | Fiber Laser | ||||

| Laser Power | 1-40KW | ||||

| Laser Generator | Raycus, Max, IPG | ||||

| Control Software | Cypcut, Au3tech | ||||

| Laser Head | Raytools, Au3tech, Boci | ||||

| Servo Motor | Yaskawa, Delta | ||||

| Guide Rail | HIWIN | ||||

| Maximum Moving Speed | 100m/min | ||||

| Maximum Acceleration | 1.0G | ||||

| Positioning Accuracy | ±0.01mm | ||||

| Repeat Positioning Accuracy | ±0.02mm | ||||

Achieves exceptional accuracy with advanced laser technology, delivering clean, intricate cuts on a variety of materials.

Combines powerful laser generators and optimized components to ensure fast, reliable performance for large-scale operations.

Features a sturdy cutting bed, aviation aluminum beam, and robust components designed for long-lasting, industrial-grade use.

Equipped with a friendly CNC control system, simplifying complex processes with intuitive controls and seamless integration.

Capable of cutting a wide range of materials, including metals, plastics, and composites, for diverse applications.

High-efficiency water chillers maintain optimal system performance while minimizing energy consumption.

High-precision servo motors and high-performance reducers ensure smooth, stable motion for flawless results.

Maximizes productivity with minimal material waste and maintenance costs, providing excellent value for businesses of all sizes.

| Laser Power | Thickness (mm) | Cutting Speed (m/min) | Focus Position (mm) | Cutting Height (mm) | Gas | Nozzle (mm) | Pressure (bar) |

|---|---|---|---|---|---|---|---|

| 6000W | 1 | 25-30 | -0.5 | 1 | O2 | 2.0S | 14 |

| 2 | 15-18 | -1 | 0.5 | O2 | 2.0S | 14 | |

| 3 | 8.0-10.0 | -2 | 0.5 | O2 | 2.0S | 12 | |

| 4 | 5.0-6.0 | -2 | 0.5 | O2 | 2.0S | 12 | |

| 5 | 3.0-4.0 | -3 | 0.5 | O2 | 2.5S | 10 | |

| 6 | 1.5-2.0 | -3 | 0.5 | O2 | 2.5S | 10 | |

| 8000W | 1 | 25-30 | -0.5 | 1 | O2 | 2.0S | 14 |

| 2 | 16-20 | -1 | 0.5 | O2 | 2.0S | 14 | |

| 3 | 12-14 | -2 | 0.5 | O2 | 2.0S | 14 | |

| 4 | 7.0-8.0 | -2 | 0.5 | O2 | 2.0S | 12 | |

| 5 | 4.0-5.0 | -3 | 0.5 | O2 | 2.5S | 12 | |

| 6 | 2.5-3.0 | -3 | 0.5 | O2 | 2.5S | 12 | |

| 8 | 1.0-1.5 | -4 | 0.5 | O2 | 3.0S | 12 | |

| 10 | 0.5-0.7 | -5 | 0.5 | O2 | 4.0S | 12 | |

| 10KW | 1 | 25-30 | -0.5 | 1 | O2 | 2.0S | 14 |

| 2 | 16-20 | -1 | 0.5 | O2 | 2.0S | 14 | |

| 3 | 12-15 | -2 | 0.5 | O2 | 2.0S | 14 | |

| 4 | 8-10 | -3 | 0.5 | O2 | 2.0S | 12 | |

| 5 | 5.0-6.0 | -4.5 | 0.5 | O2 | 2.5S | 12 | |

| 6 | 3.5-4.0 | -5 | 0.5 | O2 | 2.5S | 12 | |

| 8 | 1.5-2.0 | -6 | 0.5 | O2 | 3.0S | 12 | |

| 10 | 0.5-0.7 | -8 | 0.5 | O2 | 4.0S | 12 | |

| 12KW | 1 | 25-30 | -0.5 | 1 | O2 | 2.0S | 5 |

| 2 | 20-25 | -1 | 0.5 | O2 | 2.0S | 5 | |

| 3 | 16-18 | -2 | 0.5 | O2 | 2.0S | 6 | |

| 4 | 10-12 | -3 | 0.5 | O2 | 2.0S | 8 | |

| 5 | 6.0-8.0 | -4.5 | 0.5 | O2 | 2.5S | 8 | |

| 6 | 4.0-5.0 | -5 | 0.5 | O2 | 2.5S | 8 | |

| 8 | 2.0-2.5 | -6 | 0.5 | O2 | 3.0S | 10 | |

| 10 | 1.0-1.2 | -8 | 0.5 | O2 | 4.0S | 12 | |

| 15KW | 1 | 25-30 | -0.5 | 1 | O2 | 2.0S | 5 |

| 2 | 20-25 | -1 | 0.5 | O2 | 2.0S | 5 | |

| 3 | 18-20 | -2 | 0.5 | O2 | 2.0S | 6 | |

| 4 | 12-14 | -3 | 0.5 | O2 | 2.0S | 8 | |

| 5 | 8.0-9.0 | -4.5 | 0.5 | O2 | 2.5S | 8 | |

| 6 | 6.0-7.0 | -5 | 0.5 | O2 | 2.5S | 8 | |

| 8 | 2.5-3.5 | -6 | 0.5 | O2 | 3.0S | 10 | |

| 10 | 1.5-2.0 | -8 | 0.5 | O2 | 4.0S | 12 | |

| 20KW | 1 | 25-30 | 0 | 1 | O2 | 2.0S | 5 |

| 2 | 25-30 | 0 | 0.5 | O2 | 2.0S | 5 | |

| 3 | 20-25 | 0 | 0.5 | O2 | 2.0S | 6 | |

| 4 | 16-18 | -1 | 0.5 | O2 | 2.5S | 8 | |

| 5 | 10-12 | -1 | 0.5 | O2 | 2.5S | 8 | |

| 6 | 8.0-10.0 | -2 | 0.5 | O2 | 3.0S | 8 | |

| 8 | 4.0-6.0 | -3 | 0.5 | O2 | 3.0S | 10 | |

| 10 | 2.0-3.5 | -4 | 0.5 | O2 | 3.5S | 12 | |

| 12 | 2.0-2.5 | -5 | 0.5 | O2 | 3.5S | 12 | |

| 30KW | 1 | 25-30 | 0 | 1 | O2 | 2.0S | 5 |

| 2 | 25-30 | 0 | 0.5 | O2 | 2.0S | 5 | |

| 3 | 20-25 | 0 | 0.5 | O2 | 2.0S | 6 | |

| 4 | 18-20 | -1 | 0.5 | O2 | 2.5S | 8 | |

| 5 | 15-18 | -1 | 0.5 | O2 | 2.5S | 8 | |

| 6 | 10-15 | -2 | 0.5 | O2 | 3.0S | 8 | |

| 8 | 6.0-10.0 | -3 | 0.5 | O2 | 3.0S | 10 | |

| 10 | 2.0-3.5 | -4 | 0.5 | O2 | 3.5S | 12 | |

| 12 | 2.0-2.5 | -5 | 0.5 | O2 | 3.5S | 12 | |

| 14 | 1.5-2.0 | -6 | 0.5 | O2 | 3.5S | 12 |

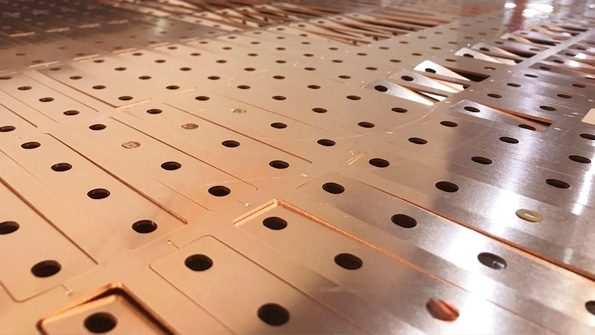

Yes, laser-cutting machines can effectively cut copper, but it presents more challenges compared to other materials due to its high reflectivity and excellent thermal conductivity. These properties can affect the efficiency of the cutting process by causing heat absorption and increased heat dissipation.

To tackle these challenges, fiber laser cutting machines are often the best choice. Fiber lasers have high power densities, making them ideal for cutting reflective metals like copper. Their focused energy is enough to counteract the reflectivity and thermal conductivity of copper, ensuring precise and clean cuts.

For optimal results, several factors must be properly configured when cutting copper, including laser power, beam quality, focal length, cutting speed, and assist gas selection. The thickness of the copper sheet also influences the settings, thicker copper requires more power and slower cutting speeds for effective results.

It’s important to note that laser-cutting copper generates fumes and may cause molten metal to splatter. Therefore, proper ventilation and personal protective equipment (PPE) should always be used to ensure operator safety. While laser-cutting copper is possible, the process requires the right equipment, settings, and safety precautions to achieve high-quality cuts.

The price of a copper laser cutting machine can vary significantly based on several factors, including the machine’s size, power output, cutting area, brand, and additional features. As copper laser cutting machines are typically high-end, sophisticated equipment, they tend to be more expensive than simpler cutting machines. Prices also fluctuate due to market conditions and technological advancements. Here is a rough breakdown of prices:

These price ranges are estimates and may vary depending on specific requirements, customization options, and the manufacturer. It’s also important to factor in additional costs such as installation, training, maintenance, and accessories, as these will impact the total cost of ownership. For accurate pricing based on your specific needs and budget, please contact us directly. Our team of engineers will help you choose the right copper laser-cutting machine and provide precise pricing details.

The operating costs of laser cutting copper depend on several factors, such as power consumption, maintenance needs, laser gas usage, and consumable replacements. Below is a rough estimate of the key cost components involved in copper laser cutting. Please note that these costs may vary based on location, market conditions, and specific service providers:

Operating costs can fluctuate significantly depending on factors such as cutting speed, material thickness, and machine efficiency. For more precise cost estimates tailored to your specific needs, please contact us directly. Our team will provide detailed information based on your setup and requirements.

Laser cutting copper itself is not inherently harmful, but there are important safety considerations and precautions to ensure the process is carried out safely. Below are key safety points to be aware of:

By following the recommended safety guidelines and ensuring a controlled environment, laser cutting copper can be performed safely, minimizing risks to operators and the workplace.

No, copper is generally harder to cut with a laser than steel. Several factors make laser cutting copper more challenging:

Although more challenging, laser cutting copper is still possible and offers high precision, especially with the right adjustments and specialized equipment.

When laser cutting copper, Nitrogen (N2) and Oxygen (O2) are the most commonly used assist gases, each offering different benefits depending on the desired outcome and the thickness of the material. Here’s how each gas works in the laser-cutting process:

The choice between nitrogen and oxygen largely depends on the specific needs of the project. Nitrogen is preferred for clean, high-quality cuts, while oxygen is better suited for faster, cost-effective cutting when some oxidation is acceptable. Additionally, gas pressure, flow rate, and nozzle design all play a role in optimizing the cutting performance.

Several properties of copper significantly influence the laser cutting speed. Here are the key factors that affect the efficiency and speed of laser-cutting copper:

Understanding these factors is crucial when determining the optimal cutting speed for copper. Adjusting the laser power, assist gases, and cutting parameters according to these properties will help balance speed with cut quality and precision.

Laser cutting copper typically does not compromise the inherent performance of the material, provided that the process is conducted correctly with the right parameters. The primary effects of laser cutting on copper are related to changes in physical size, surface characteristics, and localized material properties. Below are the main factors that influence the performance of copper when laser cut:

When handled appropriately, laser cutting should not significantly affect the performance of copper, and the material’s inherent properties should remain intact for most applications. However, for applications where the material’s characteristics are especially critical, attention to cutting parameters and post-processing may be necessary.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Copper Laser Cutting Machine

Yara –

The laser cutting machine’s advanced features streamline our workflow, delivering high-quality results with minimal downtime.

Ayesha –

With the laser cutter, we achieve precise cut copper, optimizing material usage and reducing waste in our workshop.

Sofia –

Impressed by the laser cutter’s versatility, capable of intricate designs and smooth edges on copper materials.

Genet –

With impressive cutting precision on copper, the machine’s accuracy makes it an indispensable tool for our metal fabrication projects.