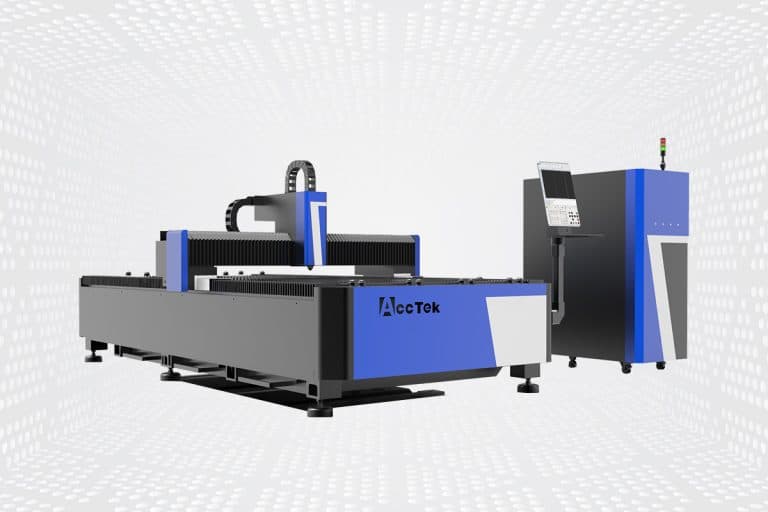

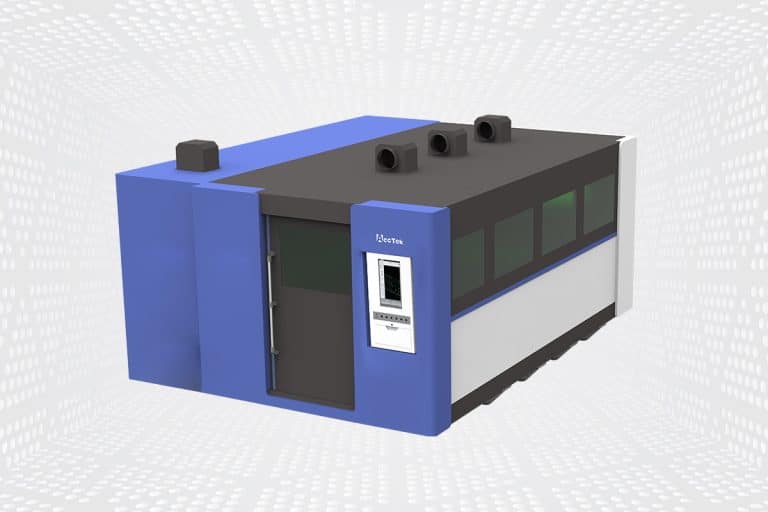

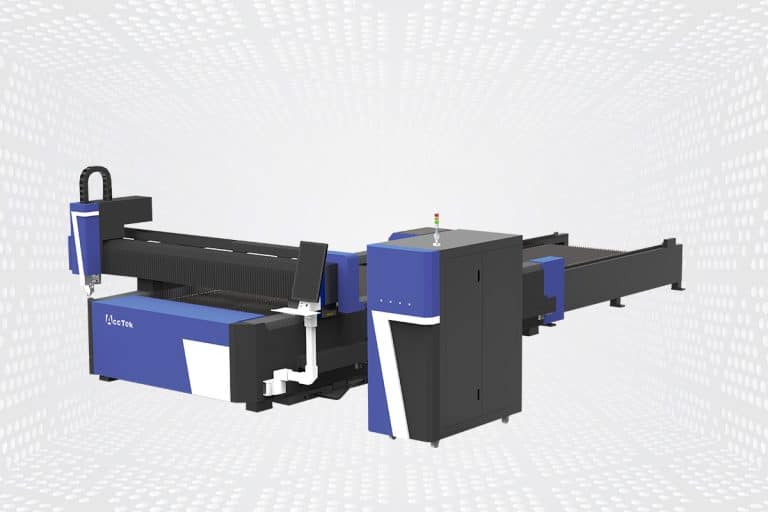

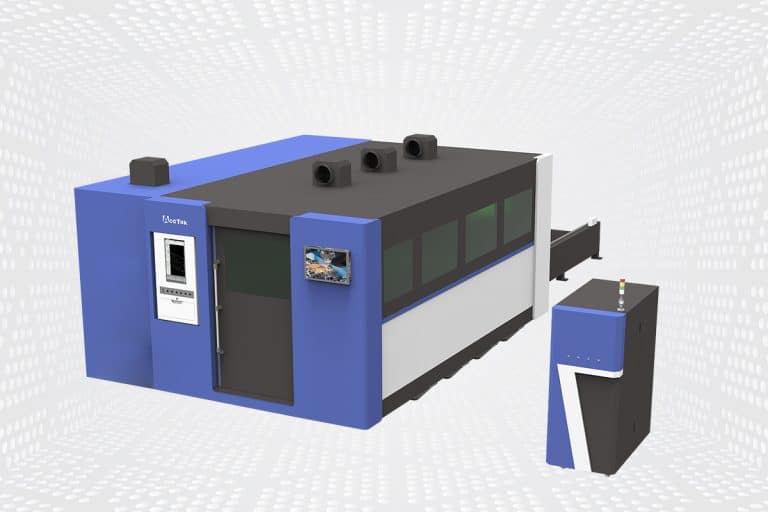

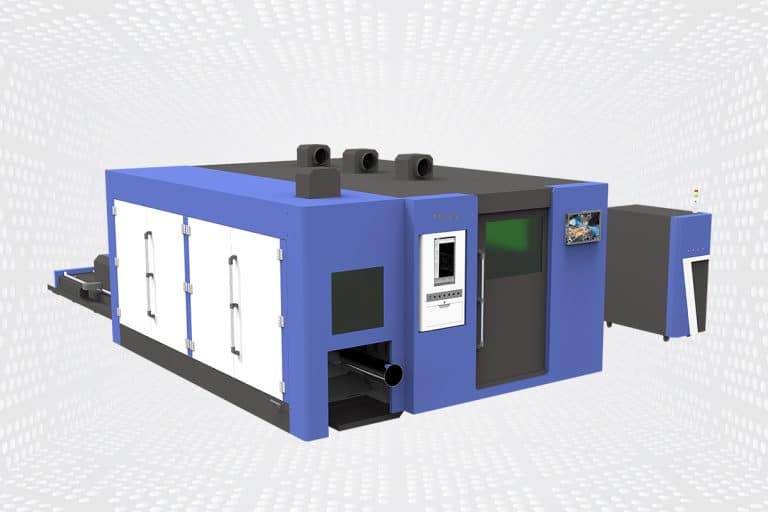

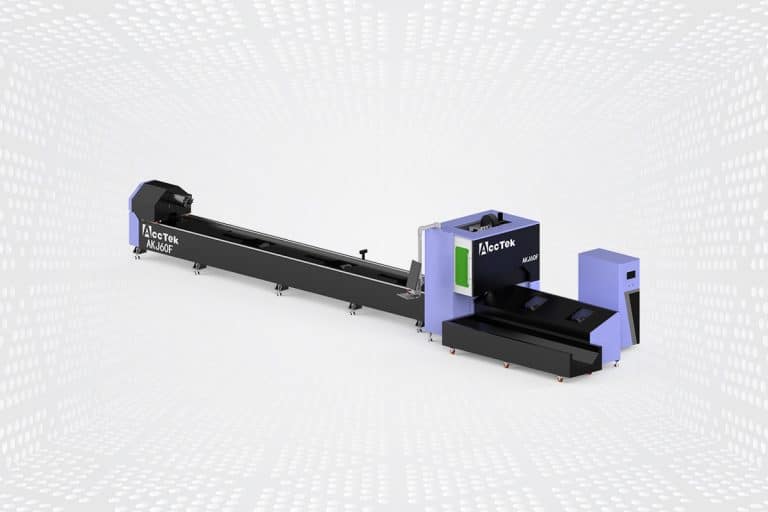

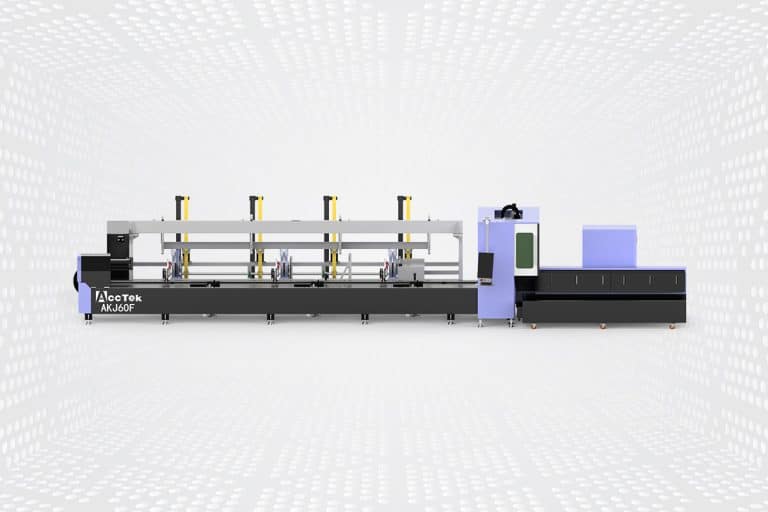

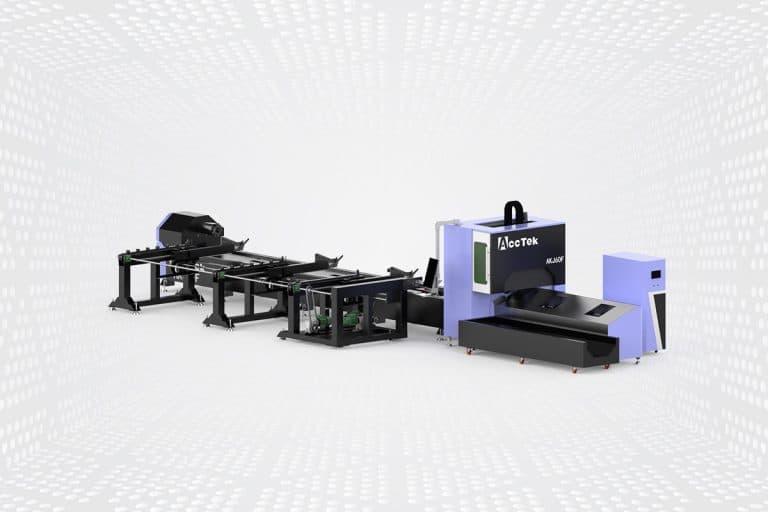

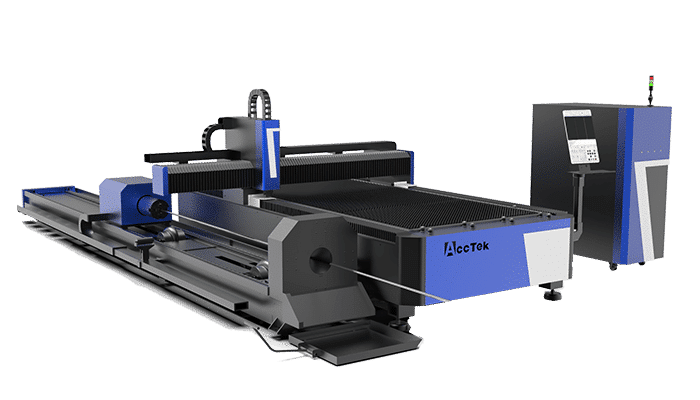

Fiber Laser Cutting Machine

Product Range

Optional Fiber Laser Cutting Machine Power

Materials That Can Be Cut

Laser Cutting VS. Other Methods

Laser Cutting vs. Mechanical Cutting

Laser cutting provides faster, more precise cuts with less material waste and no tool wear. Unlike mechanical cutting, which can leave rough edges and require frequent maintenance, laser cutting ensures cleaner edges with minimal distortion. It’s particularly effective for intricate designs and tight tolerances.

Laser Cutting vs. Waterjet Cutting

Water jet cutting is ideal for thick or heat-sensitive materials but is generally slower than laser cutting. Laser cutting offers higher cutting speeds and better edge quality, especially for thin materials, and doesn’t require costly maintenance of abrasive materials used in water jet cutting.

Laser Cutting vs. Plasma Cutting

Plasma cutting is faster for thick metals but produces rougher edges and more heat distortion compared to laser cutting. Laser cutting, on the other hand, provides higher precision, cleaner cuts, and better control for intricate designs, reducing the need for post-processing.

Why Choose AccTek Laser

Cutting-Edge Technology

AccTek Laser machines utilize the latest fiber laser technology, ensuring high precision and fast cutting speeds. Our systems provide unmatched accuracy and efficiency, ensuring the best quality cuts across various materials with minimal distortion.

Custom Solutions

We understand that every business has unique requirements. That's why we offer customizable options, including power ranges, work area sizes, and cutting speeds, allowing you to tailor our machines to fit your specific production needs and material types.

Exceptional Energy Efficiency

Our fiber laser machines are designed for maximum energy efficiency. With lower power consumption and optimized performance, AccTek Laser machines help reduce operational costs, making them a cost-effective solution for both small and large-scale manufacturing.

Durability and Reliability

AccTek Laser cutting machines are engineered for long-term durability, with high-quality components and precision manufacturing. Our machines are designed to provide consistent, reliable performance, reducing maintenance needs and extending the lifespan of your equipment.

After-Sales Support

We believe in building long-term relationships with our customers. AccTek Laser provides exceptional after-sales support, including installation, training, and ongoing technical assistance. Our team is always ready to help you optimize machine performance and resolve any issues quickly.

Competitive Pricing and Value

At AccTek Laser, we offer high-performance fiber laser cutting machines at competitive prices, ensuring that you get the best value for your investment. Our machines deliver outstanding quality at an affordable cost, making us a trusted partner for your manufacturing needs.

Frequently Asked Questions

What Are Fiber Laser Cutting Machines?

What Is The Working Principle Of Fiber Laser Cutting Machines?

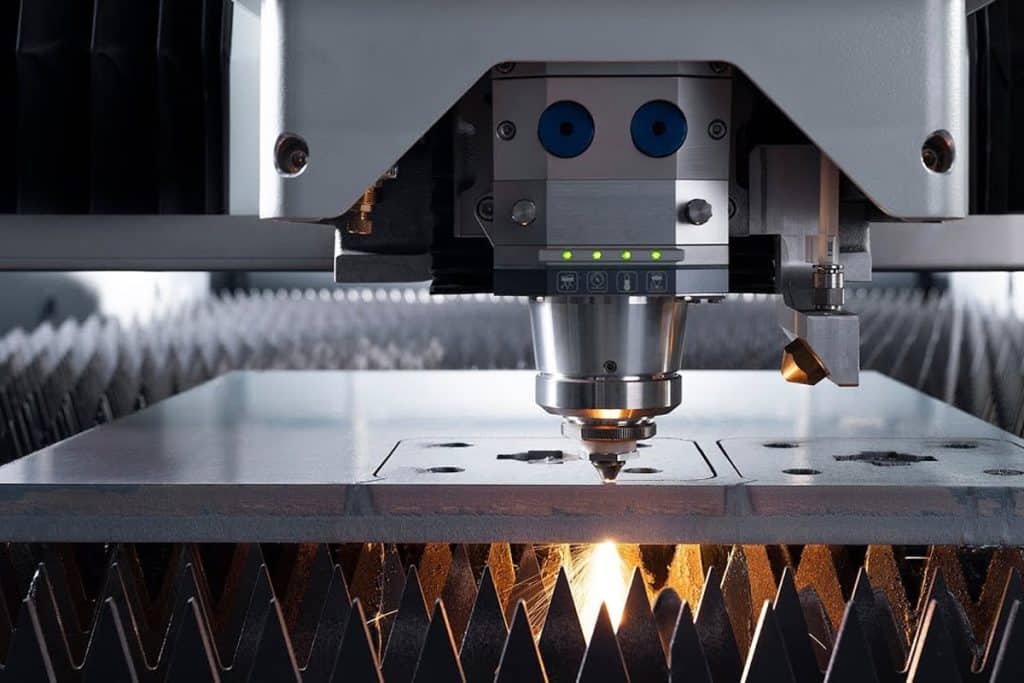

- Generation of Laser Beam: The process begins with the generation of a high-powered laser beam within the fiber laser resonator. This resonator contains an optical fiber doped with rare-earth elements such as erbium, ytterbium, or neodymium. When stimulated by an external energy source (often diode lasers), these elements emit photons, creating the laser beam.

- Beam Delivery System: The laser beam is then guided through a series of mirrors and lenses within the machine’s beam delivery system. This system directs and focuses the laser beam onto the surface of the material to be cut.

- Material Interaction: When the focused laser beam strikes the material, it delivers a high concentration of energy to a small area, causing localized heating. Depending on the material and laser parameters, this heat can either melt or vaporize the material.

- Cutting Process: As the material absorbs the laser energy, it undergoes physical changes. For example, metals may melt or vaporize, while non-metallic materials may simply burn or evaporate. The motion system of the machine (comprising motors, drive systems, and CNC controls) precisely guides the laser beam along the desired cutting path, allowing for intricate shapes and contours to be cut with high accuracy.

- Assist Gas: In many cases, an assist gas, such as oxygen, nitrogen, or air, is used during the cutting process. This gas helps to remove molten material from the kerf (the cut path) and prevents the formation of slag, resulting in cleaner cuts.

- Cooling and Exhaust: The process generates heat, so cooling systems are employed to prevent overheating of critical components like the laser source and optics. Additionally, exhaust systems remove fumes and particles generated during cutting to maintain a safe working environment.

- Control and Monitoring: Throughout the cutting process, the machine’s control system continuously monitors various parameters, such as laser power, cutting speed, and gas pressure, to ensure optimal performance and quality.

How Much Do Fiber Laser Cutting Machines Cost?

How Thick Can The Fiber Laser Cutting Machine Cut?

- Carbon Steel: Fiber laser cutting machines can typically cut carbon steel up to several inches thick, depending on the machine’s power. For example, machines with higher power outputs can cut thicker carbon steel sections more efficiently.

- Stainless Steel: Similar to carbon steel, fiber laser cutting machines can cut stainless steel up to several inches thick, again depending on the laser power and specific material properties.

- Aluminum: Aluminum is also commonly cut with fiber laser machines. The thickness capability for aluminum is generally similar to carbon steel and stainless steel, with machines capable of cutting aluminum sections several inches thick.

- Other Metals: Fiber lasers can also cut other metals such as copper, brass, titanium, and various alloys. The cutting thickness for these metals can vary depending on their properties, but fiber laser machines can typically handle a wide range of thicknesses for these materials as well.

What Are The Disadvantages Of Fiber Laser Cutting?

- High Initial Cost: Laser-cutting machines can be expensive to purchase and install, especially high-power fiber lasers. Additionally, the cost of maintenance, replacement parts, and consumables can add to the overall investment.

- Material Limitations: While laser cutting is highly effective for cutting metals and some non-metallic materials, it may not be suitable for all materials. Certain materials, such as reflective metals like copper and aluminum, can be challenging to cut with conventional laser systems due to their high reflectivity.

- Heat Affected Zone (HAZ): Laser cutting generates heat, which can result in a heat-affected zone (HAZ) along the edges of the cut. In some applications, this heat-affected zone may affect the material properties, such as hardness or microstructure, especially in heat-sensitive materials.

- Thickness Limitations: While fiber lasers can cut through relatively thick materials, there are practical limitations to the thickness of the material that can be cut efficiently. Thicker materials may require multiple passes or slower cutting speeds, which can reduce productivity and increase processing time.

- Operating Costs: Laser-cutting machines consume electricity, assist gases (such as oxygen, nitrogen, or air), and require regular maintenance to ensure optimal performance. These operating costs can add up over time, particularly in high-volume production environments.

- Safety Concerns: Laser cutting involves the use of high-powered lasers, which can pose safety risks if not operated correctly. Proper safety measures, including training, protective equipment, and machine guarding, can minimize the risk of accident or injury.

- Environmental Impact: The process of laser cutting may produce fumes, particulates, and potentially hazardous emissions, depending on the material being cut. Proper ventilation and filtration systems are necessary to mitigate environmental impact and ensure a safe working environment.

Do You Need Ventilation When Using Fiber Laser Cutting Machines?

- Fume Extraction: Laser cutting can produce fumes and smoke as the material is heated and vaporized by the laser beam. These fumes may contain hazardous substances, such as metal oxides or volatile organic compounds (VOCs), depending on the material being cut. Ventilation systems help capture and remove these fumes, preventing them from accumulating in the workspace and potentially posing health risks to operators.

- Particulate Removal: Laser cutting can also generate fine particulates or dust, especially when cutting materials like metals or composites. These particulates can pose respiratory hazards and may accumulate on surfaces, machinery, and equipment if not properly ventilated. Ventilation systems with appropriate filtration can help remove these particulates from the air, maintaining a cleaner and safer working environment.

- Temperature Regulation: In addition to removing fumes and particulates, ventilation systems can help regulate temperature and humidity levels in the cutting area. Effective ventilation can prevent overheating and ensure comfortable working conditions for operators, which is particularly important in enclosed or confined spaces.

- Equipment Protection: Proper ventilation can also help protect sensitive components of the laser cutting machine, such as optics, electronics, and cooling systems, from exposure to airborne contaminants. By reducing the accumulation of dust and debris within the machine, ventilation systems can help maintain optimal performance and prolong the lifespan of critical components.

How Long Is The Service Life Of Fiber Laser Generators?

- Quality of Components: The quality of the laser generator and its components significantly influences its service life. Higher-quality components, such as laser diodes, optical fibers, and resonator modules, tend to have longer lifespans and better reliability.

- Operating Conditions: The operating conditions in which the fiber laser generator is used can impact its service life. Factors such as temperature, humidity, vibration, and dust levels can affect the performance and longevity of the generator. Proper maintenance, including regular cleaning and inspection, can help prolong its service life.

- Maintenance Practices: Regular maintenance and upkeep help ensure optimal performance and longevity of your fiber laser generator. This includes cleaning optical components, checking for alignment issues, replacing worn parts, and monitoring key parameters such as laser power and beam quality.

- Duty Cycle: The duty cycle, or the ratio of the laser’s operating time to its cooldown time, can affect the generator’s service life. Operating the laser within its specified duty cycle limits helps prevent overheating and premature wear of components.

- Usage Patterns: The frequency and intensity of use also play a role in determining the service life of fiber laser generators. Continuous operation at high power levels may lead to faster degradation of components compared to intermittent or lower-power usage.

What Gas Do Fiber Laser Cutting Machines Use?

- Oxygen (O2): Oxygen is commonly used when cutting ferrous metals such as mild steel and stainless steel. When the laser beam interacts with the metal surface in the presence of oxygen, it oxidizes the material, resulting in an exothermic reaction that helps facilitate the cutting process. Oxygen also helps to blow away molten metal and assist in the combustion process, improving cutting efficiency and edge quality.

- Nitrogen (N2): Nitrogen is often used as an assist gas when cutting non-ferrous metals such as aluminum, copper, brass, and titanium. Unlike oxygen, nitrogen does not react chemically with these metals. Instead, it serves primarily as a coolant and helps to prevent oxidation and discoloration of the cut edges. Nitrogen is also used for cutting materials where a clean, oxide-free surface is desired, such as in electronics or medical device manufacturing.

- Air: Compressed air can also be used as an assist gas in laser cutting. It can also be used as a low-cost alternative to nitrogen when cutting non-ferrous metals, although it may not provide the same level of edge quality or protection against oxidation.

Related Resources

Understanding the Smells Associated with Laser Cutters

This article mainly discusses the causes, common types, and impacts of odors produced by laser cutting machines during processing, and proposes effective methods to reduce odors and improve the working

A Comprehensive Guide to Determining Laser Power for Laser Cutting Machines

This article mainly introduces how to determine and optimize the laser power of the laser generator to improve the accuracy, efficiency, and stability of laser cutting and welding.

Laser Cutting Machine Nozzle Guide

This article mainly introduces nozzle types, sizes, materials, and factors affecting performance, helping you choose the right nozzle and improve cutting accuracy and efficiency.