$57,000.00 – $181,000.00

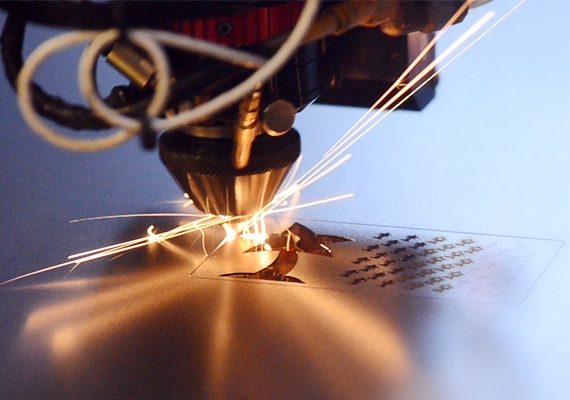

The high-quality laser cutting head delivers precision and efficiency, featuring advanced optics for superior beam focus and accuracy. Designed for durability and versatility, it ensures clean cuts on various materials, minimizing waste. With user-friendly adjustments and high-speed performance, it’s the perfect component for professional-grade laser cutting applications.

The ultra-stable laser generator is the heart of cutting-edge performance, delivering consistent power output for flawless cutting and engraving. Engineered for reliability, it ensures precision even during extended operations. Its advanced design minimizes fluctuations, enhances efficiency, and maximizes material compatibility, making it essential for professional-grade laser cutting applications.

The aviation aluminum beam combines lightweight design with exceptional strength, ensuring stability and precision during high-speed operations. Crafted from aerospace-grade aluminum, it enhances cutting accuracy while resisting deformation. Its corrosion-resistant and durable structure reduces vibration, enabling smooth, efficient performance, making it a cornerstone of advanced laser cutting technology.

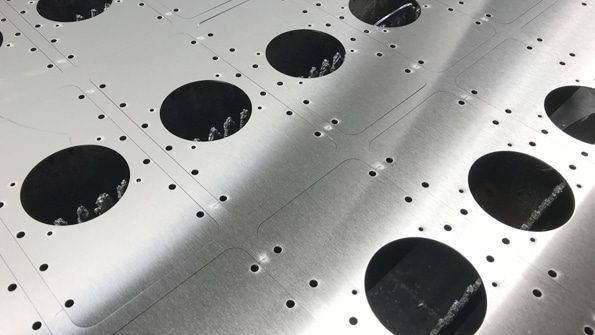

The Sturdy Cutting Bed is built for durability and precision, providing a stable platform for flawless laser cutting. Its robust construction resists wear and deformation, ensuring long-term reliability. Designed to support heavy workloads and various materials, it enhances cutting accuracy and efficiency, making it indispensable for industrial-grade performance.

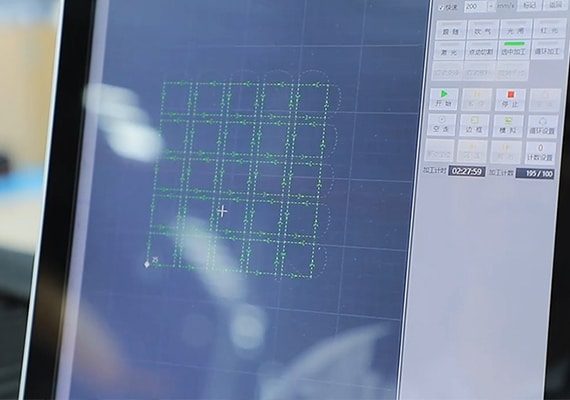

The friendly CNC control system offers intuitive operation with a user-focused interface, simplifying laser cutting processes. Equipped with advanced programming capabilities, it ensures precise control and seamless execution of complex designs. Compatible with various file formats, it boosts productivity while providing an effortless experience for professionals and beginners alike.

The high-precision servo motor ensures unmatched accuracy and smooth motion control for laser cutting operations. Its advanced design delivers rapid response and stable performance, enabling intricate cuts with exceptional detail. Built for durability and efficiency, it minimizes errors and enhances speed, making it essential for professional-grade cutting precision.

The high-performance reducer optimizes torque transmission for smooth and efficient laser-cutting operations. Engineered for durability, it minimizes vibration and ensures stable performance under high workloads. Its precision design enhances cutting accuracy and extends machine life, making it an indispensable component for achieving consistent, high-quality results.

The high-efficiency water chillers provide reliable cooling to maintain optimal laser performance during intensive operations. Designed for energy efficiency, they regulate temperature precisely, preventing overheating and ensuring consistent output. With a durable build and user-friendly controls, these chillers enhance system longevity and productivity, making them essential for peak laser-cutting efficiency.

| Model | AKJ-1325 | AKJ-1530 | AKJ-1545 | AKJ-2040 | AKJ-2560 |

| Cutting Range | 1300*2500mm | 1500*3000mm | 1500*4500mm | 2000*4000mm | 2500*6000mm |

| Laser Type | Fiber Laser | ||||

| Laser Power | 1-30KW | ||||

| Laser Generator | Raycus, Max, IPG, JPT, BWT | ||||

| Maximum Moving Speed | 100m/min | ||||

| Maximum Acceleration | 1.0G | ||||

| Positioning Accuracy | ±0.01mm | ||||

| Repeat Positioning Accuracy | ±0.02mm | ||||

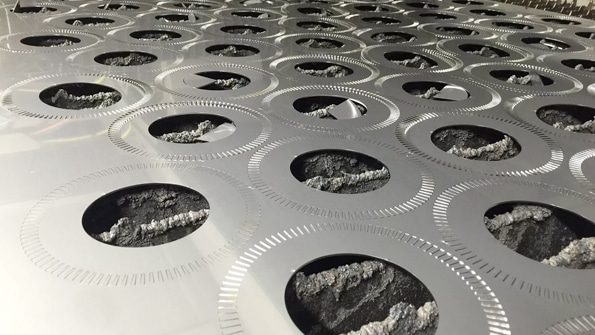

Achieves exceptional accuracy with advanced laser technology, delivering clean, intricate cuts on a variety of materials.

Combines powerful laser generators and optimized components to ensure fast, reliable performance for large-scale operations.

Features a sturdy cutting bed, aviation aluminum beam, and robust components designed for long-lasting, industrial-grade use.

Equipped with a friendly CNC control system, simplifying complex processes with intuitive controls and seamless integration.

Capable of cutting a wide range of materials, including metals, plastics, and composites, for diverse applications.

High-efficiency water chillers maintain optimal system performance while minimizing energy consumption.

High-precision servo motors and high-performance reducers ensure smooth, stable motion for flawless results.

Maximizes productivity with minimal material waste and maintenance costs, providing excellent value for businesses of all sizes.

| Material | Thickness (mm) | Cutting Speed (m/min) | Laser Power (W) | Cutting Gas | Gas Pressure (Bar) | Nozzle (mm) | Focus Position (mm) | Cutting Height (mm) |

|---|---|---|---|---|---|---|---|---|

| Carbon Steel | 1 | 50-60 | 12000 | N2/Air | 12 | 1.5S | 0 | 1 |

| 2 | 35-40 | 12000 | N2/Air | 12 | 2.0S | 0 | 0.5 | |

| 3 | 28-33 | 12000 | N2/Air | 13 | 2.0S | 0 | 0.5 | |

| 4 | 20-24 | 12000 | N2/Air | 13 | 2.5S | 0 | 0.5 | |

| 5 | 15-18 | 12000 | N2/Air | 13 | 2.5S | 0 | 0.5 | |

| 6 | 10-13 | 12000 | N2/Air | 13 | 2.5S | 0 | 0.5 | |

| 8 | 7.0-10.0 | 12000 | N2/Air | 13 | 3.0S | -1.5 | 0.5 | |

| 10 | 6.0-6.5 | 12000 | N2/Air | 13 | 4.0S | -3.0 | 0.5 | |

| 10 | 2.0-2.3 | 6000 | O2 (Negative Focal) | 0.6 | 1.2E | +6.0 | 0.8 | |

| 12 | 1.8-2.0 | 7500 | O2 (Negative Focal) | 0.6 | 1.2E | +7.0 | 0.8 | |

| 14 | 1.6-1.8 | 8500 | O2 (Negative Focal) | 0.6 | 1.4E | +7.0 | 0.8 | |

| 16 | 1.5-1.6 | 9500 | O2 (Negative Focal) | 0.6 | 1.4E | +8.0 | 0.8 | |

| 20 | 1.3-1.4 | 12000 | O2 (Negative Focal) | 0.6 | 1.6E | +8.0 | 0.8 | |

| 22 | 0.9-1.0 | 12000 | O2 (Negative Focal) | 0.7 | 1.8E | +9.0 | 0.8 | |

| 22 | 1.0-1.2 | 12000 | O2 (Negative Focal) | 0.7 | 1.4SP | +11.0 | 0.5 | |

| 25 | 0.7-0.9 | 12000 | O2 (Negative Focal) | 0.7 | 1.8E | +11.0 | 0.8 | |

| 25 | 0.8-1.0 | 12000 | O2 (Negative Focal) | 0.7 | 1.5SP | +12.0 | 0.5 | |

| 30 | 0.4-0.5 | 12000 | O2 (Negative Focal) | 1.3 | 1.8E | +11.0 | 1.2 | |

| 30 | 0.7-0.8 | 12000 | O2 (Negative Focal) | 0.8 | 1.5SP | +12.0 | 0.5 | |

| 40 | 0.25-0.3 | 12000 | O2 (Negative Focal) | 1.5 | 1.8E | +11.5 | 1.2 | |

| 12 | 3.0-3.5 | 12000 | O2 (Positive Focal) | 1 | 1.6SP | -10.0 | 1.5 | |

| 14 | 3.0-3.2 | 12000 | O2 (Positive Focal) | 1 | 1.6SP | -10.0 | 1.5 | |

| 16 | 2.8-3.0 | 12000 | O2 (Positive Focal) | 1 | 1.6SP | -12.0 | 1.5 | |

| 20 | 2.0-2.3 | 12000 | O2 (Positive Focal) | 1.2 | 1.6SP | -12.0 | 1.5 | |

| 25 | 1.1-1.3 | 12000 | O2 (Positive Focal) | 1.3 | 1.8SP | -14.0 | 1.5 | |

| 30 | 0.9-1.0 | 12000 | O2 (Positive Focal) | 1.4 | 1.8SP | -14.0 | 1.5 | |

| Stainless Steel | 1 | 50-60 | 12000 | N2 | 10 | 2.0S | 0 | 1 |

| 2 | 40-45 | 12000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 3 | 30-35 | 12000 | N2 | 13 | 2.0S | 0 | 0.5 | |

| 4 | 22-26 | 12000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 5 | 15-18 | 12000 | N2 | 15 | 2.5S | 0 | 0.5 | |

| 6 | 13-15 | 12000 | N2 | 8 | 3.5B | 0 | 0.5 | |

| 8 | 8.0-10.0 | 12000 | N2 | 7 | 5.0B | 0 | 0.5 | |

| 10 | 6.5-7.5 | 12000 | N2 | 5 | 5.0B | -1.0 | 0.5 | |

| 12 | 5.0-5.5 | 12000 | N2 | 6 | 6.0B | -4.0 | 0.5 | |

| 14 | 3.0-3.5 | 12000 | N2 | 6 | 7.0B | -6.0 | 0.3 | |

| 16 | 2.0-2.3 | 12000 | N2 | 6 | 7.0B | -8.0 | 0.3 | |

| 18 | 1.3-1.5 | 12000 | N2 | 6 | 7.0B | -9.0 | 0.5 | |

| 20 | 1.2-1.4 | 12000 | N2 | 6 | 7.0B | -11.0 | 0.3 | |

| 25 | 0.7-0.9 | 12000 | N2 | 6 | 7.0B | -13.0 | 0.3 | |

| 30 | 0.25-0.3 | 12000 | N2 | 10 | 7.0B | +7.0 | 0.3 | |

| 40 | 0.15-0.2 | 12000 | N2 | 15 | 7.0B | +8.0 | 0.3 | |

| 1 | 50-60 | 12000 | Air | 10 | 2.0S | 0 | 1 | |

| 2 | 40-45 | 12000 | Air | 10 | 2.5S | 0 | 0.5 | |

| 3 | 30-35 | 12000 | Air | 10 | 2.5S | 0 | 0.5 | |

| 4 | 22-28 | 12000 | Air | 10 | 3.5B | 0 | 0.5 | |

| 5 | 16-19 | 12000 | Air | 10 | 3.5B | 0 | 0.5 | |

| 6 | 14-17 | 12000 | Air | 10 | 3.5B | 0 | 0.5 | |

| 8 | 9.0-11.0 | 12000 | Air | 10 | 3.5B | 0 | 0.5 | |

| 10 | 7.0-8.0 | 12000 | Air | 10 | 3.5B | -1.0 | 0.5 | |

| 12 | 5.5-6.0 | 12000 | Air | 10 | 5.0B | -4.0 | 0.5 | |

| 14 | 3.5-4.0 | 12000 | Air | 10 | 5.0B | -6.0 | 0.5 | |

| 16 | 2.2-2.4 | 12000 | Air | 10 | 5.0B | -8.0 | 0.5 | |

| 18 | 1.3-1.6 | 12000 | Air | 10 | 5.0B | -9.0 | 0.3 | |

| 20 | 1.2-1.5 | 12000 | Air | 10 | 5.0B | -11.0 | 0.3 | |

| 25 | 0.7-1.0 | 12000 | Air | 10 | 5.0B | -13.0 | 0.3 | |

| 30 | 0.3-0.4 | 12000 | Air | 10 | 5.0B | -14.0 | 0.3 | |

| Aluminum | 1 | 45-50 | 12000 | N2 | 12 | 2.0S | 0 | 0.8 |

| 2 | 30-35 | 12000 | N2 | 12 | 2.0S | -1.0 | 0.5 | |

| 3 | 20-25 | 12000 | N2 | 12 | 2.0S | -1.0 | 0.5 | |

| 4 | 18-20 | 12000 | N2 | 12 | 2.0S | -2.0 | 0.5 | |

| 5 | 14-16 | 12000 | N2 | 14 | 2.5S | -3.0 | 0.5 | |

| 6 | 10-12 | 12000 | N2 | 14 | 2.5S | -3.0 | 0.5 | |

| 8 | 6.0-8.0 | 10000 | N2 | 14 | 2.5S | -4.0 | 0.5 | |

| 10 | 4.0-6.0 | 12000 | N2 | 14 | 5.0B | -5.0 | 0.5 | |

| 12 | 2.0-3.0 | 12000 | N2 | 16 | 5.0B | -5.0 | 0.5 | |

| 14 | 1.5-2.5 | 12000 | N2 | 16 | 5.0B | -5.0 | 0.5 | |

| 16 | 1.3-2 | 12000 | N2 | 16 | 5.0B | -5.0 | 0.5 | |

| 18 | 1.0-1.6 | 12000 | N2 | 16 | 5.0B | -5.0 | 0.5 | |

| 20 | 0.8-1.2 | 12000 | N2 | 16 | 7.0B | -5.0 | 0.3 | |

| 25 | 0.5-0.7 | 12000 | N2 | 16 | 7.0B | -5.0 | 0.3 | |

| 30 | 0.4-0.5 | 12000 | N2 | 18 | 7.0B | +7.0 | 0.3 | |

| 40 | 0.25-0.3 | 12000 | N2 | 18 | 7.0B | +8.0 | 0.3 | |

| Brass | 1 | 35-45 | 12000 | N2 | 12 | 2.0S | 0 | 1 |

| 2 | 30-35 | 12000 | N2 | 12 | 2.0S | -1.0 | 0.5 | |

| 3 | 18-22 | 12000 | N2 | 12 | 2.0S | -1.0 | 0.5 | |

| 4 | 15-18 | 12000 | N2 | 12 | 2.0S | -2.0 | 0.5 | |

| 5 | 12-15 | 12000 | N2 | 14 | 2.5S | -3.0 | 0.5 | |

| 6 | 8.0-10.0 | 12000 | N2 | 14 | 2.5S | -3.0 | 0.5 | |

| 8 | 5.0-7.0 | 12000 | N2 | 14 | 2.5S | -4.0 | 0.5 | |

| 10 | 4.0-5.0 | 12000 | N2 | 14 | 5.0B | -5.0 | 0.5 | |

| 12 | 1.8-2.0 | 12000 | N2 | 14 | 5.0B | -5.0 | 0.5 | |

| 14 | 1.2-1.4 | 12000 | N2 | 16 | 5.0B | -8.0 | 0.5 | |

| 16 | 0.8-1.0 | 12000 | N2 | 16 | 5.0B | -11.0 | 0.3 | |

| Copper | 1 | 25-30 | 12000 | O2 | 5 | 2.0S | -0.5 | 1 |

| 2 | 20-25 | 12000 | O2 | 5 | 2.0S | -1.0 | 0.5 | |

| 3 | 16-18 | 12000 | O2 | 6 | 2.0S | -2.0 | 0.5 | |

| 4 | 10-12 | 12000 | O2 | 8 | 2.0S | -3.0 | 0.5 | |

| 5 | 6.0-8.0 | 12000 | O2 | 8 | 2.5S | -4.5 | 0.5 | |

| 6 | 4.0-5.0 | 12000 | O2 | 8 | 2.5S | -5.0 | 0.5 | |

| 8 | 2.0-2.5 | 12000 | O2 | 10 | 3.0S | -6.0 | 0.5 | |

| 10 | 1.0-1.2 | 12000 | O2 | 12 | 4.0S | -8.0 | 0.5 |

The price of a 12KW laser cutting machine typically ranges between $60,000 and $185,000, depending on various factors such as the manufacturer, the specific model, additional features, and the level of automation.

The lower end of the price range generally applies to standard models with basic functionality, while the higher-end machines may include advanced features such as automated loading/unloading systems, enhanced software capabilities, and customizations for specific applications. Additional factors like after-sales support, warranty, and geographic location can also influence the price.

It’s important to consider the long-term value of a 12KW laser cutting machine, as the investment can provide enhanced cutting precision, faster speeds, and increased productivity for high-demand industries like automotive, aerospace, and heavy manufacturing.

The 12KW laser cutting machine excels in cutting a variety of metal materials, including carbon steel, stainless steel, aluminum, brass, and copper. Its high-powered laser enables precise and efficient cutting, delivering numerous advantages for different applications:

The 12KW laser cutting machine offers versatility and high-quality cuts across various metal materials, optimizing production efficiency while ensuring superior finish and minimal material wastage.

The 12KW laser cutting machine offers remarkable cutting capabilities across a wide range of material thicknesses. Here are the maximum thicknesses it can handle:

This versatility makes the 12KW laser cutting machine suitable for a broad spectrum of industries, providing fast, high-quality cuts on a variety of metals with varying thicknesses.

The cutting speed of a 12KW laser cutting machine depends on several factors, such as material type, thickness, cutting parameters, and assist gas used. However, here are general guidelines for cutting speeds on various materials:

The cutting speed varies based on the thickness, material, and cutting conditions. The 12KW laser cutting machine is designed for high efficiency and can achieve fast cutting speeds for various materials while maintaining quality and precision.

The power consumption of a 12KW laser cutting machine can be broken down based on its key components. Here’s an estimated breakdown of the power usage:

This power consumption is a general estimate and may vary depending on the specific machine configuration, cutting conditions, and additional features like automation systems. It is important to account for the power requirements of the entire system when planning for installation and ongoing operation.

Yes, a 12KW laser cutting machine is designed with user-friendly features that make it relatively easy to operate, even for operators with minimal experience. However, successful operation depends on proper training and understanding of the machine’s functions. Here’s a breakdown of the key factors that contribute to the ease of operation:

While the machine is designed to be user-friendly, operators should undergo proper training to maximize its potential, ensuring safe and efficient operation. Proper understanding of material properties, machine settings, and maintenance routines will contribute to optimal performance.

Operating a 12KW laser cutting machine requires specialized training to ensure both efficiency and safety. Due to the advanced technology and high power involved, proper training is essential to avoid accidents, optimize machine performance, and ensure the longevity of the equipment. Here’s an outline of the training required:

Proper training for operating a 12KW laser cutting machine is essential to maximize productivity and ensure the safe, efficient, and reliable operation of the machine. This includes a solid understanding of the machine’s operation, material characteristics, cutting settings, safety protocols, and routine maintenance. Manufacturers and training providers typically offer comprehensive programs to ensure that operators are well-prepared to handle the machine effectively.

Our laser cutting machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for 12KW Laser Cutting Machine

Maryam –

Enhanced our productivity with this laser cutting machine. It’s efficient, and versatile, and has become an integral part of our operations.

Moe –

Dependable and efficient, this fiber laser machine is a game-changer for our business. It’s reliable, precise, and delivers top-notch results.

Abena –

A reliable investment for our business, this laser machine delivers exceptional performance. It’s efficient, accurate, and easy to maintain.

Kwame –

Exceeded expectations, this laser cutting machine is a powerhouse in our workshop. It’s fast, reliable, and produces clean cuts consistently.