Understanding CO2 Laser Technology

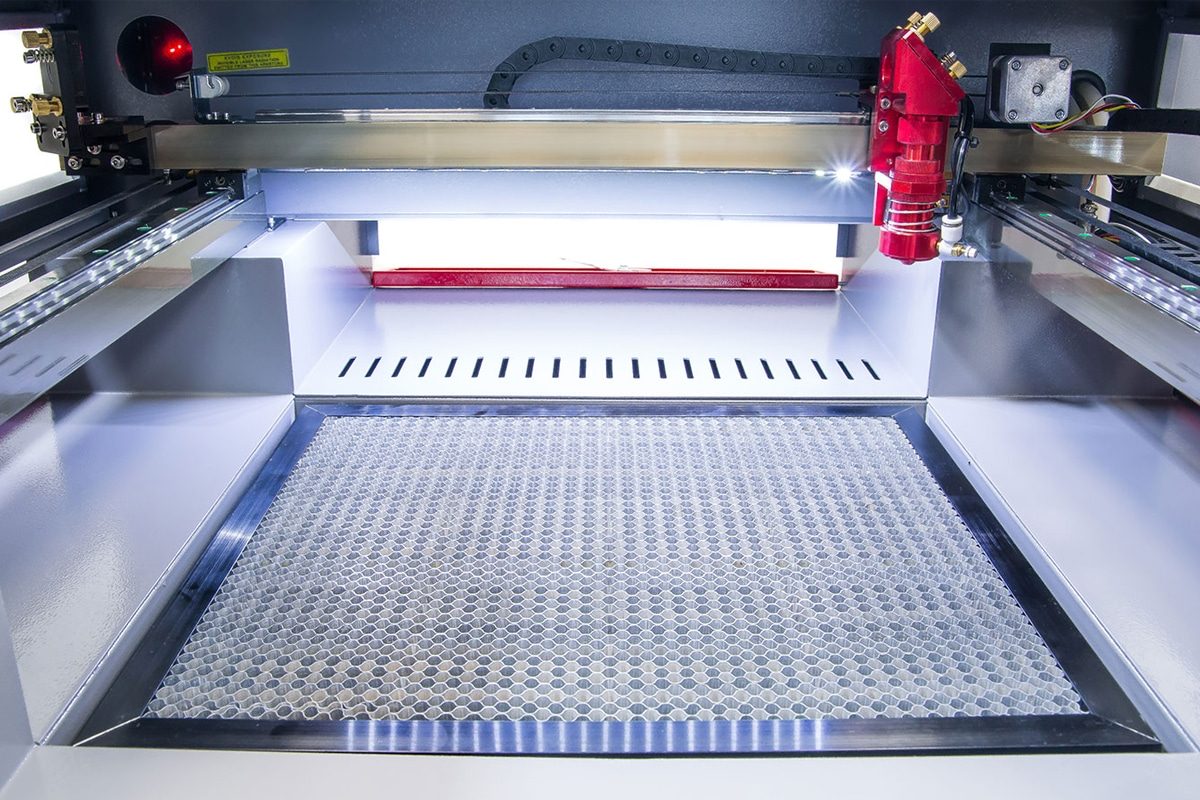

The purpose of this topic is to introduce and provide an overview of how CO2 laser cutting works, providing a foundation for understanding the environmental precautions and regulations associated with its operation. The core of CO2 laser cutting is the principle of laser radiation and uses a series of steps to achieve precise material processing:

- Gas Excitation: This process begins within a laser resonator, where a gas mixture (mainly carbon dioxide) gains energy through an electrical discharge. This excitation stimulates the gas molecules, causing them to emit photons.

- Beam Formation: As photons bounce between mirrors within the resonator, they are amplified through stimulated emission. The particle population is reversed, with more photons at higher energy levels. Eventually, the amplified photons escape through the partially reflecting mirror, forming a coherent and focused infrared beam.

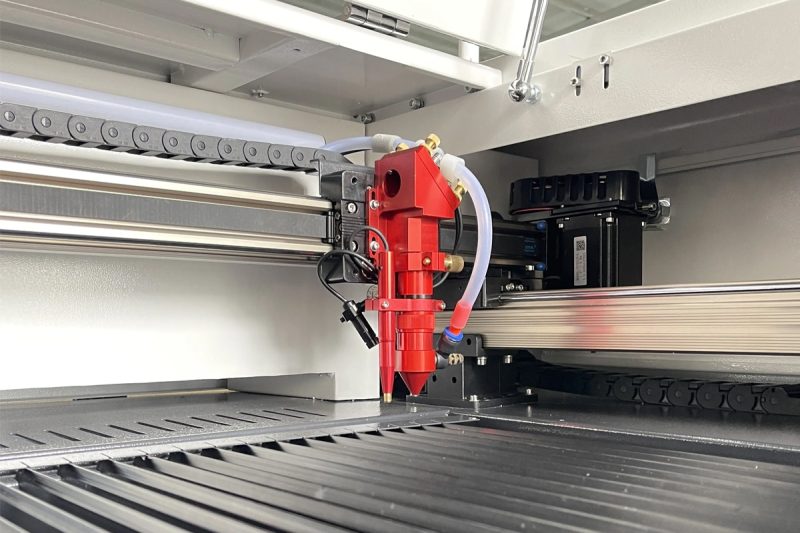

- Beam Guidance: The focused laser beam is then directed through a series of mirrors and lenses to align it with the desired cutting path.

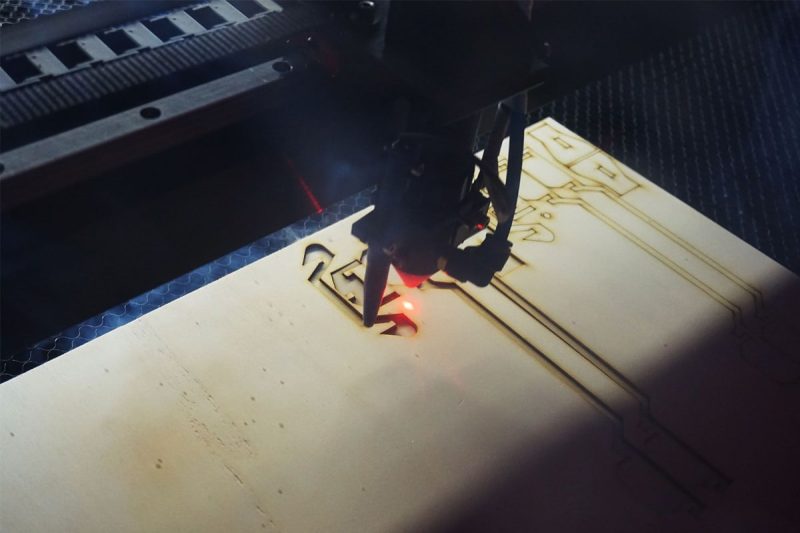

- Material Interaction: The intense energy of the laser beam interacts with the surface of the material to be cut. Depending on the material, the laser beam may melt, burn, or vaporize it.

- Material Removal: As the laser beam moves along a predetermined cutting path, it removes material layer by layer, resulting in precise cuts with minimal heat-affected areas.

- Cooling and Exhaust: To prevent overheating and maintain optimal cutting conditions, a cooling system is used to dissipate heat from the laser components. Additionally, the exhaust system removes smoke and debris generated during the cutting process.

The Impact of CO2 Laser Cutting Machines On The Environment

CO2 laser cutting machines have become an indispensable tool in modern industrial manufacturing, providing unparalleled precision, speed, and versatility. However, their widespread use has also raised concerns about environmental impacts. Understanding the multi-faceted impact of these machines on the environment enables the development of effective mitigation strategies and the promotion of sustainable practices within the manufacturing industry.

- Infrared Radiation Emission: CO2 laser cutting machines precisely cut various materials by emitting concentrated infrared beams. While this process is very efficient, it can also have thermal negative effects. If not managed properly, excess heat can cause localized thermal pollution that can impact surrounding ecosystems and wildlife habitats.

- Air Emissions: Materials that are cut with CO2 lasers, such as metals, plastics, and composites, release harmful air emissions during the cutting process. These emissions can include volatile organic compounds (VOCs), particulate matter, and hazardous chemicals, posing risks to the environment and human health. Therefore, effective ventilation and emission control systems are essential to reduce the emission of pollutants into the atmosphere.

- Energy Consumption: CO2 laser cutting machines are inherently energy-intensive and require large amounts of electricity to operate effectively. High-power laser generators, motion control systems, and auxiliary equipment all meet its huge energy needs. Therefore, unless powered by renewable energy or operated using energy-efficient practices, these machines increase greenhouse gas emissions and contribute to climate change.

- Waste Generation: The cutting process generates waste in the form of offcuts, chips, and potentially hazardous by-products. Improper handling and disposal of these waste materials can lead to environmental contamination and contamination. Implementing effective waste management strategies, such as recycling and proper disposal protocols, is critical to minimizing the environmental impact of CO2 laser cutting operations.

- Resource Consumption: In addition to energy, CO2 laser cutting machines consume other resources, including water for cooling systems, maintenance lubricants, and raw materials for manufacturing components. Sustainable resource management practices, such as water recycling and responsible sourcing, can help reduce the overall environmental footprint of these machines.

Environmental Precautions for Operating CO2 Laser Cutting Machines

Ventilation System

Emission Control

Material Selection and Handling

Energy Efficiency

Waste Management

Operator Training and Awareness

Regulatory Framework for CO2 Laser Cutting Machines

Occupational Safety and Health Administration (OSHA)

- OSHA develops and enforces workplace safety standards to protect workers from the hazards associated with CO2 laser-cutting operations.

- OSHA regulations related to CO2 laser cutters include those related to machine guarding, personal protective equipment (PPE), hazard communication, and hazardous energy control (lockout/tagout).

- Employers must ensure that CO2 laser cutters are properly guarded to prevent entry into the laser beam and other hazardous areas. Additionally, workers must be provided with appropriate personal protective equipment, such as safety glasses, to protect against laser radiation and air emissions.

- OSHA also requires employers to implement comprehensive hazard communication programs to inform workers of the potential hazards associated with CO2 laser cutting, as well as training programs to educate employees on safe operating procedures.

Environmental Protection Agency (EPA)

- The U.S. Environmental Protection Agency (EPA) regulates emissions from industrial processes, including emissions from carbon dioxide laser-cutting operations, to protect air quality and minimize environmental pollution.

- EPA regulations may include air emission standards, permitting requirements, and reporting obligations for facilities using CO2 laser cutters.

- Facilities may need to install emission control equipment, such as exhaust systems and scrubbers, to capture and treat air pollutants generated during the laser cutting process.

- Complying with EPA regulations helps ensure that CO2 laser-cutting operations do not cause air pollution or pose risks to public health and the environment.

State and Local Regulations

- In addition to federal regulations, state and local governments can impose their requirements and standards on CO2 laser-cutting operations.

- These regulations may vary based on factors such as air quality standards, permitting processes, and occupational safety requirements.

- In addition to federal requirements, facilities must comply with applicable state and local regulations to ensure full compliance and avoid potential fines or penalties.

Environmentally Friendly Operating Practices for CO2 Laser Cutting

Regular Inspection and Maintenance

- Perform regular maintenance and inspections on CO2 laser cutting machines to ensure optimal performance and minimize energy consumption.

- Maintain laser resonators, optics, and cooling systems to prevent energy inefficiencies and reduce the risk of equipment failure.

- Inspect machine components for wear and damage, replacing or repairing parts as needed to maintain efficiency and safety.

Personal Protective Equipment (PPE)

- Provide workers with appropriate personal protective equipment (PPE), including safety glasses, face shields, and protective clothing, to reduce the risks associated with CO2 laser cutting.

- Ensure that all personnel involved in laser cutting operations wear personal protective equipment properly at all times to prevent injury and exposure to hazardous materials.

Training and Education

- Provide a comprehensive training and education program for employees involved in CO2 laser cutting operations.

- Train workers on proper machine operation, safety procedures, and emergency response protocols to minimize accidents and injuries.

- Educate employees on the environmental impact of CO2 laser cutting and the importance of adopting sustainable practices in daily operations.

Waste Management

- Implement waste management practices that minimize waste generation and maximize recycling and reuse opportunities.

- Separate waste materials such as offcuts and debris for recycling or proper disposal by regulatory requirements.

- Implement a recycling program for materials that can be reused or repurposed, such as scrap metal or plastic.

Comply with Regulations

- Ensure compliance with all relevant regulations, including those set by OSHA, EPA, and state and local authorities.

- Stay informed of regulatory updates and changes that may affect your CO2 laser cutting operations and adjust your practices accordingly to stay compliant.

- Maintain complete records of regulatory compliance efforts, including training records, inspection reports, and waste management logs.

Energy Efficiency

- Implement energy-saving practices to reduce the energy consumption of CO2 laser cutting machines.

- Optimize machine settings such as laser power and cutting speed to minimize energy consumption while maintaining cut quality.

- Invest in energy-saving equipment and technology, such as regenerative braking systems and power management software, to further reduce energy consumption.

Summarize

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.