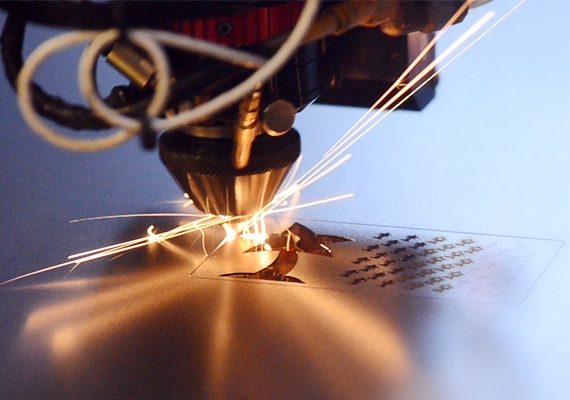

The high-quality laser cutting head delivers precision and efficiency, featuring advanced optics for superior beam focus and accuracy. Designed for durability and versatility, it ensures clean cuts on various materials, minimizing waste. With user-friendly adjustments and high-speed performance, it’s the perfect component for professional-grade laser cutting applications.

The ultra-stable laser generator is the heart of cutting-edge performance, delivering consistent power output for flawless cutting and engraving. Engineered for reliability, it ensures precision even during extended operations. Its advanced design minimizes fluctuations, enhances efficiency, and maximizes material compatibility, making it essential for professional-grade laser cutting applications.

The aviation aluminum beam combines lightweight design with exceptional strength, ensuring stability and precision during high-speed operations. Crafted from aerospace-grade aluminum, it enhances cutting accuracy while resisting deformation. Its corrosion-resistant and durable structure reduces vibration, enabling smooth, efficient performance, making it a cornerstone of advanced laser cutting technology.

The Sturdy Cutting Bed is built for durability and precision, providing a stable platform for flawless laser cutting. Its robust construction resists wear and deformation, ensuring long-term reliability. Designed to support heavy workloads and various materials, it enhances cutting accuracy and efficiency, making it indispensable for industrial-grade performance.

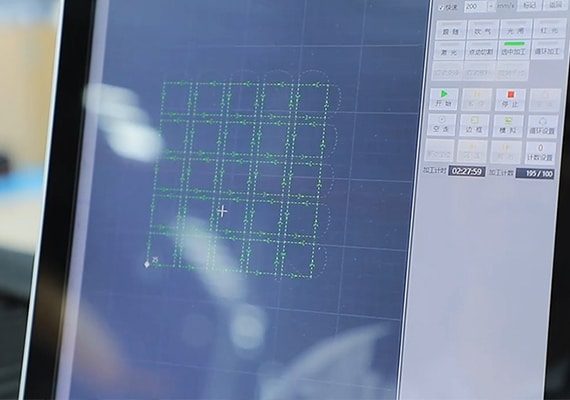

The friendly CNC control system offers intuitive operation with a user-focused interface, simplifying laser cutting processes. Equipped with advanced programming capabilities, it ensures precise control and seamless execution of complex designs. Compatible with various file formats, it boosts productivity while providing an effortless experience for professionals and beginners alike.

The high-precision servo motor ensures unmatched accuracy and smooth motion control for laser cutting operations. Its advanced design delivers rapid response and stable performance, enabling intricate cuts with exceptional detail. Built for durability and efficiency, it minimizes errors and enhances speed, making it essential for professional-grade cutting precision.

The high-performance reducer optimizes torque transmission for smooth and efficient laser-cutting operations. Engineered for durability, it minimizes vibration and ensures stable performance under high workloads. Its precision design enhances cutting accuracy and extends machine life, making it an indispensable component for achieving consistent, high-quality results.

The high-efficiency water chillers provide reliable cooling to maintain optimal laser performance during intensive operations. Designed for energy efficiency, they regulate temperature precisely, preventing overheating and ensuring consistent output. With a durable build and user-friendly controls, these chillers enhance system longevity and productivity, making them essential for peak laser-cutting efficiency.

| Model | AKJ-1325F | AKJ-1530F | AKJ-1545F | AKJ-2040F | AKJ-2560F |

|---|---|---|---|---|---|

| Cutting Range | 1300*2500mm | 1500*3000mm | 1500*4500mm | 2000*4000mm | 2500*6000mm |

| Laser Type | Fiber Laser | ||||

| Laser Power | 1-40KW | ||||

| Laser Generator | Raycus, Max, IPG | ||||

| Control Software | Cypcut, Au3tech | ||||

| Laser Head | Raytools, Au3tech, Boci | ||||

| Servo Motor | Yaskawa, Delta | ||||

| Guide Rail | HIWIN | ||||

| Maximum Moving Speed | 100m/min | ||||

| Maximum Acceleration | 1.0G | ||||

| Positioning Accuracy | ±0.01mm | ||||

| Repeat Positioning Accuracy | ±0.02mm | ||||

Achieves exceptional accuracy with advanced laser technology, delivering clean, intricate cuts on a variety of materials.

Combines powerful laser generators and optimized components to ensure fast, reliable performance for large-scale operations.

Features a sturdy cutting bed, aviation aluminum beam, and robust components designed for long-lasting, industrial-grade use.

Equipped with a friendly CNC control system, simplifying complex processes with intuitive controls and seamless integration.

Capable of cutting a wide range of materials, including metals, plastics, and composites, for diverse applications.

High-efficiency water chillers maintain optimal system performance while minimizing energy consumption.

High-precision servo motors and high-performance reducers ensure smooth, stable motion for flawless results.

Maximizes productivity with minimal material waste and maintenance costs, providing excellent value for businesses of all sizes.

| Laser Power | Thickness (mm) | Cutting Speed (m/min) | Focus Position (mm) | Cutting Height (mm) | Gas | Nozzle (mm) | Pressure (bar) |

|---|---|---|---|---|---|---|---|

| 1000W | 0.8 | 20 | 0 | 0.8 | N2 | 1.5S | 12 |

| 1 | 13 | 0 | 0.5 | N2 | 1.5S | 12 | |

| 2 | 6 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 3 | -1.5 | 0.5 | N2 | 3.0S | 12 | |

| 4 | 1 | -2 | 0.5 | N2 | 3.0S | 14 | |

| 5 | 0.6 | -2.5 | 0.5 | N2 | 3.5S | 16 | |

| 1500W | 1 | 20 | 0 | 0.8 | N2 | 1.5S | 10 |

| 2 | 7 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 4.5 | -1.5 | 0.5 | N2 | 2.5S | 12 | |

| 5 | 1.5 | -2.5 | 0.5 | N2 | 3.0S | 14 | |

| 6 | 0.8 | -3 | 0.5 | N2 | 3.0S | 16 | |

| 2000W | 1 | 28 | 0 | 0.8 | N2 | 1.5S | 10 |

| 2 | 10 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 5 | -1.5 | 0.5 | N2 | 2.0S | 12 | |

| 4 | 3 | -2 | 0.5 | N2 | 2.5S | 14 | |

| 5 | 2 | -2.5 | 0.5 | N2 | 3.0S | 14 | |

| 6 | 1.5 | -3 | 0.5 | N2 | 3.0S | 14 | |

| 8 | 0.6 | -4 | 0.5 | N2 | 3.0S | 16 | |

| 3000W | 1 | 28-35 | 0 | 0.8 | N2 | 1.5S | 10 |

| 2 | 18-24 | 0 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 7.0-10 | -0.5 | 0.5 | N2 | 2.5S | 12 | |

| 4 | 5.0-6.5 | -1.5 | 0.5 | N2 | 2.5S | 14 | |

| 5 | 3.0-3.6 | -2.5 | 0.5 | N2 | 3.0S | 14 | |

| 6 | 2.0-2.7 | -3 | 0.5 | N2 | 3.0S | 14 | |

| 8 | 1.0-1.2 | -4.5 | 0.5 | N2 | 3.5S | 16 | |

| 10 | 0.5-0.6 | -6 | 0.5 | N2 | 4.0S | 16 | |

| 4000W | 1 | 30-40 | 0 | 0.8 | N2 | 1.5S | 10 |

| 2 | 15-20 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 10-12 | -1.5 | 0.5 | N2 | 2.0S | 12 | |

| 4 | 6.0-7.0 | -2 | 0.5 | N2 | 2.5S | 12 | |

| 5 | 4.0-4.5 | -2.5 | 0.5 | N2 | 2.5S | 14 | |

| 6 | 3.0-3.5 | -3 | 0.5 | N2 | 3.0S | 14 | |

| 8 | 1.5-1.8 | -4 | 0.5 | N2 | 3.0S | 14 | |

| 10 | 1.0-1.2 | -5 | 0.5 | N2 | 4.0S | 16 | |

| 12 | 0.8 | -6 | 0.5 | N2 | 4.0S | 16 | |

| 6000W | 1 | 40-50 | 0 | 0.8 | N2 | 1.5S | 10 |

| 2 | 25-30 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 15-18 | -1.5 | 0.5 | N2 | 2.5S | 12 | |

| 4 | 10-12 | -2 | 0.5 | N2 | 2.5S | 14 | |

| 5 | 7.0-8.0 | -2.5 | 0.5 | N2 | 3.0S | 14 | |

| 6 | 6.0-7.0 | -3 | 0.5 | N2 | 3.0S | 15 | |

| 8 | 3.5-3.8 | -4 | 0.5 | N2 | 3.0S | 15 | |

| 10 | 1.6-2.0 | -6 | 0.5 | N2 | 3.5S | 15 | |

| 12 | 1.0-1.2 | -7.5 | 0.5 | N2 | 3.5S | 16 | |

| 14 | 0.8-1.0 | -9 | 0.5 | N2 | 4.0S | 16 | |

| 16 | 0.5-0.6 | -10.5 | 0.5 | N2 | 4.0S | 18 | |

| 18 | 0.4-0.5 | -11 | 0.3 | N2 | 5.0S | 20 | |

| 20 | 0.2-0.35 | -12 | 0.3 | N2 | 5.0S | 20 | |

| 8000W | 1 | 40-50 | 0 | 1 | N2 | 2.0S | 10 |

| 2 | 30-35 | 0 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 20-24 | 0 | 0.5 | N2 | 2.0S | 13 | |

| 4 | 15-18 | -1 | 0.5 | N2 | 2.0S | 12 | |

| 5 | 9.0-10.0 | -1 | 0.5 | N2 | 2.5S | 15 | |

| 6 | 7.0-8.0 | -2 | 0.5 | N2 | 3.5B | 8 | |

| 8 | 4.0-5.0 | -2 | 0.5 | N2 | 5.0B | 7 | |

| 10 | 3.0-3.5 | -3 | 0.5 | N2 | 5.0B | 5 | |

| 12 | 2.0-2.5 | -4 | 0.5 | N2 | 6.0B | 6 | |

| 14 | 1.5-2.0 | -6 | 0.3 | N2 | 7.0B | 6 | |

| 16 | 1.0-1.5 | -8 | 0.3 | N2 | 7.0B | 6 | |

| 18 | 0.8-1.0 | -9 | 0.5 | N2 | 5.0B | 14 | |

| 20 | 0.6-0.8 | -11 | 0.3 | N2 | 7.0B | 6 | |

| 25 | 0.3-0.4 | -13 | 0.3 | N2 | 7.0B | 6 | |

| 30 | 0.15-0.2 | +8 | 0.3 | N2 | 7.0B | 10 | |

| 1 | 40-50 | 0 | 1 | Air | 2.0S | 10 | |

| 2 | 30-35 | 0 | 0.5 | Air | 2.5S | 10 | |

| 3 | 22-25 | 0 | 0.5 | Air | 2.5S | 10 | |

| 4 | 14-16 | 0 | 0.5 | Air | 3.5B | 10 | |

| 5 | 9.0-10.0 | 0 | 0.5 | Air | 3.5B | 10 | |

| 6 | 7.0-8.0 | 0 | 0.5 | Air | 3.5B | 10 | |

| 8 | 5.0-5.5 | 0 | 0.5 | Air | 3.5B | 10 | |

| 10 | 3.0-3.5 | -1 | 0.5 | Air | 3.5B | 10 | |

| 12 | 2-2.5.0 | -4 | 0.5 | Air | 5.0B | 10 | |

| 14 | 1.5-2.0 | -6 | 0.5 | Air | 5.0B | 10 | |

| 16 | 0.8-1.0 | -8 | 0.5 | Air | 5.0B | 10 | |

| 18 | 0.7-0.8 | -9 | 0.5 | Air | 5.0B | 10 | |

| 20 | 0.6-0.7 | -11 | 0.3 | Air | 5.0B | 10 | |

| 25 | 0.4-0.5 | -13 | 0.3 | Air | 5.0B | 10 | |

| 30 | 0.2-0.25 | -15 | 0.3 | Air | 5.0B | 10 | |

| 10KW | 1 | 45-50 | 0 | 1 | N2 | 2.0S | 10 |

| 2 | 35-40 | 0 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 25-30 | 0 | 0.5 | N2 | 2.0S | 13 | |

| 4 | 18-20 | 0 | 0.5 | N2 | 2.0S | 12 | |

| 5 | 12-15 | 0 | 0.5 | N2 | 2.5S | 15 | |

| 6 | 8.0-9.0 | 0 | 0.5 | N2 | 3.5B | 8 | |

| 8 | 5.0-6.0 | 0 | 0.5 | N2 | 5.0B | 7 | |

| 10 | 3.5-4.0 | -1 | 0.5 | N2 | 5.0B | 5 | |

| 12 | 2.5-3.0 | -4 | 0.5 | N2 | 6.0B | 6 | |

| 14 | 2.0-2.5 | -6 | 0.3 | N2 | 7.0B | 6 | |

| 16 | 1.6-2.0 | -8 | 0.3 | N2 | 7.0B | 6 | |

| 18 | 1.2-1.5 | -9 | 0.5 | N2 | 5.0B | 14 | |

| 20 | 1.0-1.2 | -11 | 0.3 | N2 | 7.0B | 6 | |

| 25 | 0.5-0.6 | -13 | 0.3 | N2 | 7.0B | 6 | |

| 30 | 0.25 | +7 | 0.3 | N2 | 7.0B | 10 | |

| 40 | 0.15 | +9 | 0.3 | N2 | 7.0B | 15 | |

| 1 | 45-50 | 0 | 1 | Air | 2.0S | 10 | |

| 2 | 30-35 | 0 | 0.5 | Air | 2.5S | 10 | |

| 3 | 20-25 | 0 | 0.5 | Air | 2.5S | 10 | |

| 4 | 18-20 | 0 | 0.5 | Air | 3.5B | 10 | |

| 5 | 15-17 | 0 | 0.5 | Air | 3.5B | 10 | |

| 6 | 8.0-10.0 | 0 | 0.5 | Air | 3.5B | 10 | |

| 8 | 6.0-7.0 | 0 | 0.5 | Air | 3.5B | 10 | |

| 10 | 5.0-6.0 | -1 | 0.5 | Air | 3.5B | 10 | |

| 12 | 4.0-4.5 | -4 | 0.5 | Air | 5.0B | 10 | |

| 14 | 2.5-3.0 | -6 | 0.5 | Air | 5.0B | 10 | |

| 16 | 1.8-2.0 | -8 | 0.5 | Air | 5.0B | 10 | |

| 18 | 1.2-1.5 | -9 | 0.5 | Air | 5.0B | 10 | |

| 20 | 1.0-1.2 | -11 | 0.3 | Air | 5.0B | 10 | |

| 25 | 0.5-0.6 | -13 | 0.3 | Air | 5.0B | 10 | |

| 30 | 0.25-0.4 | -14 | 0.3 | Air | 5.0B | 10 | |

| 12KW | 1 | 50-60 | 0 | 1 | N2 | 2.0S | 10 |

| 2 | 40-45 | 0 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 30-35 | 0 | 0.5 | N2 | 2.0S | 13 | |

| 4 | 22-26 | 0 | 0.5 | N2 | 2.0S | 12 | |

| 5 | 15-18 | 0 | 0.5 | N2 | 2.5S | 15 | |

| 6 | 13-15 | 0 | 0.5 | N2 | 3.5B | 8 | |

| 8 | 8.0-10.0 | 0 | 0.5 | N2 | 5.0B | 7 | |

| 10 | 6.5-7.5 | -1 | 0.5 | N2 | 5.0B | 5 | |

| 12 | 5.0-5.5 | -4 | 0.5 | N2 | 6.0B | 6 | |

| 14 | 3.0-3.5 | -6 | 0.3 | N2 | 7.0B | 6 | |

| 16 | 2.0-2.3 | -8 | 0.3 | N2 | 7.0B | 6 | |

| 18 | 1.3-1.5 | -9 | 0.5 | N2 | 7.0B | 6 | |

| 20 | 1.2-1.4 | -11 | 0.3 | N2 | 7.0B | 6 | |

| 25 | 0.7-0.9 | -13 | 0.3 | N2 | 7.0B | 6 | |

| 30 | 0.25-0.3 | +7 | 0.3 | N2 | 7.0B | 10 | |

| 40 | 0.15-0.2 | +8 | 0.3 | N2 | 7.0B | 15 | |

| 1 | 50-60 | 0 | 1 | Air | 2.0S | 10 | |

| 2 | 40-45 | 0 | 0.5 | Air | 2.5S | 10 | |

| 3 | 30-35 | 0 | 0.5 | Air | 2.5S | 10 | |

| 4 | 22-28 | 0 | 0.5 | Air | 3.5B | 10 | |

| 5 | 16-19 | 0 | 0.5 | Air | 3.5B | 10 | |

| 6 | 14-17 | 0 | 0.5 | Air | 3.5B | 10 | |

| 8 | 9.0-11.0 | 0 | 0.5 | Air | 3.5B | 10 | |

| 10 | 7.0-8.0 | -1 | 0.5 | Air | 3.5B | 10 | |

| 12 | 5.5-6.0 | -4 | 0.5 | Air | 5.0B | 10 | |

| 14 | 3.5-4.0 | -6 | 0.5 | Air | 5.0B | 10 | |

| 16 | 2.2-2.4 | -8 | 0.5 | Air | 5.0B | 10 | |

| 18 | 1.3-1.6 | -9 | 0.5 | Air | 5.0B | 10 | |

| 20 | 1.2-1.5 | -11 | 0.3 | Air | 5.0B | 10 | |

| 25 | 0.7-1.0 | -13 | 0.3 | Air | 5.0B | 10 | |

| 30 | 0.3-0.6 | -14 | 0.3 | Air | 5.0B | 10 | |

| 15KW | 1 | 50-60 | 0 | 1 | N2 | 2.0S | 10 |

| 2 | 45-50 | 0 | 0.5 | N2 | 2.0S | 12 | |

| 3 | 35-38 | 0 | 0.5 | N2 | 2.5S | 13 | |

| 4 | 25-29 | 0 | 0.5 | N2 | 2.5S | 12 | |

| 5 | 18-22 | 0 | 0.5 | N2 | 2.5S | 15 | |

| 6 | 15-18 | 0 | 0.5 | N2 | 3.5B | 8 | |

| 8 | 10-12 | 0 | 0.5 | N2 | 5.0B | 7 | |

| 10 | 8.0-9.0 | -1 | 0.5 | N2 | 5.0B | 5 | |

| 12 | 6.0-7.0 | -4 | 0.5 | N2 | 6.0B | 6 | |

| 14 | 4.0-4.2 | -6 | 0.3 | N2 | 7.0B | 6 | |

| 16 | 2.6-2.8 | -8 | 0.3 | N2 | 7.0B | 6 | |

| 18 | 2.0-2.3 | -9 | 0.5 | N2 | 7.0B | 6 | |

| 20 | 1.8-2.0 | -11 | 0.3 | N2 | 7.0B | 6 | |

| 25 | 1.0-1.2 | -13 | 0.3 | N2 | 7.0B | 6 | |

| 30 | 0.6-0.7 | -15 | 0.3 | N2 | 5.0B | 10 | |

| 40 | 0.3-0.4 | +8 | 0.3 | N2 | 7.0B | 15 | |

| 50 | 0.2-0.25 | +9 | 0.3 | N2 | 8.0B | 15 | |

| 1 | 50-60 | 0 | 1 | Air | 2.0S | 10 | |

| 2 | 45-50 | 0 | 0.5 | Air | 2.5S | 10 | |

| 3 | 35-38 | 0 | 0.5 | Air | 2.5S | 10 | |

| 4 | 25-29 | 0 | 0.5 | Air | 3.5B | 10 | |

| 5 | 18-22 | 0 | 0.5 | Air | 3.5B | 10 | |

| 6 | 15-18 | 0 | 0.5 | Air | 3.5B | 10 | |

| 8 | 10-12 | 0 | 0.5 | Air | 3.5B | 10 | |

| 10 | 8.0-9.0 | -1 | 0.5 | Air | 3.5B | 10 | |

| 12 | 6.0-7.0 | -4 | 0.5 | Air | 5.0B | 10 | |

| 14 | 4.0-4.5 | -6 | 0.5 | Air | 5.0B | 10 | |

| 16 | 2.9-3.1 | -8 | 0.5 | Air | 5.0B | 10 | |

| 18 | 2.2-2.4 | -9 | 0.5 | Air | 5.0B | 10 | |

| 20 | 1.9-2.1 | -11 | 0.3 | Air | 5.0B | 10 | |

| 25 | 1.2-1.4 | -13 | 0.3 | Air | 5.0B | 10 | |

| 30 | 0.8-1 | -15 | 0.3 | Air | 5.0B | 10 | |

| 40 | 0.4-0.5 | -15 | 0.3 | Air | 6.0B | 12 | |

| 50 | 0.2-0.4 | -16 | 0.3 | Air | 8.0B | 12 | |

| 20KW | 1 | 50-60 | 0 | 1 | N2 | 2.0S | 8 |

| 2 | 50-60 | 0 | 0.5 | N2 | 2.0S | 8 | |

| 3 | 40-45 | 0 | 0.5 | N2 | 2.5S | 8 | |

| 4 | 30-35 | 0 | 0.5 | N2 | 2.5S | 8 | |

| 5 | 22-24 | 0 | 0.5 | N2 | 3.0S | 8 | |

| 6 | 18-22 | 0 | 0.5 | N2 | 3.5B | 8 | |

| 8 | 13-16 | -1 | 0.5 | N2 | 5.0B | 8 | |

| 10 | 10-12 | -1.5 | 0.3 | N2 | 5.0B | 8 | |

| 12 | 8.0-10.0 | -2 | 0.5 | N2 | 6.0B | 8 | |

| 14 | 6.0-8.0 | -4 | 0.3 | N2 | 6.0B | 8 | |

| 16 | 5.0-6.0 | -5 | 0.3 | N2 | 6.0B | 8 | |

| 18 | 3.2-4.0 | -6 | 0.3 | N2 | 6.0B | 8 | |

| 20 | 3.0-3.2 | -7.5 | 0.3 | N2 | 6.0B | 12 | |

| 25 | 1.5-2.0 | -12 | 0.3 | N2 | 7.0B | 12 | |

| 30 | 1.0-1.2 | -16 | 0.3 | N2 | 7.0B | 12 | |

| 40 | 0.5-0.8 | -16 | 0.3 | N2 | 7.0B | 16 | |

| 50 | 0.2-0.3 | +11 | 0.3 | N2 | 8.0B | 16 | |

| 60 | 0.15-0.2 | +11 | 0.3 | N2 | 8.0B | 20 | |

| 70 | 0.1-0.13 | +11 | 0.3 | N2 | 8.0B | 20 | |

| 80 | 0.08-0.1 | +11 | 0.3 | N2 | 8.0B | 20 | |

| 90 | 0.05-0.06 | +11 | 0.3 | N2 | 8.0B | 20 | |

| 100 | 0.04-0.05 | +11 | 0.3 | N2 | 8.0B | 20 | |

| 1 | 50-60 | 0 | 1 | Air | 2.0S | 8 | |

| 2 | 50-60 | 0 | 0.5 | Air | 2.5S | 8 | |

| 3 | 40-45 | 0 | 0.5 | Air | 2.5S | 8 | |

| 4 | 30-35 | 0 | 0.5 | Air | 3.5B | 8 | |

| 5 | 22-24 | 0 | 0.5 | Air | 3.5B | 8 | |

| 6 | 18-22 | 0 | 0.5 | Air | 3.5B | 8 | |

| 8 | 13-16 | 0 | 0.5 | Air | 3.5B | 10 | |

| 10 | 11-13 | -1.5 | 0.3 | Air | 3.5B | 10 | |

| 12 | 9.0-11.0 | -4 | 0.3 | Air | 5.0B | 10 | |

| 14 | 7.0-9.0 | -6 | 0.3 | Air | 5.0B | 10 | |

| 16 | 6.0-7.0 | -7 | 0.3 | Air | 5.0B | 10 | |

| 18 | 3.5-4.5 | -8 | 0.3 | Air | 5.0B | 10 | |

| 20 | 3.5-4.5 | -9 | 0.3 | Air | 5.0B | 10 | |

| 25 | 1.8-2.5 | -13 | 0.3 | Air | 5.0B | 10 | |

| 30 | 1.4-1.6 | -17 | 0.3 | Air | 5.0B | 10 | |

| 40 | 0.5-0.8 | -16 | 0.3 | Air | 7.0B | 16 | |

| 50 | 0.2-0.3 | -18 | 0.3 | Air | 8.0B | 16 | |

| 60 | 0.15-0.2 | -20 | 0.3 | Air | 8.0B | 20 | |

| 70 | 0.1-0.13 | -25 | 0.3 | Air | 8.0B | 20 | |

| 30KW | 1 | 50-60 | 0 | 1 | N2 | 2.0S | 8 |

| 2 | 50-60 | 0 | 0.5 | N2 | 2.0S | 8 | |

| 3 | 40-50 | 0 | 0.5 | N2 | 2.5S | 8 | |

| 4 | 35-40 | 0 | 0.5 | N2 | 2.5S | 8 | |

| 5 | 25-30 | 0 | 0.5 | N2 | 3.0S | 8 | |

| 6 | 22-25 | 0 | 0.5 | N2 | 3.5B | 8 | |

| 8 | 18-22 | -1 | 0.5 | N2 | 5.0B | 8 | |

| 10 | 14-18 | -1.5 | 0.3 | N2 | 5.0B | 8 | |

| 12 | 12-14 | -2 | 0.5 | N2 | 6.0B | 8 | |

| 14 | 8.0-10.0 | -4 | 0.3 | N2 | 6.0B | 8 | |

| 16 | 7.5-8.5 | -5 | 0.3 | N2 | 6.0B | 8 | |

| 18 | 6.0-7.0 | -6 | 0.3 | N2 | 6.0B | 8 | |

| 20 | 5.0-6.0 | -7.5 | 0.3 | N2 | 6.0B | 12 | |

| 25 | 2.0-3.0 | -12 | 0.3 | N2 | 7.0B | 12 | |

| 30 | 1.5-2.0 | -16 | 0.3 | N2 | 7.0B | 12 | |

| 40 | 0.6-0.8 | -16 | 0.3 | N2 | 7.0B | 16 | |

| 50 | 0.4-0.6 | -18 | 0.3 | N2 | 8.0B | 16 | |

| 60 | 0.15-0.2 | +11 | 0.3 | N2 | 8.0B | 20 | |

| 70 | 0.1-0.13 | +11 | 0.3 | N2 | 8.0B | 20 | |

| 80 | 0.08-0.1 | +11 | 0.3 | N2 | 8.0B | 20 | |

| 90 | 0.05-0.06 | +11 | 0.3 | N2 | 8.0B | 20 | |

| 100 | 0.04-0.05 | +11 | 0.3 | N2 | 8.0B | 20 | |

| 1 | 50-60 | 0 | 1 | Air | 2.0S | 8 | |

| 2 | 50-60 | 0 | 0.5 | Air | 2.5S | 8 | |

| 3 | 40-50 | 0 | 0.5 | Air | 2.5S | 8 | |

| 4 | 35-40 | 0 | 0.5 | Air | 3.5B | 8 | |

| 5 | 25-30 | 0 | 0.5 | Air | 3.5B | 8 | |

| 6 | 22-25 | 0 | 0.5 | Air | 3.5B | 8 | |

| 8 | 18-22 | 0 | 0.5 | Air | 3.5B | 10 | |

| 10 | 14-18 | -1.5 | 0.3 | Air | 3.5B | 10 | |

| 12 | 12-14 | -4 | 0.3 | Air | 5.0B | 10 | |

| 14 | 10-12 | -6 | 0.3 | Air | 5.0B | 10 | |

| 16 | 8.0-9.0 | -7 | 0.3 | Air | 5.0B | 10 | |

| 18 | 6.0-7.0 | -8 | 0.3 | Air | 5.0B | 10 | |

| 20 | 5.0-6.0 | -9 | 0.3 | Air | 5.0B | 10 | |

| 25 | 2.5-3.0 | -13 | 0.3 | Air | 5.0B | 10 | |

| 30 | 1.5-2.0 | -17 | 0.3 | Air | 5.0B | 10 | |

| 40 | 0.8-1.2 | -16 | 0.3 | Air | 7.0B | 16 | |

| 50 | 0.6-0.8 | -18 | 0.3 | Air | 8.0B | 16 | |

| 60 | 0.15-0.2 | -20 | 0.3 | Air | 8.0B | 20 | |

| 70 | 0.1-0.13 | -25 | 0.3 | Air | 8.0B | 20 |

The price of a stainless steel laser cutting machine varies significantly depending on factors such as specifications, power output, cutting bed size, brand, and additional features. Other considerations include market conditions, geographic location, and customization options.

For an accurate quote tailored to your needs, contact AccTek Laser, a trusted manufacturer of stainless steel laser cutting machines. We’ll provide detailed information on available models, features, pricing, and additional costs like shipping, installation, and training. Let us help you find the best solution for your specific requirements.

Laser cutting is a versatile and efficient process for cutting stainless steel across a range of thicknesses. The maximum thickness achievable depends on several factors, including laser power, lens focal length, cutting speed, and material properties.

To determine the exact cutting capacity for your needs, please consult AccTek Laser. We can advise on your specific requirements and help you select the right equipment.

Laser cutting typically does not result in significant hardening of stainless steel, but it can cause localized changes in the material’s properties within the heat-affected zone (HAZ) near the cut edge.

In most cases, the localized HAZ produced during laser cutting has minimal impact on the functionality of stainless steel. For critical applications, consulting with a materials expert or conducting tests can help assess and mitigate the effects of laser cutting on hardness.

Stainless steel laser cutting machines can cut a wide variety of stainless steel alloys. While the specific alloy composition does not usually restrict the cutting process, properties such as hardness, reflectivity, and thermal conductivity can influence the cutting efficiency and may require adjustments to cutting parameters. Common alloys that can be laser cut include austenitic grades like 304, 316, and 321; ferritic grades like 430 and 409; martensitic grades such as 410 and 420; duplex stainless steels such as 2205 and 2507; and precipitation-hardening grades like 17-4 PH.

Each alloy may exhibit different cutting characteristics, with factors such as material thickness, laser power, assist gas type, and cutting speed affecting the quality of the cut. Adjusting laser parameters to suit the specific alloy ensures clean cuts and optimal performance.

It is recommended to consult AccTek Laser to determine the machine settings that are best suited for your selected stainless steel alloy and application.

The choice of assist gas for laser cutting stainless steel depends on the specific requirements of the cutting process. The two most commonly used gases are oxygen (O2) and nitrogen (N2), each offering distinct advantages and characteristics:

Many modern laser-cutting machines offer the flexibility to switch between oxygen and nitrogen, allowing you to adjust the process based on specific needs. For the best results, consult your machine’s manufacturer for recommended parameters and conduct test cuts to fine-tune settings for your application.

Yes, laser cutting stainless steel can generate fumes and gases containing potentially harmful substances. While stainless steel itself is not highly toxic, the high-intensity laser beam vaporizes the material, releasing fumes that consist primarily of metal oxides and particulate matter. These emissions may also include trace amounts of alloying elements. Below are the main sources of fumes and gases produced during laser cutting:

Operators should adhere to safety guidelines and consult with both the machine manufacturer and relevant safety authorities to ensure compliance with workplace health standards. Proper safety measures, including ventilation, PPE, and material preparation, can help mitigate health risks and maintain a safe work environment.

Minimizing the heat-affected zone (HAZ) during laser cutting is essential to preserve the material’s properties and prevent issues like excessive hardness, deformation, or discoloration. Here are key measures to achieve this:

The effectiveness of these measures may depend on the specific stainless steel alloy, thickness, and capabilities of the laser cutting machine. For best results you will need to refer to the machine manufacturer’s guidelines and perform test cuts to determine the best parameters, then adjust the settings based on the application requirements to achieve a minimal HAZ and high-quality cut.

Yes, optimizing laser cutting parameters is essential to achieving superior cut quality, and efficiency, and minimizing the heat-affected zone (HAZ) when cutting stainless steel. While exact settings depend on the laser cutter, stainless steel grade, and material thickness, the following recommendations offer general guidance:

By carefully balancing these parameters and making adjustments as needed, you can achieve the best results for stainless steel laser cutting with minimal thermal impact and maximum precision.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Stainless Steel Laser Cutting Machine

Marko –

The laser cutting machine’s efficiency saves time and material costs, enhancing our workshop’s profitability.

Youssef –

Impressive performance on stainless steel, the laser cutter’s speed and accuracy exceed expectations.

Thiri –

Efficient and reliable, the laser cutting machine boosts productivity with its high-speed performance.

Ahmed –

The laser cutter’s durability withstands heavy usage, ensuring long-term reliability.