Laser Marking Machine Lifespan: Comprehensive Guide

As an advanced marking equipment, laser marking machine has been widely used in industrial production. However, with time, the life of the laser marking machine has gradually attracted attention, and people have become keenly interested in the life of the laser marking machine and its influencing factors. The life of a laser marking machine is affected by many factors. This article will delve into the average life of a laser marking machine and the various factors that affect its life. Understanding these reasons can help extend the service life of the equipment and improve production efficiency.

Table of Contents

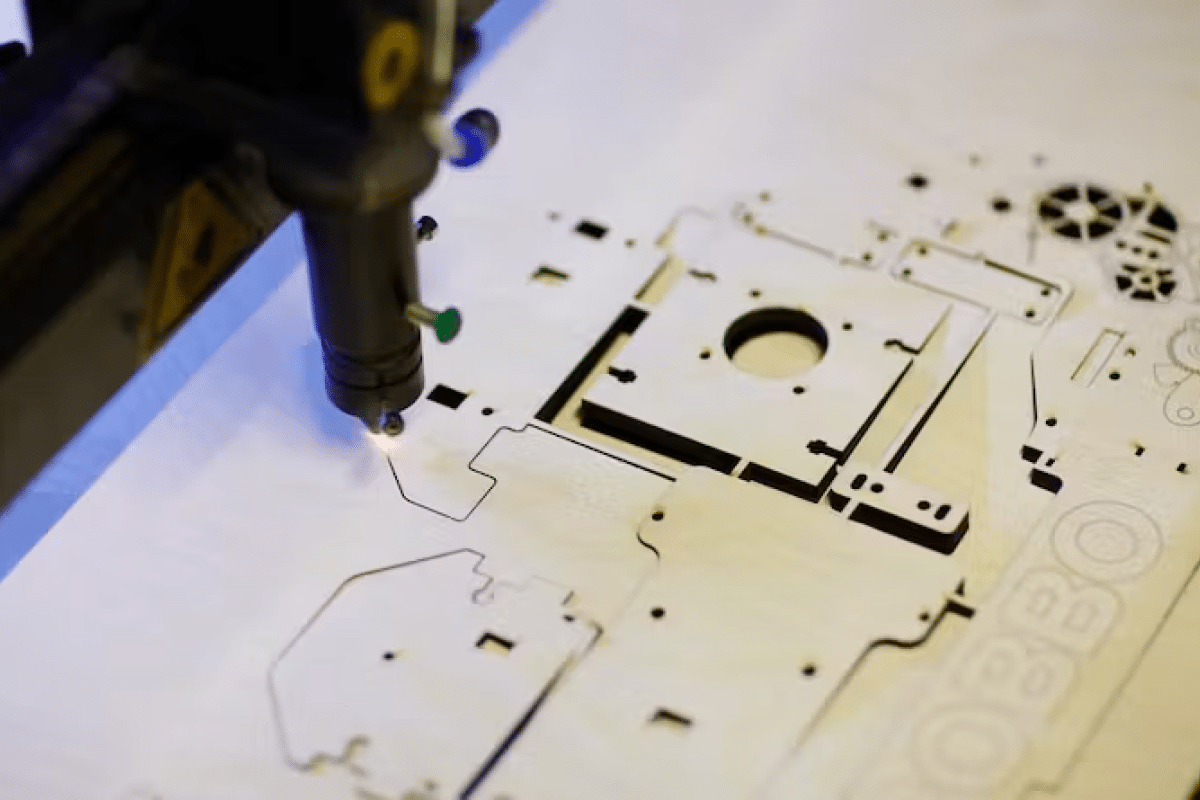

Basic principles of laser marking machine

A laser marking machine is an advanced equipment that uses laser technology to mark the surface of objects. Its basic principles involve laser emission, focusing, control system, and the interaction between the object surface and the laser. The following is a point-by-point description of the basic working principle of the laser marking machine:

- Laser emission: Laser marking machines use laser generators as energy sources. After the active medium in the laser generator is excited by electrical energy, it generates high-energy photons, which gradually amplify the photons in the laser generator to form a high-energy, highly monochromatic laser beam.

- Optical system: The laser beam passes through the optical system, including lenses and mirrors, for precise regulation and focus. The lens is used to adjust the diameter of the laser beam, while the reflector is used to change the direction of the laser beam to ensure that the laser can accurately illuminate the work surface.

- Control system: The laser marking machine is equipped with a sophisticated control system, which achieves precise control of the laser beam through a computer program. This includes controlling parameters such as laser beam intensity, marking speed, marking depth, etc. to meet different marking needs.

- Interaction between laser and object surface: When the laser beam irradiates the object surface, the laser energy is absorbed, emitted, or conducted to the object surface. This interaction causes changes in the surface of the object, such as melting, evaporation, or oxidation, forming visible marks.

- Non-contact marking: Since laser marking uses a non-contact marking method, it does not leave additional physical traces on the surface of the object. This makes laser marking suitable for materials with high surface sensitivity, while also reducing damage to the workpiece.

What is the average lifespan of a laser marking machine?

The average lifespan of a laser marking machine varies depending on the manufacturer, model, and usage conditions. Generally speaking, the average life of a laser marking machine is between 10,000 and 30,000 hours. This range is for reference only, actual life may be affected by a variety of factors. As mentioned above, factors such as laser source quality, working environment conditions, frequency of use, maintenance, etc. can all affect the life of the laser marking machine. The following are general estimates of the average lifespan of some common types of laser marking machines:

- Fiber laser marking machine: The fiber laser marking machine uses a fiber laser generator as the laser source, which has high energy conversion efficiency and small size. Under normal circumstances, the average life of a fiber laser marking machine can reach 10,000 to 30,000 hours.

- CO2 laser marking machine: The CO2 laser marking machine uses a CO2 gas laser generator as the laser source and is suitable for marking and engraving non-metallic materials. Its average lifespan is usually about 10,000 to 30,000 hours, but it may be affected by the special properties of the gas laser generator, and the laser gas needs to be replaced regularly.

- Semiconductor laser marking machine: A semiconductor laser marking machine uses a semiconductor laser generator and is commonly used in small marking equipment. Its average life is relatively short, generally less than 10,000 hours.

When purchasing and using a laser marking machine, users should make an evaluation based on the specific parameters of the equipment and the information provided by the manufacturer, combined with the actual situation. In addition, regular maintenance and upkeep are also crucial to extending the life of the laser marking machine.

What are the factors that affect the service life of laser marking machines?

As a kind of precision industrial equipment, the service life of a laser marking machine is comprehensively affected by many factors. The following are the main factors that affect the service life of laser marking machines:

Laser source quality

The core component of the laser marking machine is the laser source, and the quality of the laser source is directly related to the performance and life of the equipment. High-quality laser sources usually have higher energy conversion efficiency and more stable output power, which can extend the service life of the equipment.

Working environment conditions

The working environment has an important impact on the life of the laser marking machine. Harsh working environments such as high temperature, high humidity, and excessive dust may cause excessive wear and tear on equipment and reduce its lifespan. Therefore, providing a relatively stable working environment is crucial to protecting the laser marking machine.

Frequency of use and working hours

The frequency of use and working time of the laser marking machine are factors that directly affect the life of the equipment. Long-term and high-frequency operation may cause greater wear and tear on the equipment, accelerate the aging of key components, and thereby shorten their lifespan.

Maintenance and care

Regular maintenance and upkeep are important means to ensure the normal operation of the laser marking machine. Operations including cleaning the laser generator, replacing wearing parts, adjusting alignment, etc. can effectively extend the service life of the equipment and reduce the occurrence of failures.

Quality Control and Production Process

The manufacturer’s production process and quality control level are directly related to the quality and life of the laser marking machine. First-class production technology and strict quality control can improve the stability and reliability of the equipment, thereby extending its life.

Cooling system design

The laser marking machine will generate a certain amount of heat when working, and good heat dissipation system design is the key to ensuring long-term stable operation of the equipment. An unreasonable cooling system may cause equipment to overheat and accelerate the aging of key components.

Working with materials and workpieces

Different workpiece materials have different degrees of wear on the laser marking machine. Some special materials may cause corrosion or other adverse effects on the equipment, affecting the life of the equipment.

Operator’s skills

The life of the laser marking machine is also affected by the operator’s skills. Correct operation and maintenance methods can reduce damage caused by misoperation and improve the stability and life of the equipment.

In practical applications, to maximize the service life of the laser marking machine, users need to comprehensively consider the above factors and take effective measures for management and maintenance.

Methods to extend the service life of laser marking machines

Laser marking is a high-precision industrial equipment, and its life span is directly related to production efficiency and the economy of equipment investment. To maximize the service life of the laser marking machine, users can take the following series of methods:

Fair use

Avoid excessive use of laser marking machines and plan working time and frequency reasonably. Long-term and high-frequency work can easily cause equipment wear and tear, so it is necessary to reasonably arrange the work and rest time of the equipment according to actual needs.

Good working environment

Providing a good working environment is an important means to protect the laser marking machine. Ensure that the temperature and humidity are appropriate when the equipment is working and avoid excessive dust, which will help reduce wear and aging of the equipment.

Regular maintenance

Regular maintenance is a necessary step to ensure the normal operation of the laser marking machine. Regular cleaning of the laser generator, replacement of wearing parts (such as laser source, reflector, lens, etc.), adjustment of alignment, and other operations will help extend the service life of the equipment and reduce the possibility of failure.

Use quality accessories

When replacing spare parts, choose high-quality original parts. High-quality accessories have higher durability and stability, and can better protect the equipment and extend its life.

Pay attention to heat dissipation

The laser marking machine will generate a certain amount of heat when working, so the design of the heat dissipation system is crucial. Ensuring good heat dissipation can effectively reduce the temperature of the equipment and slow down the aging of key components.

Regular calibration

Calibrate equipment regularly to maintain its accuracy. Precise calibration helps reduce errors and places additional strain on critical components, thereby extending equipment life.

Usage skills training

Provide professional skills training to operators so that they can master the correct operation methods and maintenance skills of laser marking machines. Reduce misoperation and incorrect maintenance, helping to improve equipment stability.

Keep software updated

Regularly update the control software of the laser marking machine. New versions of software usually fix bugs in previous versions and improve device stability and performance.

Check the power supply regularly

Maintain the normal operation of the power system. Unstable power can adversely affect equipment, resulting in shortened equipment life.

Avoid overloading

Avoid placing excessive load on the equipment. When the equipment is working, avoid operations beyond its design specifications and working capabilities.

By comprehensively considering these methods, users can effectively extend the service life of the laser marking machine and improve the stability and reliability of the equipment.

Summarize

To sum up, the average life of a laser marking machine is affected by many factors, from the quality of the laser source to the working environment conditions, to the frequency of use and maintenance, all of which need to be reasonably considered. Through scientific and reasonable use and regular maintenance, the life of the laser marking machine can be effectively extended and its work efficiency and economy can be improved.

In future development, technological innovation and manufacturing process improvements will further promote the performance and lifespan of laser marking machines, providing more reliable marking solutions for industrial production. AccTek Laser has a professional laser marking technology team. We have various systems from hardware to software and can customize any specific needs you may have. Ask us for help learning more about laser marking.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions