$4,200.00 – $5,000.00

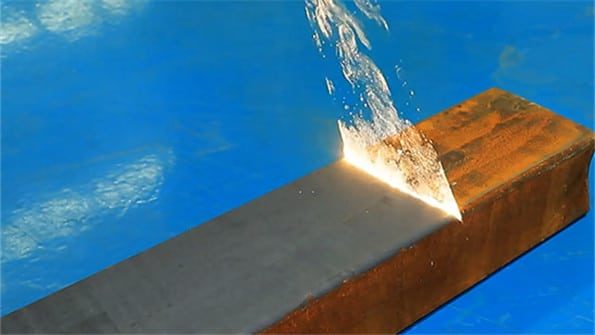

Using a well-known brand laser generator (Raycus, JPT, Max, IPG), the pulse width and frequency are independently adjustable and can maintain a stable peak power output, suitable for a wider range of cleaning scenarios. The high photoelectric conversion rate ensures the laser power and makes the cleaning effect better. Acctek Laser can design different configurations to meet customer needs.

The industrial water cooler ensures the heat dissipation of the core optical path components, allowing the welding machine to provide consistent welding quality and helping to improve the overall quality of the clean itself. It can also increase welding output by reducing the downtime of fiber laser cleaning machines. In addition, an excellent industrial water cooler can also prolong the service life of the laser cleaning machine.

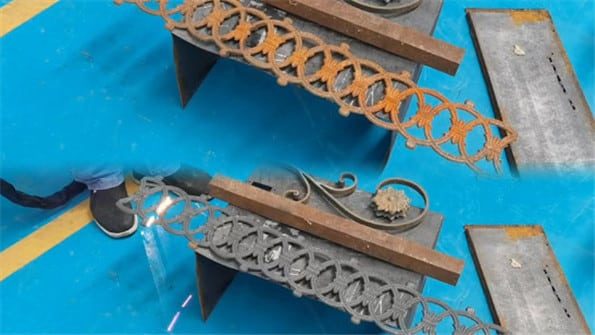

The laser cleaning head is ergonomically designed, small in size, comfortable to hold, and easy to control and operate. The hand-held cleaning head is easy to hold can be used for a long time, and can be operated at any angle, making cleaning more convenient and flexible.

Acctek Laser provides high-performance, intuitive, and easy-to-use operating systems. You can quickly set cleaning power, width, and other parameters through the screen, and provide a better cleaning effect. The operating system supports Chinese, English, Korean, Russian, Vietnamese, and other languages.

| Model | AKQ-1000 | AKQ-1500 | AKQ-2000 | AKQ-3000 |

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Fiber Laser | |||

| Pulse Formation | Q-Switched (Quality Factor) | |||

| Laser Generator | Raycus, Max, BWT | |||

| Output Range (If Adjustable) | 0-100% | |||

| Cleaning Efficiency | 12㎡/h | |||

| Scanning Width | 10-80mm | |||

| Cleaning Width | 80-450mm | |||

| Fiber Length | 10-15m | |||

| Expected Focal Distance | 160mm | |||

| Cooling Type | Water Cooling | |||

| Comparison | Laser Cleaning | Chemical Cleaning | Mechanical Grinding | Dry Ice Cleaning |

|---|---|---|---|---|

| Washing Method | Non-Contact Cleaning | Contact Cleaning | Abrasive Contact Cleaning | Non-Contact Cleaning |

| Harm To Base Material | None | Yes | Yes | None |

| Washing Efficiency | High | Low | Low | Mid |

| Consumable | Power | Chemical Detergent | Abrasive Paper, Grinder, Abrasive Stone | Dry Ice |

| Washing Result | Very Good, Very Clear | Medium, Uneven | Medium, Uneven | Good, Uneven |

| Precision Washing | Accuracy Controllable, High Precision | Uncontrollable, Low-Precision | Uncontrollable, Medium-Precision | -Uncontrollable, Poor Precision |

| Safety/Environment | No Pollution | Chemical Pollution | Dust Pollution | No Pollution |

| Operation | Easy to operate, portable, or automation optional | Complicated processes, higher technical requirements of the operator, and Pollution prevention measures are required | With more time & manpower, pollution prevention measures are required | Easy to operate, portable, or automatic |

| Investment | High investment in machines, but no consumable, low maintenance cost | Low investment in machines, but expensive consumables | Medium investment in the machine, high manpower cost | Medium investment in the machine, high consumable cost |

The price of a 2000w laser cleaning machine can vary widely based on several factors including brand, quality, features, additional accessories, and specific suppliers or manufacturers. It’s difficult to give an exact price without specific details about the machine and manufacturer. Typically, a 2000w laser cleaning machine ranges from $4,300 to $5,000 depending on the complexity and capabilities of the machine.

It is important to note that pricing information may change over time due to market fluctuations and technological advancements. Therefore, it is recommended to contact the laser cleaning machine manufacturer, supplier, or distributor directly to obtain accurate and up-to-date pricing information for the specific 2000w laser cleaning machine model that meets your requirements. They can provide you with detailed quotes and pricing information based on your specific needs and any other services or accessories you may require. If you are looking for a laser cleaning machine, you can contact us. AccTek Laser engineers will provide you with customized laser cleaning solutions according to your needs.

The AccTek Laser 2000W laser cleaning machine supports a standard cleaning width of 270mm. However, it also offers optional configurations for wider cleaning widths of 450mm and 600mm. You can choose the right cleaning width option while purchasing the machine based on your specific needs and requirements.

When operating a 2000w laser cleaning machine or any high-power laser equipment, proper safety precautions need to be followed to ensure personnel safety and prevent accidents. Here are some key safety precautions to consider:

Note that these safety precautions are general guidelines only, and specific safety requirements may vary by laser cleaning machine manufacturer and model. Always refer to the manufacturer’s instructions, safety manual, and relevant safety regulations in your jurisdiction for comprehensive safety guidance.

The 2000w laser cleaning machine is capable of cleaning a wide variety of materials, but there are some limitations to consider. The suitability of a laser cleaning process for a particular material depends on factors such as the material’s optical properties, thermal conductivity, and response to the laser wavelength. It can be applied to a variety of materials, including metals (such as steel, aluminum, copper, etc.), ceramics, composites, plastics, stone, and more. However, some materials may not be suitable for laser cleaning or may require special considerations. Here are some factors that can affect the effectiveness of laser cleaning on different materials:

While a 2000w laser cleaning machine can handle a wide variety of materials, the specific characteristics and requirements of the material you are cleaning must be considered. Testing or consulting with manufacturers and laser cleaning experts can help determine the best laser parameters and cleaning methods for different materials. In addition, laser cleaning is a versatile process that will continue to expand the capabilities of laser cleaning machines as technology advances, allowing for more efficient cleaning of a variety of materials.

The life expectancy of a 2000w laser cleaning machine depends on several factors, including the quality of the machine, its brand, the specific components used, and the maintenance methods followed. Generally speaking, a well-maintained and properly used laser cleaning machine can last for thousands of hours.

Regular maintenance is essential to ensure optimum performance and extend the life of your machine. Here are some common maintenance requirements for laser cleaning machines:

It is important to note that different laser cleaning machine models and manufacturers may have different maintenance requirements. Always refer to the manufacturer’s guidelines and recommendations for maintenance procedures and intervals specific to your machine. Additionally, proper operator training and following safety procedures can also prevent damage to the machine and prolong its life.

Yes, there are specific power requirements and installation considerations that should be considered when setting up a 2000w laser cleaning machine. Here are some key factors to consider:

Be sure to refer to the manufacturer’s guidelines and recommendations for the specific model of the 2000w laser cleaning machine you are installing. They can provide detailed information on power requirements, cooling systems, installation considerations, and any other specific requirements for the safe and efficient operation of the machine.

Yes, 2000w laser cleaning machines usually need additional cooling equipment to dissipate the heat generated during operation. A laser cleaning machine will have a high-power laser generator that generates a lot of heat. Proper cooling can keep the laser cleaning machine stable and prevent system damage.

The cooling equipment used may vary depending on the specific design and requirements of the laser cleaning machine. Here are some common cooling methods:

Specific cooling requirements may vary by the make and model of the laser cleaning machine. It is necessary to follow the manufacturer’s recommendations for a proper cooling system and to ensure it is properly installed, maintained, and monitored during operation. During installation, proper ventilation and clearance around cooling equipment must be ensured to facilitate efficient heat dissipation. Regular maintenance and monitoring of the cooling system can prevent any malfunctions and problems that may affect the performance and service life of the laser cleaning machine.

Proper cooling is critical to maintaining the longevity and performance of your laser cleaning machine. Insufficient cooling can result in overheating, reduced efficiency, and potential damage to machine components. Therefore, it is imperative to ensure that the cooling system is properly selected, installed, and maintained according to the manufacturer’s recommendations.

The 2000w laser cleaning machine usually incorporates multiple safety measures to protect the user and the surrounding environment. While specific features may vary by manufacturer and model, here are some common safety measures found in laser cleaning machines:

It’s important to note that specific safety measures and features may vary between different laser cleaning machine models and manufacturers. Always refer to the manufacturer’s documentation, safety guidelines, and relevant safety regulations in your jurisdiction for comprehensive information on the safety measures employed with a particular 2000w laser cleaning machine. Additionally, proper training and adherence to laser safety best practices can keep your laser cleaning machine operating safely.

At AccTek Laser, we understand that different businesses have different needs, which is why we offer you a range of models to choose from. Whether you need a portable mini laser cleaning machine or a high-speed industrial laser cleaning machine, we have the right machine for you. Invest in our fiber laser cleaning machines and take your cleaning capabilities to the next level.

With years of experience in laser cleaning technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser cleaning machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser cleaning machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser cleaning machine is rigorously tested and adhered to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cleans every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser cleaning machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for 2000W Laser Cleaning Machine

David –

Impressed with its durability and performance. Delivers consistent cleaning results. A valuable addition to any workshop.

Eleni –

Revolutionizes cleaning processes. Enhances productivity and quality standards. Delivers impressive results every time.

Valeria –

Consistent performance, and exceptional results. Exceeds expectations and improves productivity. Great investment for any manufacturing facility.

Yaw –

Efficient and powerful cleaning machine. Simplifies maintenance tasks and boosts productivity. A valuable asset for workshops and production lines.