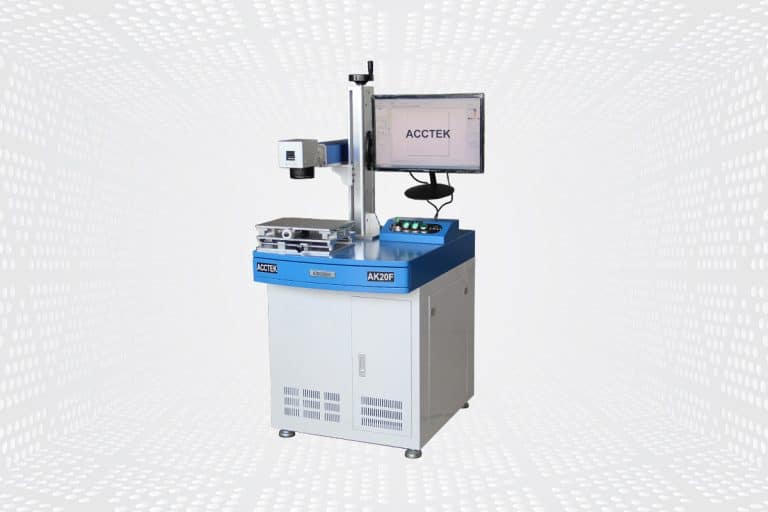

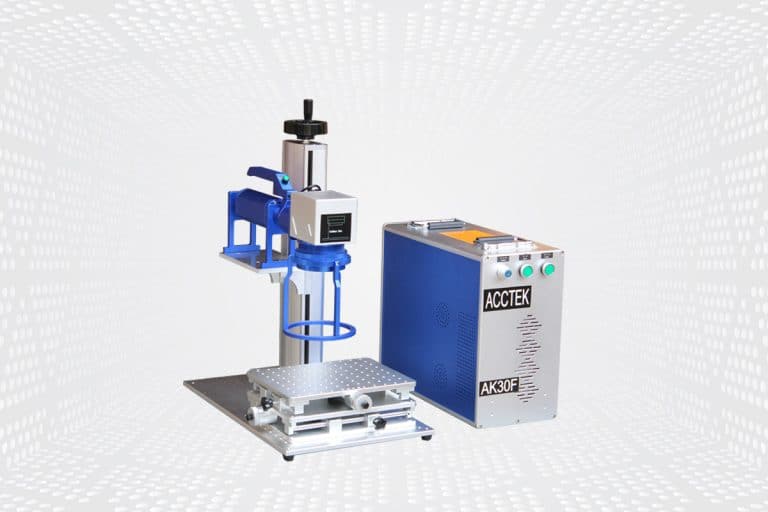

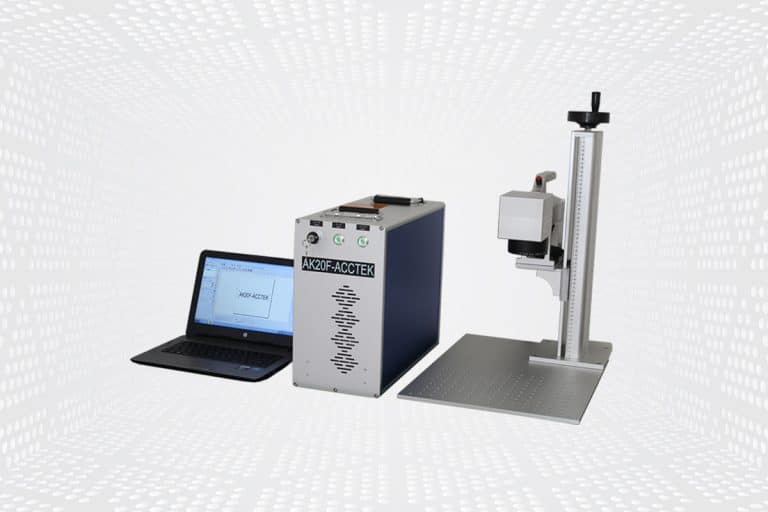

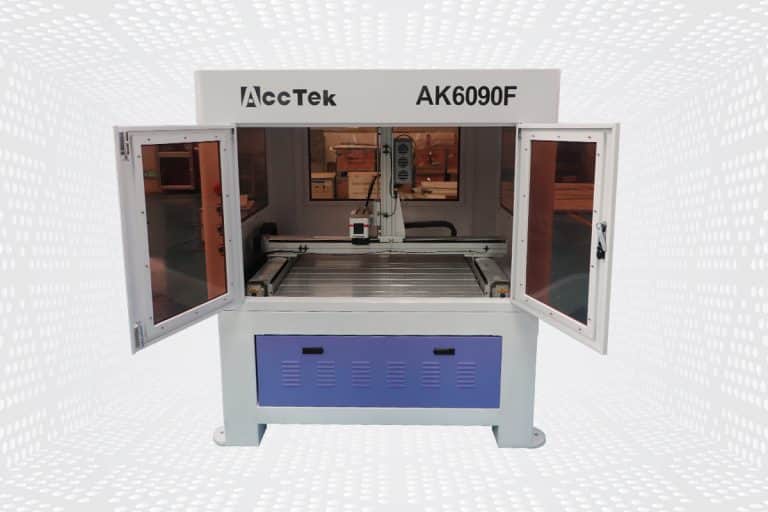

Fiber Laser Marking Machine

Product Range

Optional Fiber Laser Marking Machine Power

Materials That Can Be Marked

Laser Marking VS. Other Methods

Laser Marking vs. Mechanical Engraving

Mechanical engraving physically carves the material, which can lead to tool wear and slower processing times. In contrast, laser marking is non-contact, faster, and more precise, offering cleaner, more durable markings without causing material damage or tool degradation, ideal for intricate designs on various surfaces.

Laser Marking vs. Ink Printing

Ink printing involves applying ink onto the surface, which can fade, smudge, or wear off. Laser marking, however, uses heat to permanently engrave marks, providing high-contrast, long-lasting results. Laser markings are resistant to wear, chemicals, and environmental factors, making them ideal for products with longevity demands.

Laser Marking vs. Chemical Etching

Chemical etching requires the use of harmful chemicals to etch designs into the material, which can create environmental and safety concerns. Laser marking eliminates the need for chemicals, offering a cleaner, safer alternative that produces precise, permanent marks with no risk of harmful waste or toxic exposure.

Why Choose AccTek Laser

Unrivaled Precision and Accuracy

Our laser marking systems provide unparalleled precision, enabling you to achieve high-quality marks with sharp details and perfect clarity. Whether you're working with intricate designs or fine text, AccTek Laser ensures that your markings are accurate and durable, no matter the material.

Wide Range of Material Compatibility

AccTek Laser machines are designed to work with a broad spectrum of materials, including metals, plastics, ceramics, wood, and more. Our technology ensures flawless markings on both hard and soft surfaces, making our machines versatile enough for industries like automotive, aerospace, medical, and consumer goods.

Cutting-Edge Technology

We utilize the latest laser technologies, including fiber, CO2, and UV lasers, to offer solutions that are fast, efficient, and reliable. Our machines are engineered to meet high-volume production demands while maintaining top-tier performance, speed, and precision, increasing your production efficiency.

Tailored Solutions

At AccTek Laser, we understand that each business has unique requirements. That’s why we offer customizable solutions, allowing you to modify power, speed, and other parameters to fit your specific marking needs. We work with you to ensure our machines integrate seamlessly into your existing production line.

Comprehensive Customer Support

Our commitment to customer satisfaction extends well beyond the purchase. We offer thorough training, easy-to-follow installation guides, and ongoing support to ensure that your team can operate the laser marking system with ease. Our dedicated support team is always available to assist with troubleshooting or technical queries.

Cost-Effective Solutions

AccTek Laser machines are built to provide long-term value. They are designed to minimize energy consumption, reduce maintenance costs, and extend service life, offering you a cost-effective solution that doesn’t compromise on quality. This results in a low total cost of ownership and a high return on investment for your business.

Frequently Asked Questions

What Are Fiber Laser Marking Machines?

How Much Do Fiber Laser Marking Machines Cost?

How Do Fiber Laser Marking Machines Work?

- Generation of Laser Beam: The heart of a fiber laser marking machine is the fiber laser source. This source generates a high-energy laser beam typically in the infrared spectrum.

- Beam Delivery: The laser beam is guided through a series of mirrors and lenses to direct it toward the marking area. Fiber lasers are named for the optical fiber used to deliver the laser beam, which offers flexibility and precise control.

- Focusing: The laser beam passes through a focusing lens, which concentrates the energy into a small spot size. This focused beam is crucial for achieving high-resolution marks.

- Interaction with Material: When the focused laser beam hits the surface of the material, it creates intense heat. This heat affects the material in various ways depending on its composition. For example, metals may melt or vaporize.

- Mark Creation: As the laser beam interacts with the material, it forms the desired mark by altering its surface properties. This alteration could be through engraving, ablation, foaming, annealing, or color change, depending on the specific process parameters and material properties.

- Control and Precision: The machine’s control system precisely regulates parameters such as laser power, pulse duration, and scanning speed to achieve the desired mark quality and consistency.

- Cooling and Exhaust: Fiber laser marking machines typically incorporate cooling systems to manage the heat generated by the laser source and the marked material. They also often include exhaust systems to remove any fumes or debris produced during the marking process.

- Automation and Integration: Many fiber laser marking machines are equipped with computer numerical control (CNC) systems, allowing for automated marking processes. They can also integrate with other manufacturing systems for seamless production line integration.

What Are Fiber Laser Marking Machines Used For?

- Metal Engraving and Marking: Fiber lasers can etch or engrave serial numbers, barcodes, logos, and product information onto metals like steel, aluminum, titanium, and brass. This is commonly used for traceability and identification.

- Plastic Marking: Fiber laser marking can be used to mark plastics without damaging the material. It is ideal for creating logos, part numbers, and safety warnings on products like phones, medical instruments, and packaging.

- Jewelry Marking: Fiber lasers are used for fine, precise engraving on precious metals like gold, silver, and platinum. They can create intricate designs, logos, and personalization (e.g., names, and dates) on jewelry items.

- Barcode and QR Code Marking: Fiber lasers can engrave barcodes and QR codes on a variety of materials for inventory management and product tracking.

- Plastic and Rubber Parts: Fiber lasers are used to mark plastic and rubber components, including creating logos, brand names, and part numbers.

- Medical Device Marking: Fiber laser marking machines are used to mark medical instruments, tools, and implants with serial numbers, manufacturing information, and certification marks. It’s critical for compliance with medical device regulations.

- Tooling and Industrial Parts: Fiber laser marking is used for industrial tools, machine components, and dies, allowing for the marking of identification codes, part numbers, or wear indicators that will last the lifetime of the part.

- Electronics and Circuit Boards: Fiber lasers are used to mark and engrave serial numbers, logos, and other identifiers on electronic parts like microchips, circuit boards, and connectors.

- Signage and Branding: Fiber lasers are used for creating signage, labels, and brand marks on metal or plastic surfaces. They can create highly detailed logos and text that are permanent and resistant to wear.

- Art and Personalization: Fiber lasers are used to personalize items such as trophies, awards, and gifts, with names, dates, logos, and images, creating intricate and detailed designs.

What Is The Difference Between CO2 Lasers And Fiber Lasers?

- Laser Medium

- CO2 Lasers: CO2 lasers use a gas mixture, typically consisting of carbon dioxide, nitrogen, and helium, as the laser medium. The lasing action occurs within a sealed tube filled with this gas mixture.

- Fiber Lasers: Fiber lasers use a solid-state laser medium, usually a doped fiber optic cable. The lasing material is typically ytterbium, erbium, or a combination of rare earth elements embedded in the fiber core.

- Wavelength

- CO2 Lasers: CO2 lasers emit infrared light at a wavelength of around 10.6 micrometers. This wavelength is well-suited for processing organic materials like wood, paper, plastics, fabrics, and some metals.

- Fiber Lasers: Fiber lasers emit light at a wavelength typically around 1 micrometer. This wavelength is particularly effective for processing metals, including steel, aluminum, brass, copper, and alloys, as well as some plastics and ceramics.

- Energy Efficiency

- CO2 Lasers: CO2 lasers are less energy-efficient compared to fiber lasers. They require higher electrical power consumption and generate more heat during operation.

- Fiber Lasers: Fiber lasers are more energy-efficient, with higher wall-plug efficiency. They require less electrical power and generate less heat, making them suitable for continuous operation and reducing operating costs.

- Maintenance

- CO2 Lasers: CO2 lasers typically require more maintenance due to the complexity of their gas-filled tubes, which may degrade over time and require replacement.

- Fiber Lasers: Fiber lasers generally require less maintenance because they have fewer moving parts and a solid-state design. The fiber laser’s longevity is typically higher compared to CO2 lasers.

- Marking and Cutting Capabilities

- CO2 Lasers: CO2 lasers are well-suited for cutting and engraving organic materials such as wood, paper, fabric, and plastics. They can also mark certain metals using specialized coatings.

- Fiber Lasers: Fiber lasers excel at marking and cutting metals and metal alloys, including steel, aluminum, brass, copper, and titanium. They can achieve high-quality, high-contrast marks on metals without the need for additional coatings.

What Are The Disadvantages of Fiber Laser Marking?

- Material Limitations: While fiber lasers excel at marking metals and certain plastics, they may not be as effective for marking some non-metallic materials or materials with highly reflective surfaces. In such cases, additional surface preparation or coatings may be required to achieve satisfactory marking results.

- Initial Cost: Fiber laser marking machines can have higher initial costs compared to other marking technologies, such as CO2 lasers or inkjet printers. The investment in a fiber laser system may be substantial, particularly for small businesses or those with limited budgets.

- Complexity of Setup: Setting up a fiber laser marking system requires expertise in laser technology and material processing. Calibration of parameters such as laser power, scanning speed, and focal length is critical to achieving optimal marking results. This complexity may pose challenges for users who are not familiar with laser technology.

- Maintenance Requirements: While fiber lasers generally require less maintenance than other types of lasers, they still require periodic servicing and upkeep to ensure optimal performance. Maintenance tasks may include cleaning optical components, aligning laser beams, and replacing consumable parts such as lenses or protective windows.

- Safety Considerations: Fiber laser systems emit high-intensity laser beams that can cause eye injury or skin burns if not properly controlled. Operators must adhere to strict safety protocols, including wearing appropriate protective eyewear and clothing, and ensuring that the work area is properly enclosed to prevent exposure to laser radiation.

- Limited Depth of Marking: Fiber lasers are primarily surface marking tools and may have limitations in marking deep into certain materials. While they can create precise surface marks, they may not be suitable for applications requiring deep engraving or volumetric marking.

- Environmental Impact: Like all industrial processes, laser marking generates waste in the form of fumes, dust, and debris. Proper ventilation and exhaust systems are necessary to remove these byproducts and maintain a safe working environment. Additionally, disposal of waste materials may pose environmental concerns and require proper handling.

Do Fiber Lasers Lose Power Over Time?

- Laser Diode Degradation: Fiber lasers often use laser diodes as pump sources to excite the lasing medium (e.g., ytterbium or erbium-doped fibers). Over time, these laser diodes can degrade due to factors such as usage, temperature variations, and manufacturing imperfections. As the diodes degrade, they may become less efficient at converting electrical energy into laser light, leading to a reduction in laser output power.

- Fiber Damage: The optical fibers used in fiber lasers are subject to various forms of degradation, including photodarkening, fiber end-face contamination, and mechanical stress. These factors can cause light absorption and scattering within the fiber, reducing the efficiency of light transmission and ultimately leading to a decrease in laser output power.

- Optical Component Degradation: Other optical components within the laser cavity, such as mirrors, lenses, and isolators, can also degrade over time due to factors like contamination, thermal cycling, and laser-induced damage. Degradation of these components can lead to increased optical losses and reduced laser output power.

- Thermal Effects: Fiber lasers generate heat during operation, and excessive heat buildup can cause thermal damage to laser components, particularly in high-power systems. Thermal cycling and temperature fluctuations can accelerate degradation processes and contribute to a decline in laser performance over time.

- Contamination: Contaminants such as dust, dirt, or particulate matter can accumulate on optical surfaces within the laser system, leading to increased optical losses and reduced laser output power. Regular cleaning and maintenance of optical components maintain laser performance.

How Precise Are The Markings Produced By The Fiber Laser Marking Machine?

- Beam Quality: Fiber lasers typically produce a high-quality laser beam with a small spot size and excellent beam divergence characteristics. This allows for precise focusing and control of the laser energy onto the marking surface, resulting in fine details and sharp edges in the markings.

- Optical Systems: Fiber laser marking machines are equipped with advanced optical systems, including high-quality lenses, mirrors, and galvanometer scanners. These components enable precise beam control, rapid scanning speeds, and accurate positioning, ensuring that markings are placed exactly where intended with minimal deviation.

- Control Software: Modern fiber laser marking machines are driven by sophisticated control software that allows users to define and adjust marking parameters with precision. This software enables precise control over laser power, pulse duration, marking speed, and other parameters, allowing for optimal customization of marking processes for different materials and applications.

- Mechanical Stability: The mechanical stability of the marking system, including the rigidity of the machine structure and the stability of motion control systems, is crucial for achieving precise markings. High-quality machines are designed to minimize vibrations and mechanical distortions that could affect marking accuracy.

- Material Compatibility: Fiber laser marking machines are capable of marking a wide range of materials, including metals, plastics, ceramics, and organic materials. The versatility of these machines allows for precise markings on diverse materials with varying surface properties and compositions.

- Resolution and Linearity: Fiber laser marking systems typically offer high resolution and linearity, allowing for the creation of intricate designs, small text, and complex patterns with precise control over line thickness and spacing.

Related Resources

What Are the Advantages and Limitations of Laser Marking?

This article systematically analyzes the characteristics, advantages and disadvantages, and application scenarios of three marking technologies: fiber laser, CO2 laser, and UV laser, and provides some guidance for selecting a

What Are the Common Defects in Laser Marking?

This article introduces the application of laser marking technology, common defects, and solutions, and provides optimization measures to improve marking quality and efficiency.

How to Remove Laser Markings

This article focuses on the different methods of removing laser marks, including mechanical, chemical and thermal treatment, and provides safe and effective best practices guidance.