Tube And Sheet Laser Cutting Machine

Product Range

-

AKJ-FR Laser Cutting Machine

Rated 4.75 out of 5$30,000.00 – $166,800.00 Select options This product has multiple variants. The options may be chosen on the product page -

AKJ-FCR Laser Cutting Machine

Rated 4.75 out of 5$34,000.00 – $171,000.00 Select options This product has multiple variants. The options may be chosen on the product page -

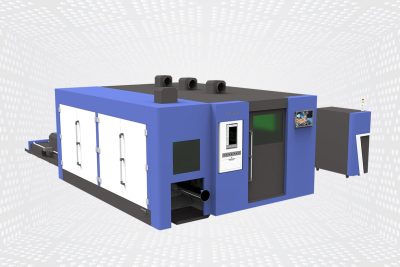

AKJ-FBCR Laser Cutting Machine

Rated 4.75 out of 5$39,000.00 – $176,000.00 Select options This product has multiple variants. The options may be chosen on the product page

Optional Laser Cutting Machine Power

Materials That Can Be Cut

Laser Cutting VS. Other Methods

Laser Cutting vs. Mechanical Cutting

Laser cutting offers higher precision and faster cutting speeds compared to mechanical cutting. It eliminates physical tool wear and tear, resulting in smoother edges and minimal post-processing. Mechanical cutting, while suitable for thicker materials, can lead to rough edges and more material waste.

Laser Cutting vs. Water Jet Cutting

Water jet cutting is effective for thick materials but is slower and less efficient than laser cutting. Laser technology provides faster, more accurate cuts, particularly for thinner metals. Water jet cutting also requires constant maintenance of abrasives, whereas laser cutting is more cost-effective and requires less maintenance.

Laser Cutting vs. Plasma Cutting

While plasma cutting is faster for thicker materials, laser cutting produces higher precision with smoother edges and less heat distortion. Plasma cutting creates rougher edges and a larger heat-affected zone, which can require additional finishing, making laser cutting a more precise, clean, and cost-effective choice.

Why Choose AccTek Laser

Cutting-Edge Technology

AccTek Laser machines utilize the latest laser technology, ensuring high precision and fast cutting speeds. Our systems provide unmatched accuracy and efficiency, ensuring the best quality cuts across various materials with minimal distortion.

Custom Solutions

We understand that every business has unique requirements. That's why we offer customizable options, including power ranges, work area sizes, and cutting speeds, allowing you to tailor our machines to fit your specific production needs and material types.

Exceptional Energy Efficiency

Our laser cutting machines are designed for maximum energy efficiency. With lower power consumption and optimized performance, AccTek Laser machines help reduce operational costs, making them a cost-effective solution for both small and large-scale manufacturing.

Durability and Reliability

AccTek Laser cutting machines are engineered for long-term durability, with high-quality components and precision manufacturing. Our machines are designed to provide consistent, reliable performance, reducing maintenance needs and extending the lifespan of your equipment.

After-Sales Support

We believe in building long-term relationships with our customers. AccTek Laser provides exceptional after-sales support, including installation, training, and ongoing technical assistance. Our team is always ready to help you optimize machine performance and resolve any issues quickly.

Competitive Pricing and Value

At AccTek Laser, we offer high-performance laser-cutting machines at competitive prices, ensuring that you get the best value for your investment. Our machines deliver outstanding quality at an affordable cost, making us a trusted partner for your manufacturing needs.

Frequently Asked Questions

What Are Tube And Sheet Laser Cutting Machines?

How Much Do Tube And Sheet Laser Cutting Machines Cost?

How Accurate Are Laser Cutting Machines For Tubes And Sheets?

What Shapes Can Tube And Sheet Laser Cutting Machines Cut?

- Flat Sheet Shapes

- Straight Lines: The machine can cut straight lines with precision, allowing for the creation of simple geometric shapes such as squares, rectangles, and triangles.

- Curves: It can cut curved shapes, including circles, arcs, and ellipses, enabling the fabrication of rounded or organic forms.

- Intricate Designs: The machine’s high precision allows for the cutting of intricate patterns, intricate designs, and detailed shapes with fine features.

- Tube and Profile Shapes

- Round Tubes: The machine can cut round tubes accurately, allowing for the creation of components such as pipes, cylinders, and circular profiles.

- Square and Rectangular Tubes: It can cut square and rectangular tubes with precision, useful for fabricating frames, structures, and other components with angular profiles.

- Open Profiles: The machine can cut open profiles with complex shapes, such as C-channels, U-channels, and other custom profiles used in various applications.

- Angled Cuts: It can make angled cuts on tubes and profiles, facilitating the fabrication of components with mitered edges or beveled features.

How Much Do Tube And Sheet Laser Cutting Machines Cost To Operate?

- Electricity: Laser-cutting machines consume electricity to power their laser sources, motion systems, cooling systems, and other components. The electricity cost depends on factors such as the machine’s power consumption, cutting speed, and duration of operation.

- Consumables: Laser cutting machines use consumable parts that need regular replacement, including cutting nozzles, lenses, protective windows, and assist gases (such as nitrogen or oxygen). The cost of consumables can vary depending on the machine’s usage and the materials being cut.

- Maintenance and Repairs: Regular maintenance tasks such as cleaning, lubrication, and component replacement ensure machine reliability and performance. The cost of maintenance and repairs can vary depending on the machine’s age, usage, and any unexpected issues that arise.

- Operator Labor: The labor cost associated with operating the machine, including setup, programming, loading/unloading materials, and monitoring the cutting process.

- Gas Consumption: If the machine uses assist gases (such as nitrogen or oxygen) for cutting, there will be costs associated with purchasing and refilling gas cylinders or maintaining gas generation systems.

- Waste Disposal: Depending on local regulations and the materials being cut, there may be costs associated with disposing of waste materials, such as scrap metal or laser-cut waste.

What Safety Features Are Included With Tube And Sheet Laser Cutting Machines?

- Enclosed Work Area: Most laser cutting machines have enclosed work areas to contain the laser beam and prevent exposure to radiation and flying debris during cutting operations.

- Safety Interlocks: Interlock systems prevent the machine from operating if access doors, panels, or enclosures are open. This ensures that operators cannot access the cutting area while the machine is in operation.

- Emergency Stop (E-stop) Buttons: Emergency stop buttons allow operators to quickly halt machine operations in case of emergencies or unsafe conditions.

- Safety Light Curtains: Light curtains or sensors around the machine’s perimeter detect the presence of objects or people and automatically stop the machine if someone enters the danger zone.

- Beam Collision Detection: Sensors or systems that monitor for potential collisions between the laser beam and the workpiece, cutting head, or other machine components, automatically pausing or shutting down the machine to prevent damage or injury.

- Exhaust and Fume Extraction Systems: Effective exhaust and fume extraction systems remove smoke, fumes, and particulates generated during cutting, minimizing exposure to harmful airborne contaminants.

- Safety Glasses and Protective Equipment: Operators and bystanders may be required to wear safety glasses or other personal protective equipment (PPE) to protect against laser radiation, flying debris, and other hazards.

- Machine Status Indicators: Visual and audible indicators provide real-time feedback on the machine’s status, including power-on, standby, cutting in progress, and error conditions.

- Training and Safety Procedures: Comprehensive operator training programs and safety procedures ensure that operators understand how to safely operate the machine, handle materials, and respond to emergencies.

- Compliance with Safety Standards: Tube and sheet laser cutting machines are designed and manufactured by industry safety standards and regulations to ensure safe operation and compliance with legal requirements.

How Long Is the Life of Tube and Sheet Laser Cutting Machines?

- Laser Source Lifespan: The fiber laser source typically lasts around 20,000-30,000 hours of cutting time, depending on the power and quality of the laser. Higher-quality fiber lasers tend to last longer.

- Machine Maintenance: Regular maintenance, such as cleaning the lenses, ensuring proper cooling, and monitoring the mechanical components, can significantly extend the lifespan. Well-maintained machines can work for decades.

- Usage Intensity: Heavy, continuous use (e.g., 24/7 operations) may wear the machine down more quickly, while occasional use can extend its life. Machines that operate at lower capacities or less frequently tend to last longer.

- Technology Advancements: As technology evolves, older models may become outdated in terms of features and efficiency, even if the machine is still operational. However, the core components like the laser source and mechanical parts can still function for many years.

What Are The Maintenance Requirements For Tube And Sheet Laser Cutting Machines?

- Daily Cleaning

- Remove debris, dust, and metal shavings from the cutting area, including the workpiece support surfaces and the machine’s enclosure. Clean the machine’s lenses, mirrors, and other optical components to ensure consistent laser beam quality.

- Regular Inspection

- Check for signs of wear or damage on critical components such as cutting nozzles, focusing lenses, mirrors, and protective windows. Replace them as needed.

- Inspect belts, chains, and other mechanical parts for signs of wear, tension, or misalignment. Adjust or replace as necessary.

- Examine the machine’s motion systems, including linear guides, ball screws, and drive motors, to ensure smooth operation and accuracy.

- Lubrication

- Lubricate moving parts according to the manufacturer’s recommendations to prevent excessive wear and friction.

- Clean and lubricate the cutting head’s autofocus mechanism, if applicable.

- Optical Alignment

- Periodically check and adjust the alignment of the laser beam delivery system, including mirrors and focusing optics, to maintain cutting accuracy.

- Align the laser beam with the nozzle for optimal cutting performance.

- Cooling System Maintenance

- Monitor and maintain the cooling system, including water chillers or air coolers, to prevent overheating of the laser source.

- Check coolant levels, filters, and hoses regularly and replace or clean them as needed.

- Software Updates and Calibration

- Keep the machine’s control software up to date with the latest updates and patches provided by the manufacturer.

- Perform periodic calibration of the machine’s positioning systems and laser power output to ensure accurate cutting results.

- Operator Training

- Provide ongoing training for machine operators to ensure proper operation, safety practices, and awareness of potential maintenance issues.

Related Resources

How to Achieve the Minimum Incision Width in CO2 Laser Cutting?

This article will analyze the key factors affecting the kerf width of CO2 laser cutting and provide optimization strategies to help manufacturers improve accuracy, and production efficiency, reduce material waste,

The Influence of Autofocus on the Cutting Accuracy of Fiber Laser Cutting Machine

This article discusses the definition and types of autofocus technology and its impact on fiber laser cutting accuracy and analyzes the challenges and optimization solutions it faces to improve production

The Influence of Fiber Laser Beam Quality on Cutting Accuracy and Quality

The quality of fiber laser beam has an important influence on the accuracy, efficiency and surface quality of laser cutting. Optimizing the beam quality can significantly improve the cutting effect