$5,700.00 – $6,600.00

Using well-known brand laser generators (Raycus, JPT, Reci, Max, IPG), a high photoelectric conversion rate ensures the laser power and makes the welding effect better. AccTek can design different configurations to meet customer needs.

The industrial water cooler ensures the heat dissipation of the core optical path components, allowing the welding machine to provide consistent welding quality and helping to improve the overall quality of the weld itself. It can also increase welding output by reducing the downtime of fiber laser welding machines. In addition, an excellent industrial water cooler can also prolong the service life of the laser welding machine.

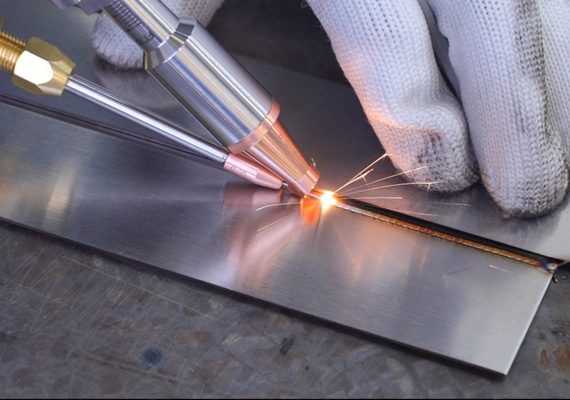

The laser welding gun is ergonomically designed, light in shape, comfortable to hold, and easy to control and operate. The hand-held welding gun is easy to hold and can be operated at any angle, making welding more convenient and flexible.

AccTek provides high-performance, intuitive, and easy-to-use operating systems. It expands the tolerance range and weld width of machined parts and provides better weld formation results. The operating system supports Chinese, English, Korean, Russian, Vietnamese, and other languages.

| Model | AKH-1000 | AKH-1500 | AKH-2000 | AKH-3000 |

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Fiber Laser | |||

| Range of Adjustable Power | 1-100% | |||

| Laser Wavelength | 1080nm | |||

| Way of Working | Continuous/Modulation | |||

| Speed Range | 0-120mm/s | |||

| Repeat Precision | ±0.01mm | |||

| Welding Gap Requirements | ≤0.5mm | |||

| Cooling Water | Industrial Thermostatic Water Tank | |||

| Material | Welding Form | Thickness (mm) | Laser Power (W) | Welding Speed (mm/s) | Defocus Amount | Protective Gas | Blowing Method | Flow (L/min) | Welding Effect |

|---|---|---|---|---|---|---|---|---|---|

| Carbon Steel (Q235B) | Butt Welding | 0.5 | 2000 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 2000 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 2000 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 2000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 2000 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Stainless Steel (SUS304) | Butt Welding | 0.5 | 2000 | 100~110 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 2000 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 2000 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 2000 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 2000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Brass | Butt Welding | 0.5 | 2000 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 2000 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 2000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 2000 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 1-3 Series Aluminum Alloys | Butt Welding | 0.5 | 2000 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 2000 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 2000 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 2000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 4-7 Series Aluminum Alloys | Butt Welding | 0.5 | 2000 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 2000 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 2000 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Copper | Butt Welding | 0.5 | 2000 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

The cost of a 2000w laser welding machine can vary widely based on various factors such as manufacturer, model, features, quality, and other accessories or options. Generally speaking, the price range of a 2000w laser welding machine is from $8000 to $25000. Higher-end models of laser welding machines with advanced features and functions tend to be more expensive.

Note, however, that prices may change over time due to factors such as technological advancements, market demand, and currency fluctuations. In addition, the purchase cost of the machine is only part of the overall investment and may include some additional costs. Additional costs may include installation, training, maintenance, and any required safety equipment or infrastructure.

If you want to get accurate and latest pricing information for a 2000w laser welding machine, you can contact us directly. AccTek Laser is a professional laser welding machine manufacturer. We can provide details on pricing and any additional costs associated with your machines, such as shipping, installation, or training. Additionally, our engineers will advise you on pricing and options and recommend the best laser welding machine for your application and budget.

Proper maintenance of a 2000w laser welding machine helps ensure its optimum performance, longevity, and safety. While specific maintenance requirements may vary depending on the make and model of your machine, here are some common general maintenance guidelines:

Be sure to consult the manufacturer’s specific maintenance guidelines for your particular laser welding machine. They will provide detailed instructions on maintenance schedules, recommended procedures, and any specific considerations for your machine model. Following the manufacturer’s recommendations will help ensure the longevity, performance, and safety of your laser welding machine. Also, consider hiring a qualified technician or service provider to perform complex maintenance tasks on laser welding machines.

2000w laser welding machine is capable of welding many kinds of metals and alloys. The specific suitability and success of laser welding for a particular material depend on factors such as optical properties, thermal conductivity, and melting behavior. Here are some common metals and alloys that can be welded with a 2000w laser welding machine:

It should be noted that although the 2000w laser welding machine can weld various metals and alloys, specific parameters such as laser power, welding speed, and beam focus may need to be optimized according to the material being welded. Additionally, certain metals and alloys may require the use of appropriate shielding gases, filler materials, or surface treatments to achieve high-quality welds. It is recommended to consult the manufacturer’s guidelines, carry out sample testing, or seek the advice of a laser welding expert to ensure the best times and parameters for welding specific metals and alloys with a 2000w laser welding machine.

The overall reliability and durability of a 2000w laser welding machine may vary depending on the specific manufacturer, model, build quality, and maintenance practices of the machine. Generally speaking, laser welding machines are known for their reliability and durability when properly maintained and operated within their specified parameters. Here are some factors that affect the reliability and durability of a laser welding machine:

While laser welding machines are generally reliable and durable, unforeseen issues or component failures can still occur. Warranty coverage, customer support, spare parts, and service availability can also affect the overall experience with a laser welding machine. When considering a specific 2000w laser welding machine, it is advisable to check customer reviews, ratings, and feedback to gain insight into its reliability and durability. Additionally, contacting the manufacturer or supplier for details on warranty, support, and maintenance practices can provide a clearer picture of a machine’s expected reliability and durability.

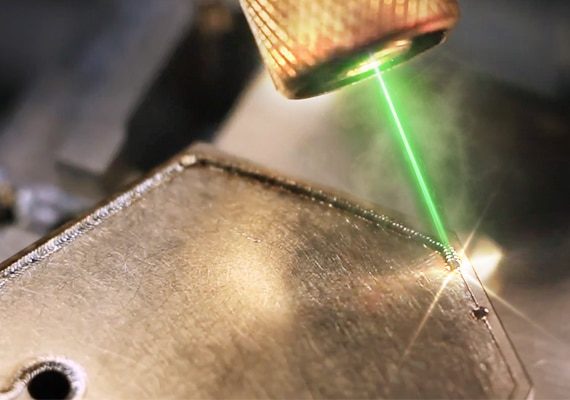

Yes, a 2000w laser welding machine can provide precise and accurate welding ability. Laser welding is known for its high precision and accuracy, making it suitable for applications requiring fine control and a minimal heat-affected zone. Here are some of the reasons why a 2000w laser welding machine can deliver precise welds:

It should be noted that achieving precise and accurate welding with a laser welding machine also depends on factors such as material preparation, joint design, and operator skill. Proper machine operation training and experience can help operators effectively utilize the precise capabilities of a laser welding machine. Achieve the desired welding precision and accuracy by optimizing welding parameters and ensuring that the machine is properly calibrated and aligned. Proper use of a 2000w laser welding machine can achieve high precision and accurate welding, making it suitable for applications requiring tight tolerances and fine details.

Yes, the 2000w laser welding machine can support various accessories and functions to enhance the welding process. These accessories and features are designed to increase productivity, flexibility, and overall performance. While specific accessories and features may vary by manufacturer and model, here are some common examples:

It’s important to note that not all laser welding machines include all of these accessories or features as standard options. Availability and compatibility of accessories and additional features may vary, so it is recommended to consult the manufacturer or supplier to determine specific options that can be integrated with the 2000w laser welding machine.

The life expectancy of a 2000w laser welding machine and its components depends on a variety of factors, including machine quality, manufacturer, operating conditions, maintenance practices, and usage patterns. Typically, a well-maintained and high-quality laser welding machine has a life expectancy ranging from 15,000 to 30,000 hours. However, it is important to note that these are estimates and actual lifespan may vary.

A laser welding machine is a complex system of various components, each with its own life expectancy. Here are some key components and their typical life expectancy:

The service life of a laser welding machine and its components can be affected by factors such as workload, operating environment, operator skill, and maintenance time. Proper maintenance, following manufacturer guidelines, and regular servicing will help prolong the life of your laser welding machine and its components. When considering a laser welding machine, it is advisable to consult the manufacturer or supplier for more specific information on the life expectancy of the machine and its components, based on its design and specifications.

2000w laser welding machines usually have several safety features to ensure the safety of the operator and the workplace. Specific safety features may vary by machine make and model. Here are some common safety measures in laser welding machines:

Note that these are general security features and specific features and security precautions may vary. Be sure to consult the manufacturer’s documentation and follow their guidelines for the specific model 2000w laser welding machine you are referring to as they will provide details on the safety measures in place.

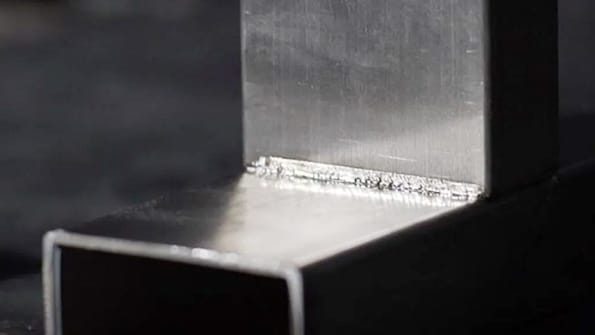

Simple preset selection ensures consistently high-quality laser welding results. The presets include wobble welding to accommodate wider seams and poorly assembled parts. Operators can instantly switch between different presets to easily handle multiple material thickness combinations.

The machine is ergonomic, compact, and proven to be the most comfortable and easy-to-use laser gun. The 2-step trigger and part contact sensor increase operator safety. It can quickly switch from standard laser welding to wire welding, making the operation simple and fast.

The clear logo on the rear of the machine makes connection easy and fast. Plug in the power cord and gas connections, attach the clips to the work surface, and you’re ready to start your welding operation. The ethernet computer connection provides access to advanced parameter settings for fine-tuning and saving welding process parameters.

Key switch control to protect the system from unauthorized welding operations. The emergency stop button can ensure that the machine can be shut down immediately when there is a problem. Safety interlocks verify the integrity of laser delivery to the welding gun.

4 reviews for 2000W Laser Welding Machine

Hla –

Revolutionizes our welding operations. Saves time and resources. Highly recommended for industrial use.

Yasmin –

Impressive precision and reliability. Easy setup and operation. Makes welding tasks efficient and effective.

Mary –

Effortlessly handles intricate welds. Reliable performance, minimal maintenance. A must-have for welding workshops.

Yuto –

Consistent performance, and minimal downtime. Enhances weld quality and productivity. Exceeds expectations.