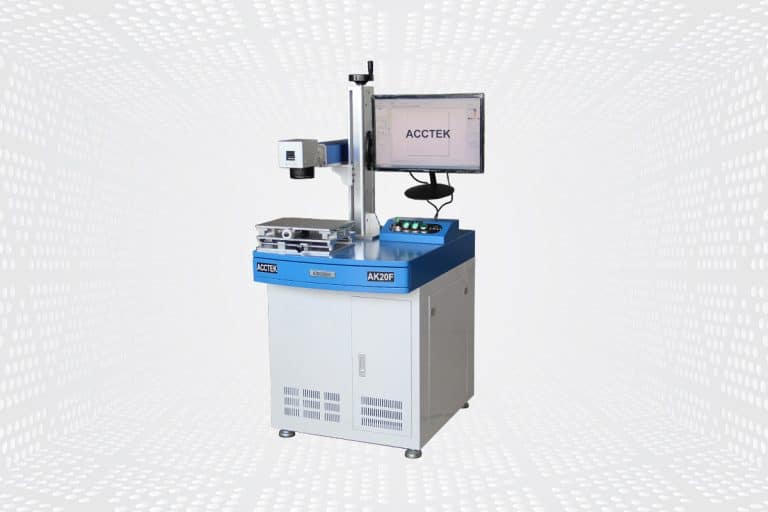

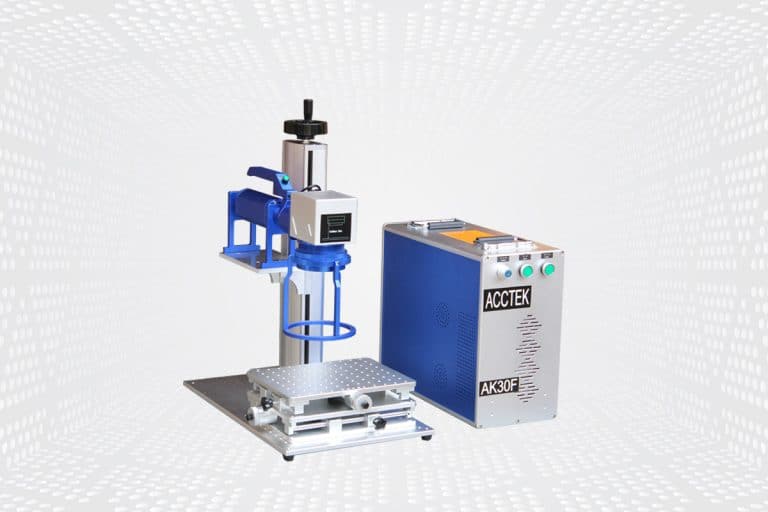

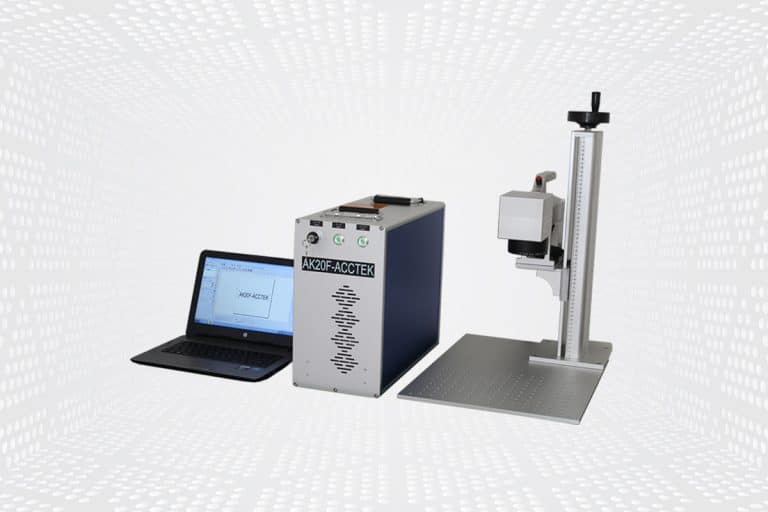

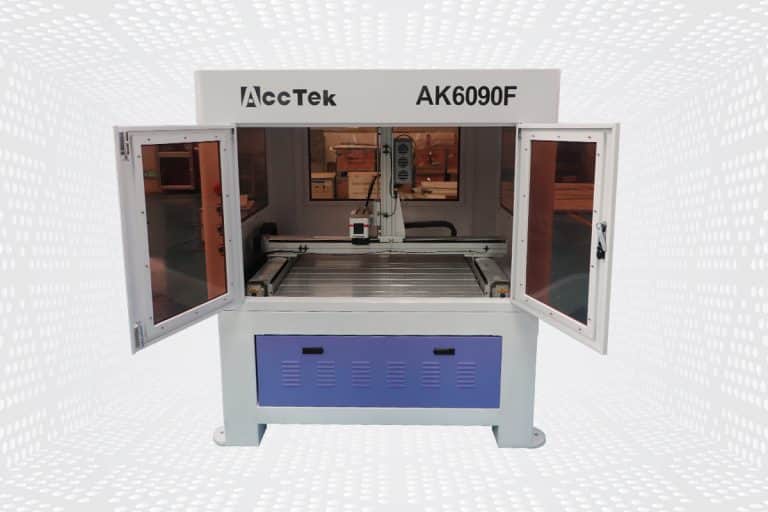

Laser Marking Machine

Product Range

Optional Laser Marking Machine Power

Materials That Can Be Marked

Laser Marking VS. Other Methods

Laser Marking vs. Mechanical Engraving

Mechanical engraving physically carves the material, which can lead to tool wear and slower processing times. In contrast, laser marking is non-contact, faster, and more precise, offering cleaner, more durable markings without causing material damage or tool degradation, ideal for intricate designs on various surfaces.

Laser Marking vs. Ink Printing

Ink printing involves applying ink onto the surface, which can fade, smudge, or wear off. Laser marking, however, uses heat to permanently engrave marks, providing high-contrast, long-lasting results. Laser markings are resistant to wear, chemicals, and environmental factors, making them ideal for products with longevity demands.

Laser Marking vs. Chemical Etching

Chemical etching requires the use of harmful chemicals to etch designs into the material, which can create environmental and safety concerns. Laser marking eliminates the need for chemicals, offering a cleaner, safer alternative that produces precise, permanent marks with no risk of harmful waste or toxic exposure.

Why Choose AccTek Laser

Unrivaled Precision and Accuracy

Our laser marking systems provide unparalleled precision, enabling you to achieve high-quality marks with sharp details and perfect clarity. Whether you're working with intricate designs or fine text, AccTek Laser ensures that your markings are accurate and durable, no matter the material.

Wide Range of Material Compatibility

AccTek Laser machines are designed to work with a broad spectrum of materials, including metals, plastics, ceramics, wood, and more. Our technology ensures flawless markings on both hard and soft surfaces, making our machines versatile enough for industries like automotive, aerospace, medical, and consumer goods.

Cutting-Edge Technology

We utilize the latest laser technologies, including fiber, CO2, and UV lasers, to offer solutions that are fast, efficient, and reliable. Our machines are engineered to meet high-volume production demands while maintaining top-tier performance, speed, and precision, increasing your production efficiency.

Tailored Solutions

At AccTek Laser, we understand that each business has unique requirements. That’s why we offer customizable solutions, allowing you to modify power, speed, and other parameters to fit your specific marking needs. We work with you to ensure our machines integrate seamlessly into your existing production line.

Comprehensive Customer Support

Our commitment to customer satisfaction extends well beyond the purchase. We offer thorough training, easy-to-follow installation guides, and ongoing support to ensure that your team can operate the laser marking system with ease. Our dedicated support team is always available to assist with troubleshooting or technical queries.

Cost-Effective Solutions

AccTek Laser machines are built to provide long-term value. They are designed to minimize energy consumption, reduce maintenance costs, and extend service life, offering you a cost-effective solution that doesn’t compromise on quality. This results in a low total cost of ownership and a high return on investment for your business.

Frequently Asked Questions

What Are Laser Marking Machines?

How Much Do Laser Marking Machines Cost?

What Is The Difference Between Laser Marking And Laser Engraving?

- Technique

- Laser marking typically involves altering the surface of a material by causing a color change, oxidation, or other chemical reaction, without significantly removing material. It often creates high-contrast, permanent marks on the surface.

- Laser engraving involves removing material from the surface of the material, either by vaporization, melting, or ablation, to create depressions or indentations. This process usually results in deeper marks compared to laser marking.

- Depth of Mark

- Laser marking typically creates shallow marks on the surface, usually less than 0.001 inches deep, depending on the material and laser parameters.

- Laser engraving creates deeper marks, often ranging from a few thousandths to several hundredths of an inch deep, depending on the material and the desired depth.

- Appearance

- Laser marking often results in marks with contrasting colors or shades on the surface of the material, such as dark marks on metals or lighter marks on plastics.

- Laser engraving produces recessed marks with defined edges, resulting in a tactile and visually distinct effect.

- Applications

- Laser marking is commonly used for adding logos, serial numbers, barcodes, or decorative designs onto surfaces while maintaining the integrity of the material.

- Laser engraving is often used for creating deep, permanent markings, intricate patterns, or detailed artwork on a wide range of materials, including metals, plastics, wood, and more.

- Speed

- Laser marking is generally faster than laser engraving since it involves less material removal.

- Laser engraving can be slower due to the need to remove material to a greater depth.

What Are The Disadvantages of Laser Marking Machines?

- High Initial Investment: Laser marking machines typically require a higher upfront investment compared to traditional marking methods (like inkjet or dot peen). The sophisticated technology and components involved in laser systems, including the laser source, optics, and software, contribute to their higher cost. This can be a barrier for small businesses or those with limited budgets.

- Material Limitations: Although laser marking can be applied to a variety of materials, it may not work well on all surfaces. For instance, highly reflective metals or certain types of transparent plastics may present challenges. Specialized systems or additional equipment, such as rotary fixtures or advanced optics, may be required to mark these materials effectively.

- Heat-Affected Zones (HAZ): Laser marking works by focusing intense heat onto the material’s surface, which can lead to a heat-affected zone (HAZ). This zone may cause unwanted changes in material properties such as discoloration, warping, or surface deformation, especially in heat-sensitive materials like plastics or thin metals.

- Limited Depth of Marking: Laser marking is generally a surface-level process, which means it is best suited for light engraving or surface etching. If a project requires deeper, more permanent engravings or deep cutting, other methods such as mechanical engraving or chemical etching might be more appropriate.

- Complexity and Need for Training: Operating laser marking machines requires specialized knowledge and skills. Operators need to understand how to properly set the machine, program designs, and adjust parameters based on the material being marked. Improper setup or operation can lead to poor quality marks, damage to the material, or even machine malfunctions. This may require dedicated training and expertise.

- Maintenance and Repair Costs: Laser marking machines require regular maintenance to maintain optimal performance. This includes cleaning lenses, ensuring proper alignment, and servicing the laser tube or other key components. Depending on the machine and its usage, repair costs for components like the laser source or cooling system can be significant.

- Power and Cooling Requirements: High-powered laser systems need consistent and reliable power supplies. They also often require an efficient cooling system to prevent overheating during continuous operation. This means that additional infrastructure, such as dedicated power sources and cooling units, may be required, which adds to the operational costs.

- Limited Flexibility for Certain Designs: While laser marking is precise, it is sometimes limited in terms of the types of designs it can create, especially for highly intricate or detailed 3D designs. Other methods, such as engraving or milling, may offer greater flexibility for complex patterns, textures, or three-dimensional shapes.

- Environmental Considerations: Laser marking processes can produce fumes, especially when marking materials like plastics or rubber. These fumes may require a ventilation system to ensure a safe working environment. Additionally, the energy consumption of high-powered lasers can be a concern for businesses looking to reduce their carbon footprint.

- Speed Limitations in High-Volume Production: While laser marking machines are typically faster than traditional methods, they may still face limitations in extremely high-volume or high-speed applications. For operations requiring mass marking of many small parts quickly, other methods like inkjet printing may be more efficient.

Is The Laser Marking Permanent And Resistant To Wear?

- Chemical Bonding: Laser marking often involves inducing chemical changes on the surface of the material, such as oxidation or color change. These changes create a bond between the mark and the material, making it resistant to fading, rubbing off, or washing away.

- Material Compatibility: Laser marking can be performed on a wide range of materials, including metals, plastics, ceramics, and more. The choice of material and laser parameters can ensure compatibility and long-term stability of the mark.

- High Precision: Laser marking offers precise control over the depth, width, and intensity of the mark, resulting in sharp, well-defined markings that are less susceptible to wear and distortion over time.

- Intrinsic Properties: Certain materials, such as metals and some plastics, naturally lend themselves to durable laser marks due to their inherent properties, such as heat resistance, chemical stability, and hardness.

- Surface Treatments: In some cases, additional surface treatments or coatings can be applied after laser marking to enhance the durability and resistance to wear of the marks, especially in harsh environments or high-wear applications.

What Level of Precision Can The Laser Marking Machine Achieve?

- Spot Size: The spot size of the laser beam, determined by the optics and focusing system, directly affects the precision of the marking. Smaller spot sizes allow for finer details and higher precision marks.

- Laser Control: Modern laser marking machines offer precise control over laser parameters such as power, pulse duration, frequency, and scanning speed. Optimizing these parameters allows for precise control over the depth, width, and intensity of the mark.

- Motion Control: The accuracy of the machine’s motion control system, including positioning accuracy and repeatability, helps achieve precise and consistent marking. High-quality linear stages and galvanometer scanners are commonly used for precise motion control in laser marking systems.

- Material Properties: The material being marked can influence the achievable precision. Materials with consistent properties and smooth surfaces typically allow for higher precision marks compared to rough or uneven surfaces.

- Resolution of Design: The resolution of the design or artwork being marked also impacts precision. Higher-resolution designs with finer details require a laser marking system capable of accurately reproducing those details.

Can The Laser Marking Machine Handle Different Design Requirements?

- Text and Numbers: Laser marking machines can easily mark alphanumeric characters, including letters, numbers, and symbols, in different fonts, sizes, and orientations. This capability is commonly used for adding part numbers, serial numbers, date codes, and other text-based information onto products or components.

- Logos and Graphics: Laser marking machines can accurately reproduce complex logos, graphics, and images onto various materials. Whether it’s a company logo, product branding, or decorative artwork, laser marking offers precise control over the marking process, allowing for high-quality reproduction of intricate designs.

- Barcodes and QR Codes: Laser marking machines can generate high-resolution barcodes, QR codes, and other machine-readable codes directly onto surfaces. These codes are commonly used for product identification, inventory tracking, and traceability purposes in industries such as manufacturing, automotive, and healthcare.

- 2D Matrix Codes: Laser marking machines can produce 2D matrix codes, such as DataMatrix and QR codes, which can encode large amounts of data in a compact format. These codes are used for applications requiring robust data storage and retrieval capabilities, such as product serialization, part tracking, and authentication.

- Variable Data and Serialization: Laser marking machines can be integrated with database systems and automation software to mark products with variable data, such as sequential serial numbers, batch numbers, and production dates. This capability enables mass customization and serialization of products for traceability and anti-counterfeiting purposes.

- Customized Marking Parameters: Laser marking machines offer customizable marking parameters, allowing users to adjust settings such as laser power, pulse duration, frequency, and scanning speed to achieve the desired mark quality, contrast, and depth for different design requirements and materials.

What Maintenance Is Required For Laser Marking Machines?

- Regular Cleaning: Keep the machine clean by removing dust, debris, and residue from the work area, optics, lenses, and surrounding components. Use appropriate cleaning materials and techniques recommended by the manufacturer to avoid damage to sensitive parts.

- Optics Inspection and Cleaning: Periodically inspect the laser optics, focusing lenses, mirrors, and beam delivery system for signs of contamination, scratches, or misalignment. Clean or replace the optics as needed to maintain optimal beam quality and marking accuracy.

- Laser Source Maintenance: Follow the manufacturer’s guidelines for maintaining and servicing the laser source, including checking for signs of degradation, adjusting power settings, and replacing worn components or consumables (such as laser diodes or fiber optic cables) as necessary.

- Cooling System Maintenance: If the laser marking machine uses a water or air cooling system, ensure that it is properly maintained and monitored to prevent overheating and ensure efficient operation. Clean or replace filters, check coolant levels, and inspect hoses and connections regularly.

- Motion System Lubrication: Lubricate the linear stages, bearings, rails, and other moving parts of the machine’s motion control system according to the manufacturer’s recommendations to reduce friction, minimize wear, and maintain smooth and precise motion.

- Software Updates: Keep the machine’s control software and firmware up to date by installing recommended updates and patches provided by the manufacturer. Updated software can improve performance, add new features, and address potential security vulnerabilities.

- Safety Checks: Conduct regular safety inspections to ensure that all safety interlocks, enclosures, laser warning labels, and emergency stop mechanisms are functioning correctly and compliant with safety regulations and standards.

- Operator Training: Provide operators with comprehensive training on machine operation, maintenance procedures, safety protocols, and troubleshooting techniques to ensure the safe and efficient use of the laser marking machine.

- Professional Servicing: Schedule periodic maintenance and servicing by qualified technicians or service providers, as recommended by the manufacturer, to address more complex issues, perform calibration and alignment procedures, and ensure compliance with regulatory requirements.

Related Resources

What Are the Advantages and Limitations of Laser Marking?

This article systematically analyzes the characteristics, advantages and disadvantages, and application scenarios of three marking technologies: fiber laser, CO2 laser, and UV laser, and provides some guidance for selecting a

What Are the Common Defects in Laser Marking?

This article introduces the application of laser marking technology, common defects, and solutions, and provides optimization measures to improve marking quality and efficiency.

How to Remove Laser Markings

This article focuses on the different methods of removing laser marks, including mechanical, chemical and thermal treatment, and provides safe and effective best practices guidance.