Warranty

0

Years

Orders

0

+

Models

0

+

AccTek Intelligent Laser Equipment

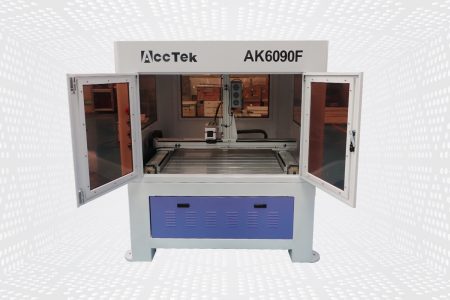

Intelligent laser equipment is a cutting-edge device that combines advanced laser systems with CNC control systems, which can provide unprecedented precision, speed, and efficiency for various manufacturing industries. The CNC control system embedded in the equipment enables it to analyze the data in real time, optimize the performance of the laser generator, and adapt to any changes in the production process.

Intelligent laser equipment is capable of performing a wide range of tasks, including cutting, welding, cleaning, and marking a variety of materials such as metals, plastics, ceramics, and composites. The lasers used in the equipment are highly focused and generate a lot of heat, allowing precise material removal and shaping. Smart laser equipment can be customized to meet specific manufacturing requirements, making it ideal for industries such as automotive, aerospace, medical devices, and electronics. It is particularly useful in the production of complex geometries where conventional manufacturing methods are often limited.

Smart laser equipment can offer numerous benefits to manufacturers looking to improve production processes, increase accuracy, and reduce costs. Its advanced laser system and CNC control system algorithms make it an invaluable tool for industries requiring high precision and flexibility in manufacturing operations. With these advantages, smart laser equipment is increasingly favored by manufacturers in various industries.

Play Video about Fiber Laser Cutting Machine

Play Video about CO2 Laser Cutting Machine

Play Video about Fiber And CO2 Laser Cutting Machine

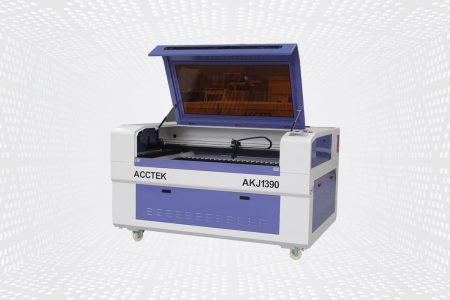

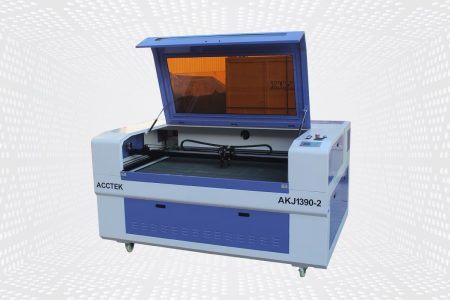

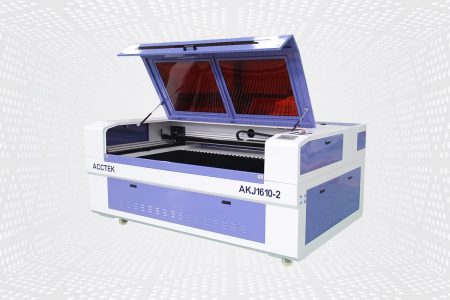

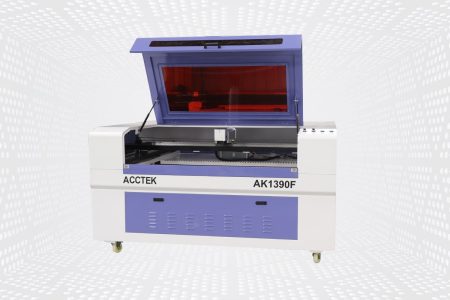

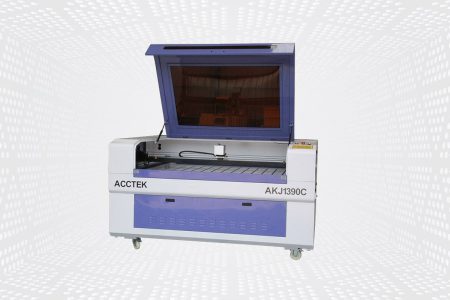

The laser cutting machine is an automated device that uses a high-powered laser beam to cut a variety of materials, including metal, plastic, and wood. It is cut with high precision and can produce complex shapes and designs with high precision. It provides a highly precise and efficient method of cutting a wide variety of materials, making it an essential tool in modern manufacturing processes.

The laser welding machine is a device that uses a high-powered laser beam to join two pieces of metal together. The laser beam generates intense heat that melts the edges of the metal and fuses them together. Compared with traditional welding methods, laser welding machines have several advantages, including faster welding speed, higher precision, and less thermal distortion. They are also ideal for welding thin materials and complex geometries that are difficult or impossible to weld using other methods.

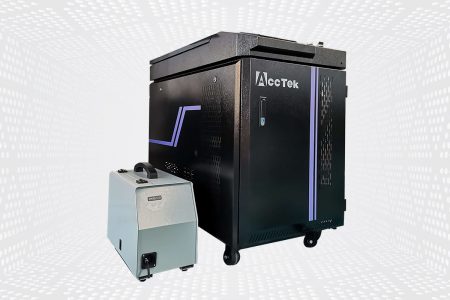

Laser cleaning machines use a high-powered laser beam to remove contaminants such as rust, paint, and oil from a variety of surfaces. The laser beam generates intense energy to vaporize or ablate the layer of contamination without damaging the underlying material. Unlike traditional cleaning methods, laser cleaning machines do not use harsh chemicals or abrasive materials, making them more environmentally friendly and safer for operators. It is also so precise that it can remove only the targeted layer of contamination, leaving the underlying material intact.

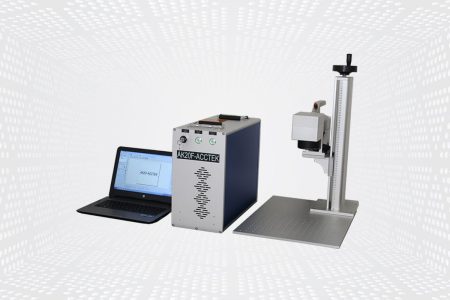

The laser marking machine is a manufacturing device that uses a high-powered laser beam to create permanent marks or engravings on a variety of materials. The laser beam produces intense energy that vaporizes or ablates the surface layer of the material and leaves a mark. The marking accuracy of the laser marking machine is high, and it can make detailed and complex marks with high precision. It can also mark a wide variety of materials, including metals, plastics, ceramics, and composites, making it a popular choice in many industries.

Advantages of Intelligent Laser Equipment

Precision and Accuracy

Precision and Accuracy

Lasers offer high precision and repeatability, essential for tasks requiring exact measurements.

Speed and Efficiency

Speed and Efficiency

Fast processing and automation integration increase productivity and reduce operational time.

Versatility

Versatility

Suitable for various materials and applications, from manufacturing to healthcare.

Minimal Material Deformation

Minimal Material Deformation

Low thermal impact reduces the risk of warping or damage to materials.

Non-Contact Processing

Non-Contact Processing

No tool wear and ability to reach hard-to-access areas, enhancing longevity and maintenance.

Enhanced Safety and Environment

Enhanced Safety and Environment

Safer operations with reduced exposure to hazards; eco-friendly with less waste.

Cost-Effectiveness

Cost-Effectiveness

Lower operating costs and long-term savings despite high initial investment.

Innovation and Advancement

Innovation and Advancement

Continuous technological improvements enhance capabilities and open new application areas.

Get Laser Solutions

We can customize the design according to your requirements. You only need to tell us your requirements, and our engineers will provide you with turnkey solutions in the shortest possible time. Our laser equipment prices are very competitive, please contact us for a free quote. If you need other laser equipment-related services, you can also contact us.